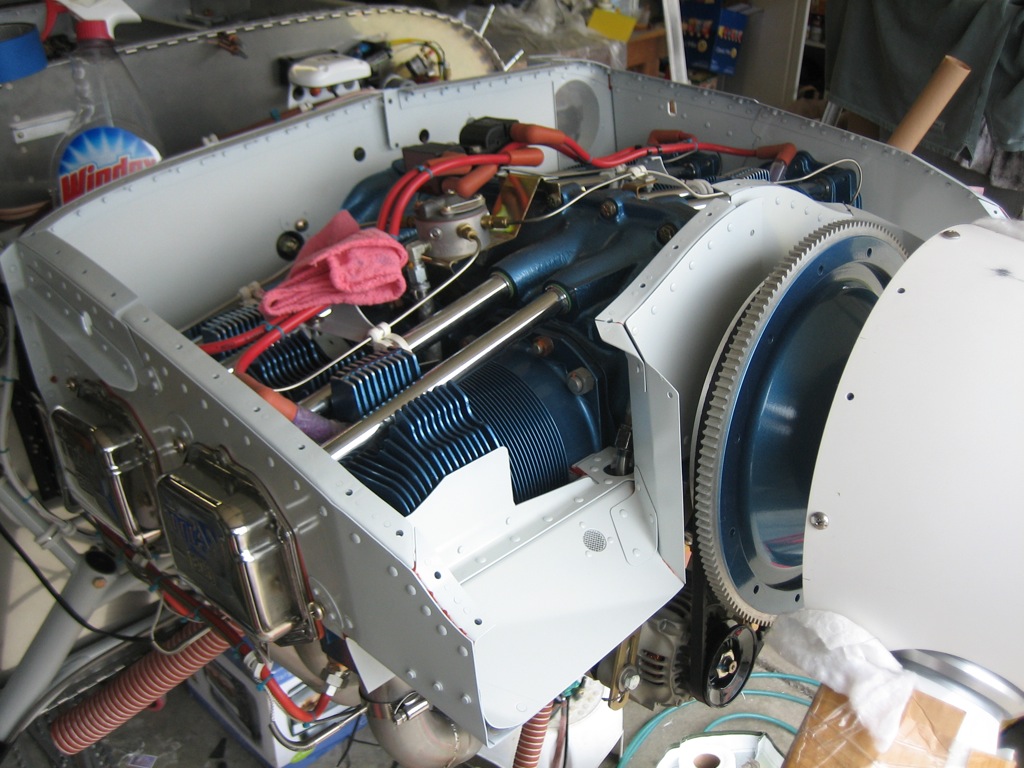

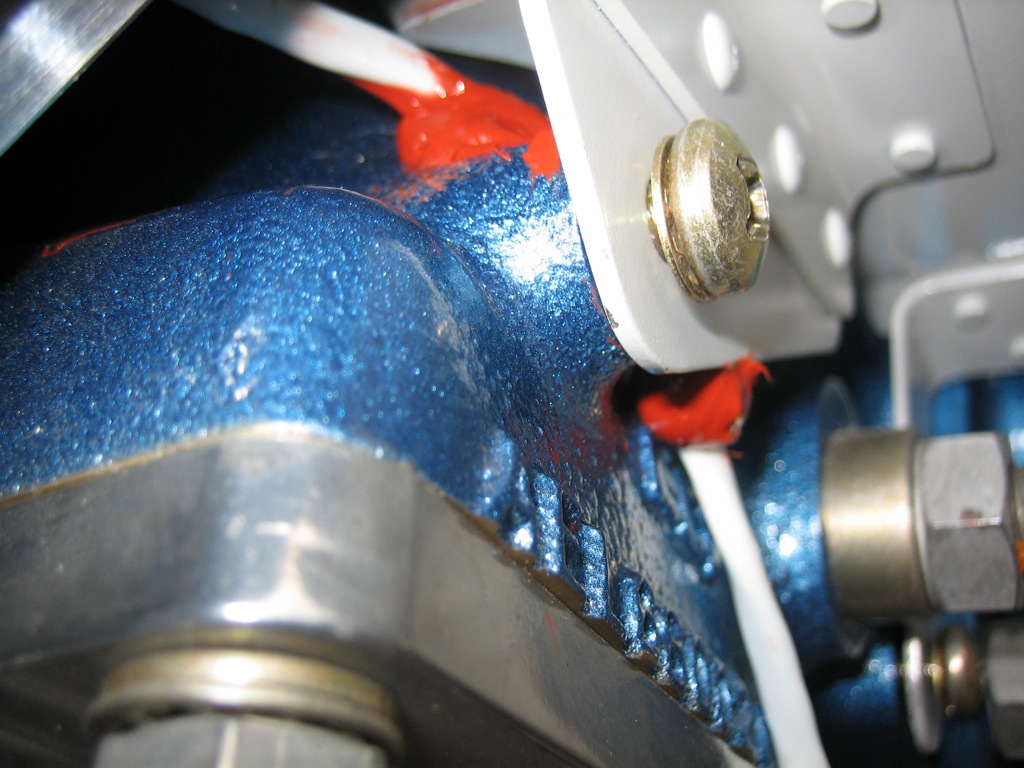

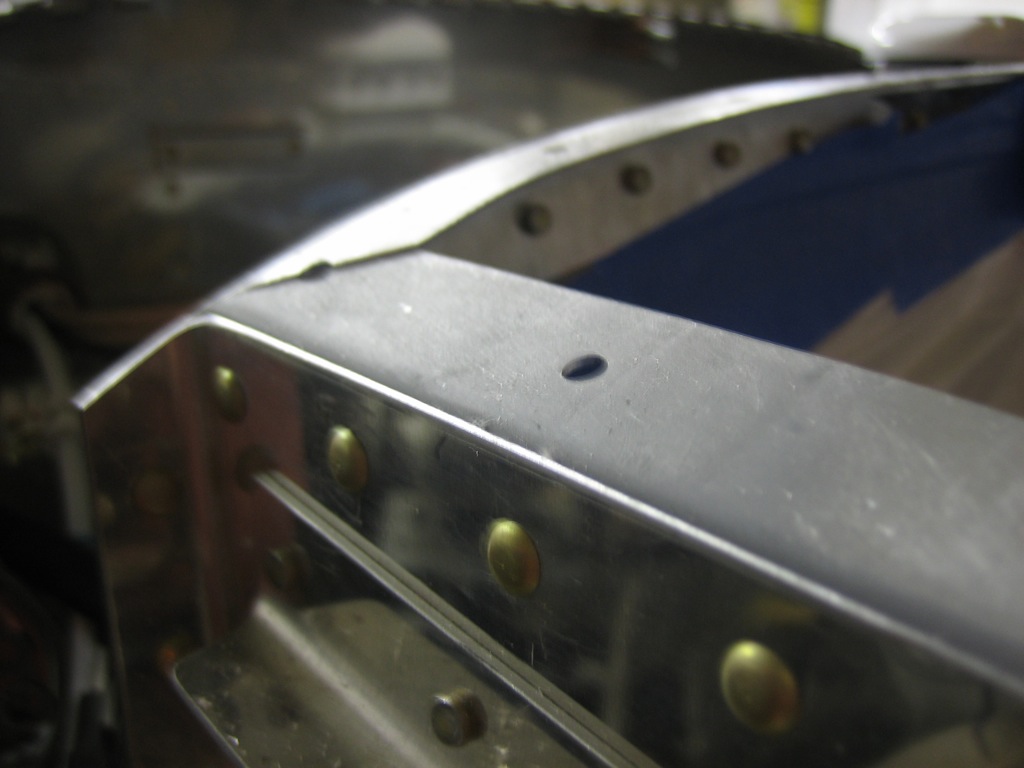

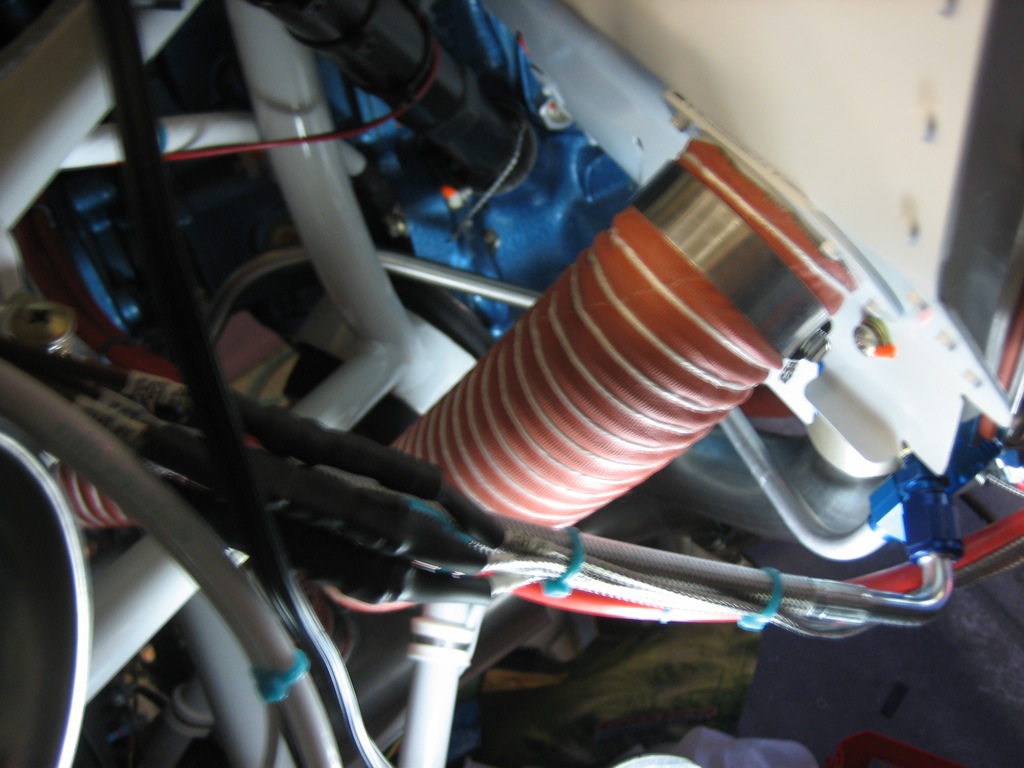

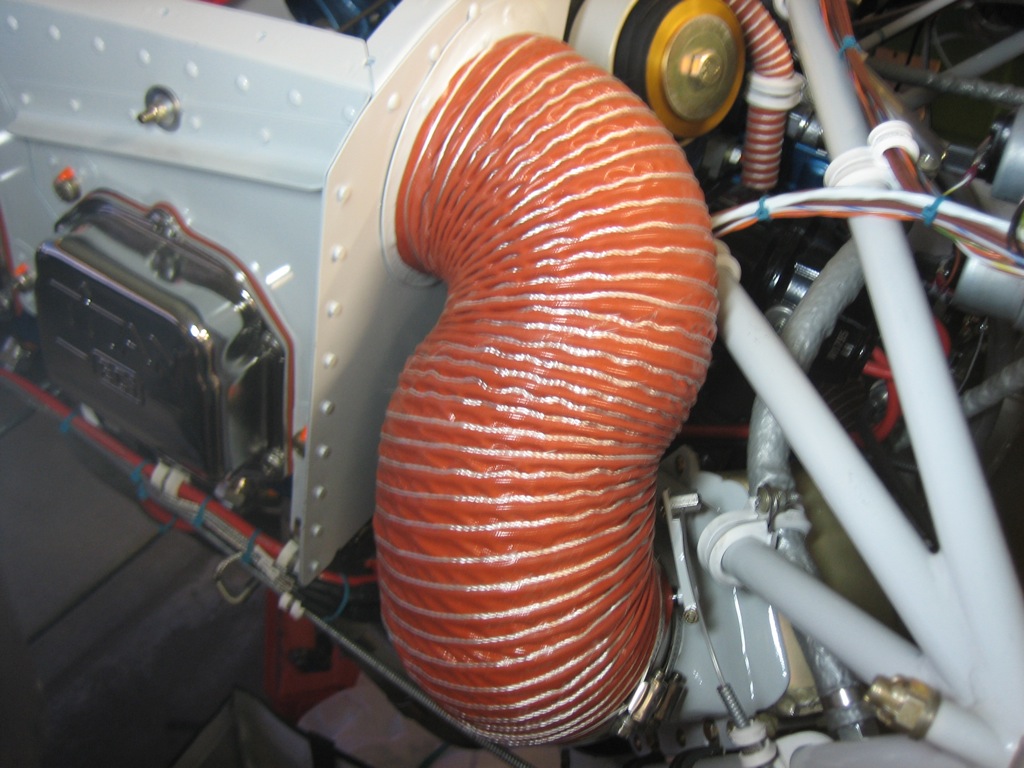

