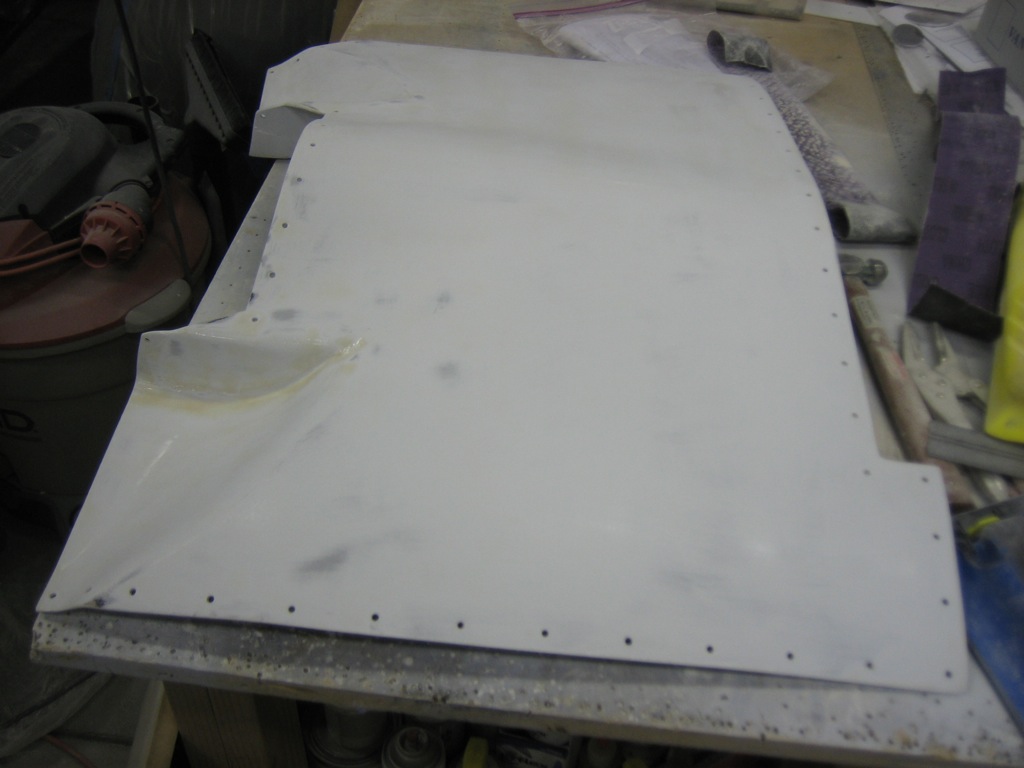

I finished sanding the upper cowl so that there is a minimum amount of filler and all of the edges are feathered. I then put the cowl back on the plane so that I could apply filler to the lower cowl.

