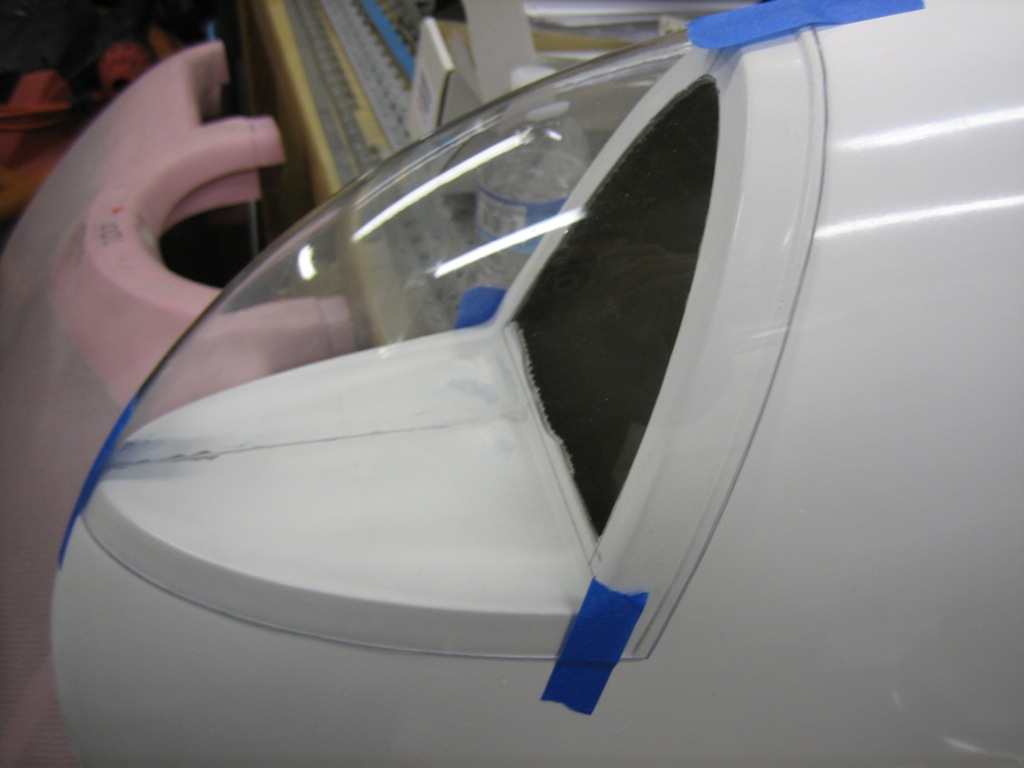

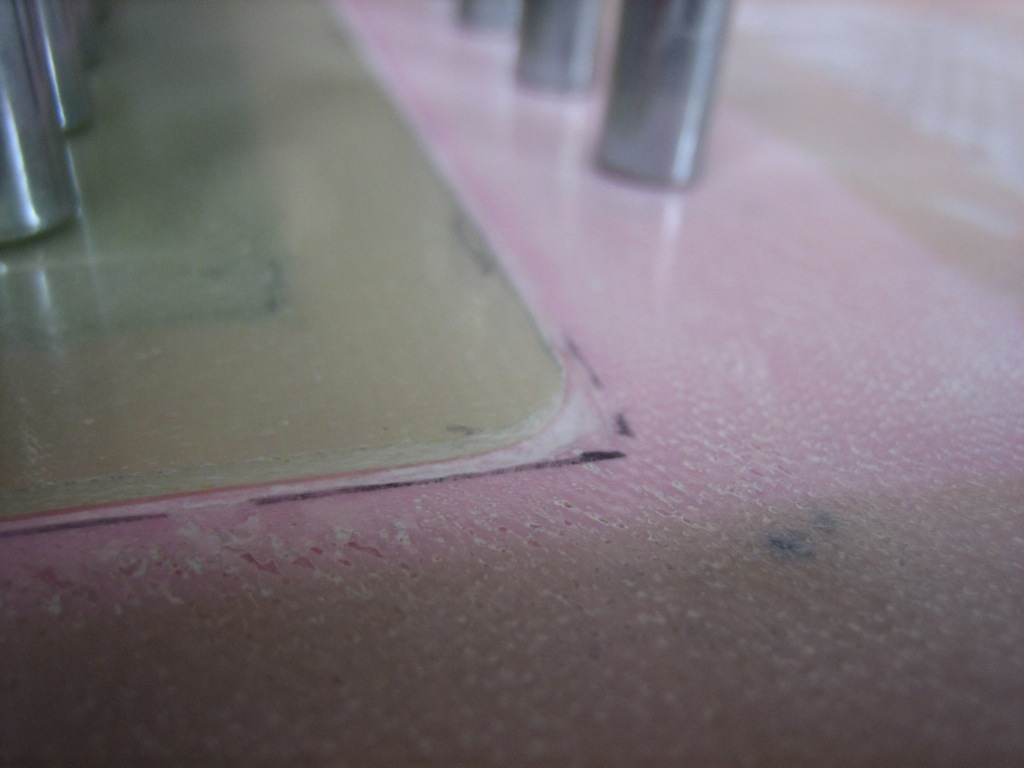

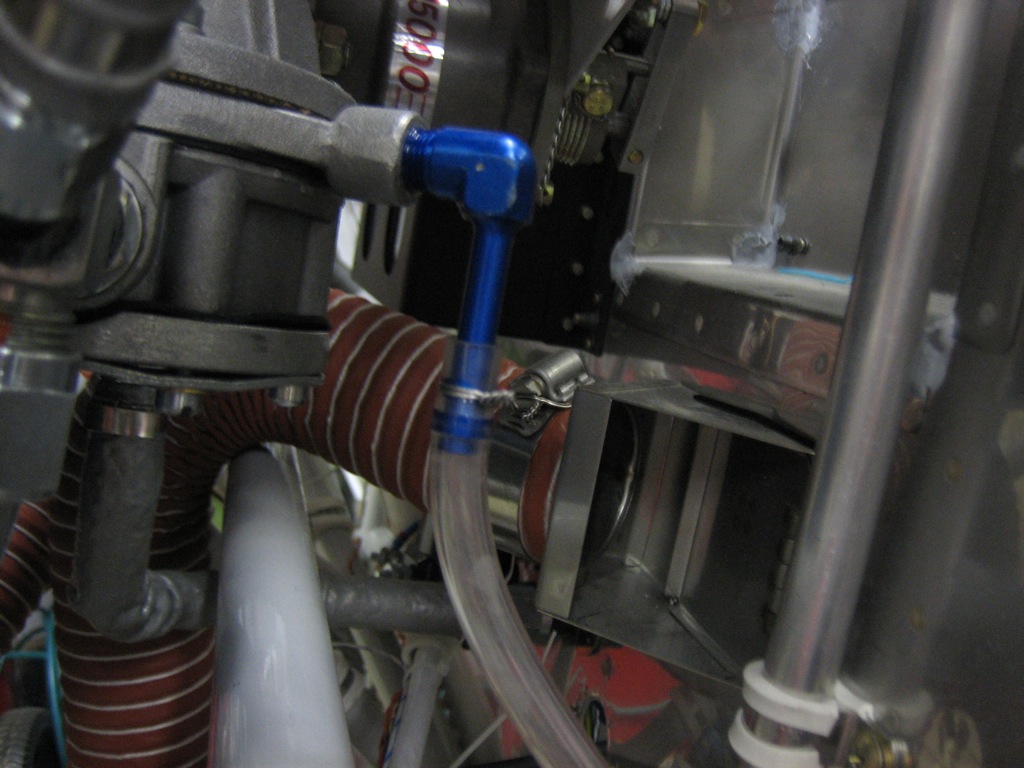

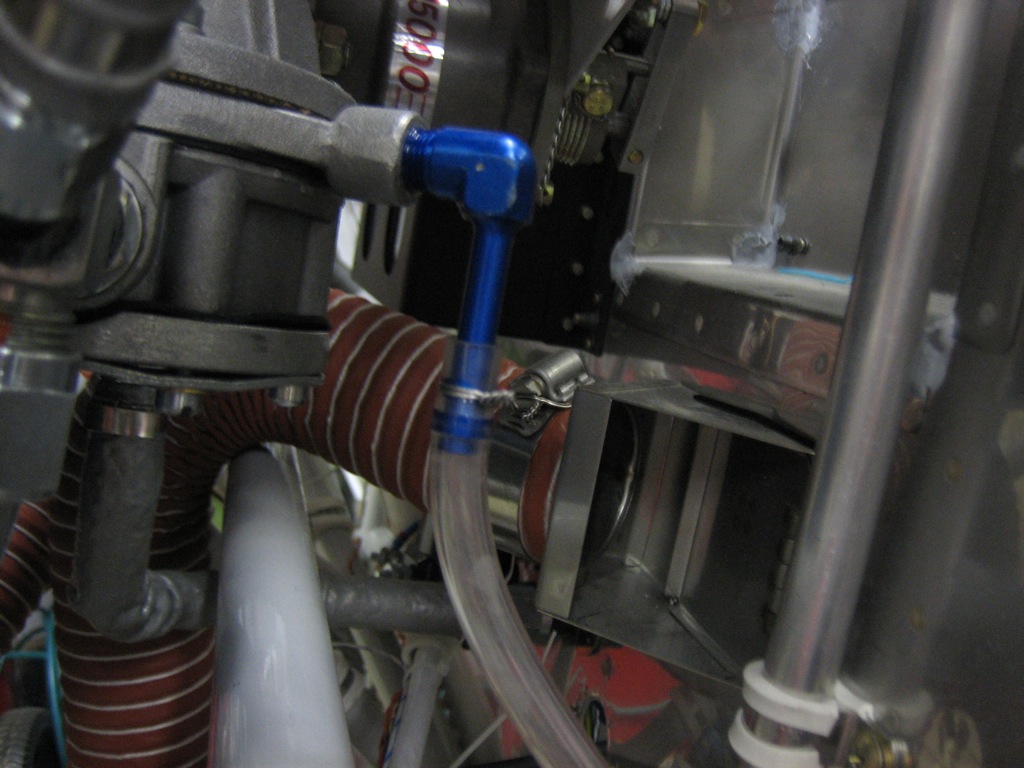

I installed the fittings in the oil cooler tonight. The top fitting is a standard AN822-8 elbow, but the bottom fitting is an AN826-8 tee with the pipe thread on the run. You can also see that I trimmed part of the oil cooler flange to provide a little more clearance with the firewall.

Here’s a better shot of the tee fitting. The blue tape covers the flare port that will connect to one of the oil cooler lines to the engine. The other flare port has an AN929-8D cap that can be removed during oil changes to drain the oil from the cooler and lines. Without this, at least a quart of oil would remain in the cooler and lines during an oil change.

