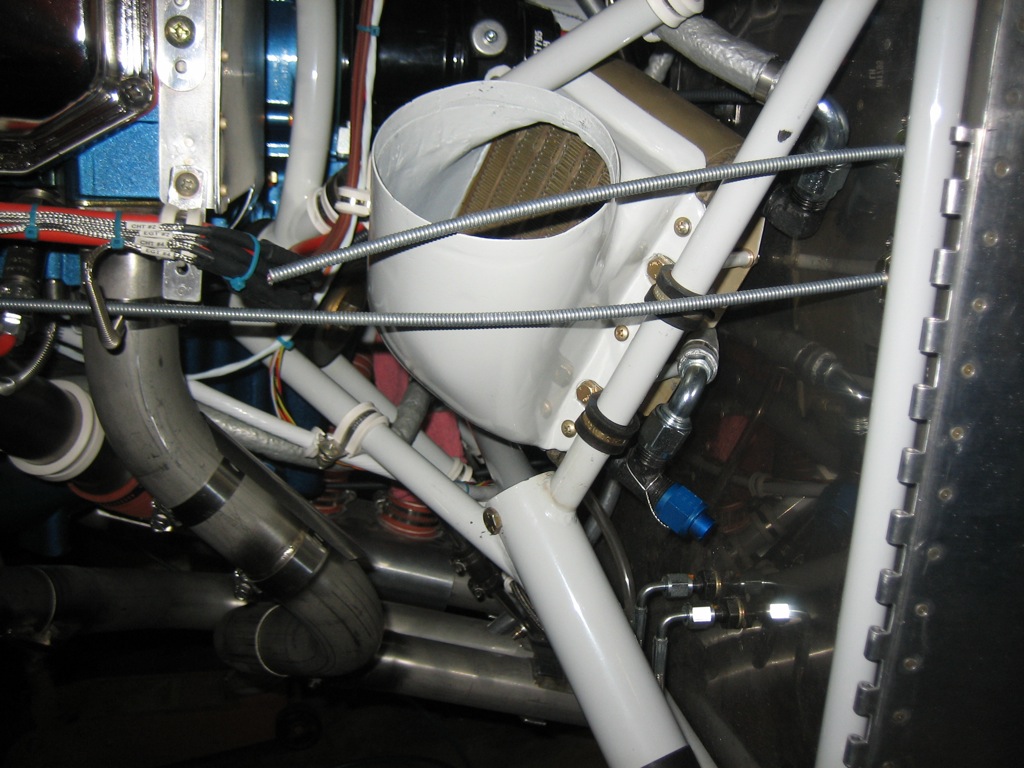

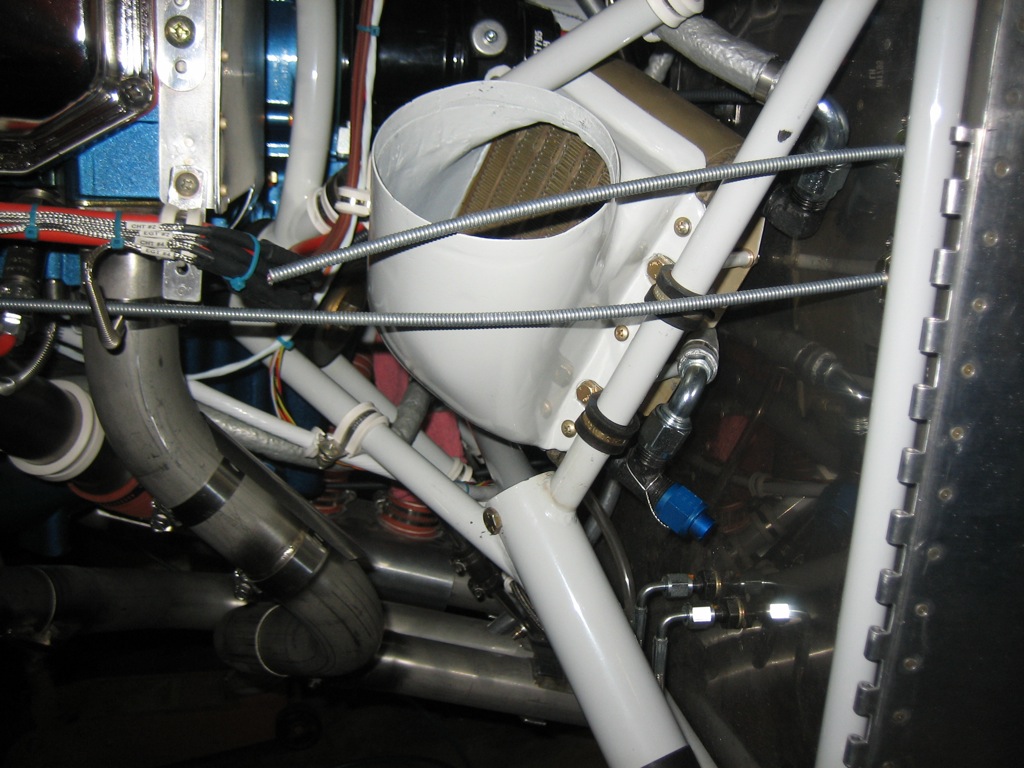

I mounted the oil cooler tonight. This was a major pain in the ass. There is very little room back here to get