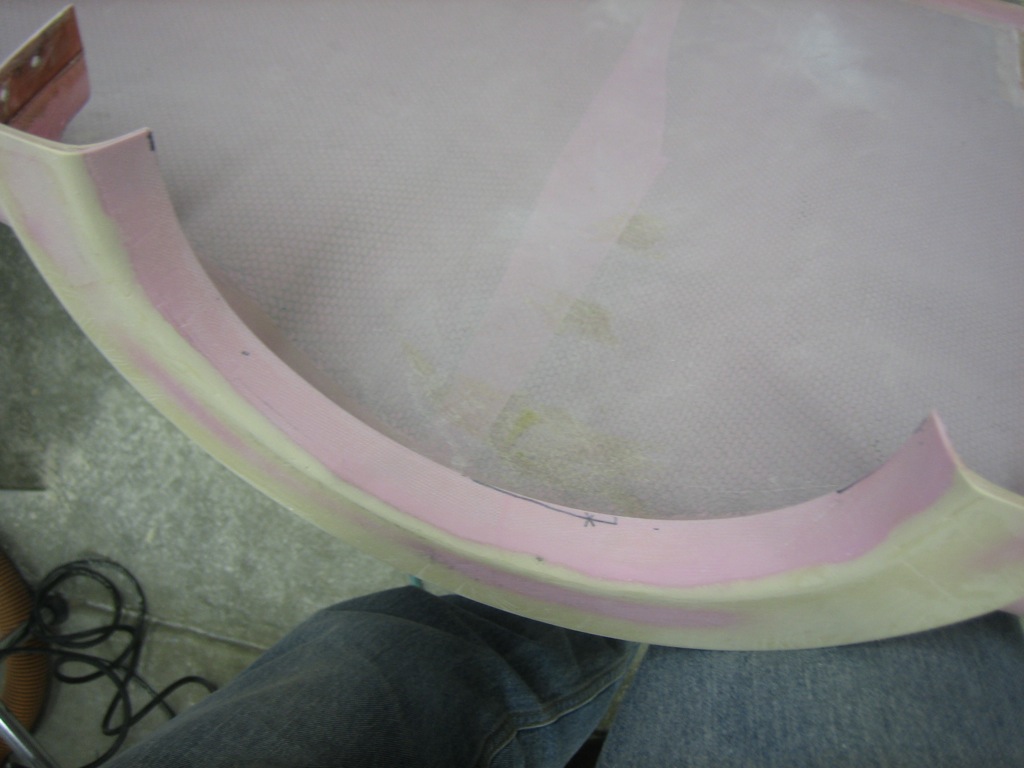

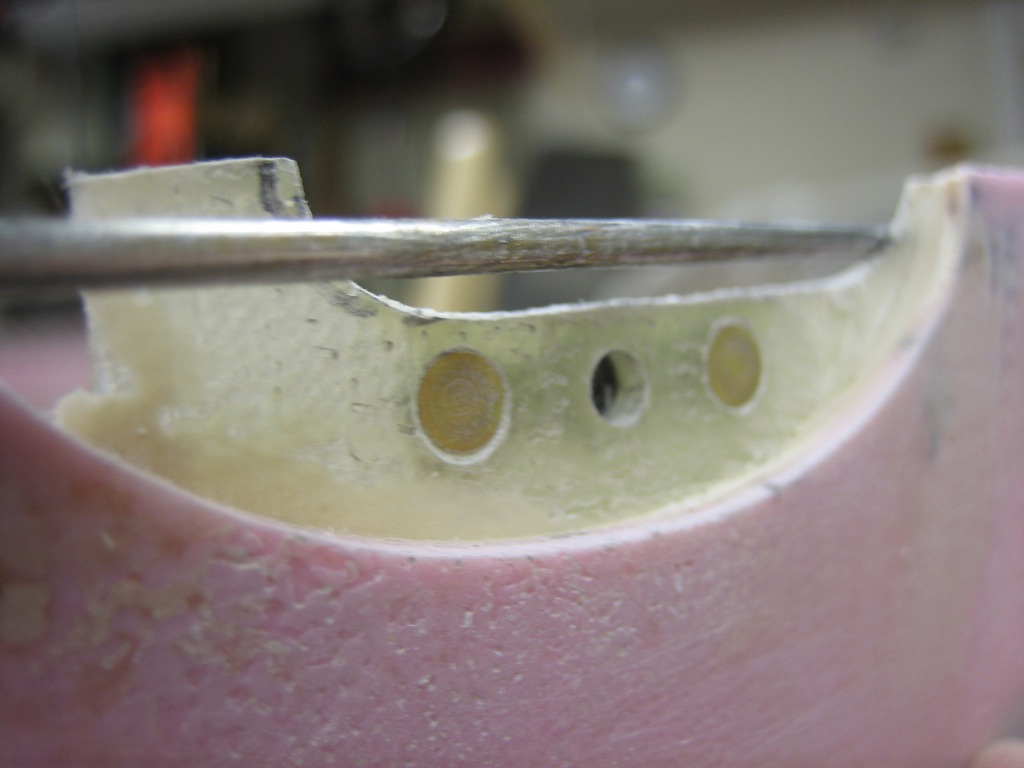

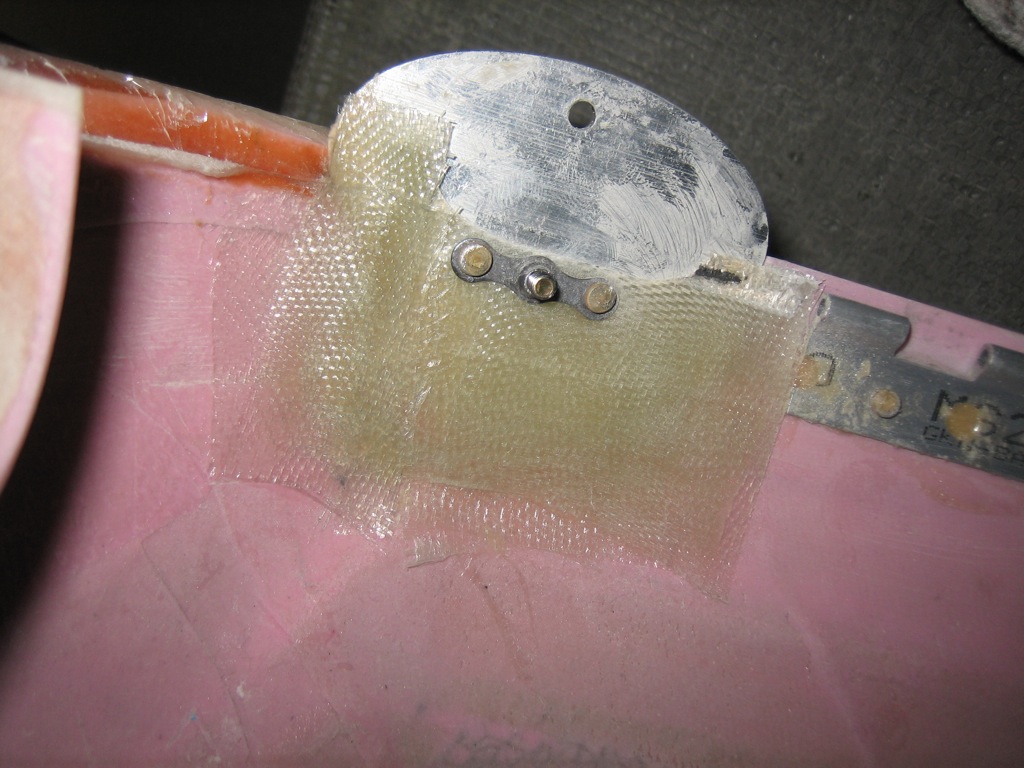

The upper cowl protruded about 1/16″ beyond the lower cowl, so I put a piece of electrical tape on the upper cowl and applied some epoxy with