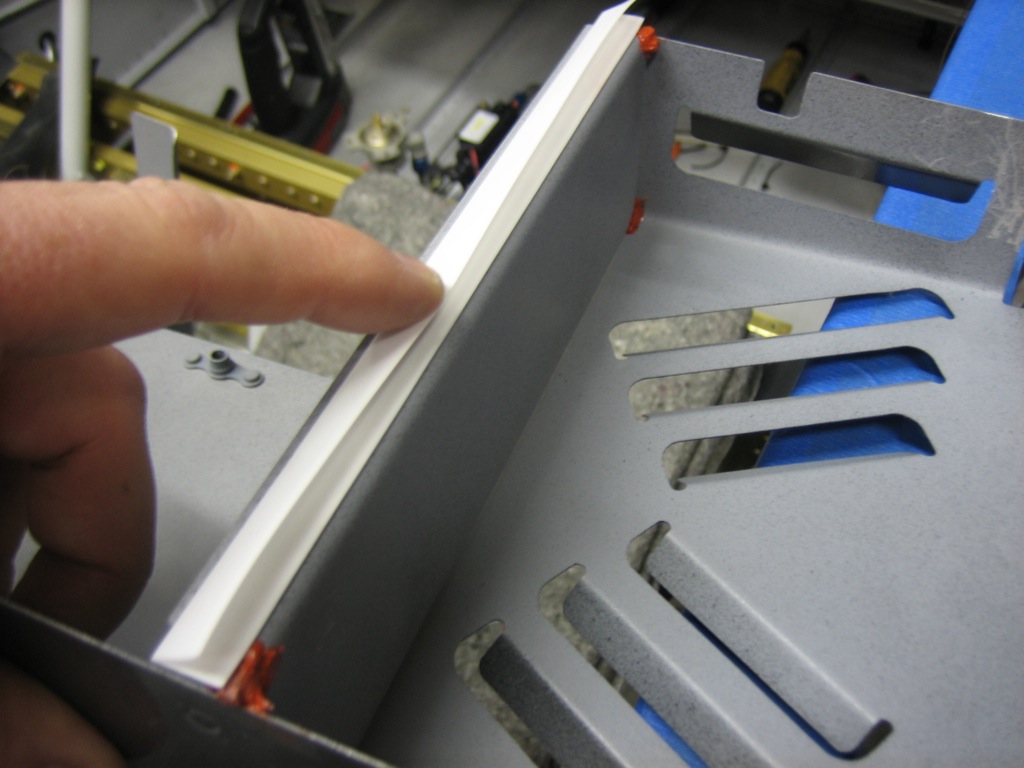

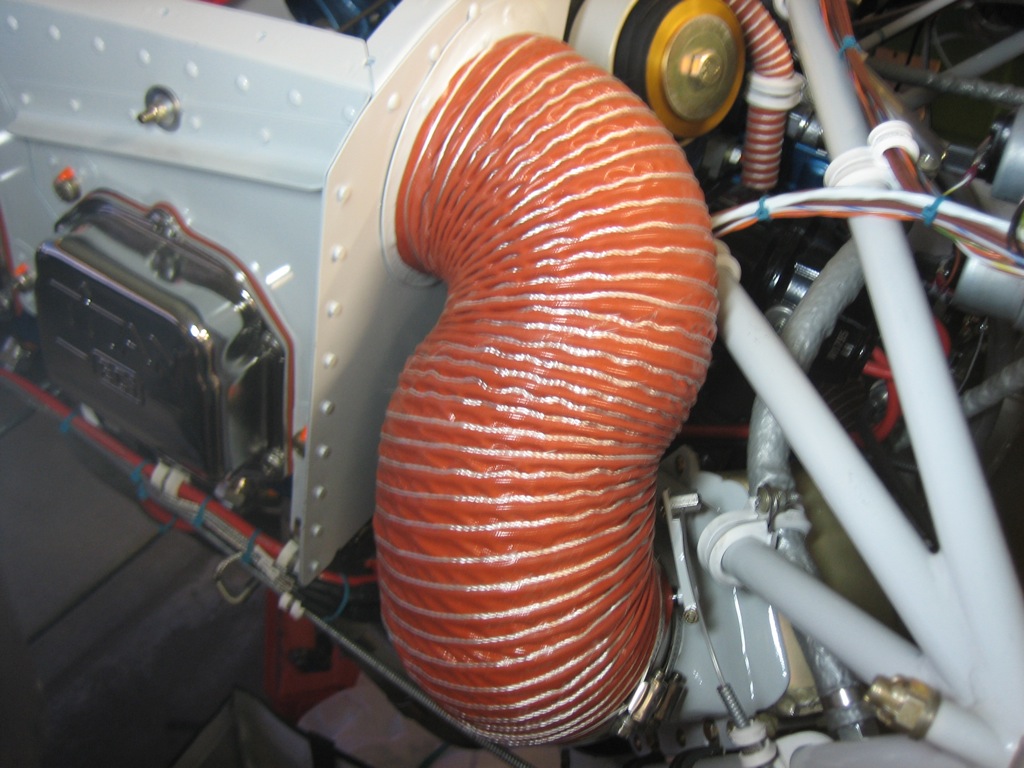

With the baffles installed for good, I wanted to wrap up everything that attaches to them. Here’s the heater air supply duct. You can also see that I put torque seal on all of the screws that attach the baffles. I had to remove and reinstall the oil filler tube to get to one of the screws.

