No pictures tonight, but I sanded the filler I applied to the plenum and then marked all the way around the edge to trim it flush with the baffles. I did part of the trimming, but I think I’m going to try and fully cure the plenum before finishing.

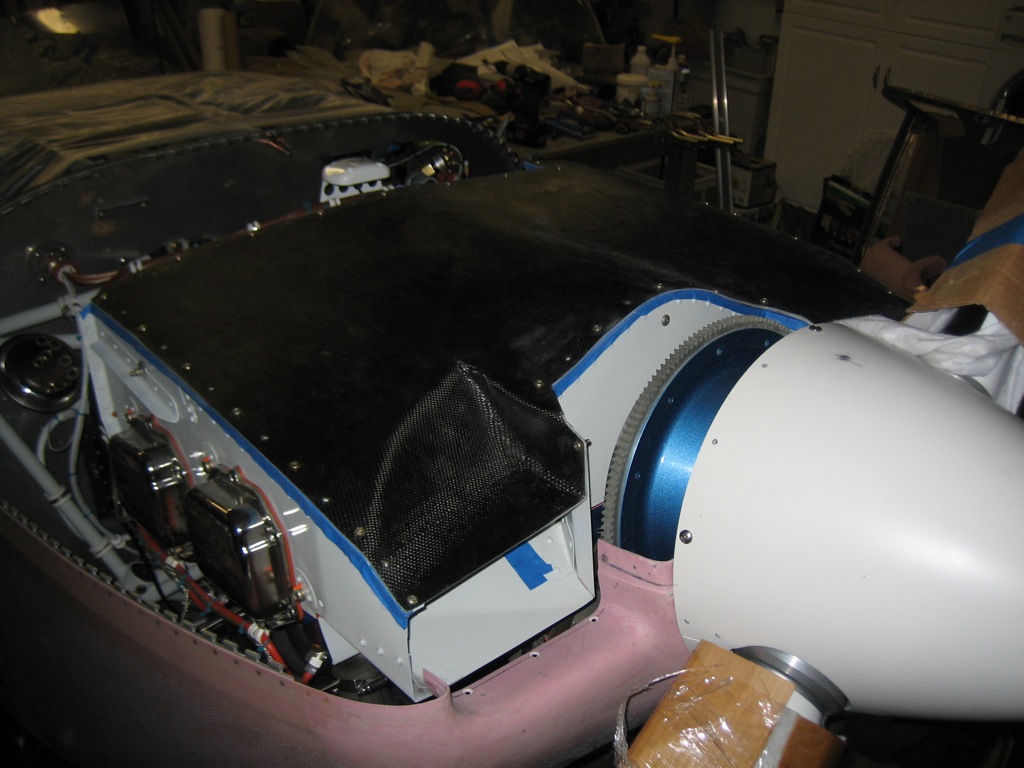

Started Fitting Upper Cowl Inlet Seals

I finished trimmed the front edge of the plenum so that it’s flush with the baffles, then reinstalled it on the plane. I then reinstalled the cowl and began fitting the upper cowl inlet seals. We’ve been having a cold snap here, so it became too uncomfortable to work in the garage with the door open, so I called it an early night.

Finished Trimming Plenum

The high-temp epoxy that I used on the plenum needs to be post-cured in order to withstand the high temperatures it will be exposed to after engine shutdown. I took it down to the Tech Shop and used their large powder coating over to cure it at 150º for three hours. The heat substantially softened it and it flattened out a bit in the oven. After I brought it home, it didn’t really fit the baffles correctly and would have cracked if I tried to force it into position. I set up my space heater over each side and heated the plenum past 150º and it softened right up. I then pushed it into position and screwed it down. This worked beautifully, and the plenum now fits the baffles really well.

I finished trimming around the edge and then sanded the plenum flush with the baffles. I still need to sand and fill the plenum in preparation for paint, but I think the fabrication is finally done.

