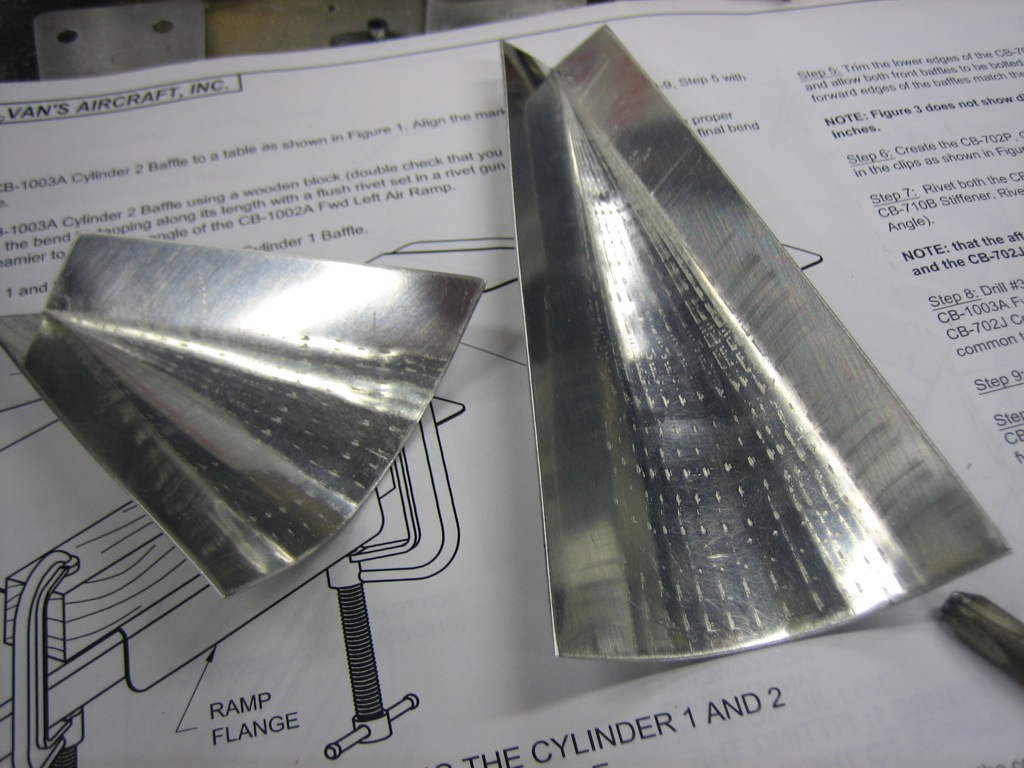

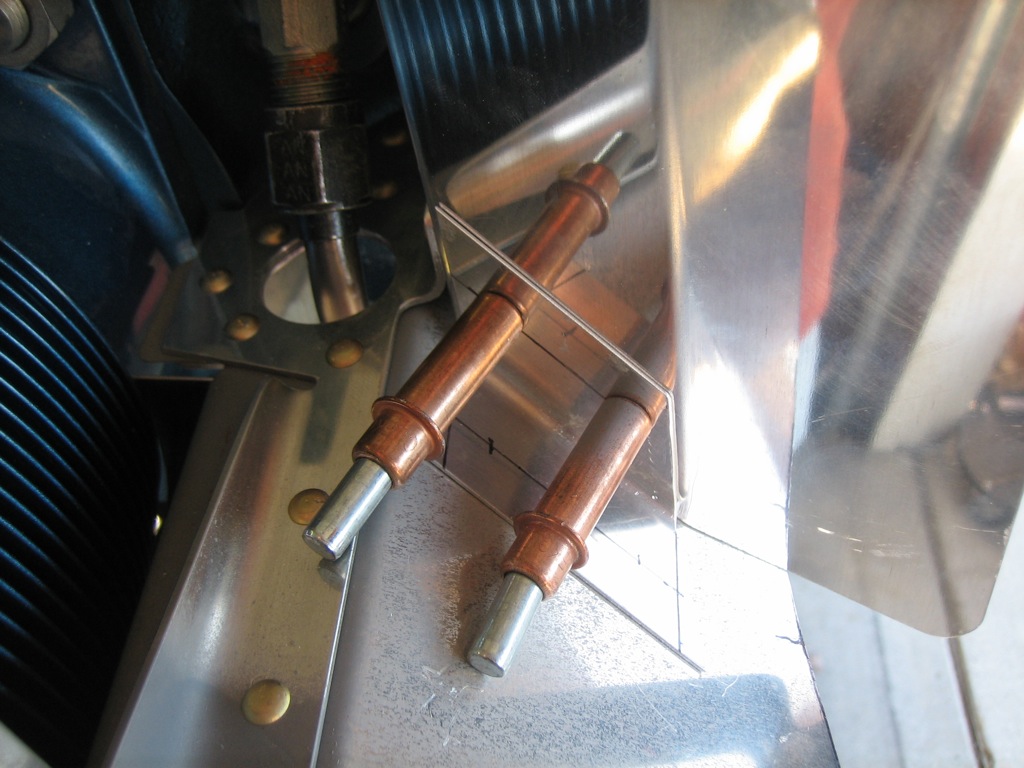

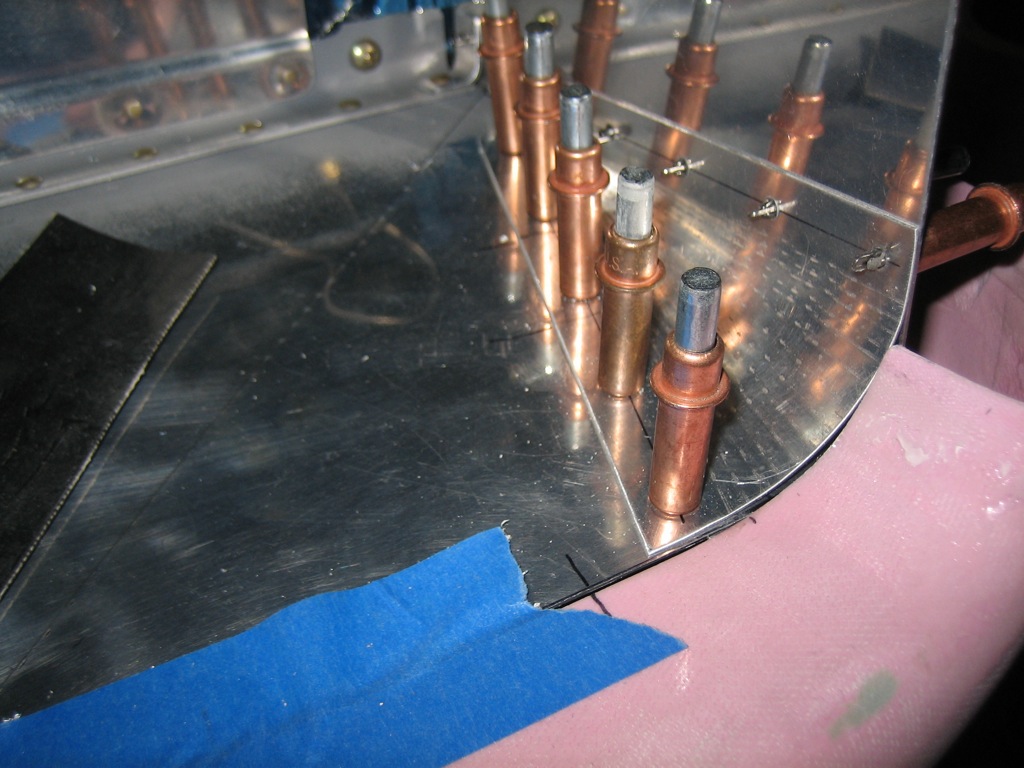

Where the baffles end, a tapered shim needs to be fabricated so that the baffles seal tight against the fins. This forces all of the cooling air to go between the fins instead of around them.