your hands and there are a bunch of parts to get aligned.

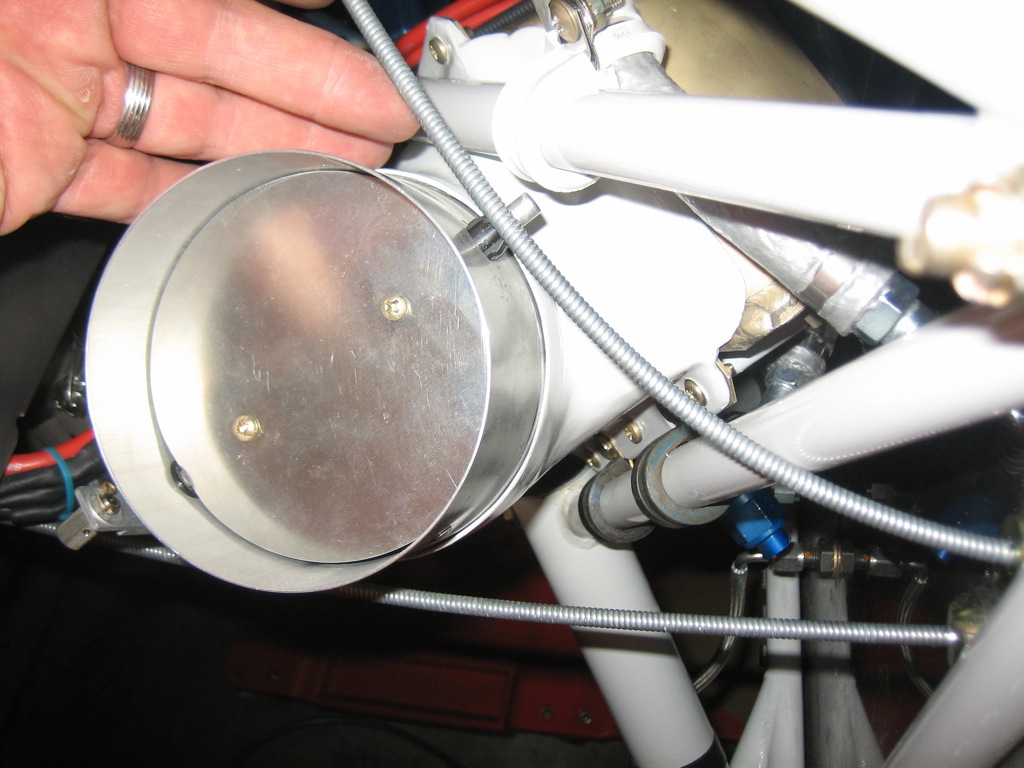

There is about 1/4″ of clearance between the bottom of the oil cooler and the engine mount.

