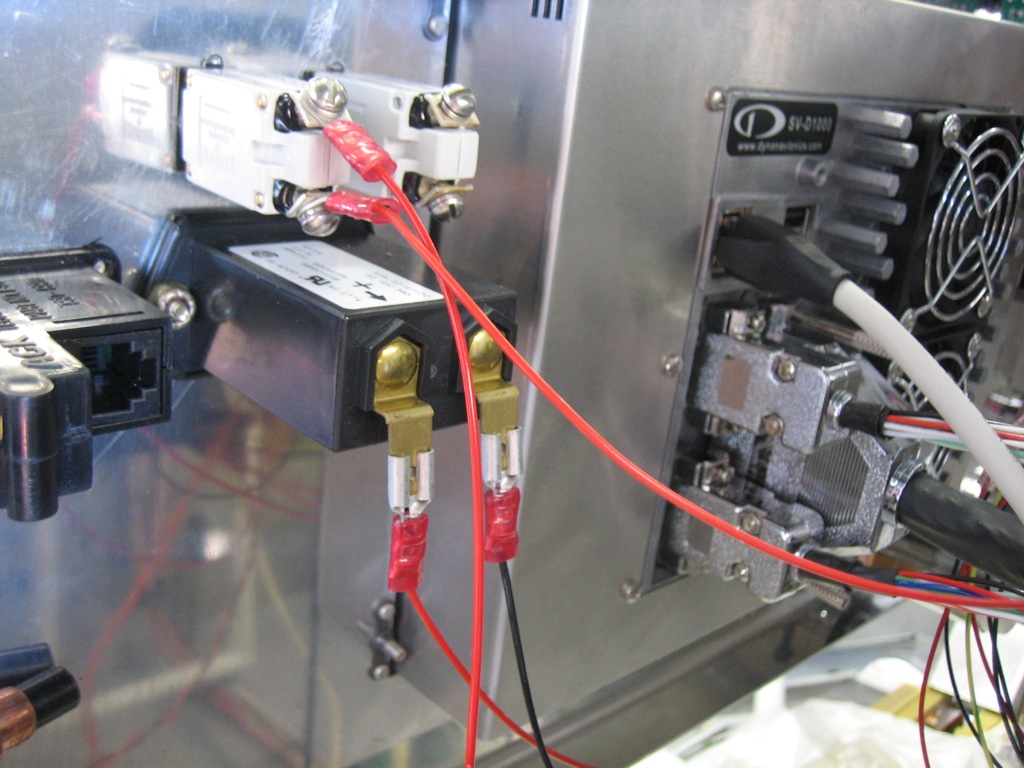

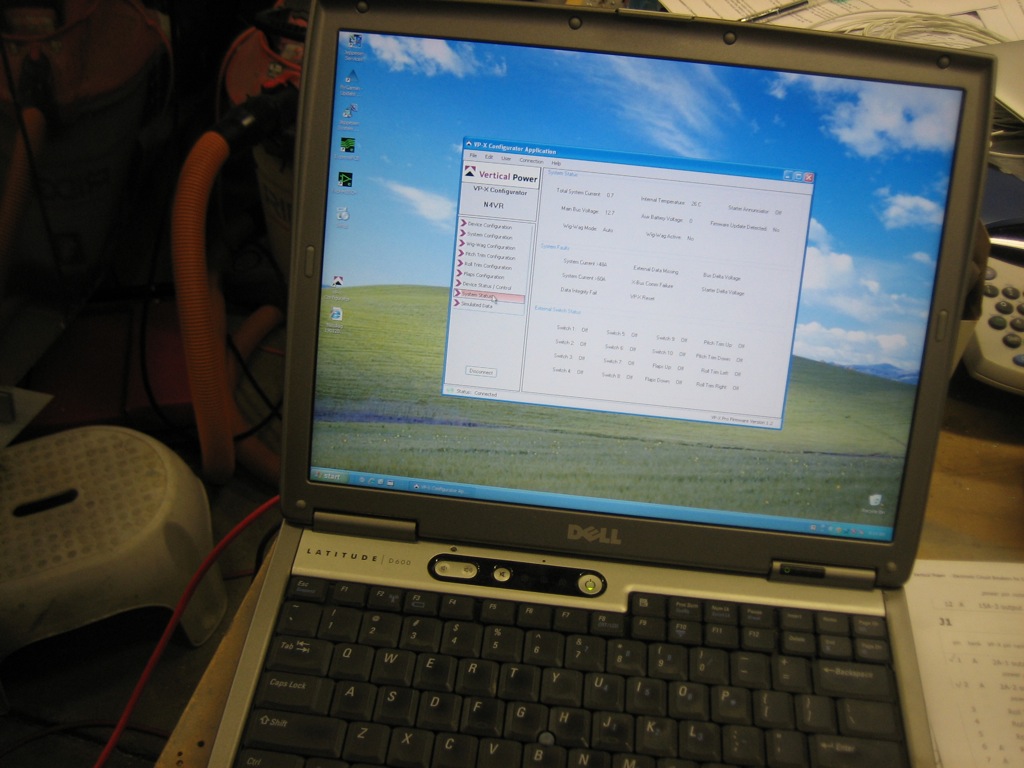

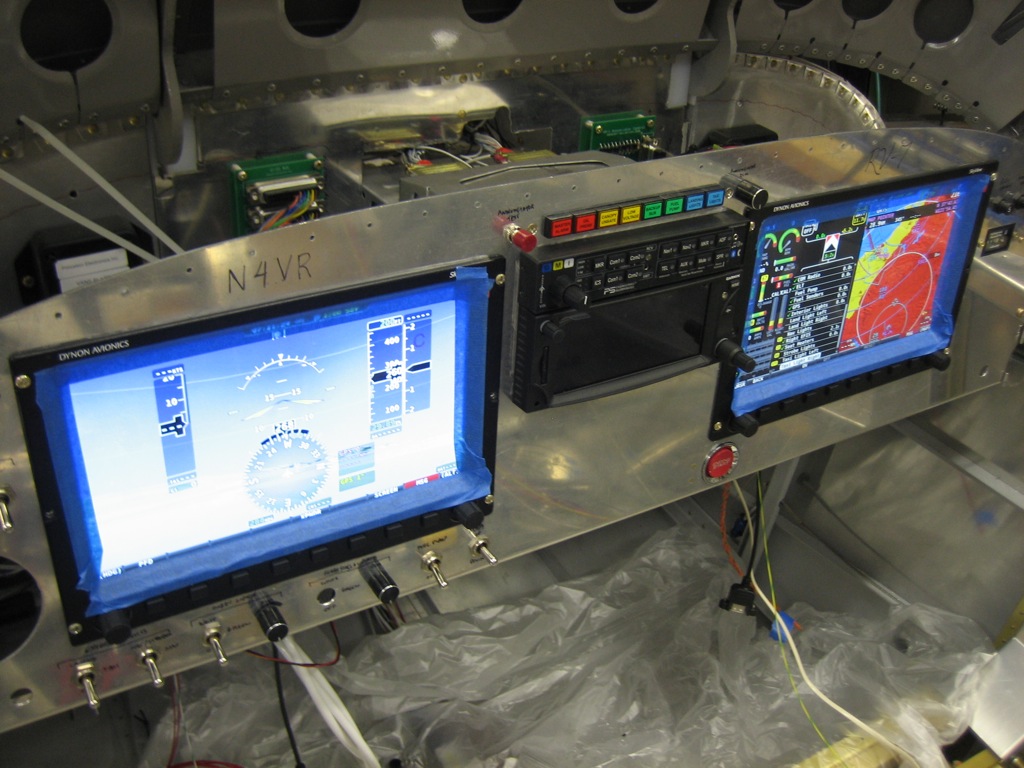

With the VP-X installed and running, I connected a crappy old PC laptop (I stopped using Windows many many years ago). I ran the VP-X Configurator and configured all of the devices and verified all of the switches are sensed properly.

