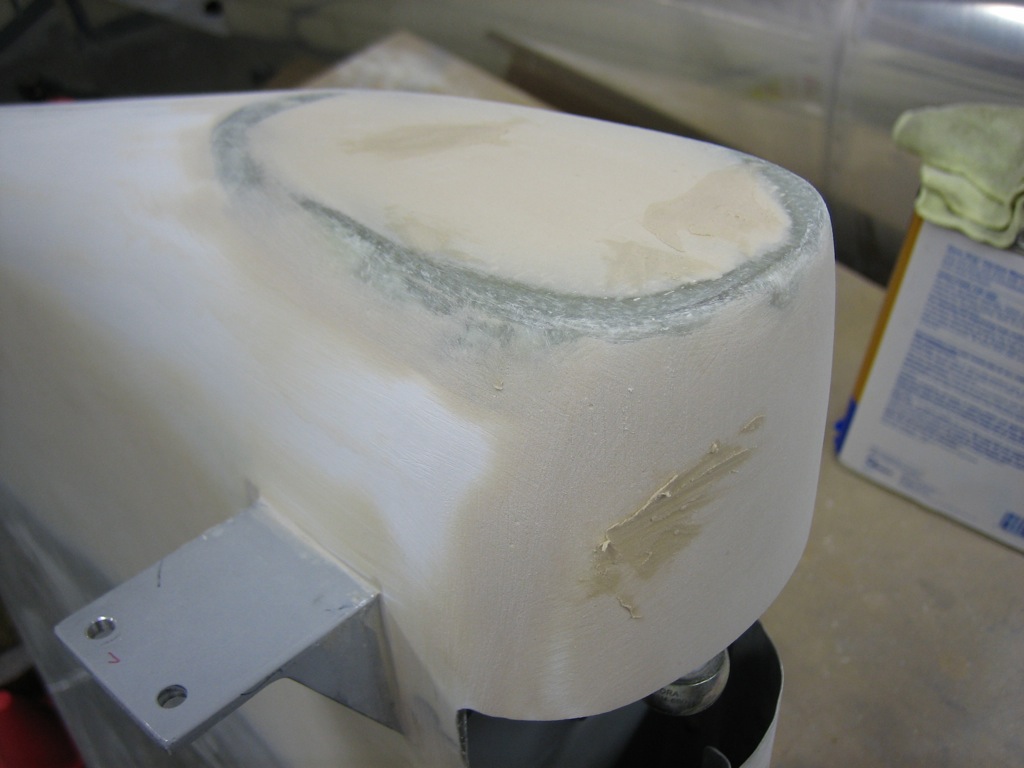

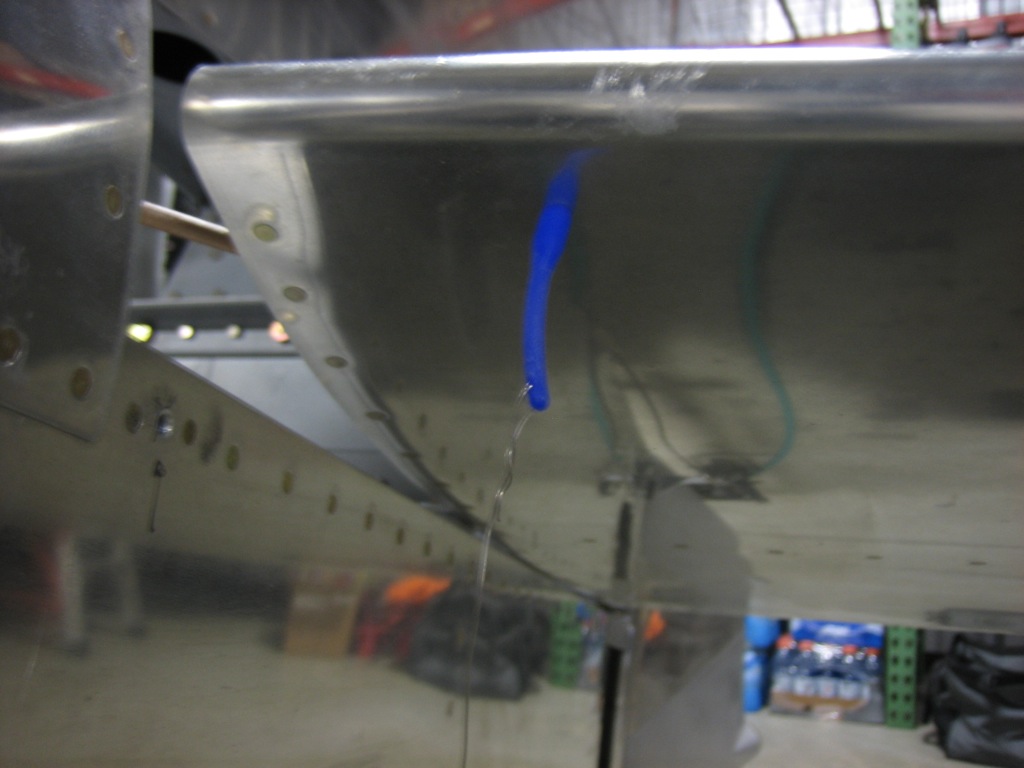

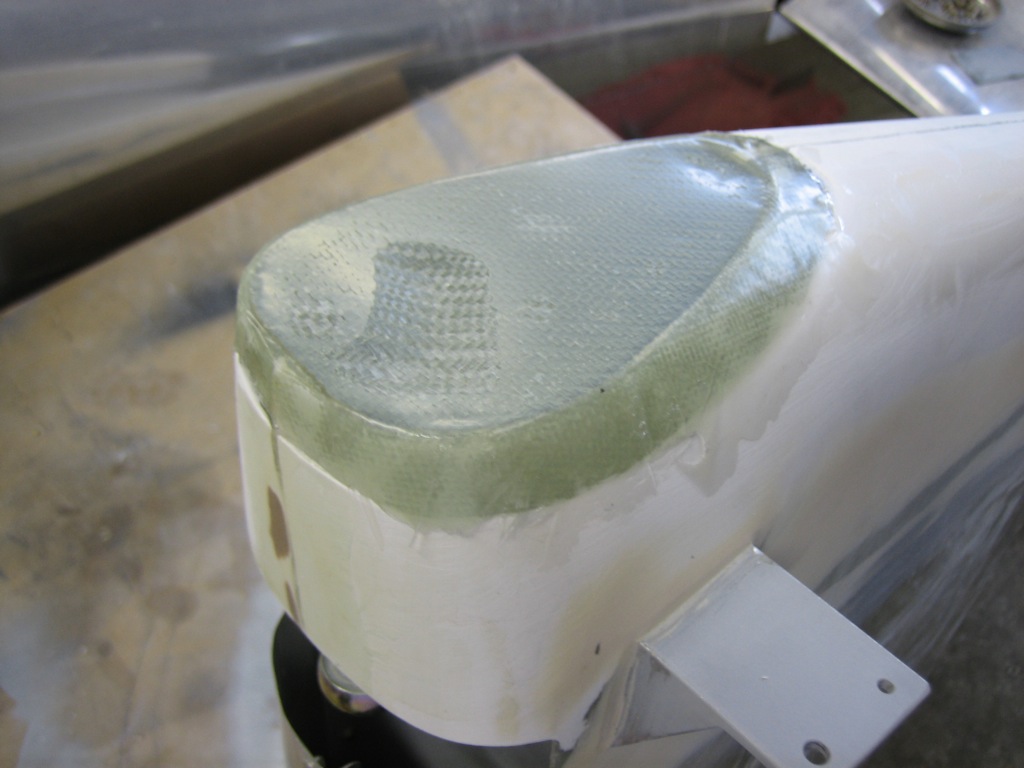

The rudder bottom fairing patch has cured. After filing down the high spots and giving it a quick sanding, I applied some epoxy/microlight filler. The leading edge of the fairing also needs to be built up a bit to match the rolled leading edge of the rudder.

