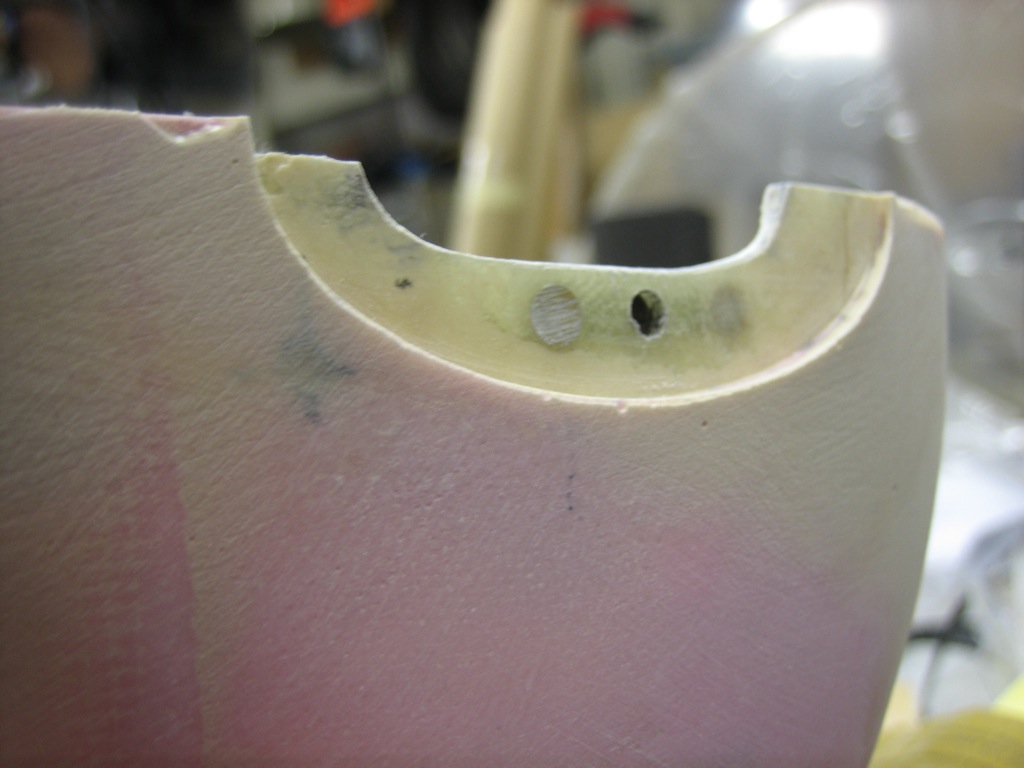

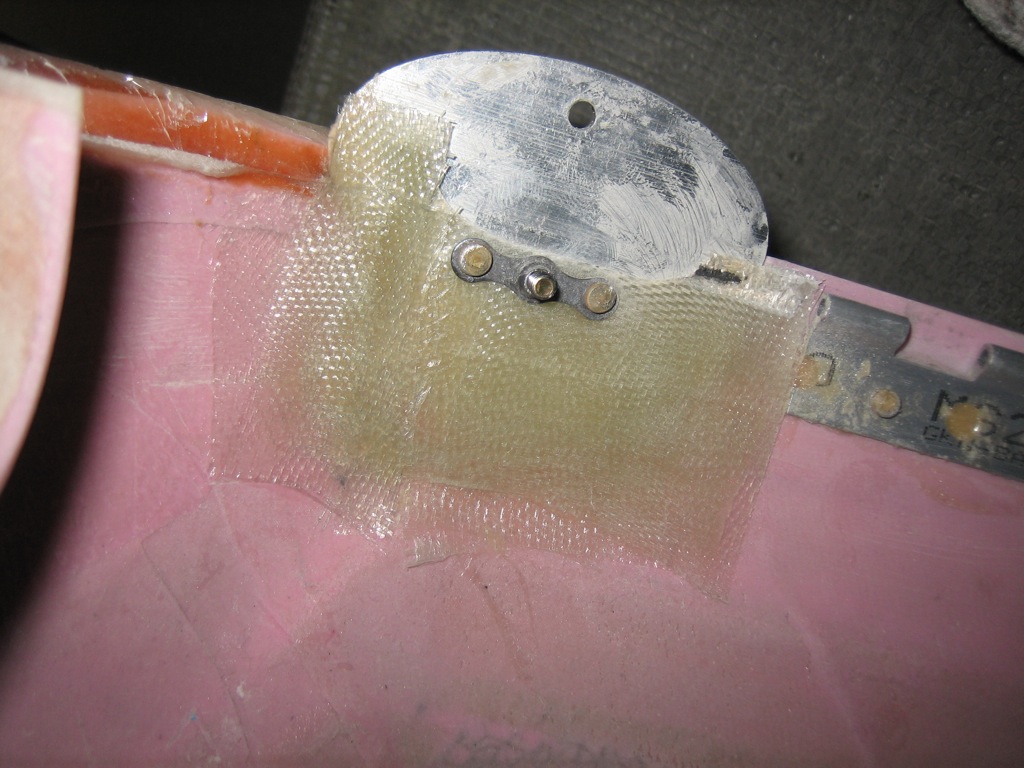

I laid up some additional glass near the front of the hinge pin covers where the gaps I pointed out yesterday were located. I’ll trim and sand this back tomorrow after it cures.

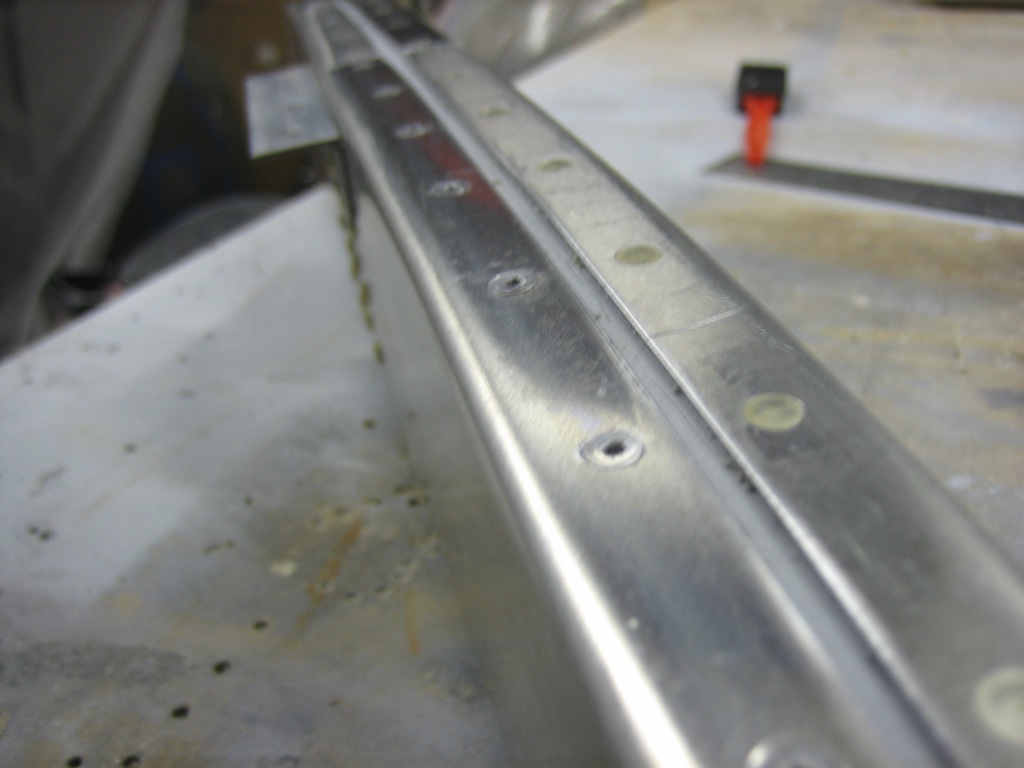

I need to get started wrapping up the cabin area, so I got started by cleaning up the roll bar. I haven’t touched this in more than two years, but I left some masking tape along the top edge. Old tape is a real pain in the ass to remove. It took me about an hour to remove all the tape and residue.