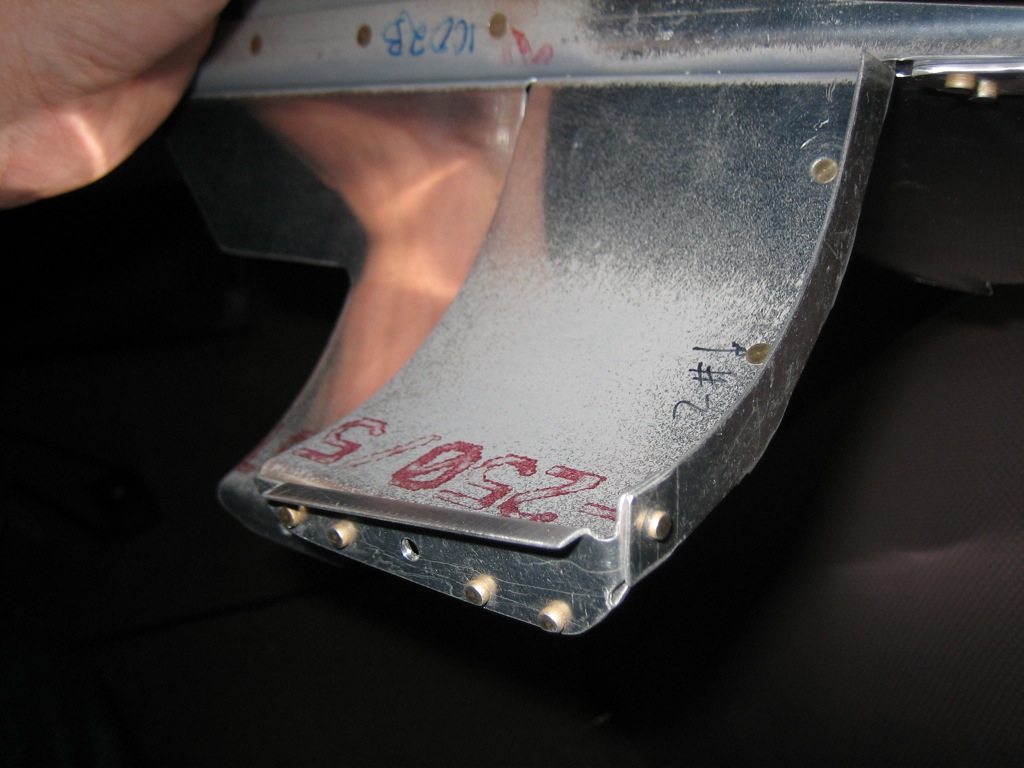

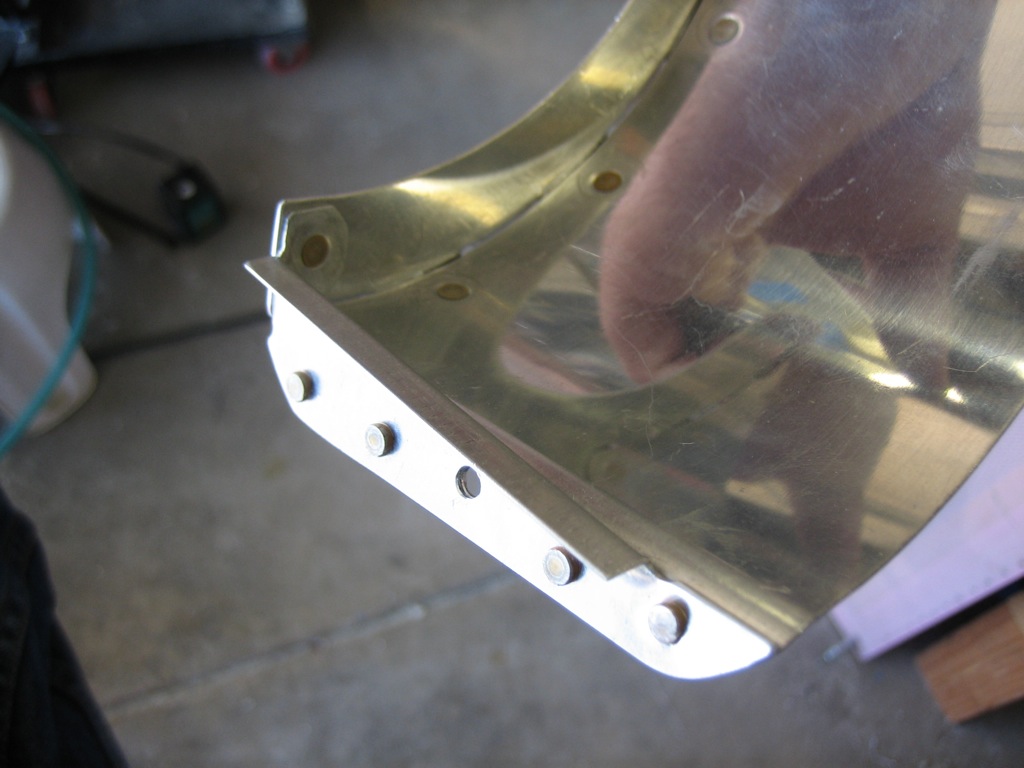

This shim will be riveted to the flange on the end of the curved portion of the baffles.

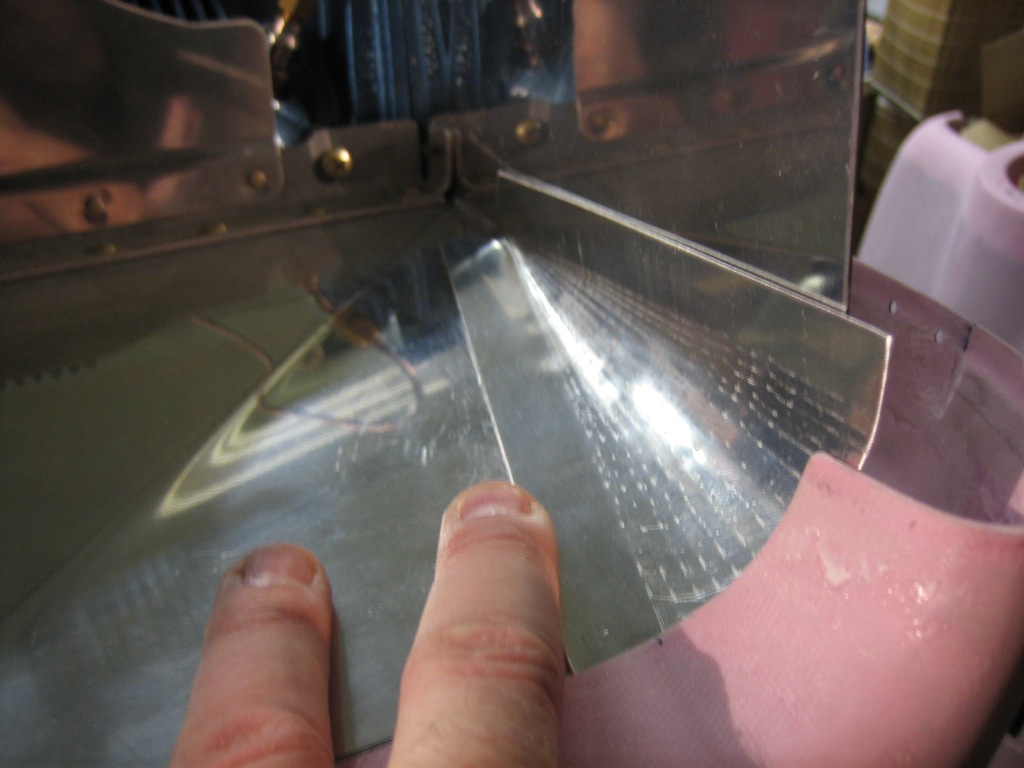

