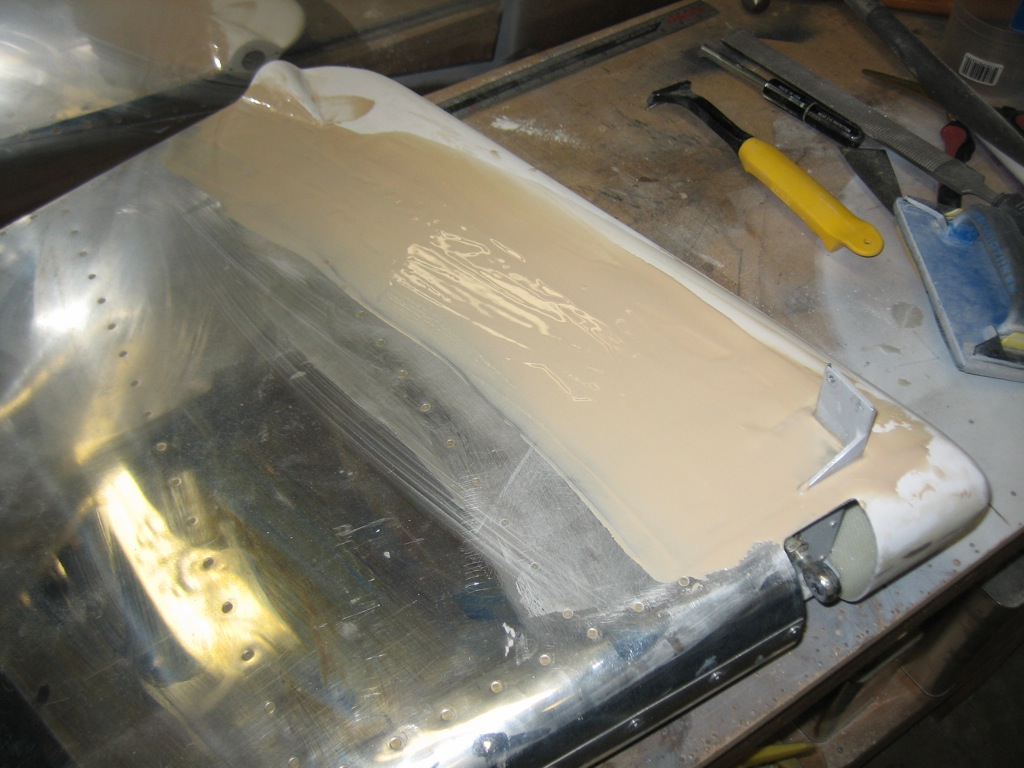

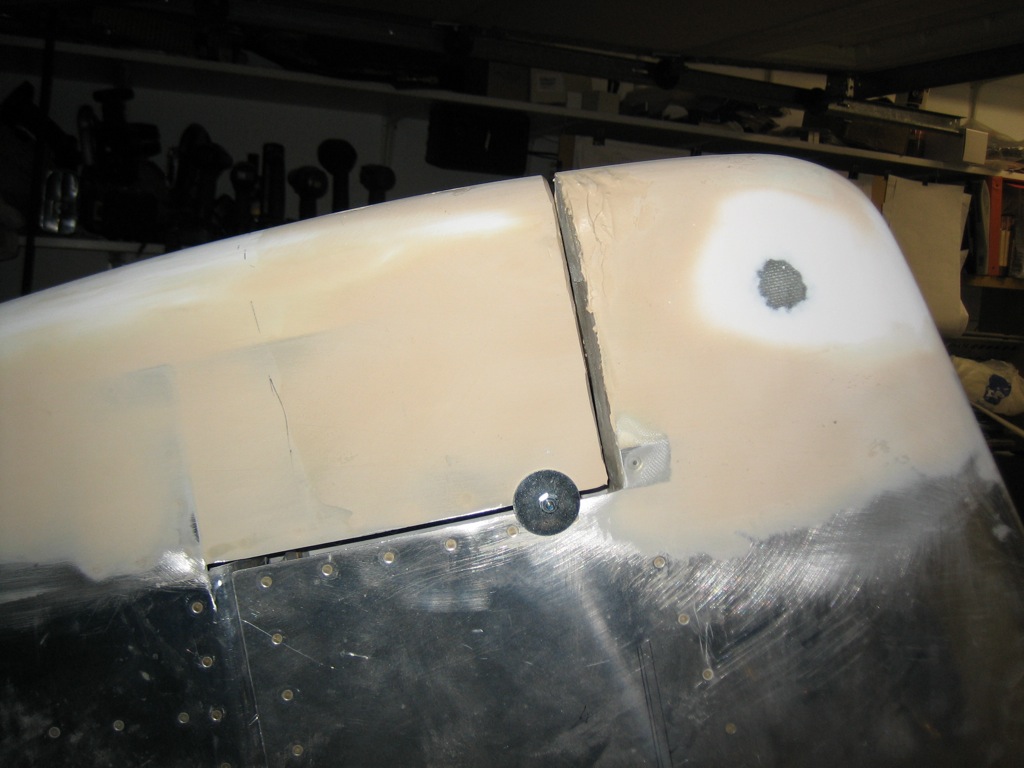

I added a coat of filler to each of the horizontal stabilizer tips.

I also added a coat to each elevator tip as well.

Well, my attempt at reinforcing the bottom of the wingtip was a failure. The Coremat didn’t come with instructions, and apparently, it needs to be saturated with epoxy in order to work. I managed to pop the glass off and the Coremat released pretty easily from the inside surface of the wingtip. I tried saturating the Coremat and reinstalling it, but it took a shocking amount of epoxy. It would have easily weighed a couple of pounds, and I would need to do the same thing on the top and both surfaces of the other wingtip. This would be far too much weight to add to the plane just to stiffen up the wingtips.