microlight to the horizontal joint and vertical joint along the firewall. Here’s the right side of the cowl.

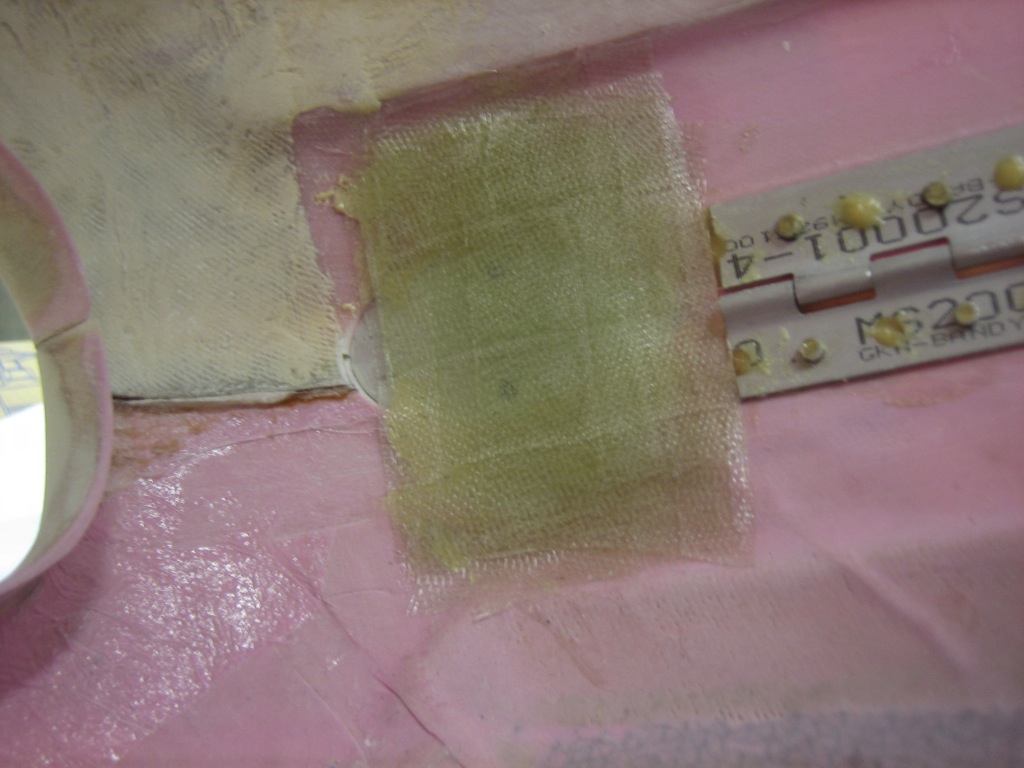

And here’s the left side. Once this has cured, I can remove the tape and sand across the joint to make it perfectly smooth.