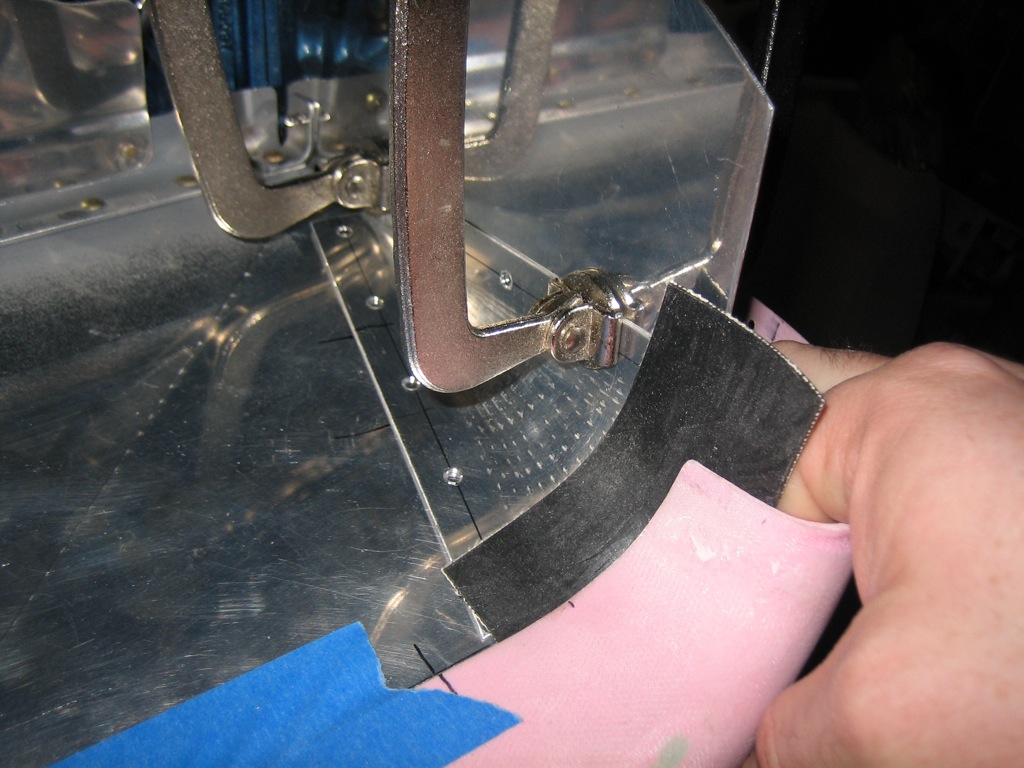

I left the new piece long while fitting it. I’ll trim it off flush with the existing flange now that the holes are drilled and its position is fixed.