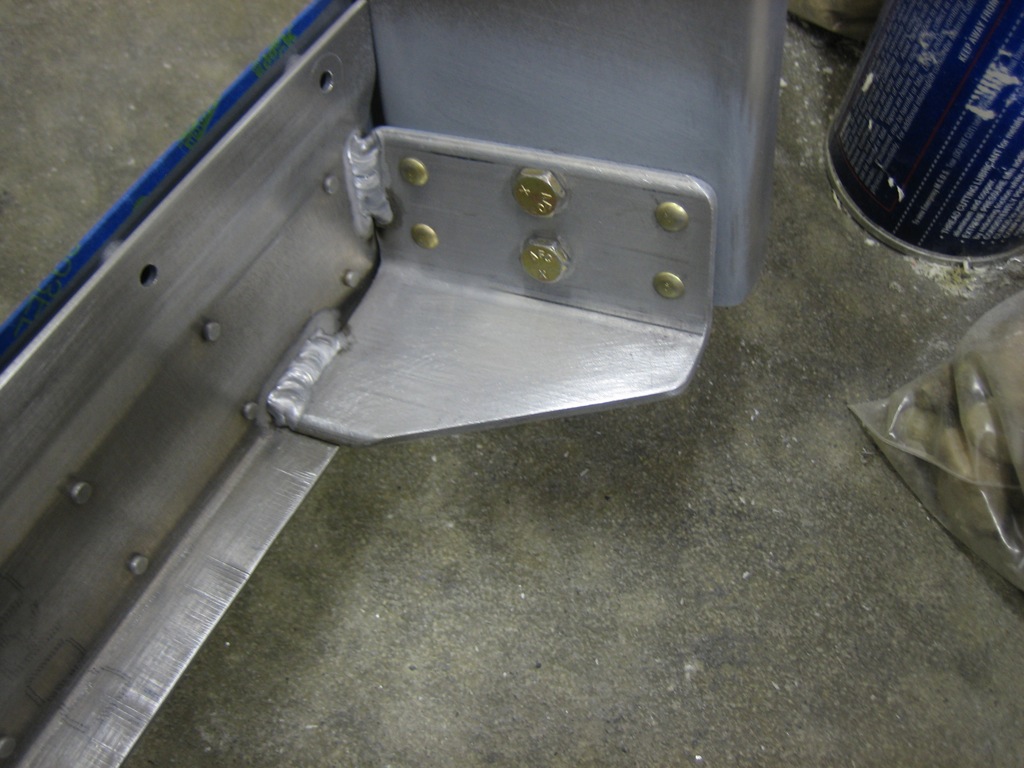

I also added some filler to fair in the horizontal stabilizer and elevators. Here’s the right side.

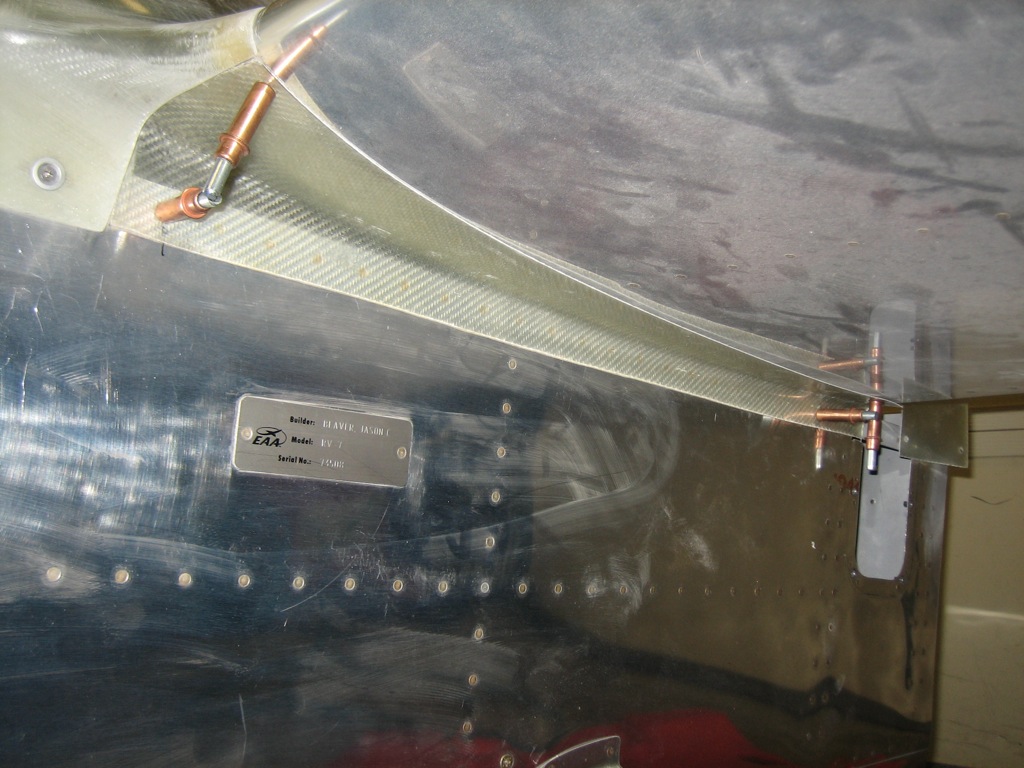

…and here’s the left.

