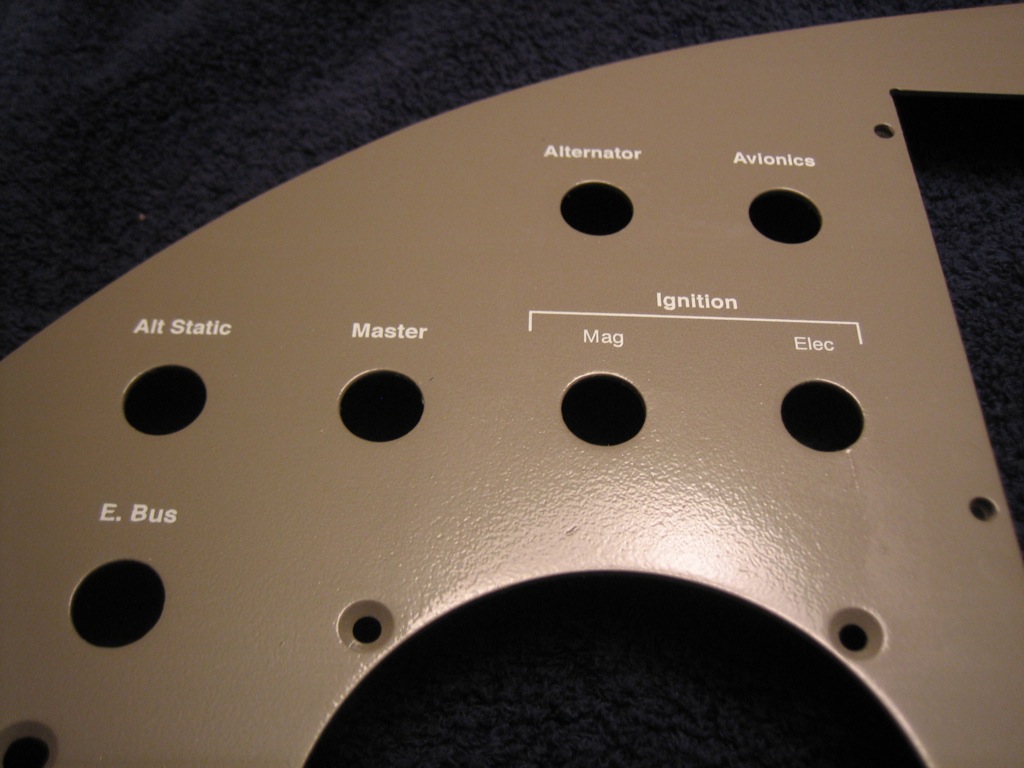

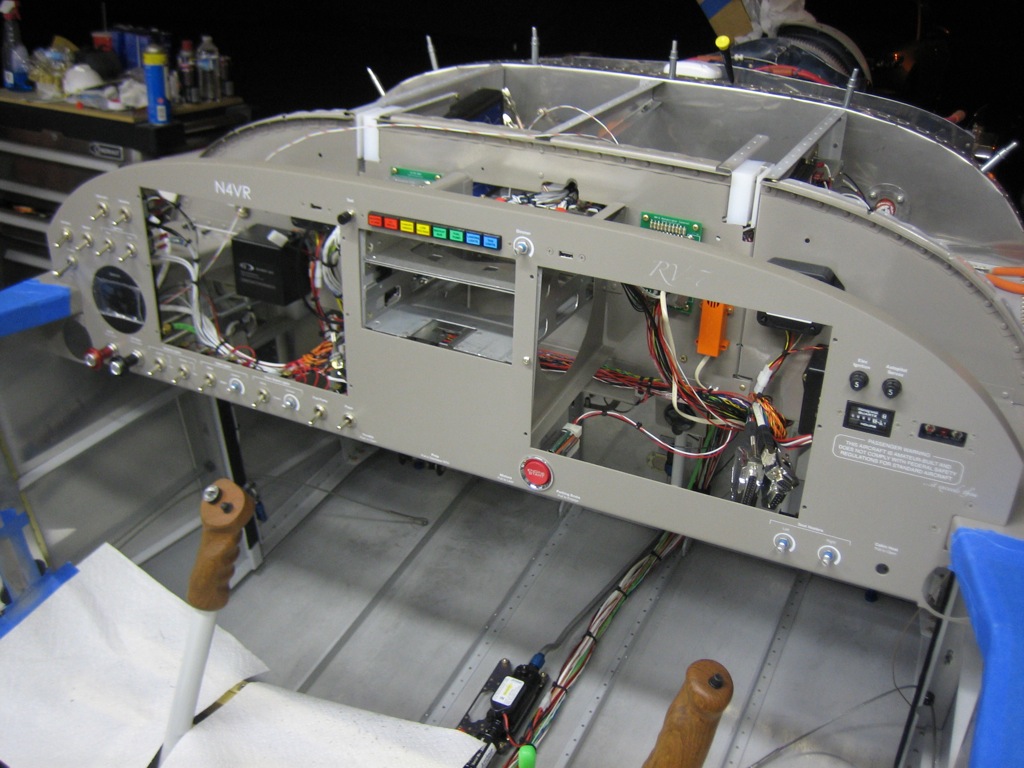

I finished labeling the panel today since we were off work for the 4th and my wife had to work all day. Here’s an overall shot.