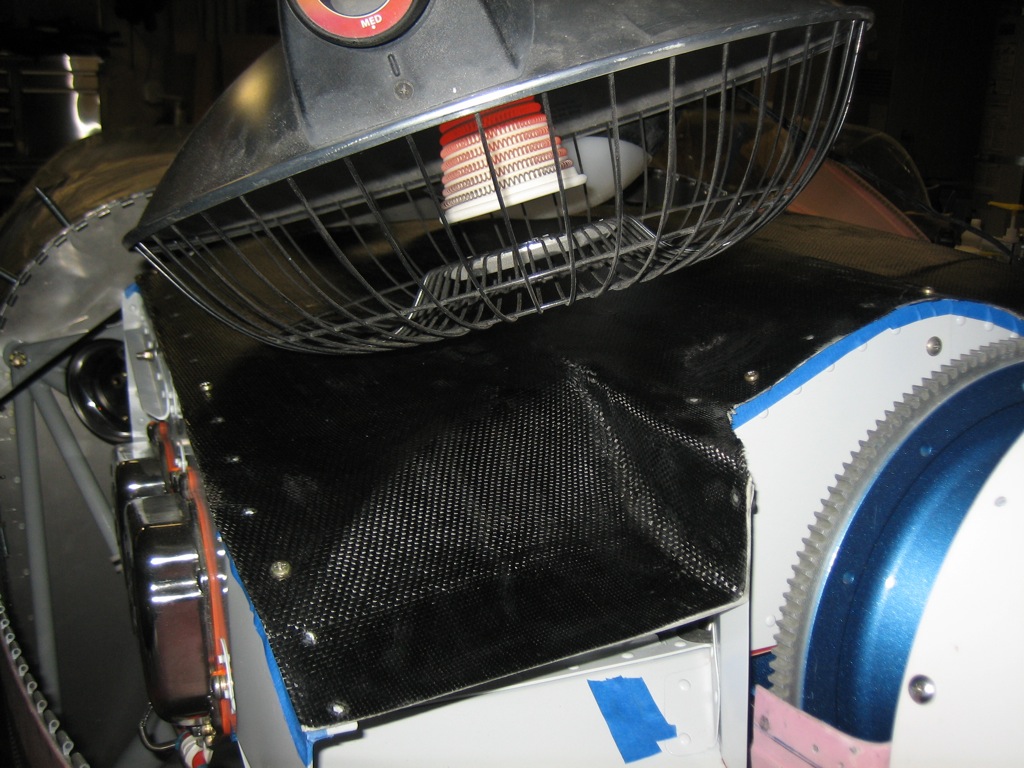

Bonded Cowl Inlet Seals and Cowl/Plenum Filler

I haven’t worked on the plane in a bit because I’ve been laid up with the flu. Now I’m fine but Jenn and the kids have it, so I headed out to the garage after everyone went to bed early. I used some contact cement to bond the cowl inlet seals to the mounting strips. I only took a picture of the lower left one, but all four are done.

Next, I mixed up some epoxy/micro and filled the weave and low spots on the plenum.

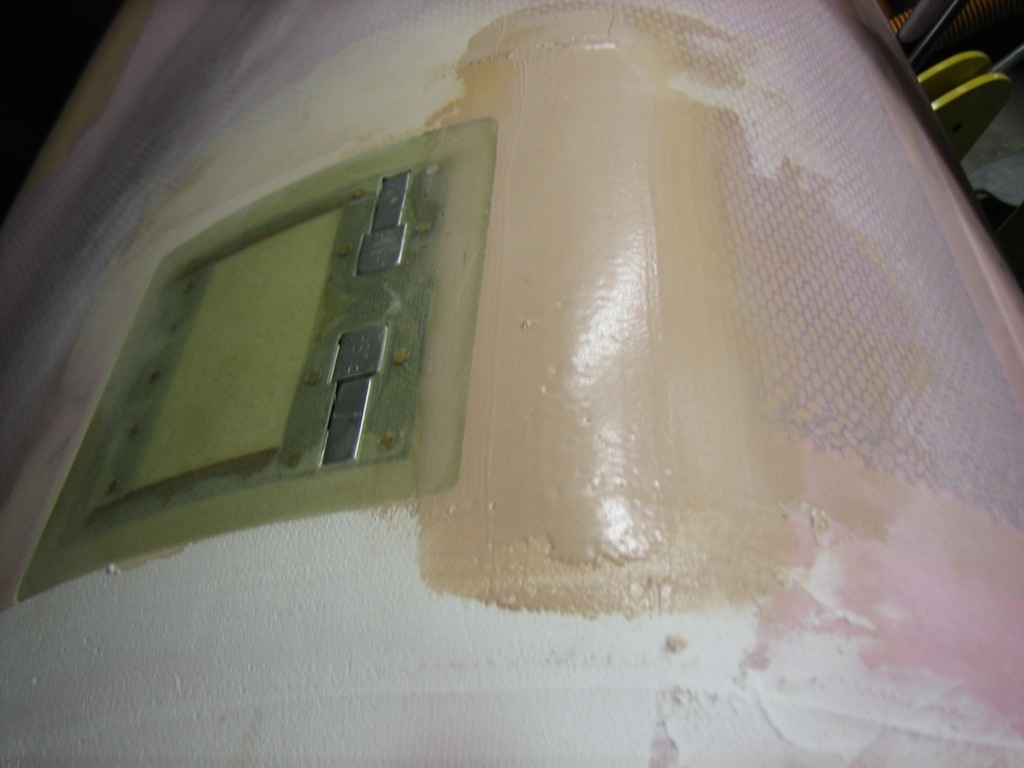

I had a little extra, so I put a little more on the upper cowl to fair out the area below the oil door in order to match the curvature.