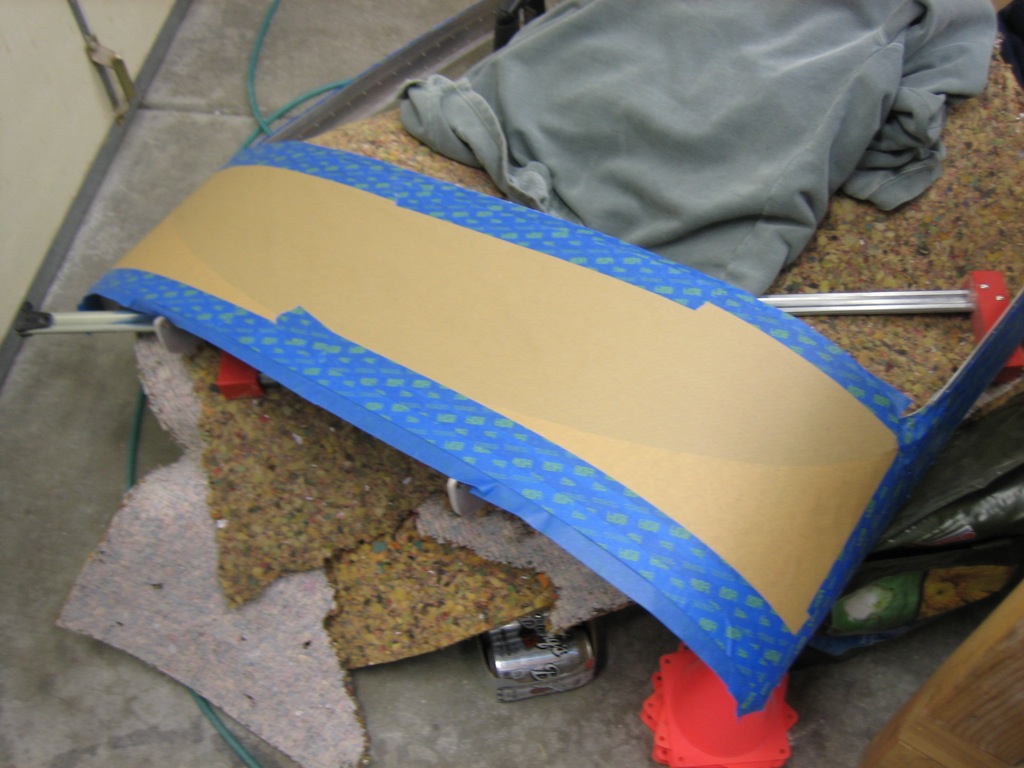

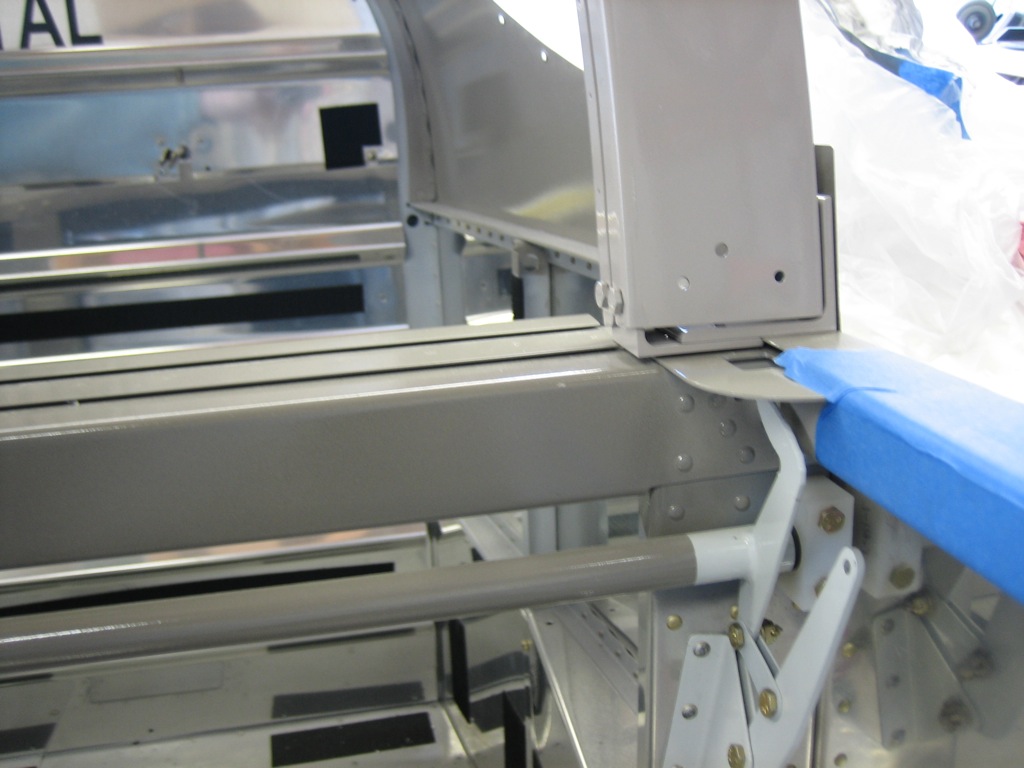

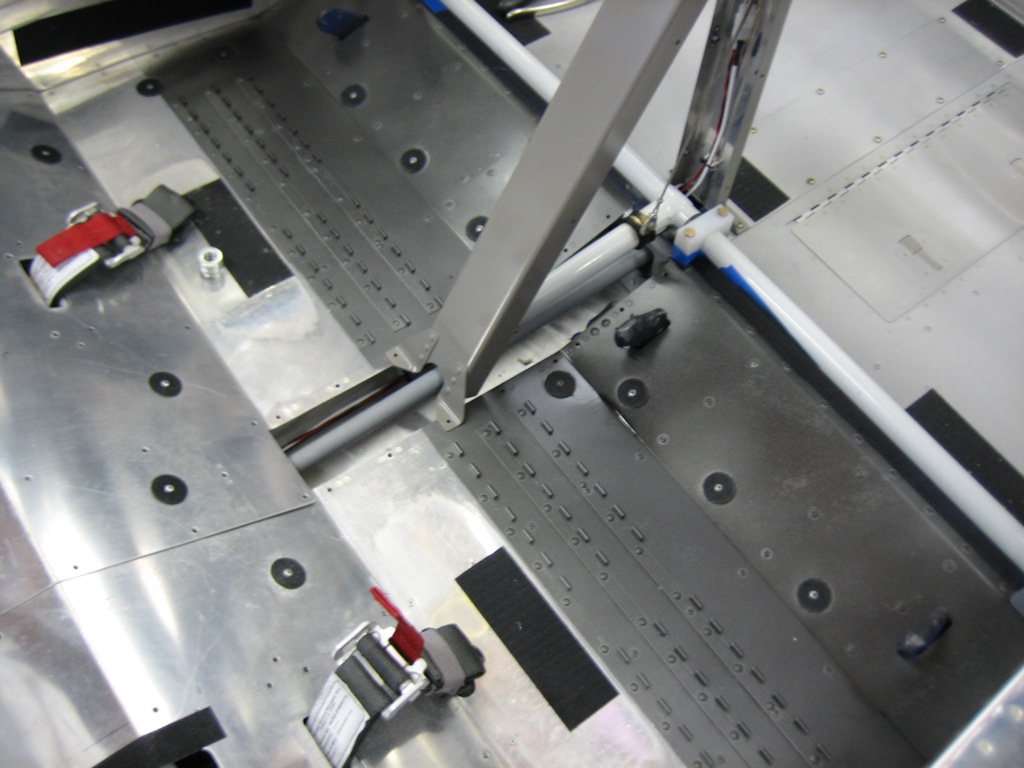

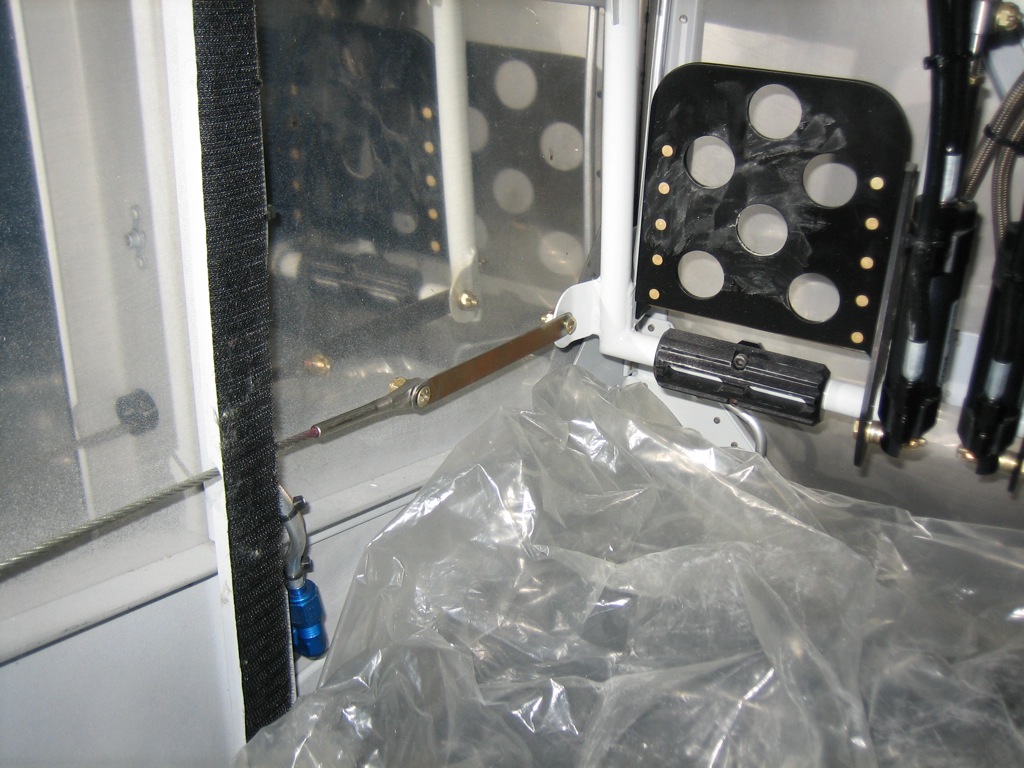

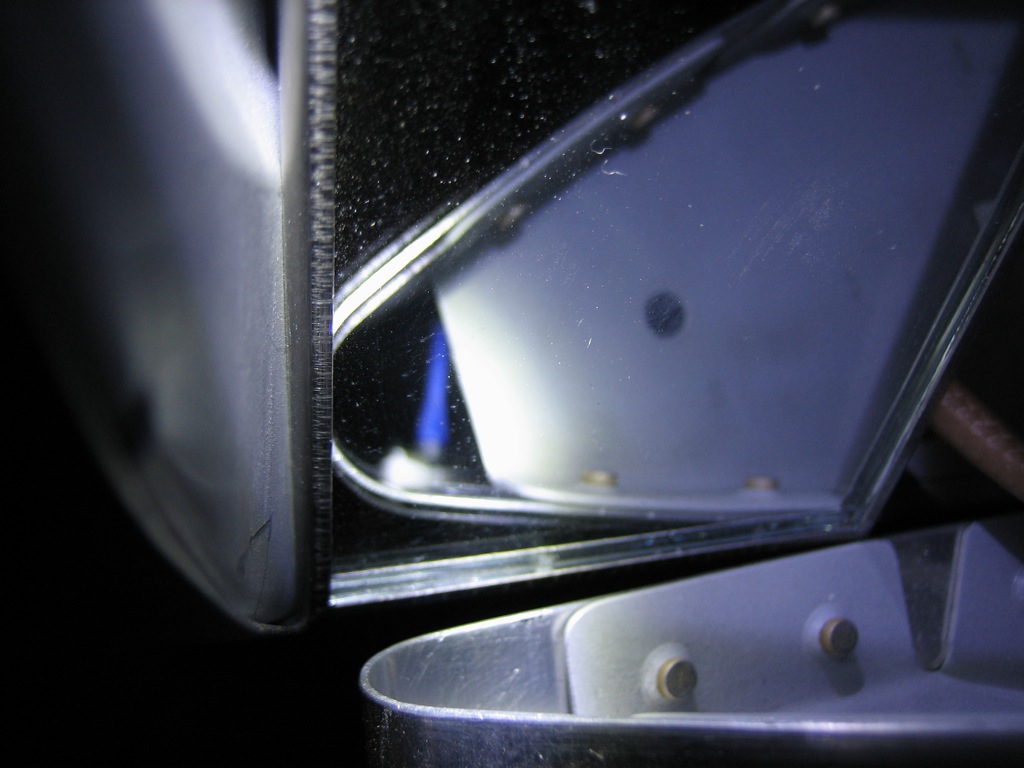

I removed the rear window because the masking tape I applied a few years ago was all dried out and