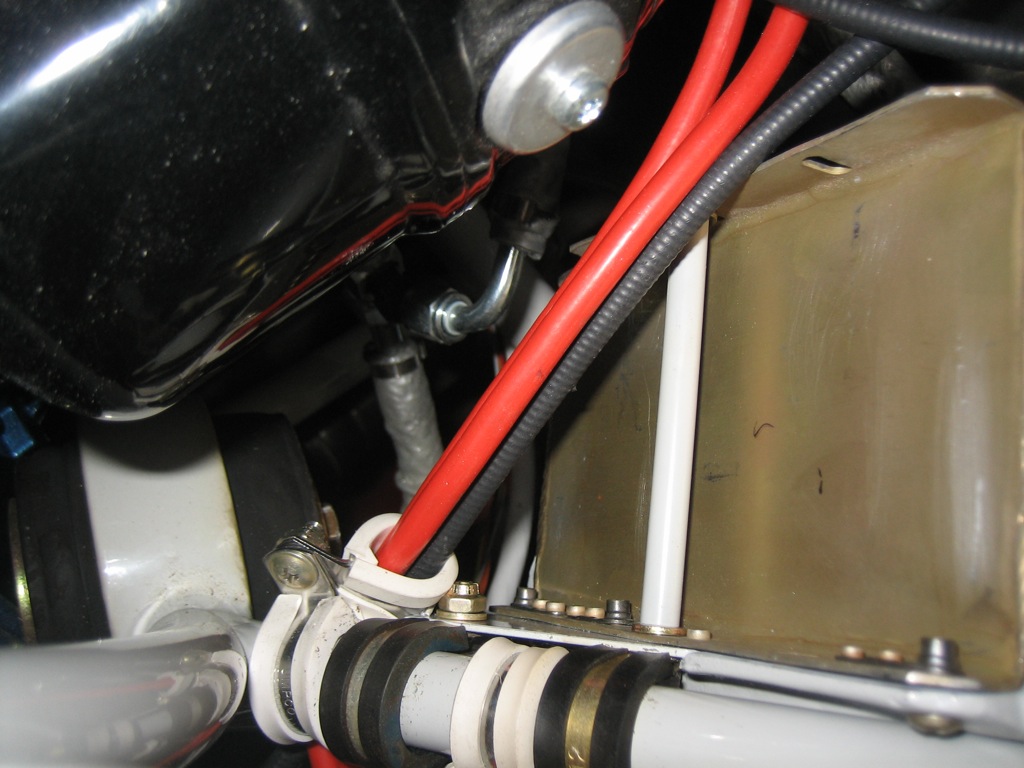

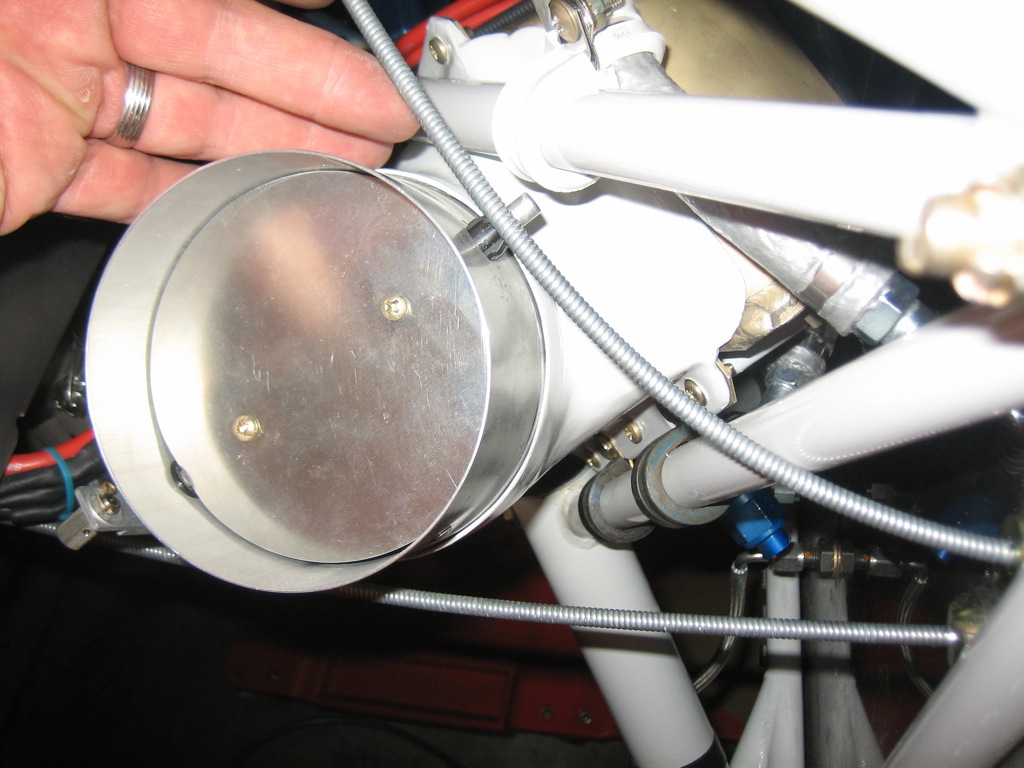

Here’s the left side of the oil cooler. You can see the aluminum tube spacers that let the AN3-41A bolts clamp both the front and back flanges. You can also see that there are washers between the spacers and the oil cooler flanges to prevent the spacers from cutting into the flanges. You can also see that the lower oil line snakes around behind the oil cooler through a cutout in the flange. I’ll add some RTV here to prevent the flange from cutting into the line.