Before calling it quits for the evening, I decided to apply some filler to the left side of the rudder. I mixed up the epoxy/microlight a little bit thinner tonight, so it should self-level somewhat which will make it easier to sand.

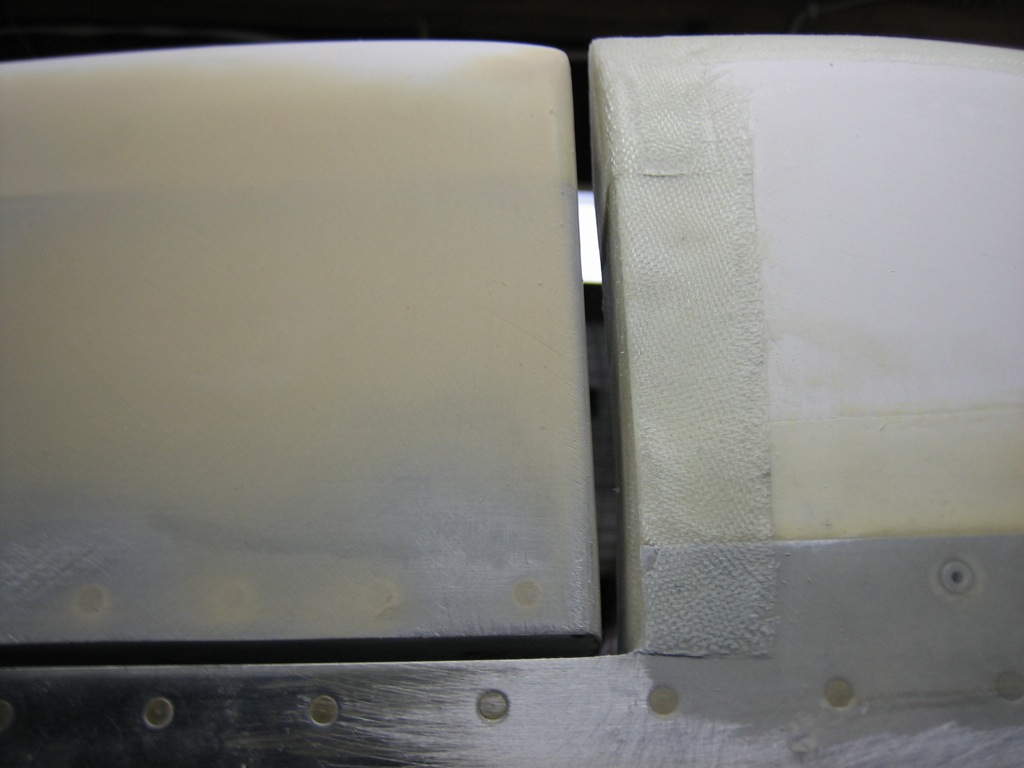

I decided to reinforce the wingtips by glassing in some foam rod. I mixed up some epoxy/microlight/flox and bonded the rod to the inside of the wingtip and formed a fillet along both sides. Afterward, I layed up a couple of layers of glass over each rod and then reinstalled the wingtip to put the right curvature in the skin.