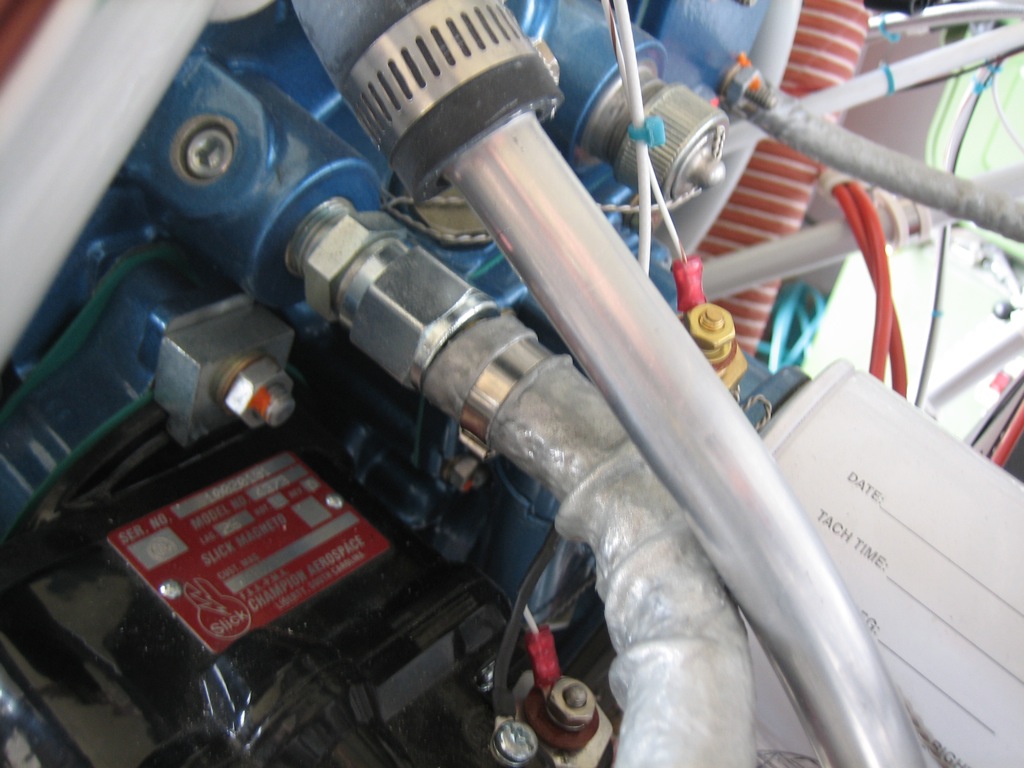

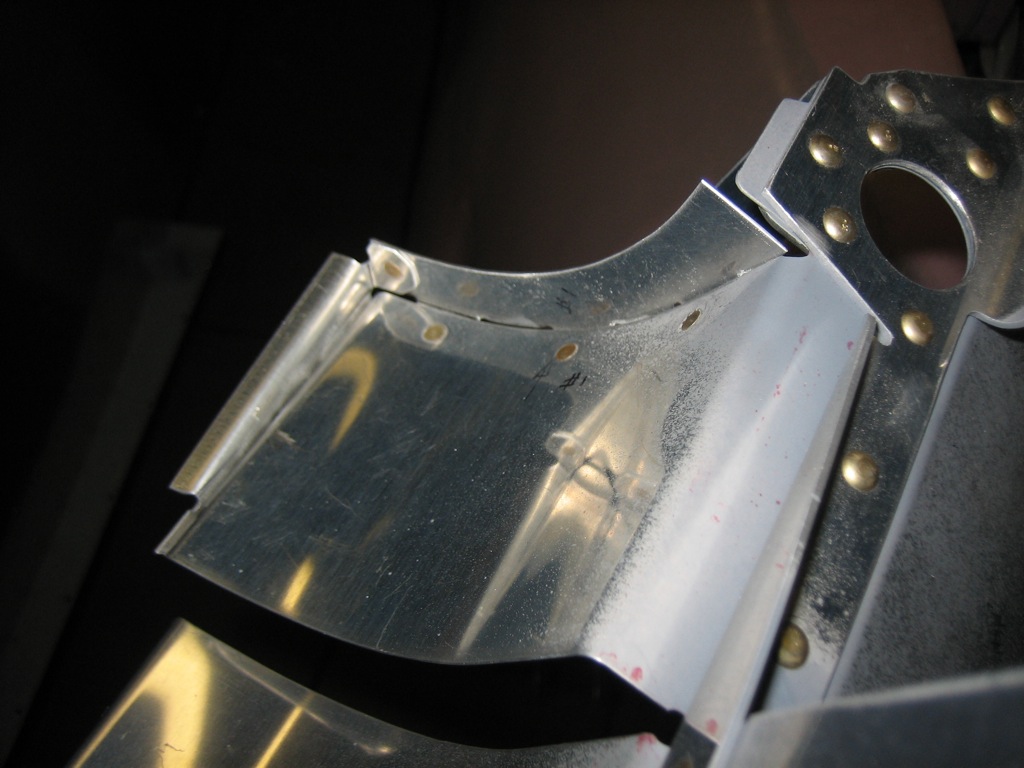

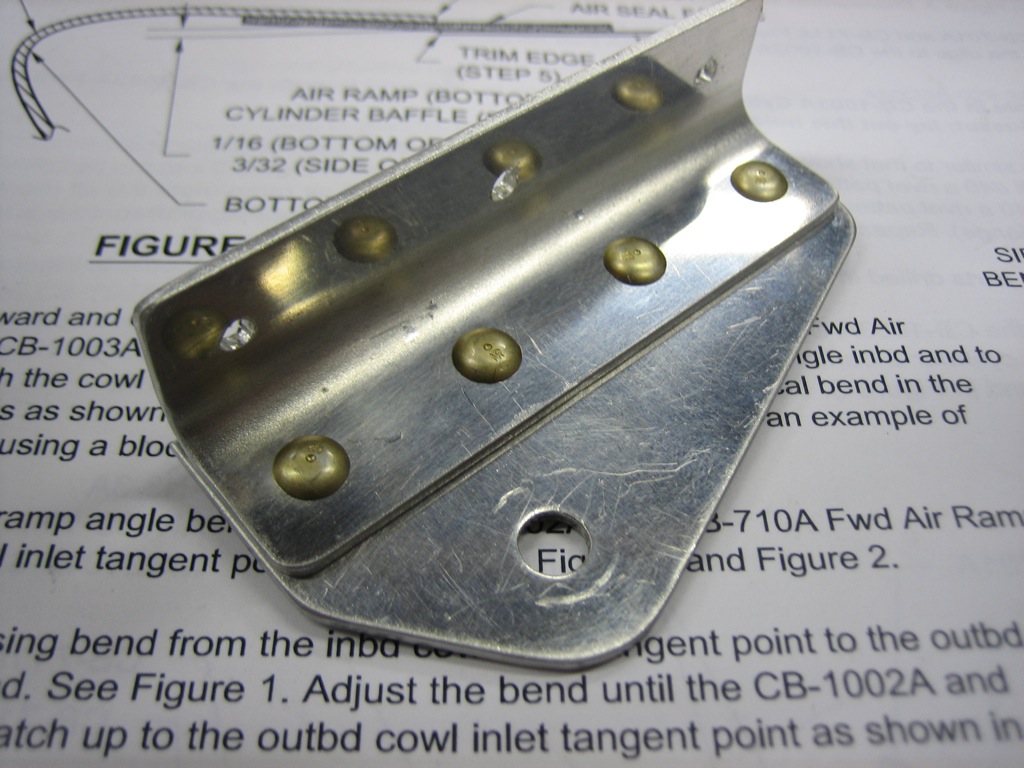

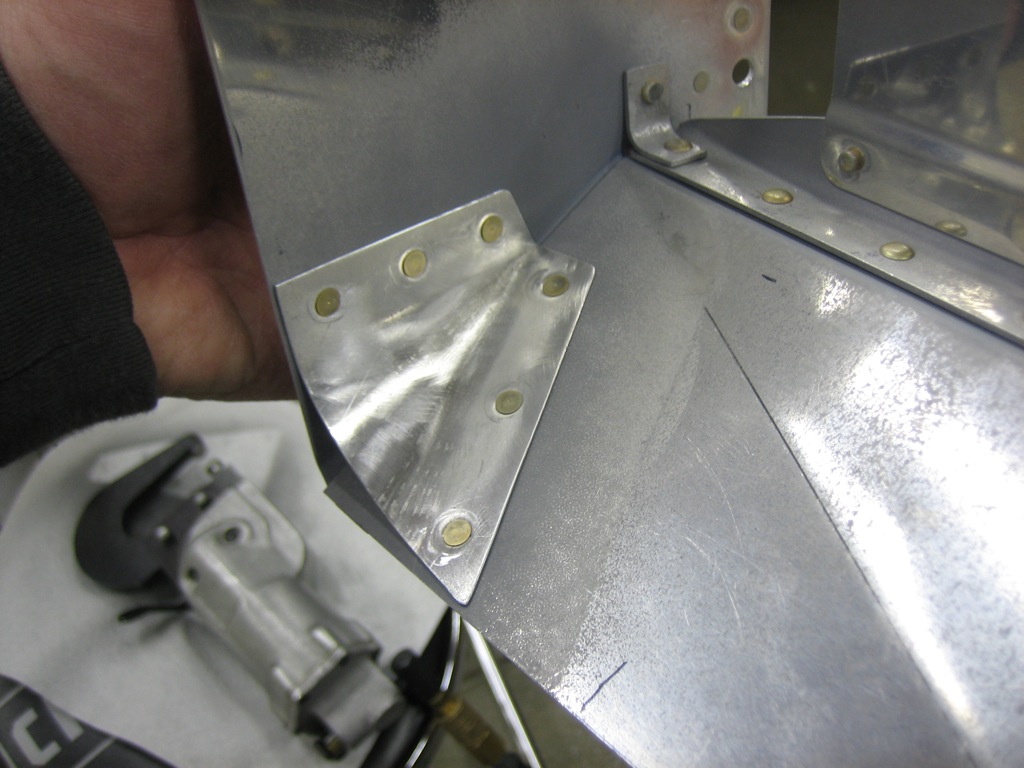

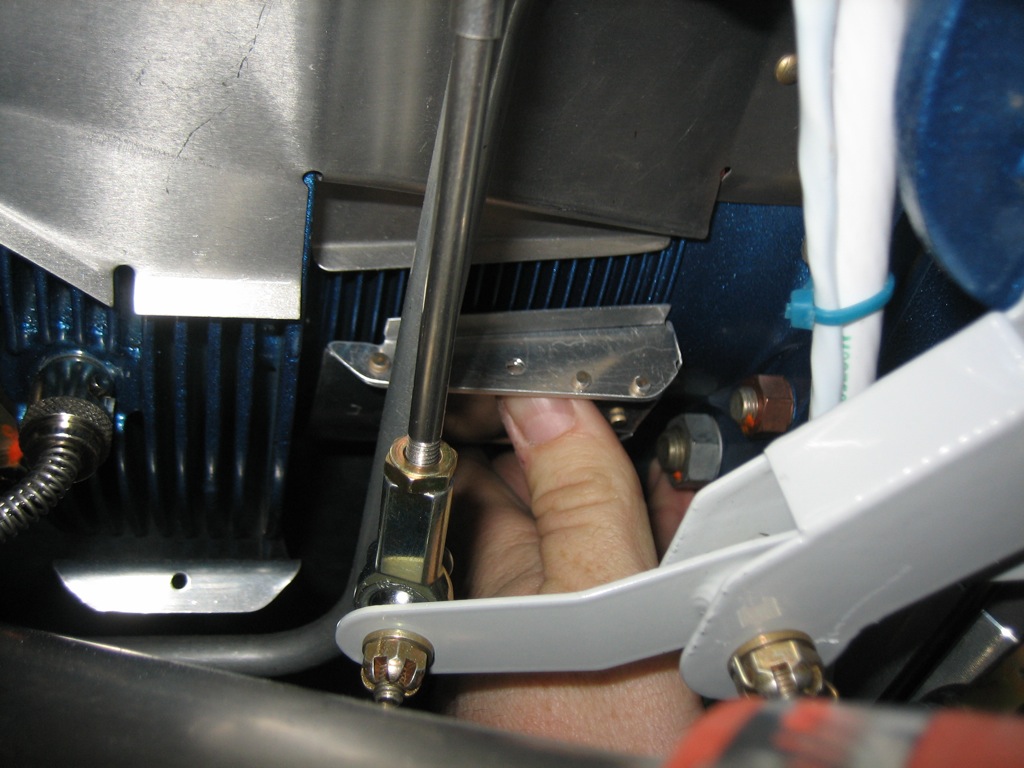

Here’s what it looks like with everything riveted together.

From the other side, you can see the ears of the side piece and the rivet that ties it to the tapered shim.