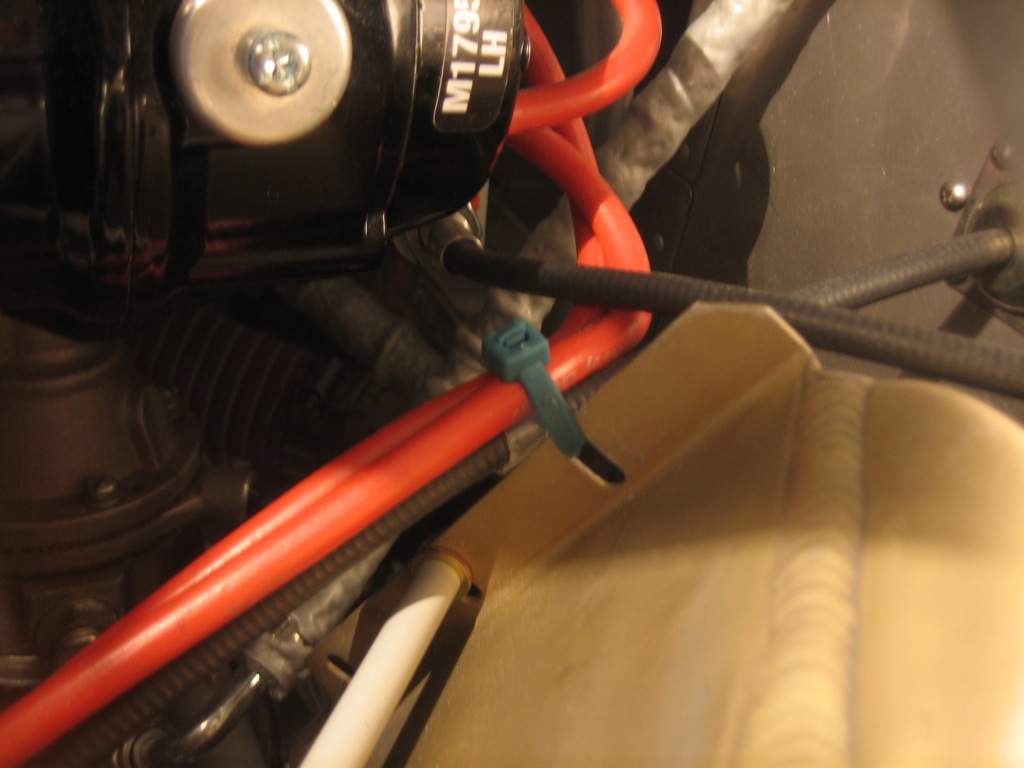

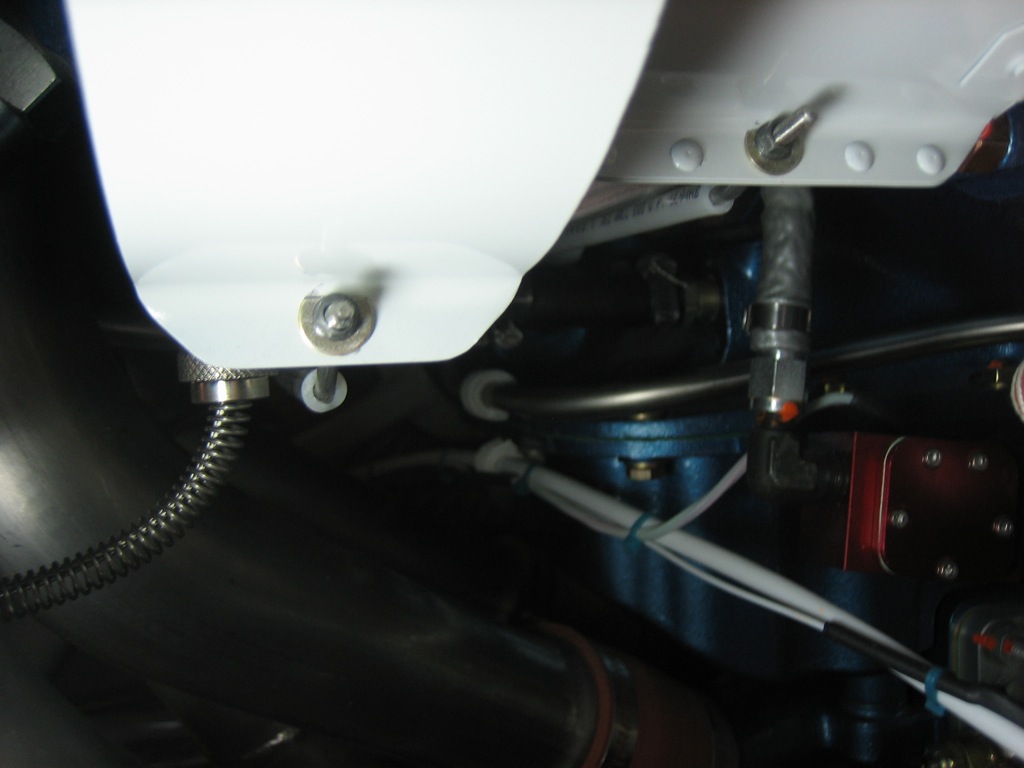

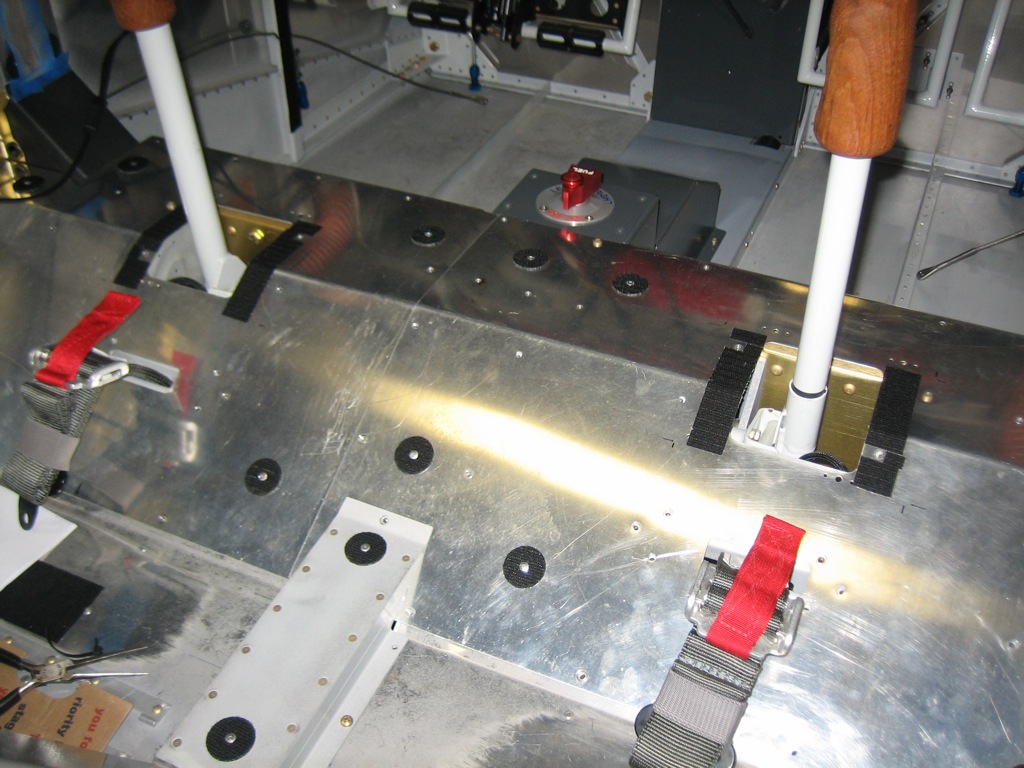

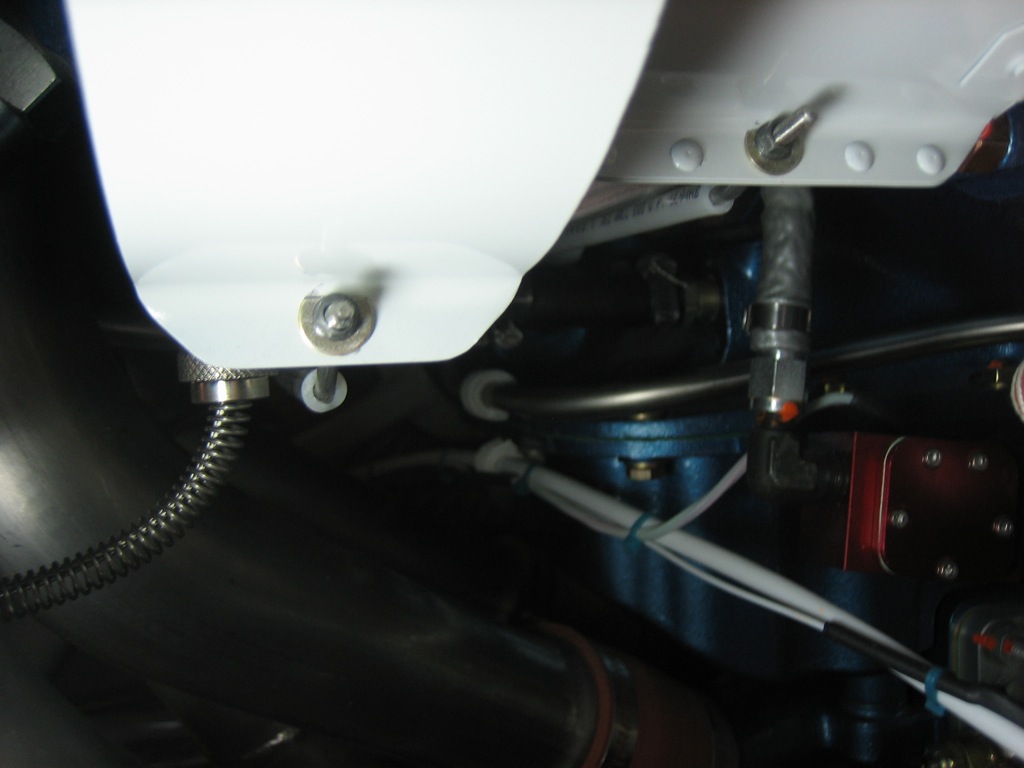

I then installed all of the baffle connecting rods. The rear nut on the left, inner rod was a real pain in the ass with all of the stuff in the way, but I eventually got it.