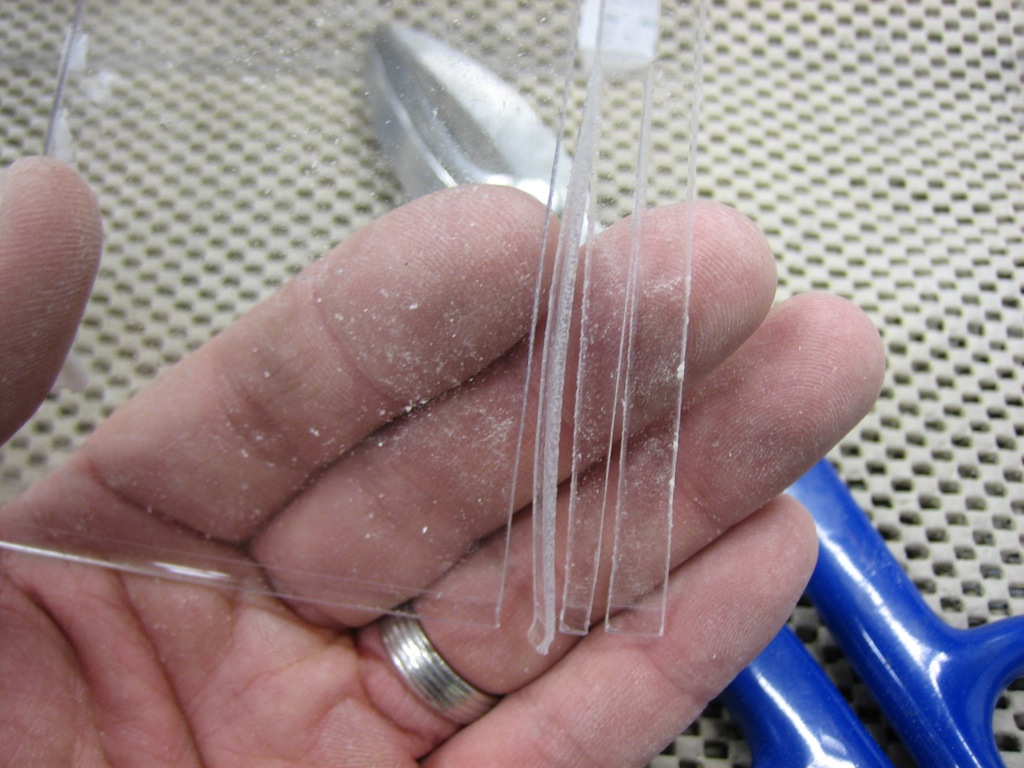

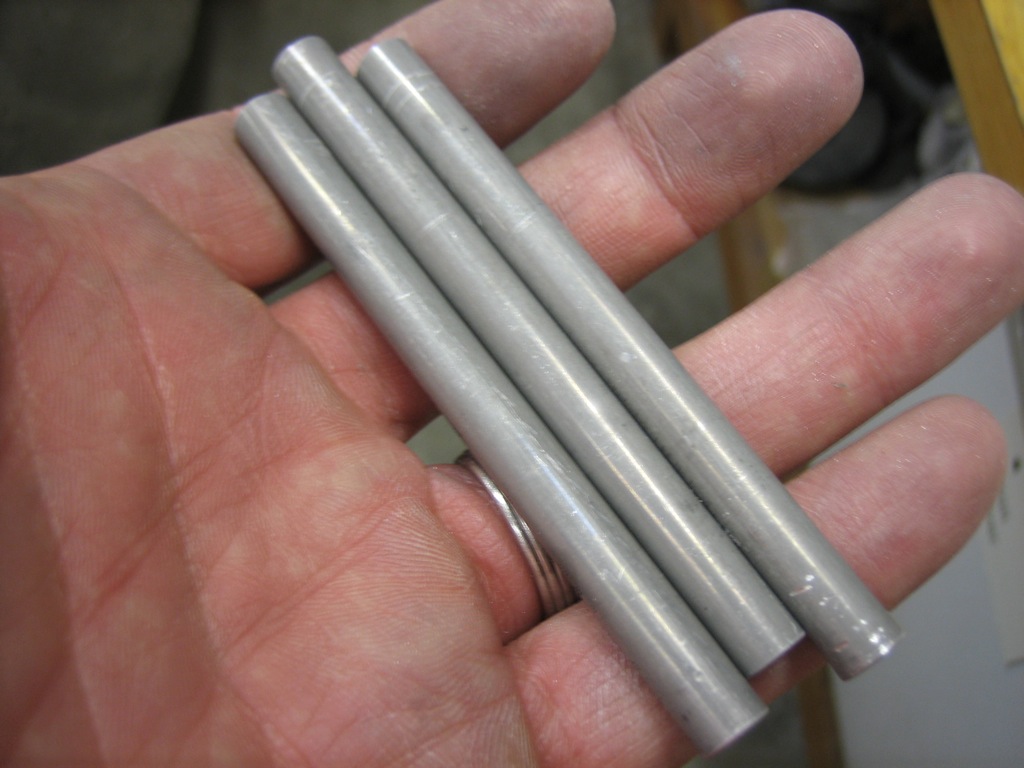

I fabricated three spacers that will used when installing the oil cooler.

They will fit between the flanges (along with some washers) to allow the mounting bolts to support both the front and back sides of the oil cooler.