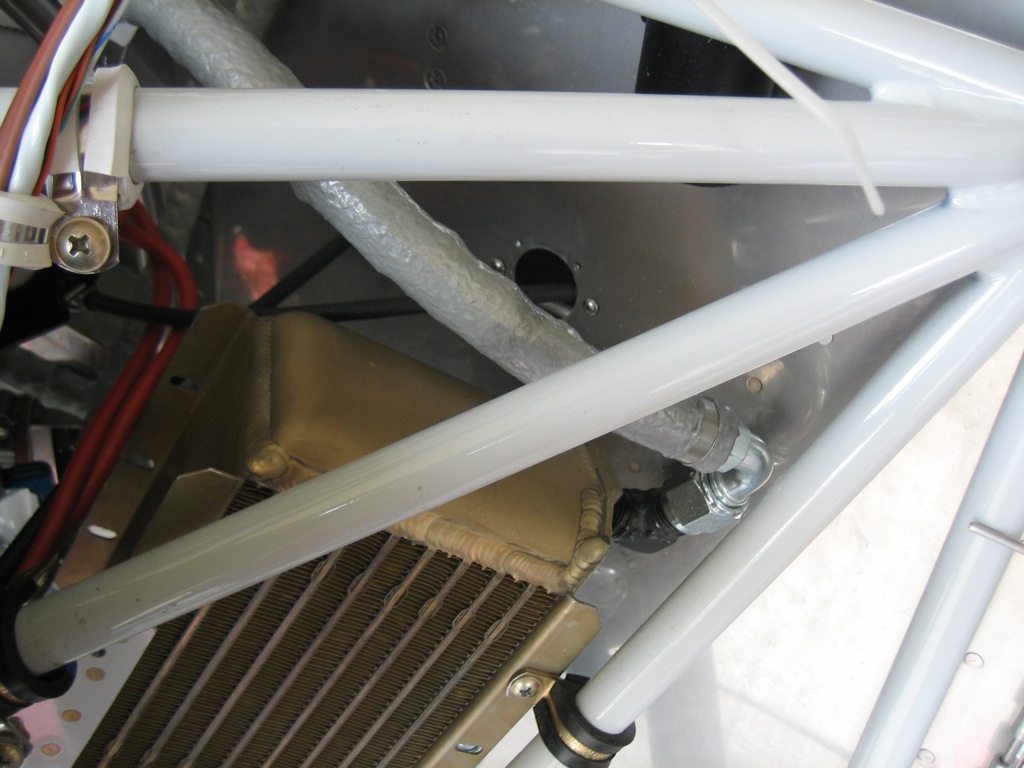

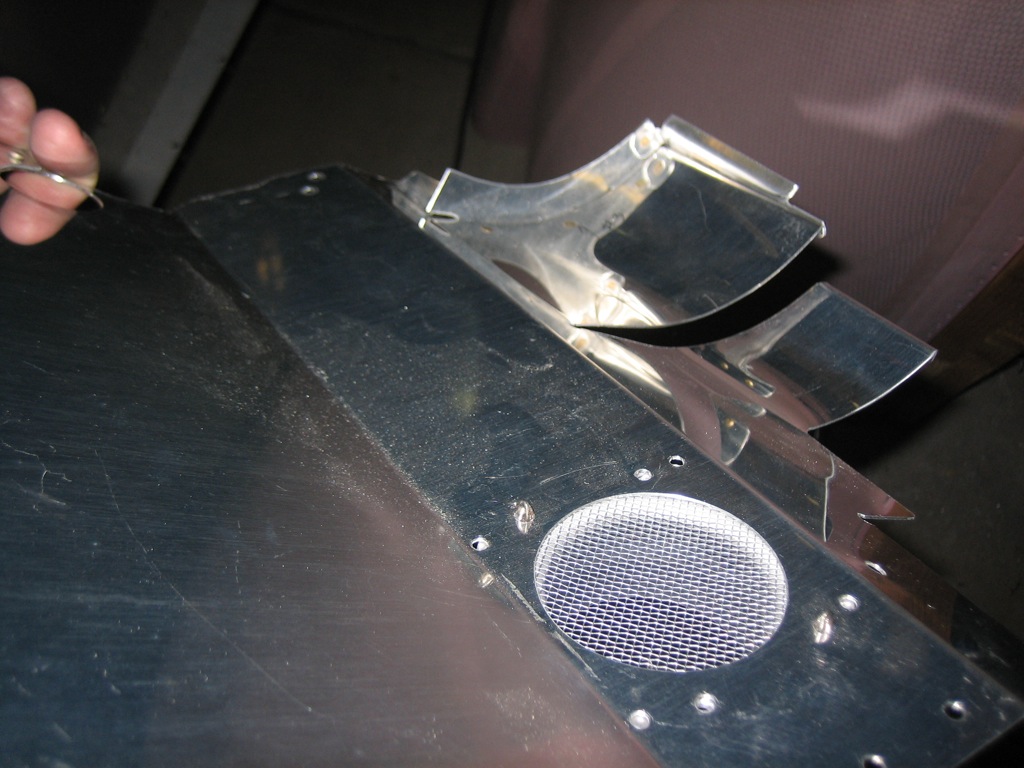

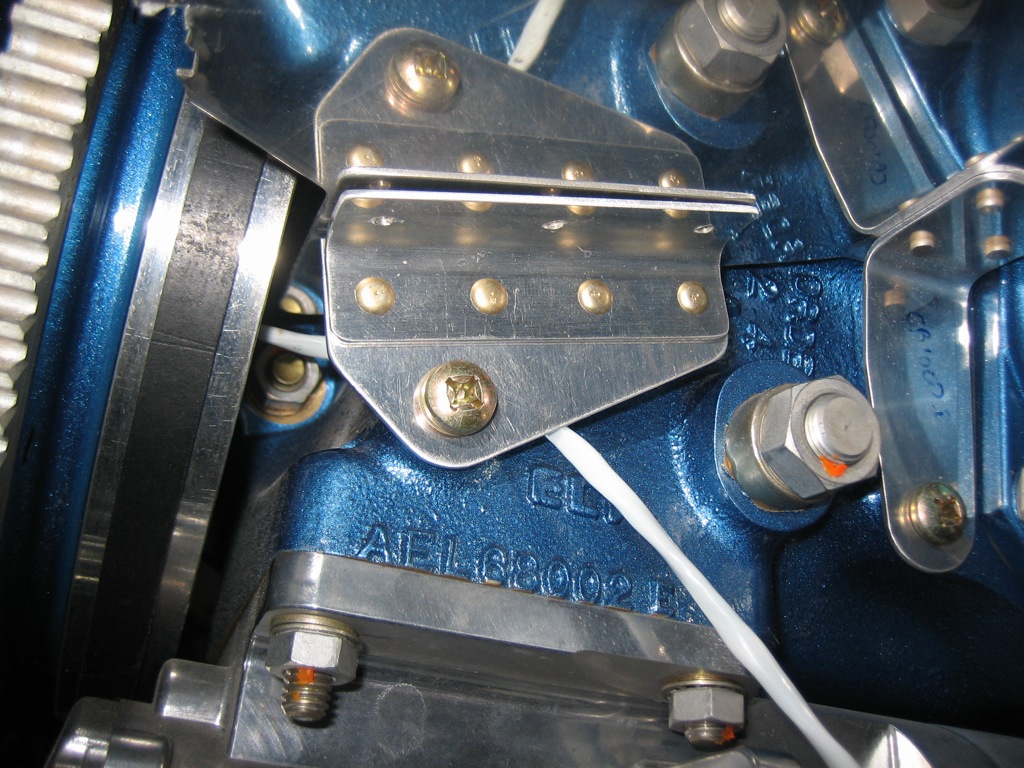

The modifications for cylinders 1-3 are pretty much the same. The modification for cylinder #4 is quite a bit different. It wraps much farther around the cylinder and the width of this