I sanded down the filler on the left side of the rudder and then applied some filler to the right side. I also removed the foam from the fiberglass tip at the top of the vertical stabilizer. I need to reshape the tip a bit to fair it in with the rudder.

Here’s the cured fiberglass over the foam rod. This worked great. It’s incredibly light (just a couple of ounces per rod at the most), and added a surprising amount of stiffness to the wingtip. The Coremat I was going to add would have made it stiffer for sure (probably close to the stiffness of the cowl), but that would have been overkill. The wingtips simply do not need to be that strong and the weight penalty was excessive.

I’ve been meaning to reshape the vertical stabilizer fairing for some time. I originally installed the foam rib based on the shape of the tip right out of the box, and not how it looked relative to the rudder horn. Unfortunately, it turned out fatter and shorter than the rudder horn, so I needed to reshape it. I removed the old foam rib and used a clamp to squeeze it (making it both narrower and taller). I then used a heat gun to soften the epoxy so that it would take the new shape. I wrapped the rib in some fiberglass which will stiffen everything up a lot. I’ll still need to add a bunch of filler to both the fairing and rudder horn and sand them at the same time to fair them together.

While that’s curing, I added some foam rod and glass to the upper side of the right wingtip and then reinstalled it on the plane to set the curvature.

You can clearly see the profile of the vertical stabilizer tip and rudder tip together don’t form a single continuous curve.

You can also see that the gap between them isn’t uniform. I’ll fill this later to create a uniform 3/16″ gap which is the same as the lower horizontal gap.

I mixed up some filler and applied it to both fairings. You can see that I built up the rudder tip quite a bit. I also widened the rudder horn about 1/16″. I’ll sand all this down with the rudder clamped in trail so that they’re perfectly faired together.