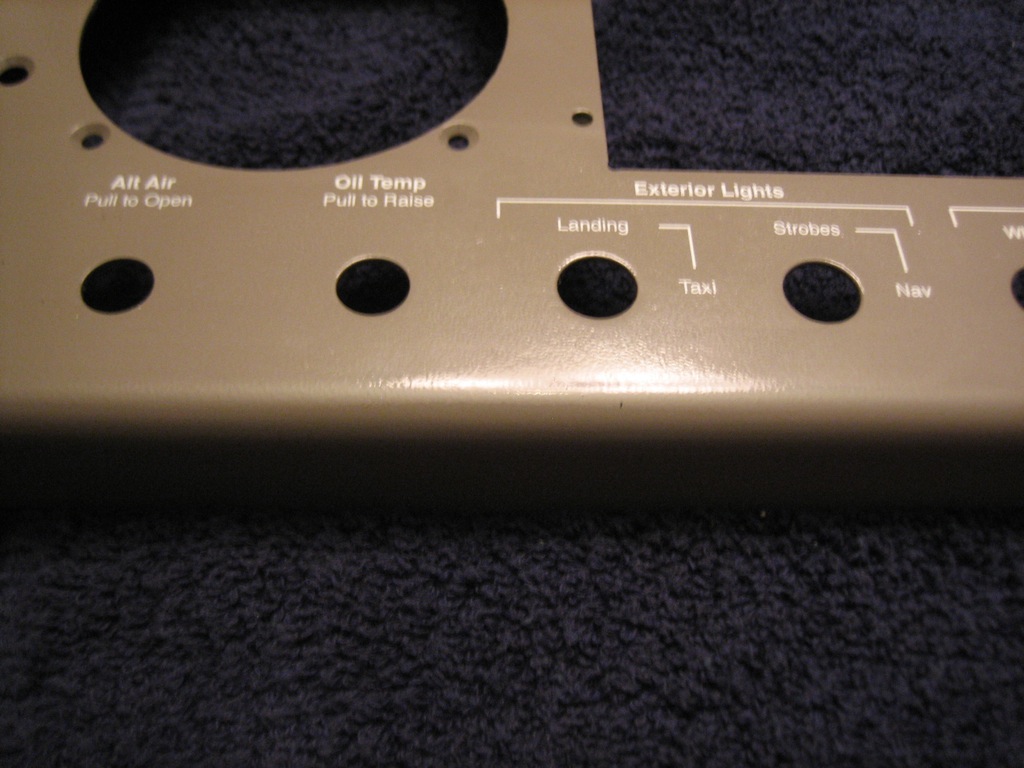

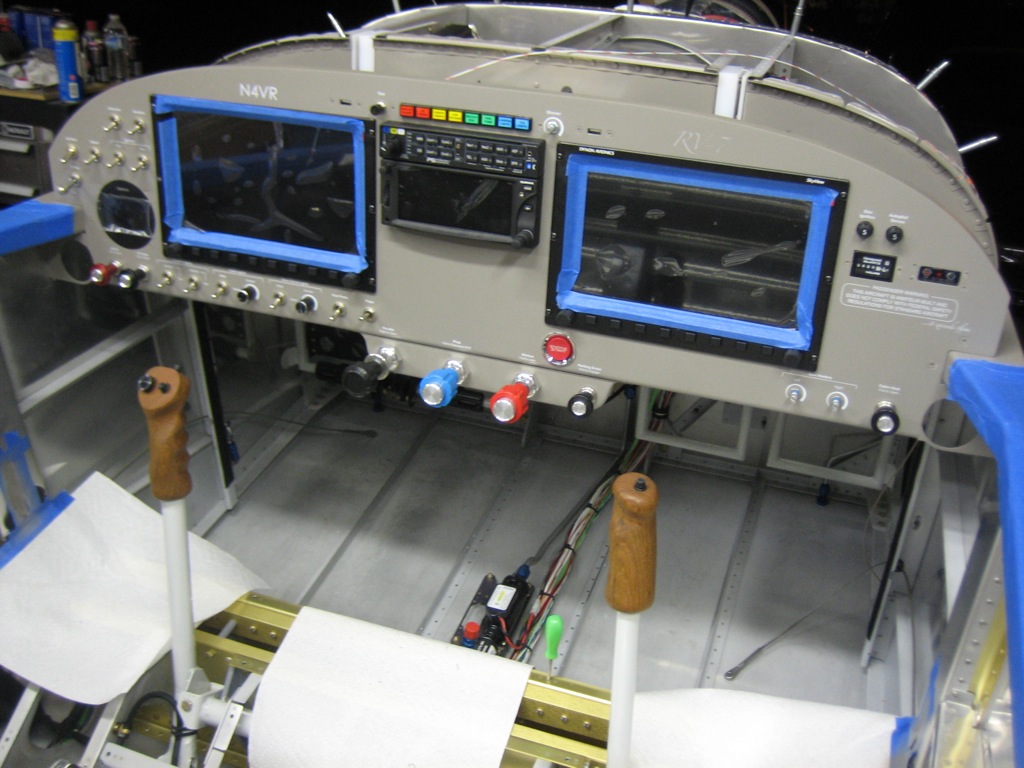

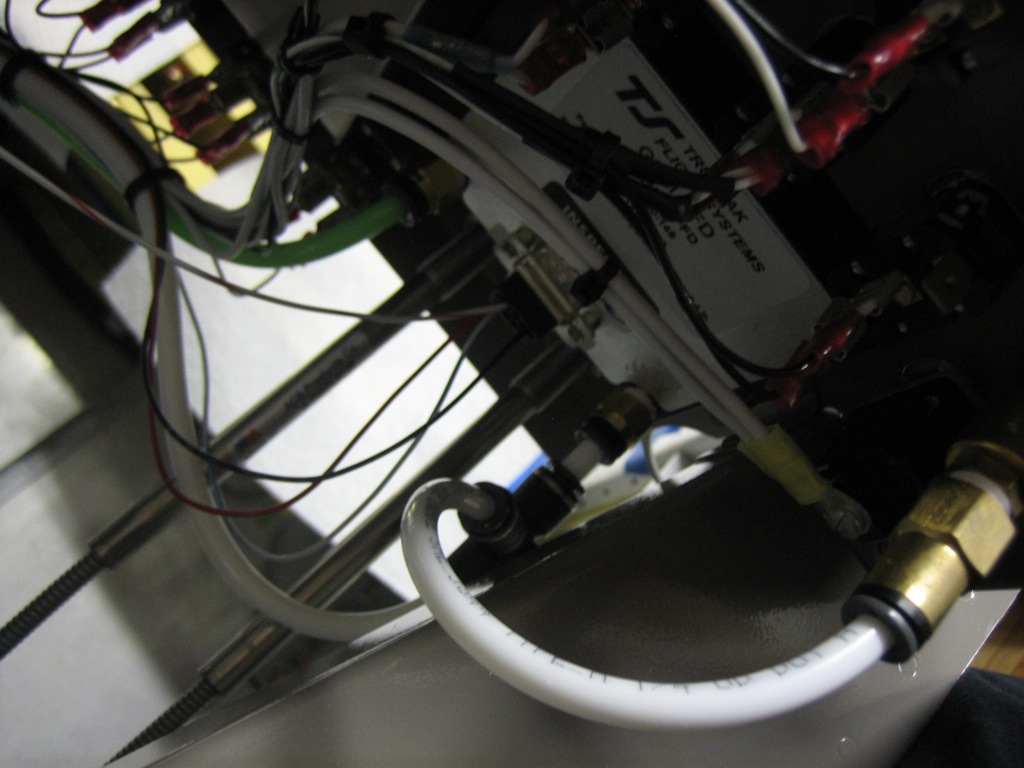

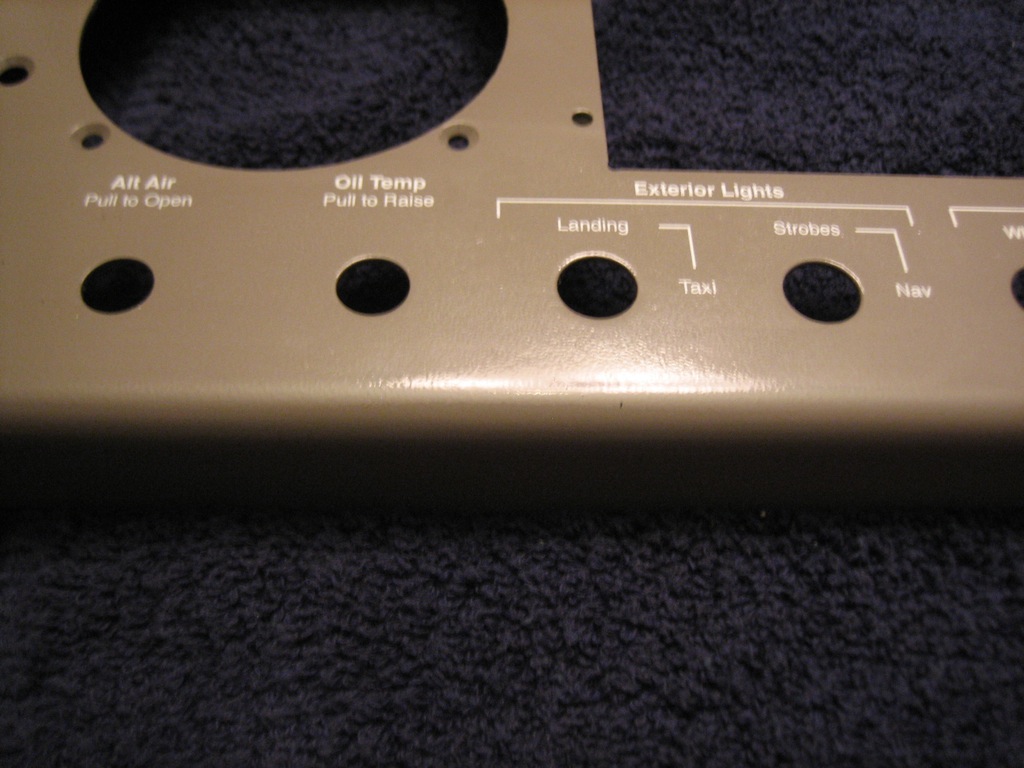

In the lower left, there are two spots for control cables to control the alt air and the oil cooler butterfly valve. To the right of that are the exterior lights.

To the right of the exterior lights are two separate groups of interior lights. Each can be set to either white or green light and has a dimmer. Finally, the fuel pump and flaps switches round out the row.

The engine controls and parking brake labels are on the main panel since I shortened the height of the control bracket.