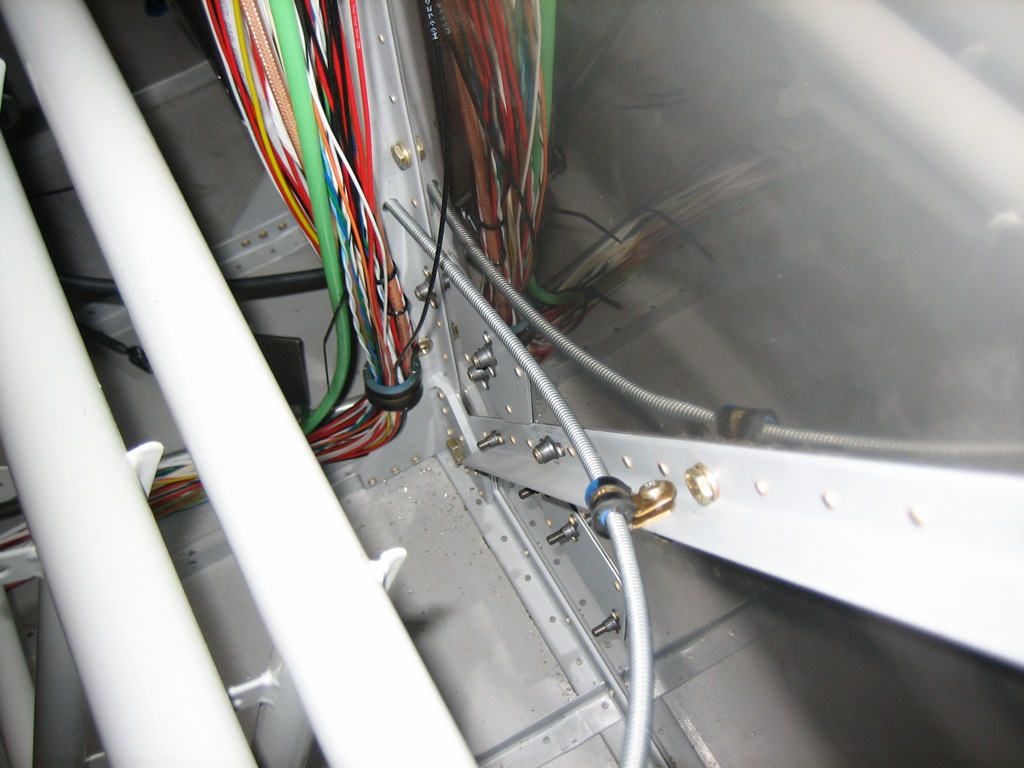

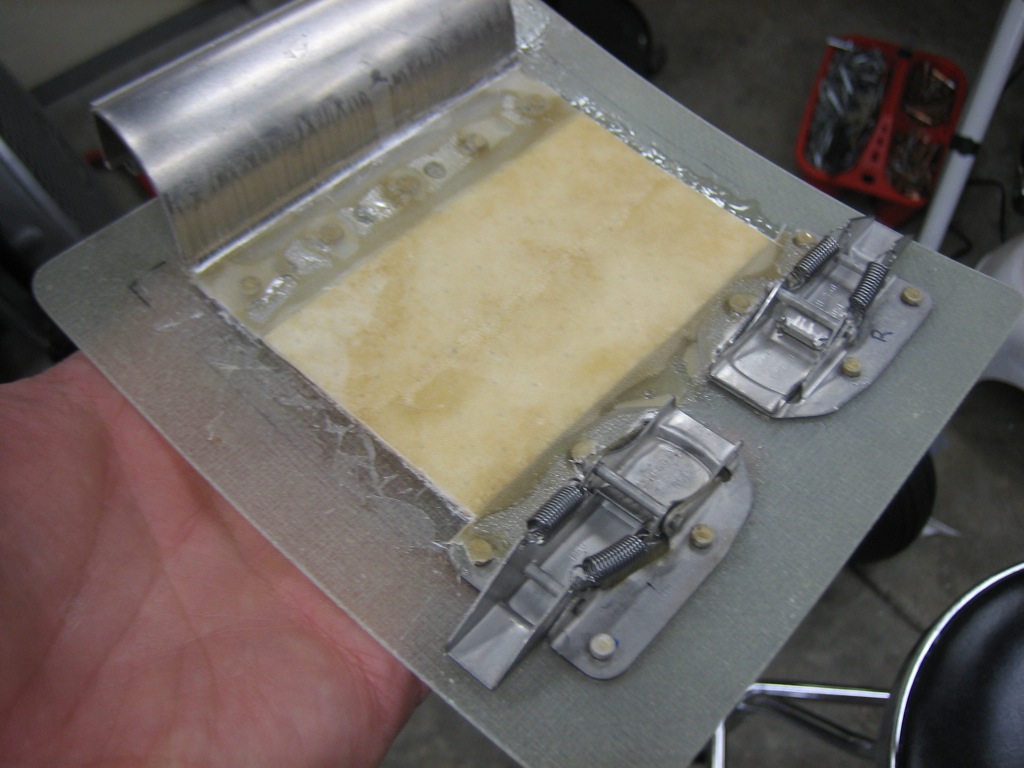

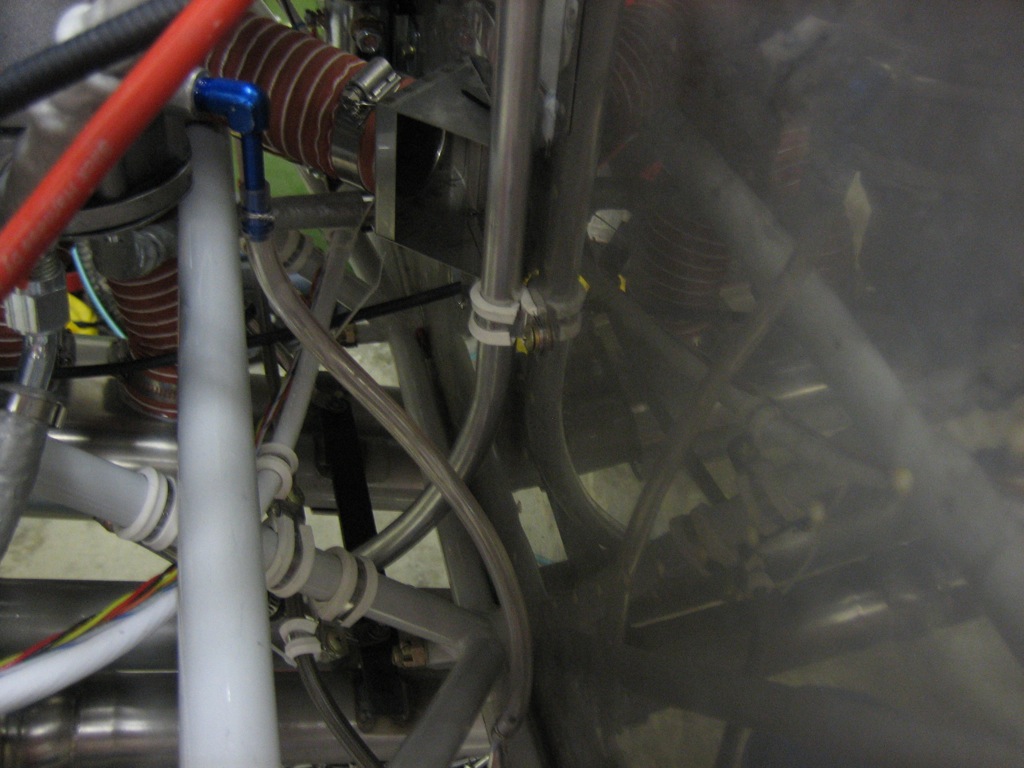

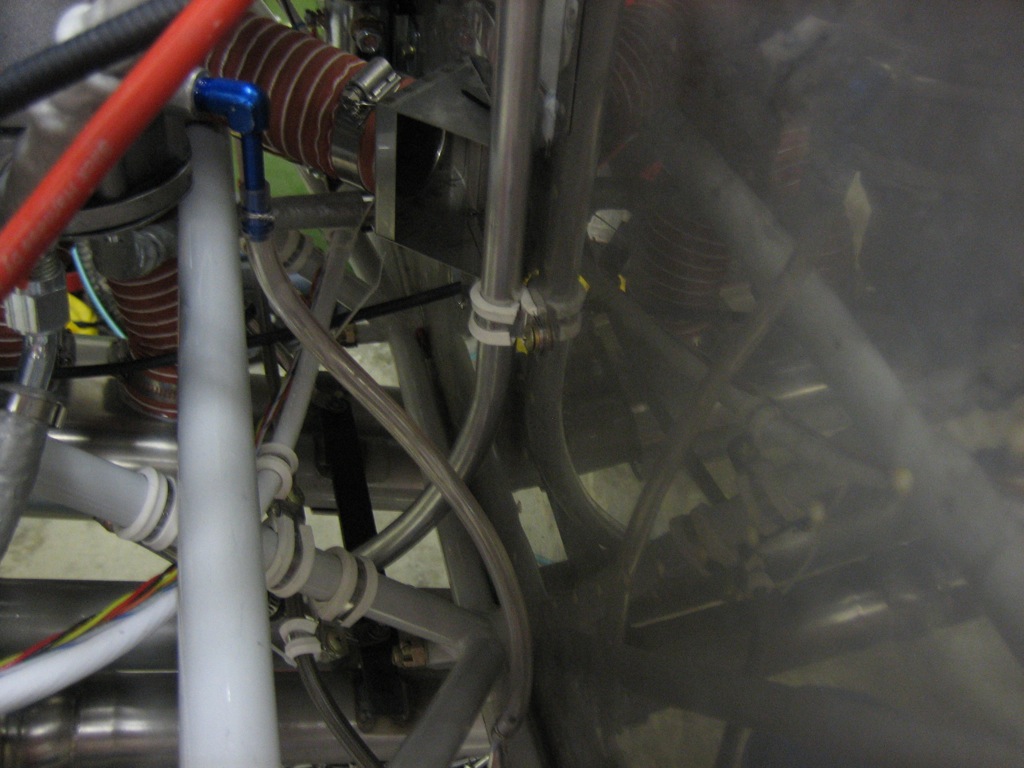

I fabricated a small oil cooler support plate and painted it (I’ll show a picture tomorrow). While waiting for the paint to dry, I decided to install the fuel