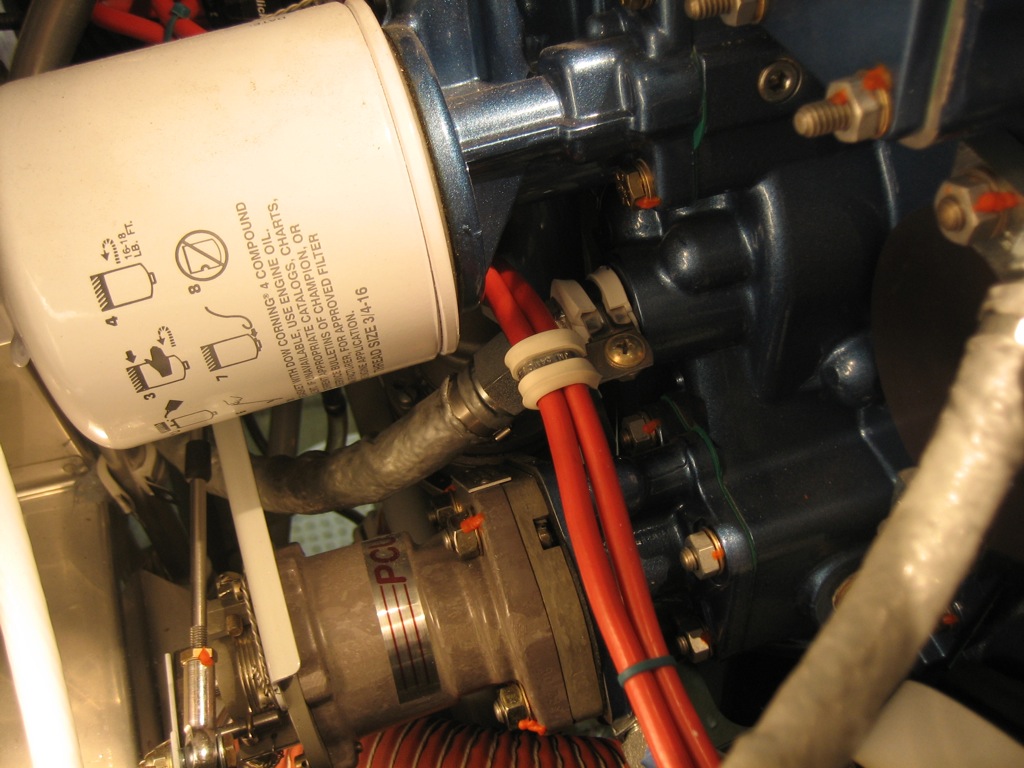

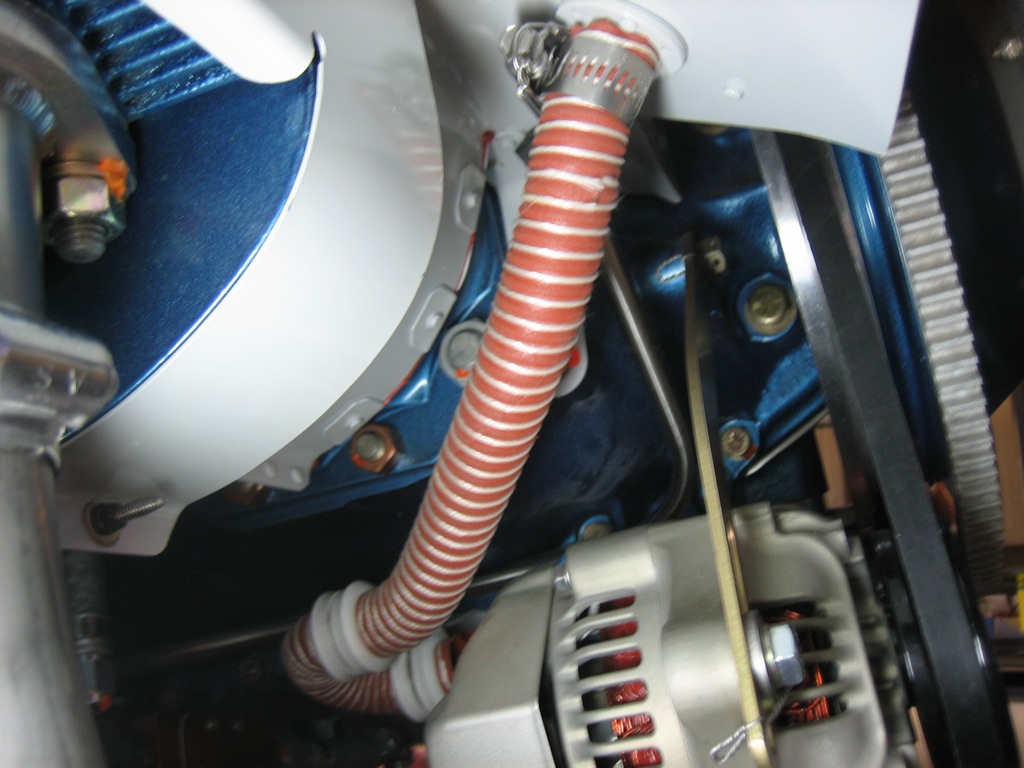

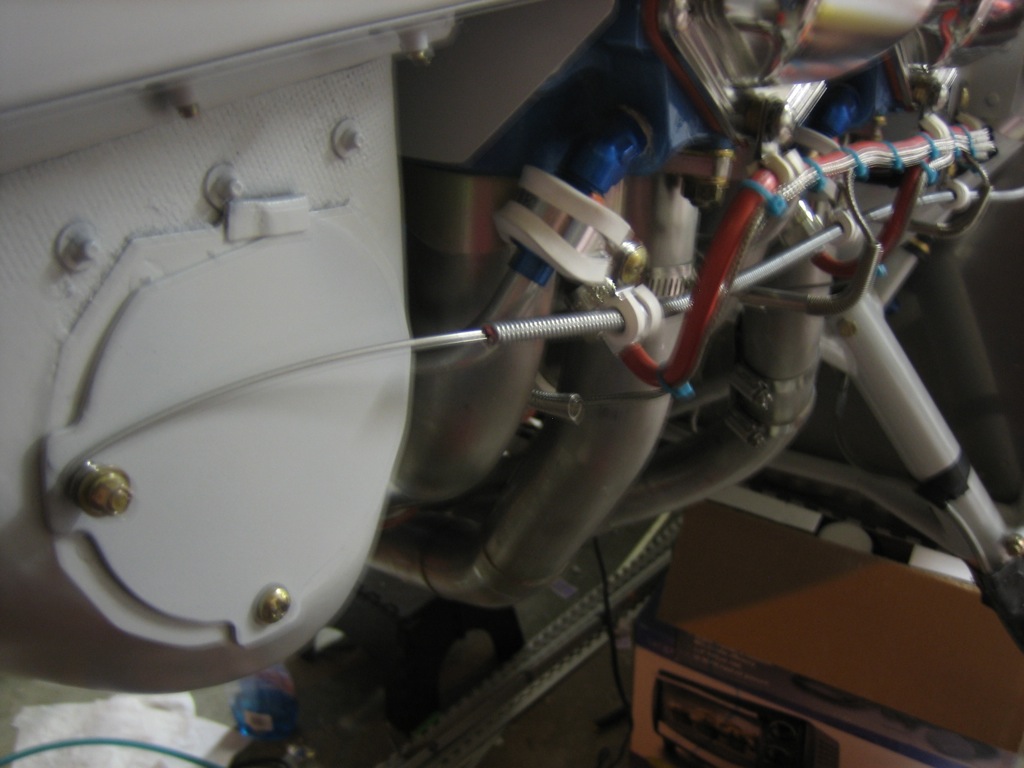

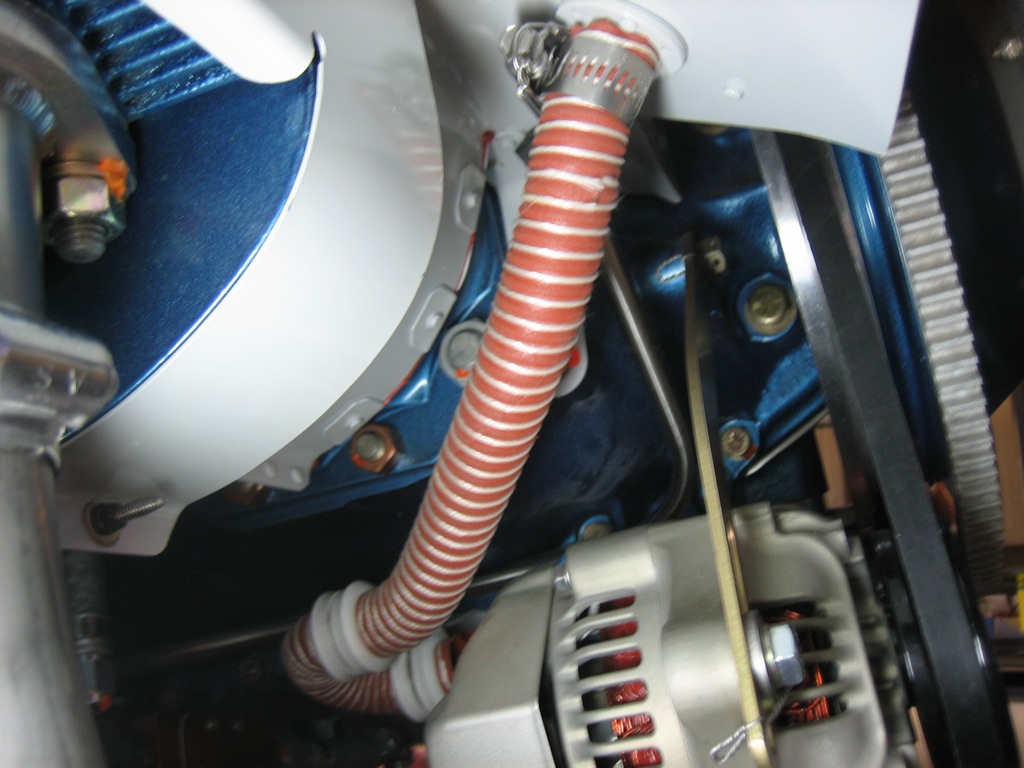

I hooked up the alternator cooling duct to the bottom of the baffles.