stuck tight. I used some mineral spirits to soften the adhesive and removed all of the tape. This took much longer than expected, but I wanted to use a mild solvent to avoid damaging the plexiglass. After reinstalling the window, I laid a line of tape to mark where the Sikaflex primer will go.

I’m going to paint the inside of the rear window where it passes over the roll bar support channel. I’ve noticed on other planes that it’s often fairly dusty on top of the channel, and it’s pretty tight against the window, especially toward the back.

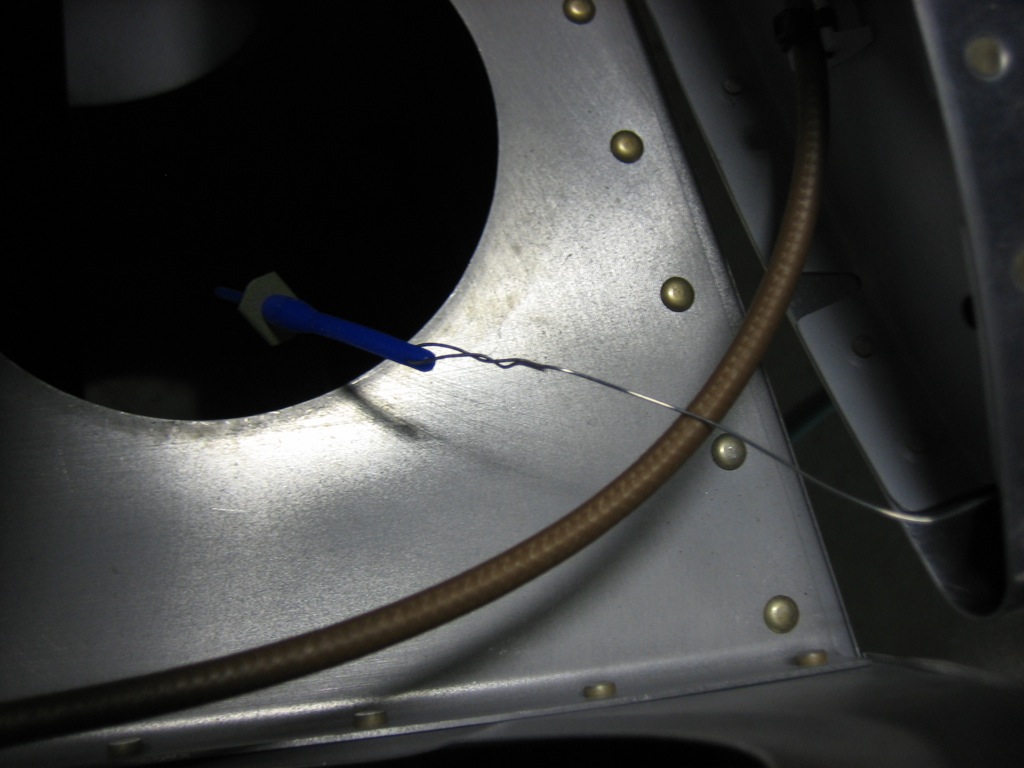

After the horizontal stabilizer and elevator filler cured, I filed and sanded it down so that they’re faired together nicely.

I needed just a little bit more along the leading edges of the elevators.

I also sanded down the filler I applied to the bottom of the rudder. There were a couple of low spots, so I added a little bit more.