side piece gets larger near the top. I trimmed it to roughly follow the ear that rests above one of the cylinder mounting nuts. All of the gaps will be filled with high-temp RTV silicone.

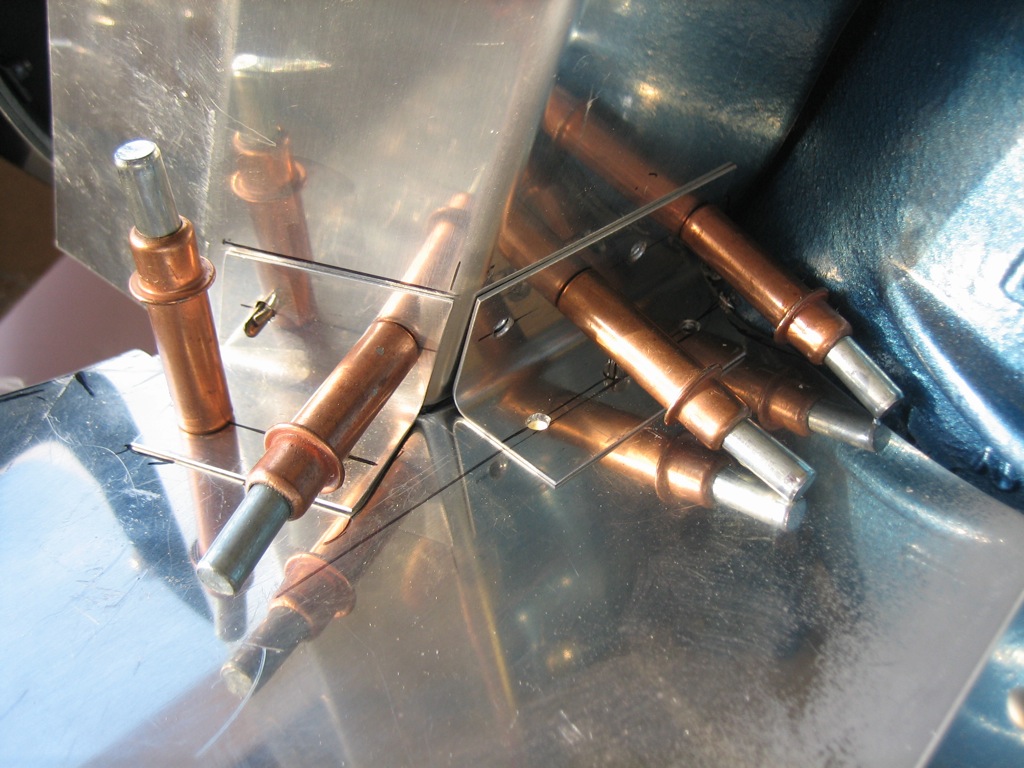

This picture gives you an idea how the shim follows the taper of the barrel fins.