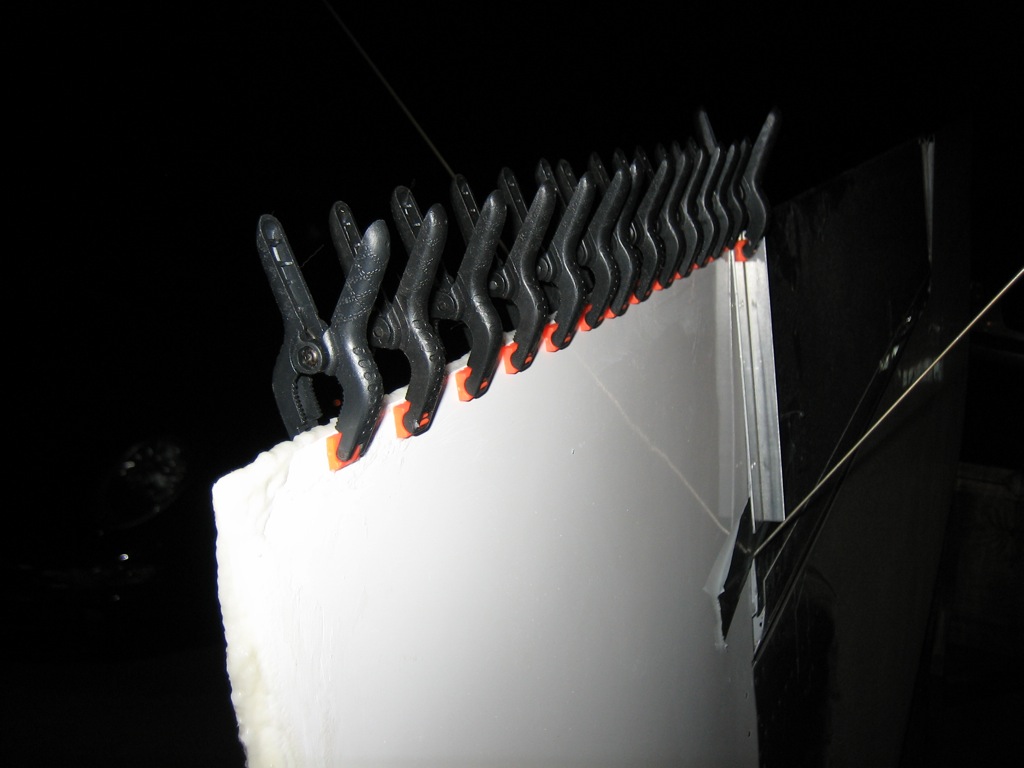

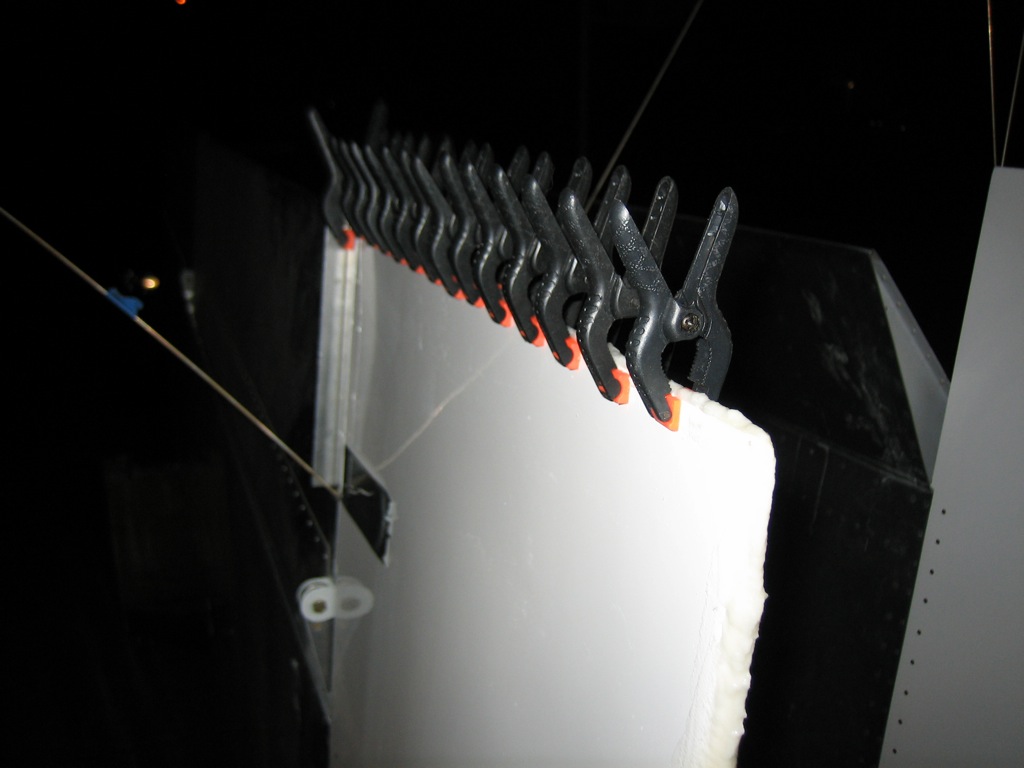

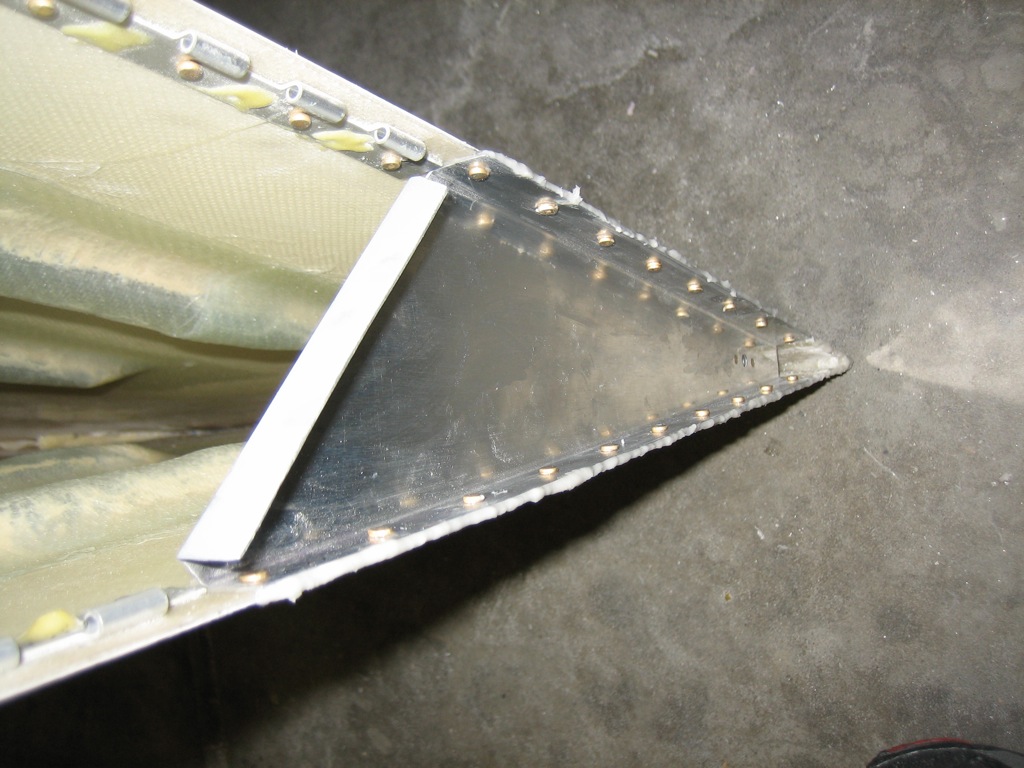

With the internal stiffeners glassed in, I could glue the trailing edge back together. I mixed up some epoxy/flox and put a bead down the back. I used a bunch of small spring clamps to hold the trailing edge closed while the epoxy cures. The clamp in the back is holding a couple of scrap pieces of aluminum angles and span the gap between the aileron and wingtip ensuring that the wingtip perfectly follows the edges of the aileron.

You can also see some epoxy/flox on the outer edge of the wingtip. I needed to add a little bit so that the outer edge of the wingtip could be filed to a straight line.

I finished up the last of the wingtip reinforcement. I’m super happy with how this has turned out. It’s very light and the tips are substantially stiffer.

I needed to start fairing the rudder and vertical stabilizer, but I wanted to do it on the plane since it will be at a more comfortable working height. With the rudder bottom fairing in place though, the rudder couldn’t be mounted since the fairing hits the tailwheel spring. I measured and chopped off a chunk of the fairing.

This fits a little too tight at the front, so I’ll cut off more later. I can’t just parallel the tailwheel spring though since the spring can flex quite a bit. I need more room at the back to account for this.

I started fairing in the rudder and vertical stabilizer. You can see that there is now a continuous curve along the top and the sides match nicely. I need to add a little more filler in a few low spots, but this is turning out very nice.