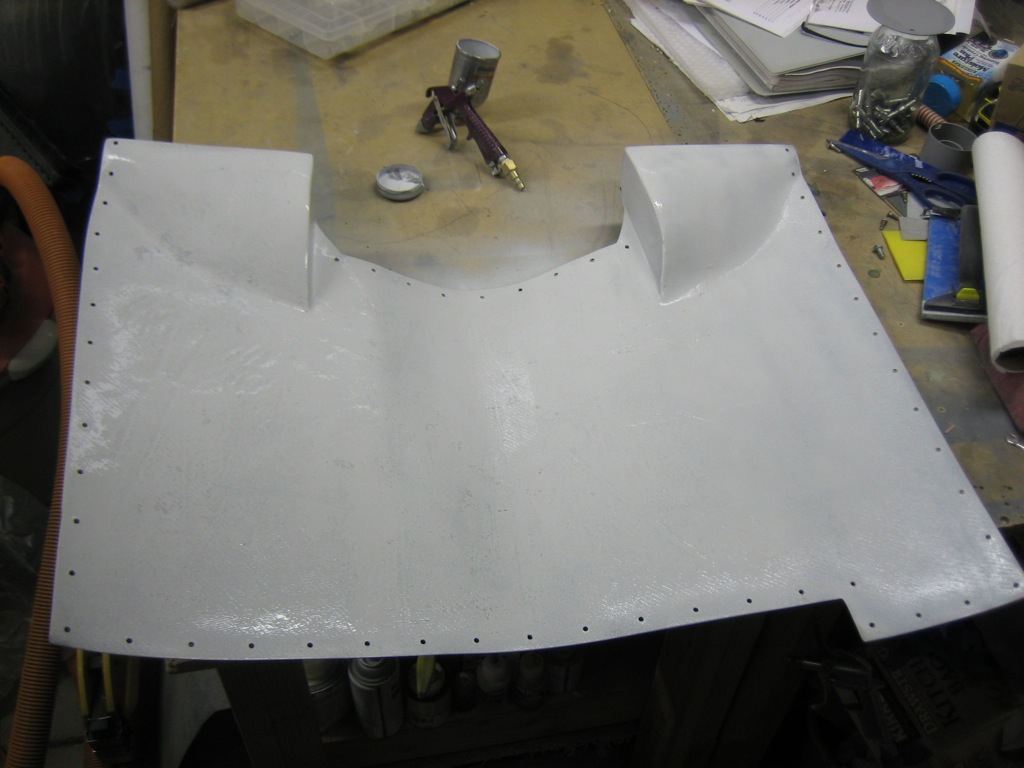

Painted Underside of Plenum

Well, the battery was dead again today. I’ve known what the problem is, but I haven’t decided what to do about it. When I was first putting together the electrical system design, I decided that I wanted the interior lights to work even if the battery master was off to help with baggage loading, boarding, etc. Later, when I settled on the dual color light and dimmer, the design required running power to the dimmer first, and then to the color selection switch and then the lights. I didn’t realize until the entire system was wired up that the dimmer leaks about 43mA even with the lights off. With a 17AH battery, that leakage current effectively drains the battery in about two weeks. I kept putting it off hoping I could find a way to preserve the behavior, but fix the current leak. I ended up deciding to just move the cabin lights to the interior light circuit on the VP-X. After doing that, my leakage current is now well less than 1mA which is more than acceptable.

I also mixed up some epoxy primer and painted the underside of the plenum.