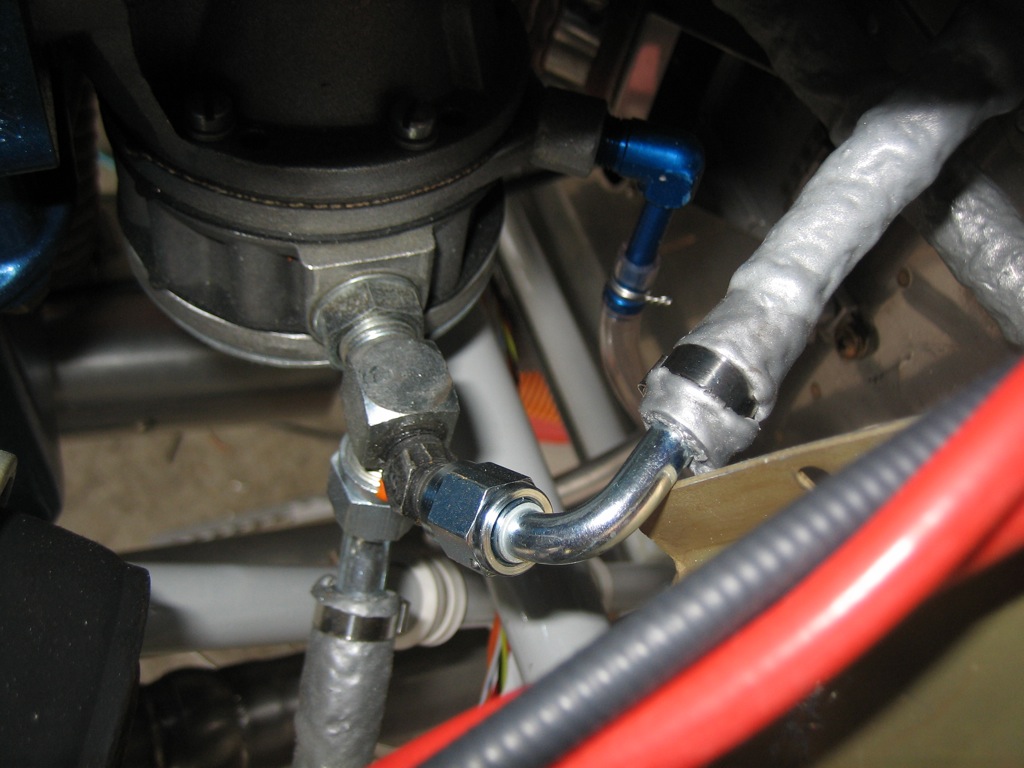

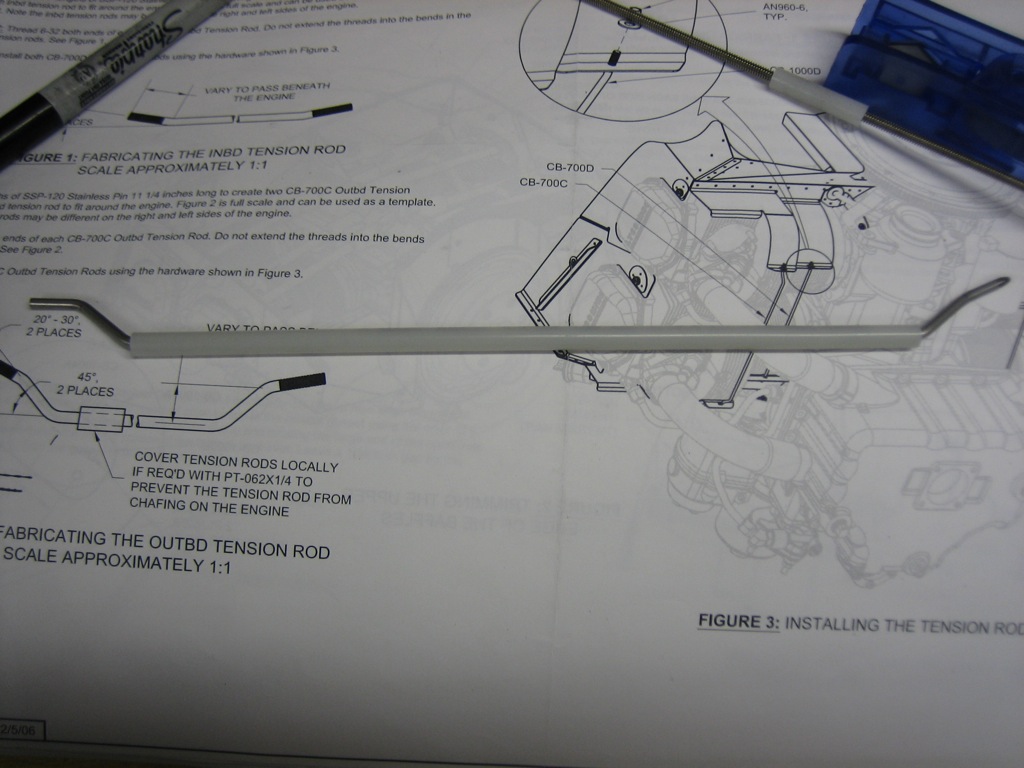

Here’s the completed #2 cylinder baffle mod. I still have the #1 and #3 cylinders to do, but that will have to wait until tomorrow.