Here’s the other side of the oil cooler. I added another adel clamp at the bottom to keep the mixture cable and lower left ignition wires away from the engine mount. I’ll have to do something similar to keep them away from the rear oil cooler flange.

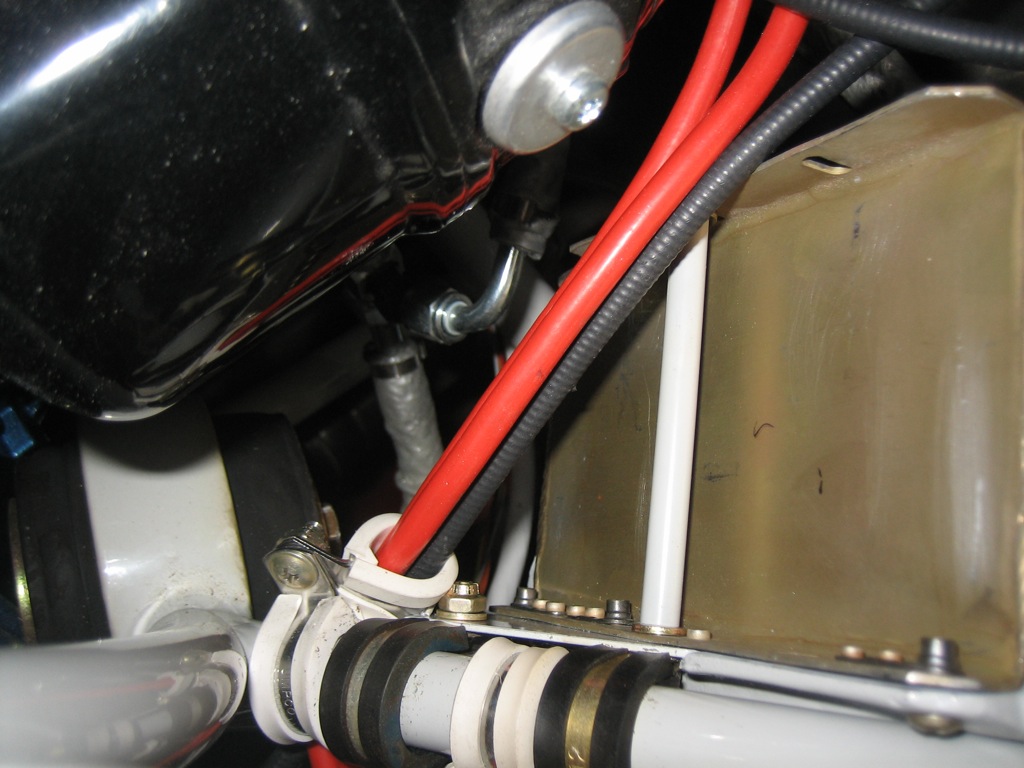

I think this is how I’m going to route the cable to control the oil cooler butterfly valve. This not only keeps the cable and control arm away from the cowl, but will help keep them from getting caught when working on the engine. I’ll need to fabricate a longer control arm and ensure it doesn’t interfere with the scat tubing.