Filled and Primed Top of Plenum

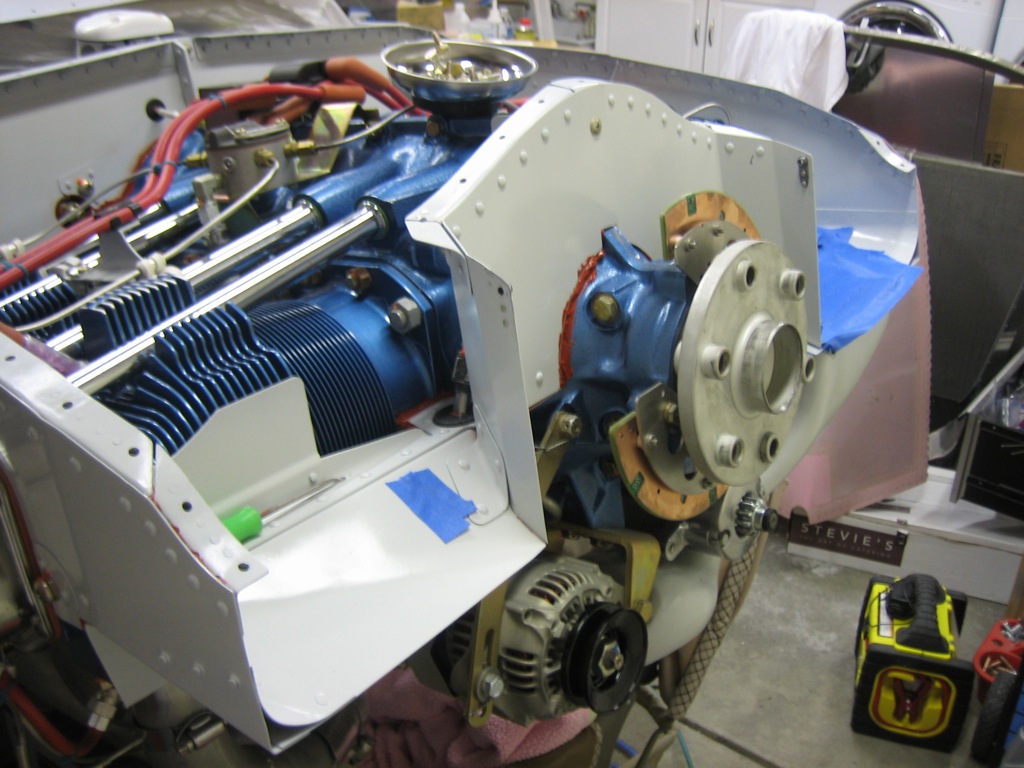

Removed Propeller

I had planned on removing the propeller for a while since it’s really in the way while wrapping up the plane. Doing this solo is kind of a pain, but can be done. With this out of the way, I can walk from one side of the plane to the other with the garage door down. It’s also going to make applying the rest of the RTV around the forward end of the baffles substantially easier.

Finished Sealing Baffles

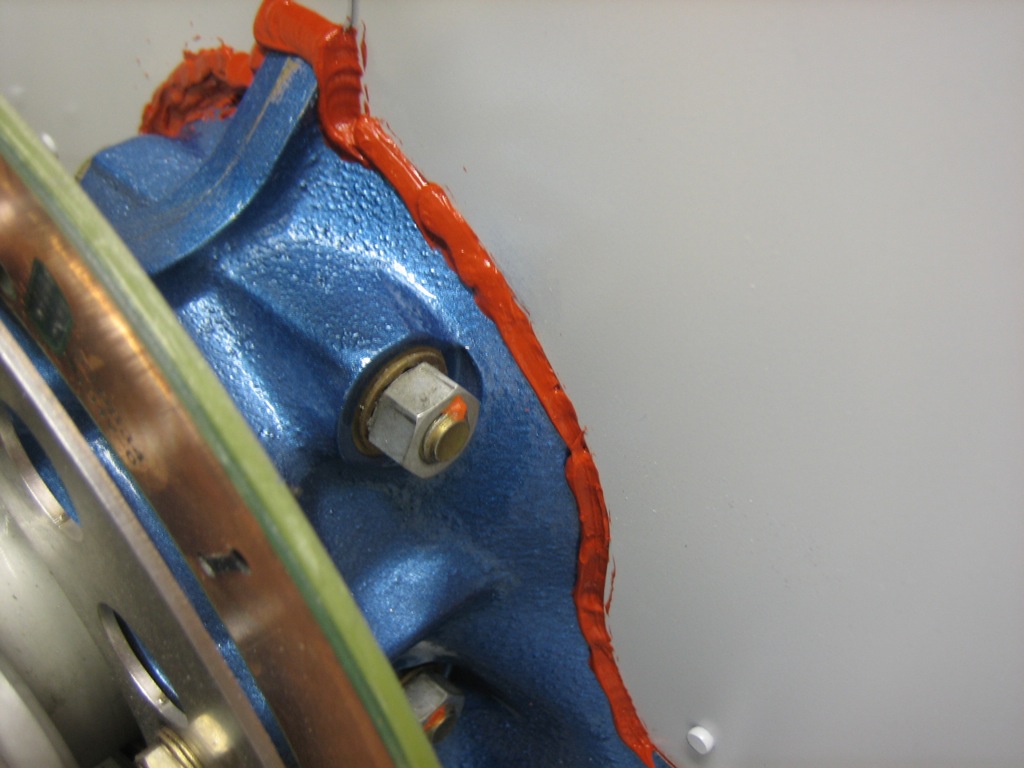

I finished applying RTV around all of the junctions between the baffles and engine. Here’s the forward end just behind the propeller.