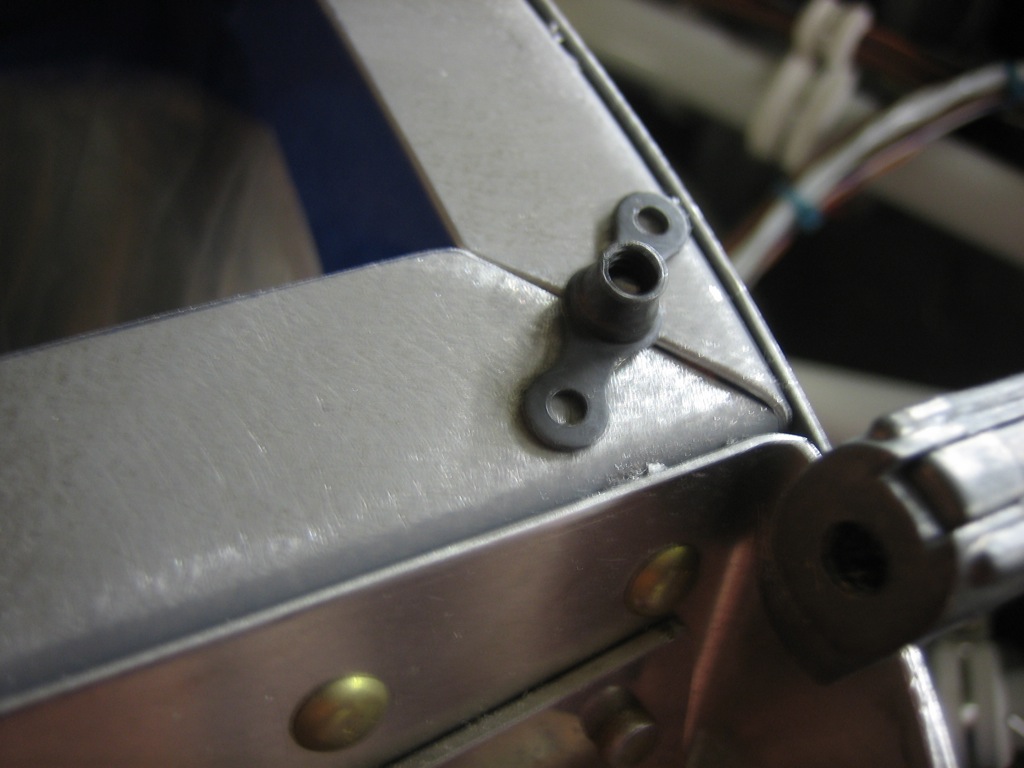

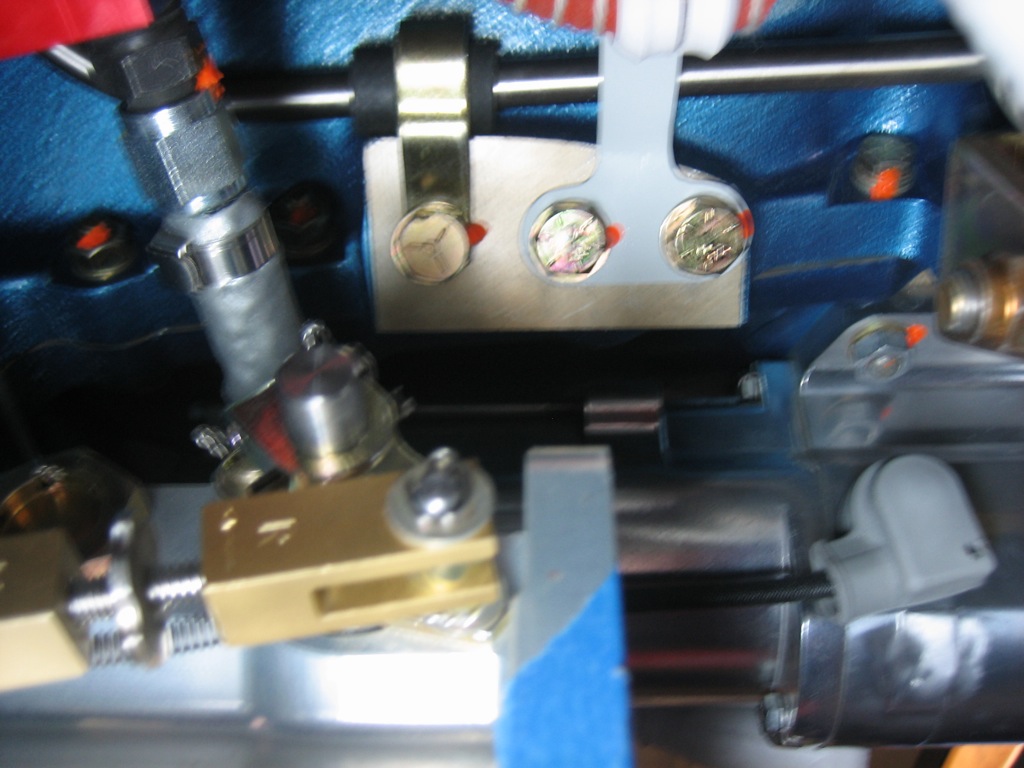

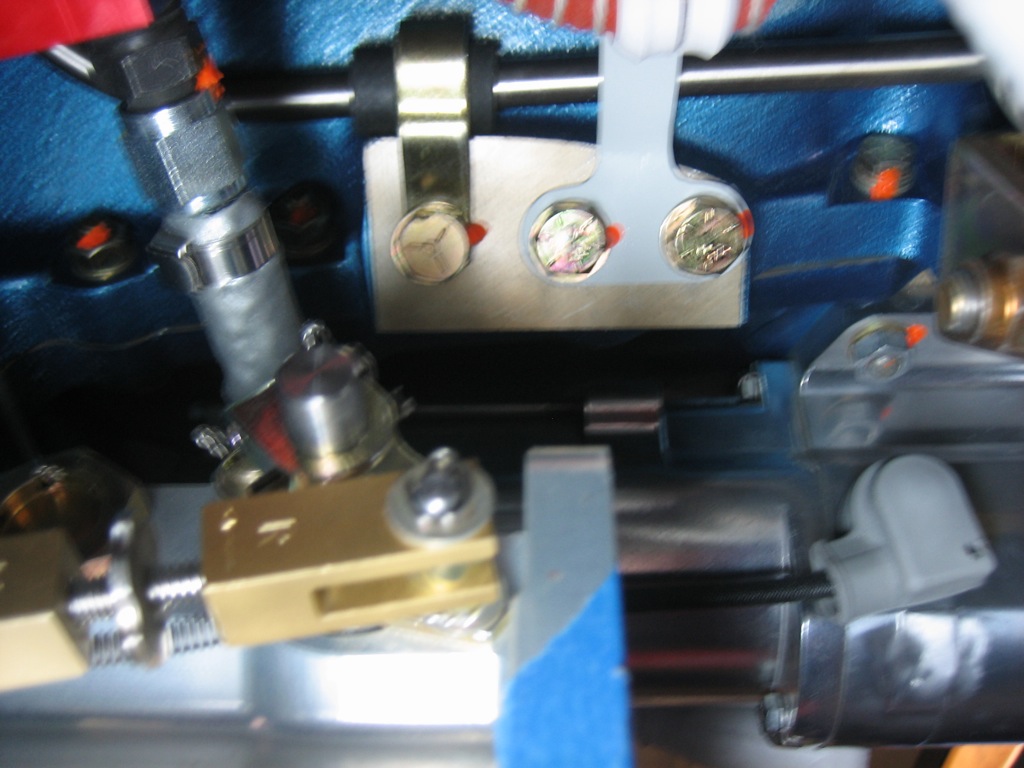

After torquing both ends of the propeller oil line, I reinstalled the support on the bottom of the engine (the shiny clamp on the left here). I also installed the alternator cooling duct support for good and torqued everything down.