After upgrading the SkyView screens to 3.2 and entering the VP-X license code, I configured the serial port to talk to the VP-X. It wasn’t immediately obvious how to get the VP-X screen to appear, but a quick glance at the SkyView installation manual revealed the method.

When you’re in the engine page, a new VP-X button appears that brings up the VP-X page. At the top, you can see an electrical system diagram that shows the power flowing from the main alternator and the battery into the VP-X. This is a little misleading though since it doesn’t include power that bypasses the VP-X such as the power to keep the master contactor closed and the power to run the electronic ignition. I *think* this will cause this display to always show some power flowing into the battery even when the actual current flowing into the battery is zero (since the alternator will produce the extra power drawn by the master contactor and electronic ignition, but the VP-X will only show the power consumed by the devices connected to it).

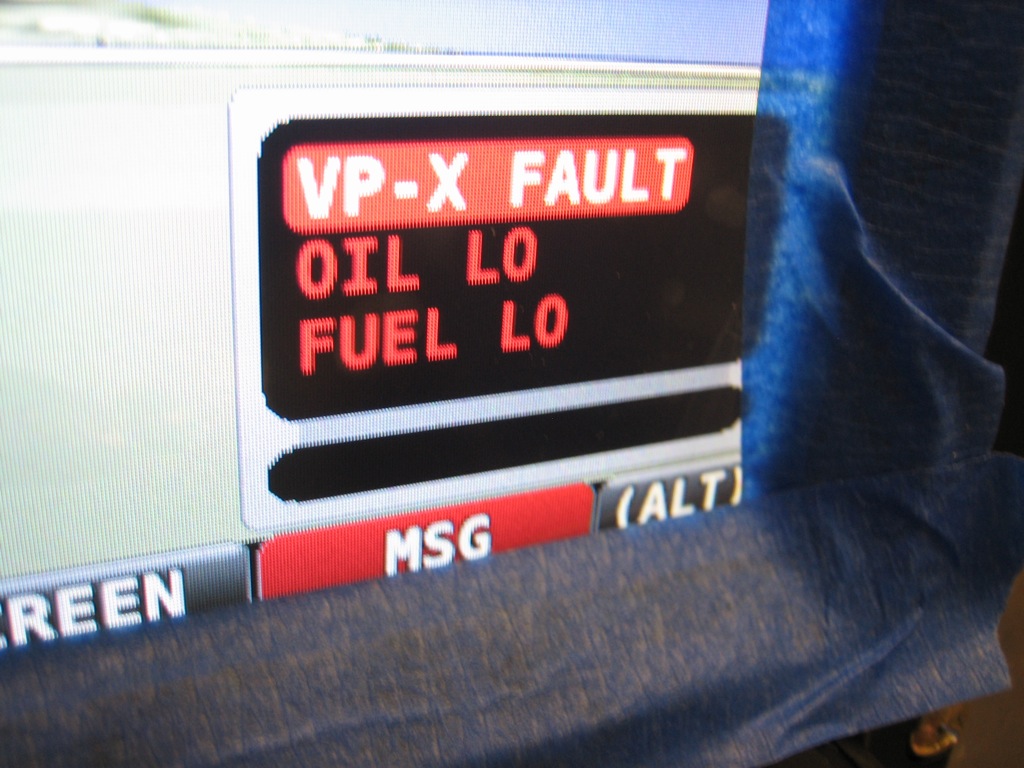

I don’t have the exterior lights hooked up, but this is a good way to test the VP-X fault detection. I turned on the taxi lights…

…and the SkyView screen shows a VP-X fault.

The VP-X screen on the SkyView indicates the problem is that the taxi lights aren’t drawing any current. From here, you can scroll down and reset the fault. The other nice thing is that device can be turned on or off or controlled directly from this page. For example, if my fuel pump switch were to fail, I could navigate to that device here and press the “ON” button seen at the bottom of the screen to turn the device on regardless of the state of the switch. You can even control the trim and flap motors from here. The buttons change to “Left” and “Right”, or “Up” and “Down” as appropriate. This is really slick, and I’m very glad I waited for the VP-X and SkyView integration.