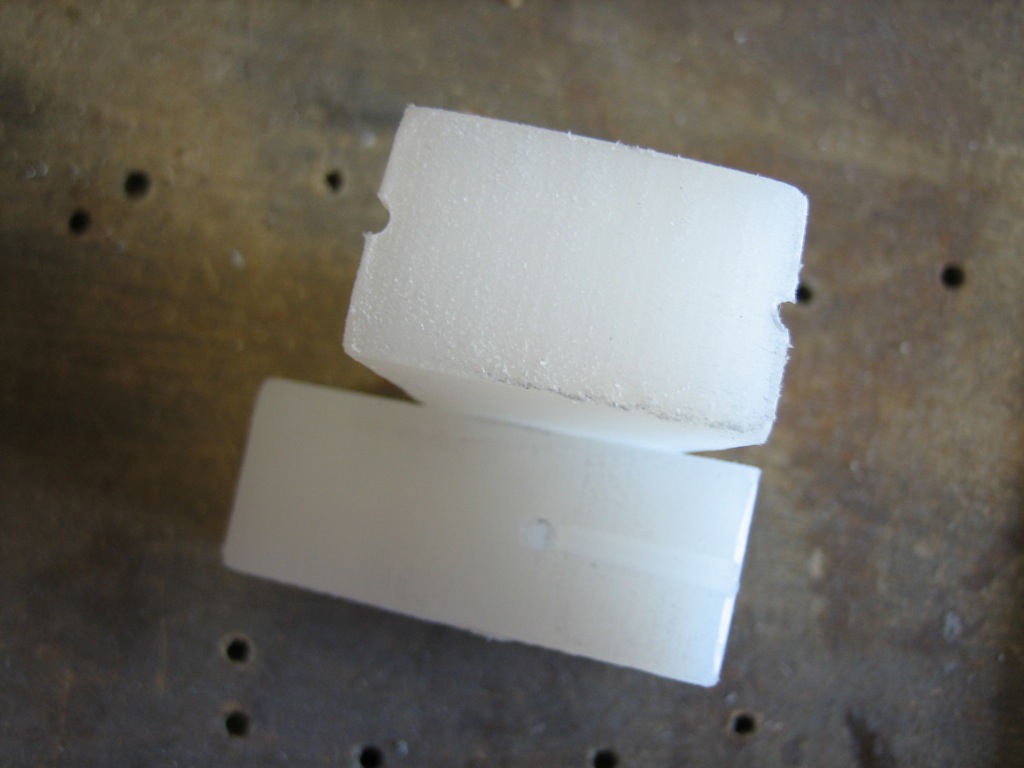

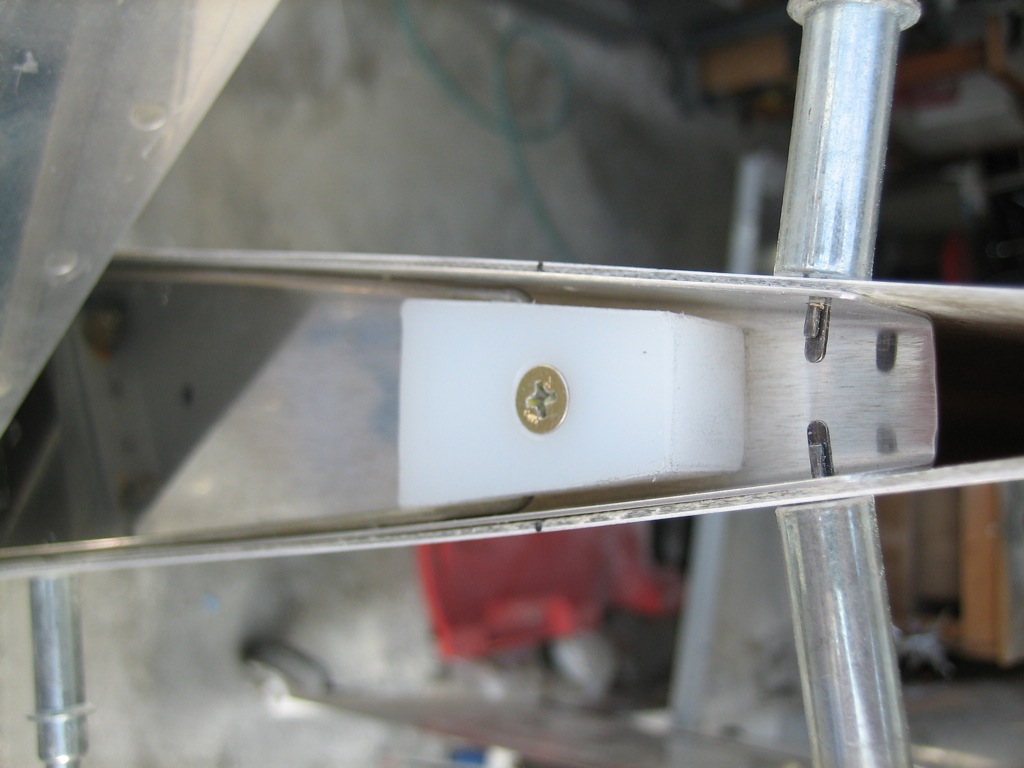

Since the wingtip is held on with hinges, I needed a method to secure the hinge pins so that they can’t come out. I fabricated these retaining blocks out of a chunk of Delrin that I machined down to fit inside the trailing edge of the wingtip rib. It’s held on by an AN509-8 screw.

The screw screws into a nutplate mounted on the back of the rib and through the tooling hole that was already present in the rib.

In the sides of the blocks, I drilled a #43 hole and machined grooves aligned with the holes to capture the hinge pins. I bent the aft ends of the hinge pins 90º so that they will go into the holes.

Here’s how they look when installed. The hinge pins can’t back out of the block because they’re trapped by the flange of the rib. The block also provides a convenient handle to extract the pins.

With those done, I primed the backside of the ribs and installed them with epoxy/flox and soft rivets.

I also sanded down the additional filler I applied yesterday. I still need to apply some filler inside the gap, but the outside shape looks great.