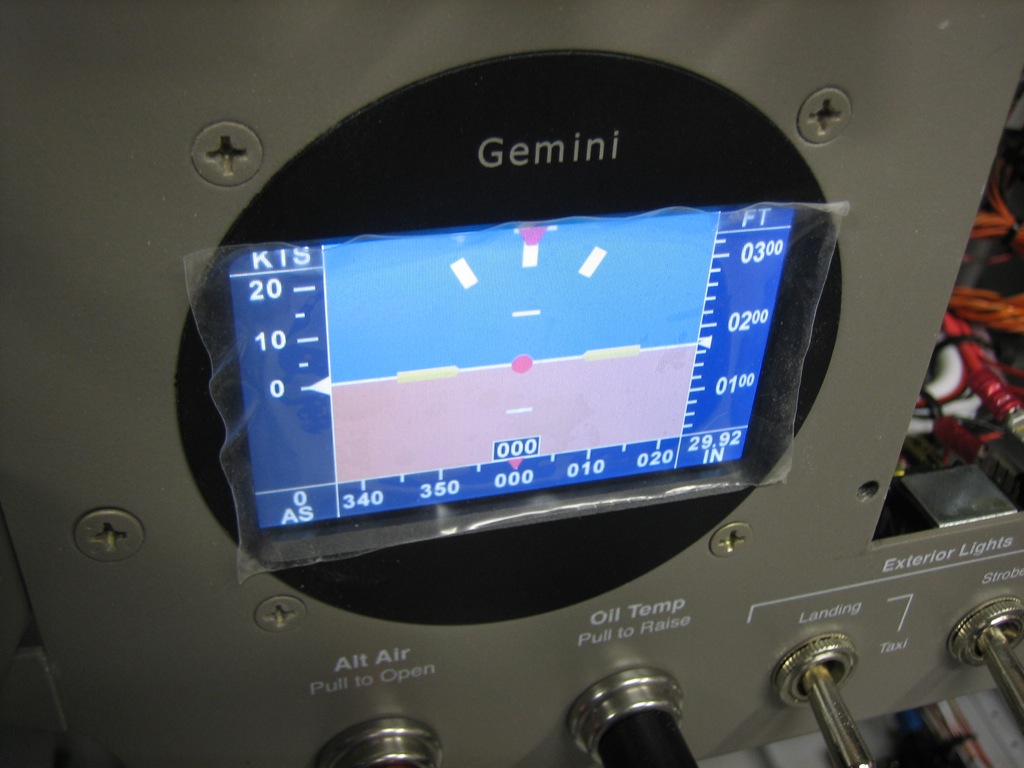

At the top of the radio stack are the test button for the annunciator lights and the dimmer which will dim both the annunciator lights and the TruTrak Gemini PFD (which unfortunately doesn’t have a light sensor and self-dimming capability).

Above the pilot’s PFD is the tail number.