This was one of the wider gaps between the baffles and engine. I partially filled it yesterday to provide some support to allow the RTV to fill the gap.

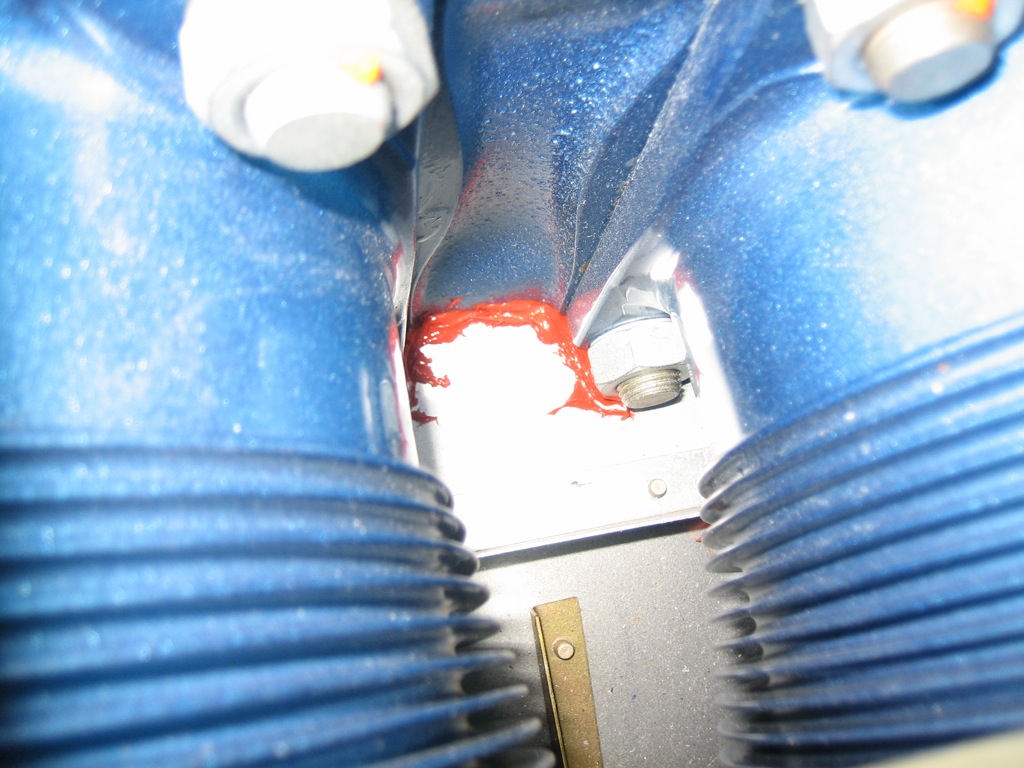

Getting around the edges of the inter-cylinder baffles was a real pain. I had to apply the RTV with a long aluminum rod. I could reach this part by reaching down through the cylinders from the top, but the rest required reaching from the bottom around the intake and exhaust pipes, oil return lines, wires, cables, etc. This isn’t the prettiest application, but it should be air tight.

The propeller control line wasn’t quite sealed by the grommet, so I had to apply a small dab of RTV to fill the gap. I really hope I don’t have to take off these baffles for a really long time.

Painted Inside of Plenum, Installed Sniffle Valve Drain Line

I painted the underside of the plenum with some two-part epoxy paint which matches the baffles. I wish I had ordered this paint prior to painting the baffles since it’s much more solvent resistant than the rattle can paint I used on them.

Between coats, I knocked out a couple of other small tasks. First up was to wrap the engine mount tube with some silicone wrap where the fuel overflow tube is tie-wrapped. I’ve read cautions about tie-wraps sawing through engine mount tubes due to vibration and trapped abrasive particles. I’m not sure how likely that is here, but better safe than sorry.

I also fabricated the sniffle valve drain line and anchored it to the sniffle valve with a short piece of MIL6000 hose. The line parallels the exhaust pipes, but jugs slightly left to clear the oil drain fitting. The aft end is flush with the end of the exhaust pipes and includes a 15º turn down to match them.

I fabricated a short stand-off to space the line away from the exhaust brace. This was primarily done to make the line parallel with the exhaust pipes.