I also reinstalled the butterfly valve and 4″ duct feeding it and hooked up the control cable for good. I need to order one more worm clamp for the top and this will be done.

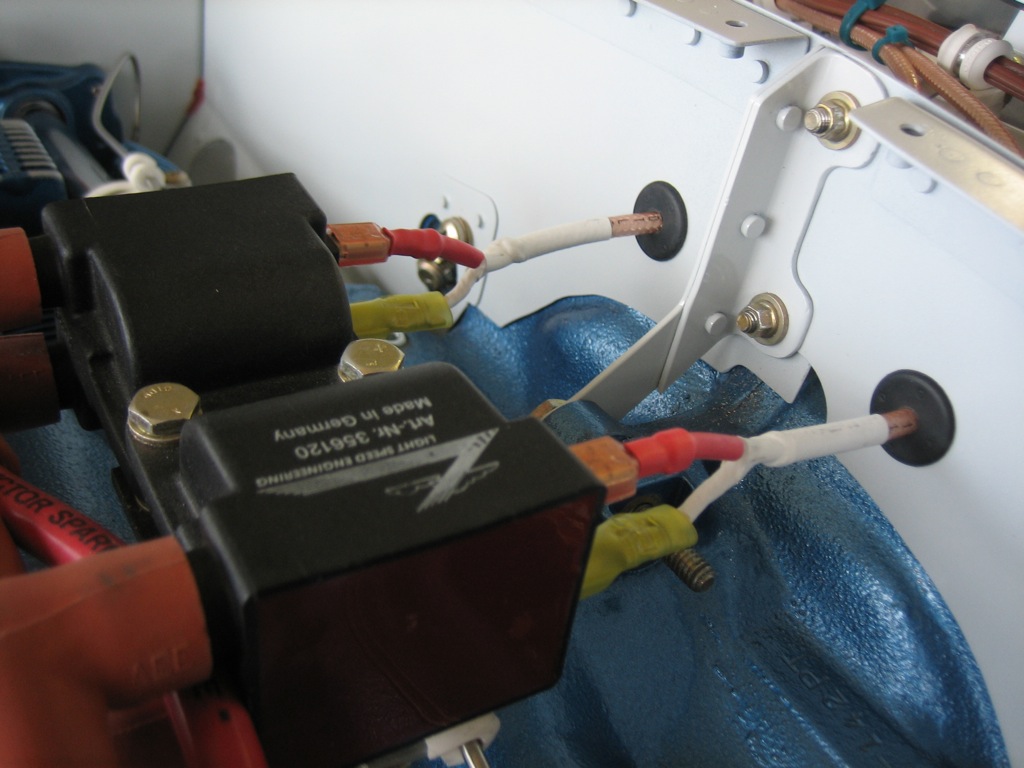

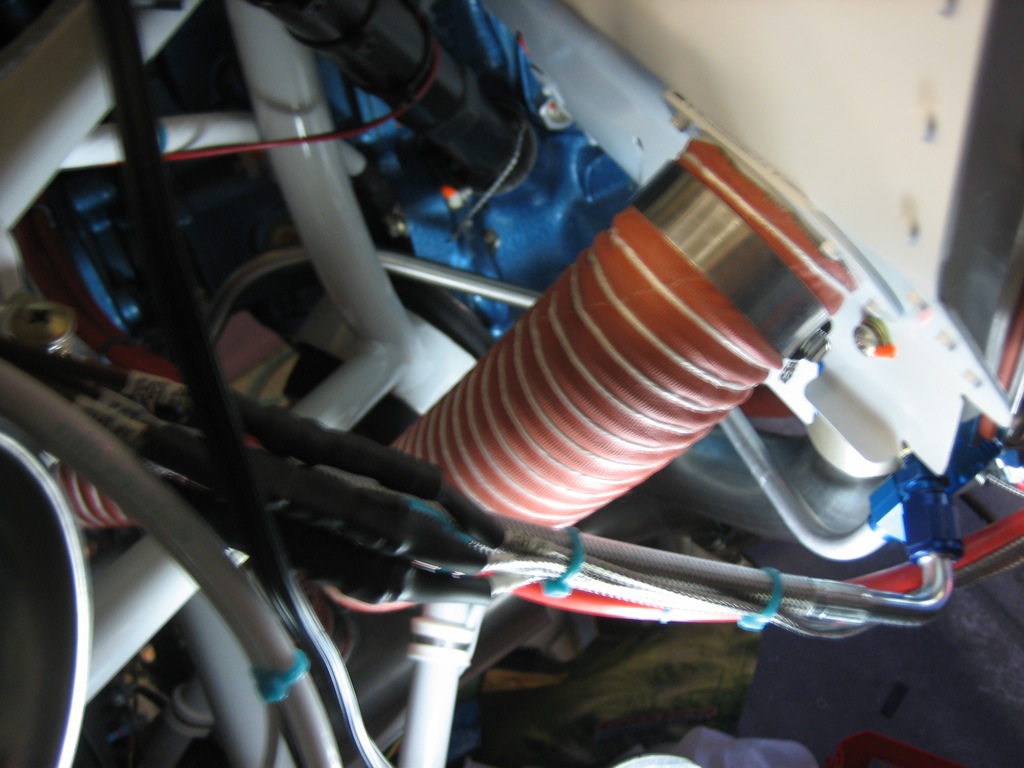

Finally, I installed the magneto blast duct to the back of the baffles. I still need to seal up all of the gaps in the baffles with RTV, but other than that, the baffles are done.