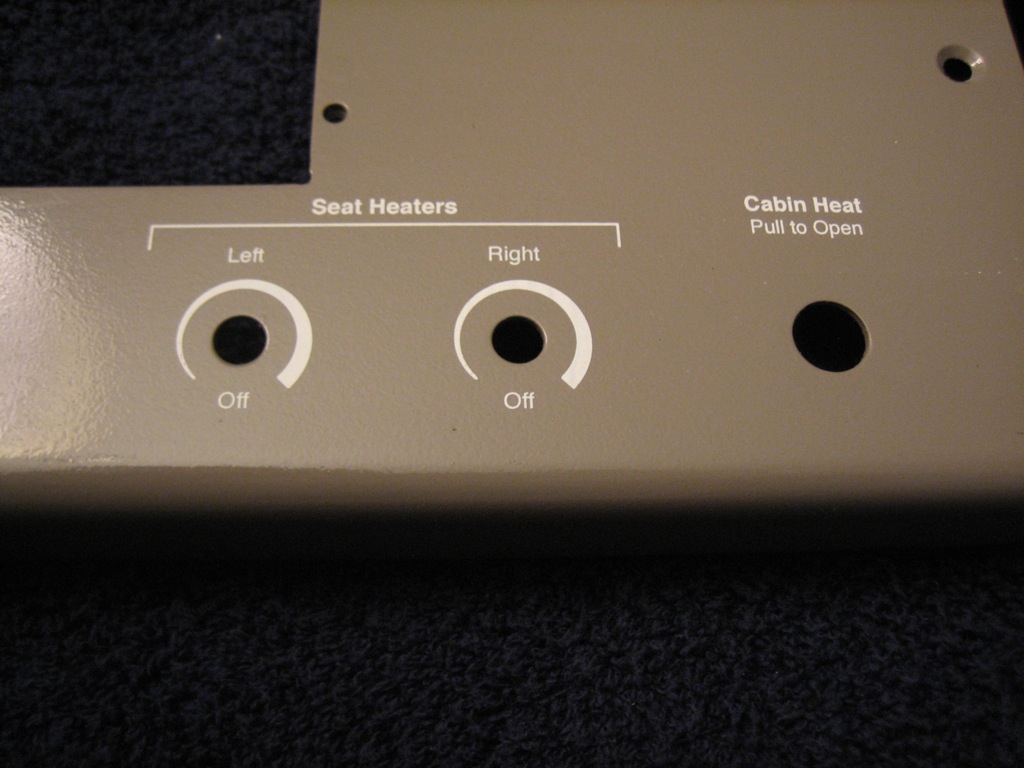

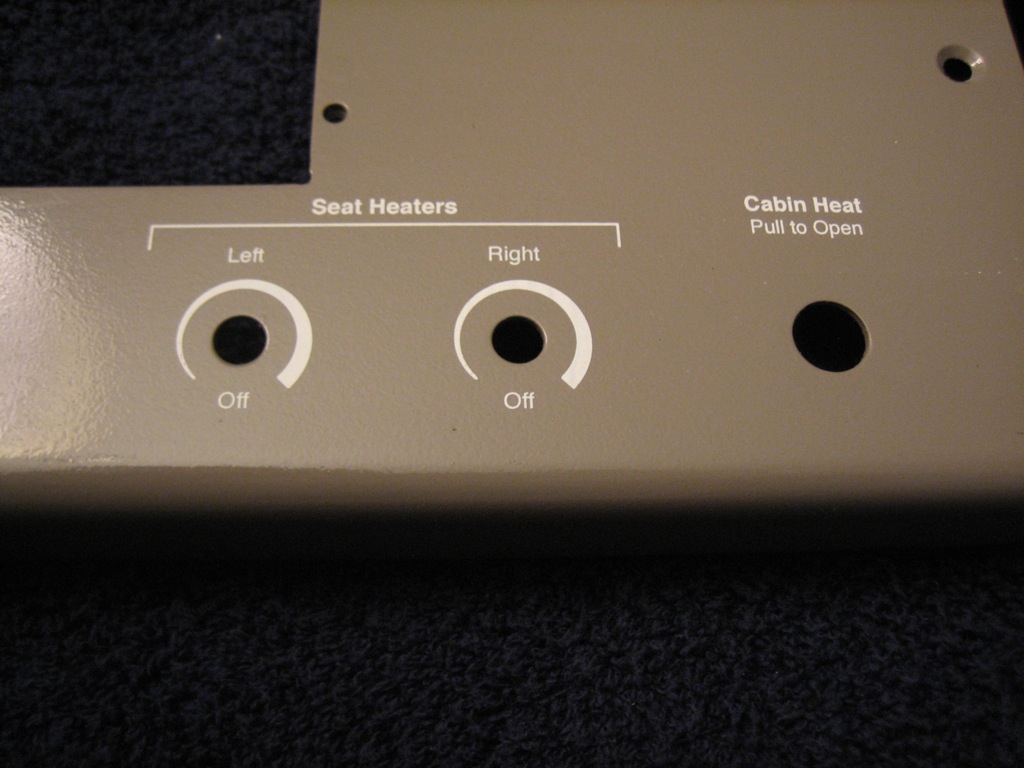

On the lower right of the panel is the controls for the seat heaters and cabin heat.

The top right has the only two breakers in the plane, pullable units for the electronic ignition and autopilot servos.

Above the copilot’s display is the RV-7 badge in the Zapfino font using a silver holographic foil. The picture really can’t capture how this looks, but the color changes depending on the angle you view this from. This would look tacky if you used too much of it, but it looks really sweet on just this one detail.