overflow tubing. I used a piece of 1/4″ ID Tygon tubing to run from the AN842-4D fitting on the fuel pump down to a piece of 1/4″ tubing on the firewall.

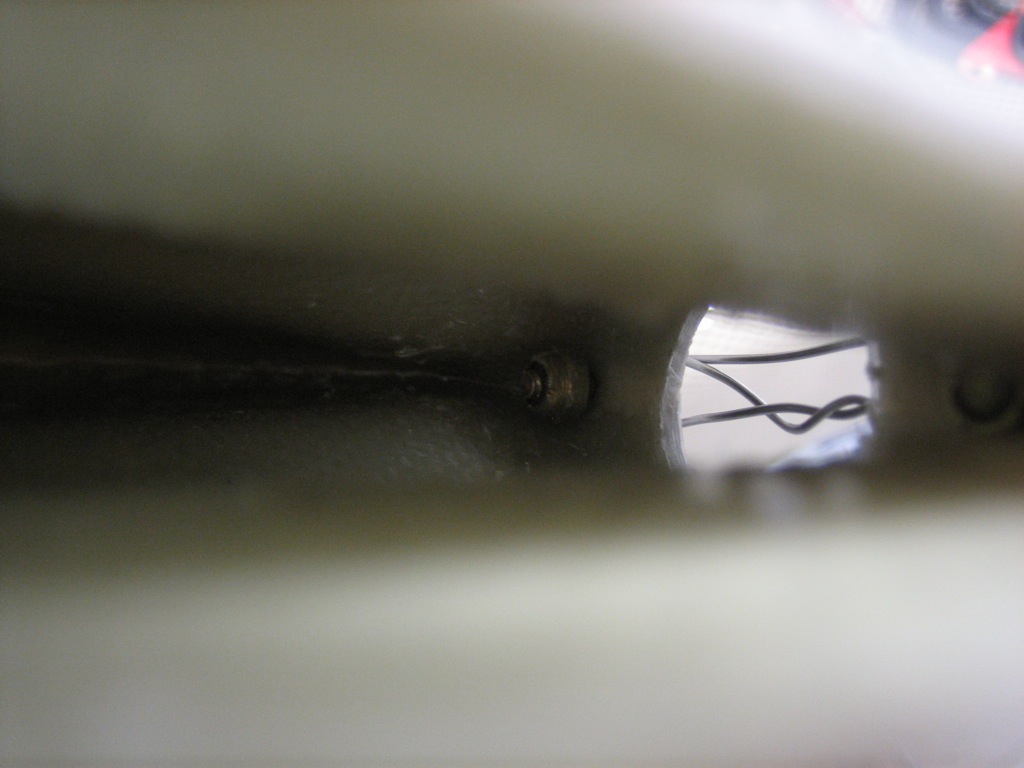

The tubing is held on to the fitting with a piece of safety wire that is double wrapped around the tubing.

At the bottom end, I bent a short piece of 1/4″ soft aluminum tubing so that it cleared the engine mount tube and poked through a 1/4″ hole I drilled through the firewall flange and hinge. I slipped a short piece of Tygon tubing over the aluminum tubing and zip-tied it to the engine mount. I then used some safety wire to attach the Tygon tubing from the fuel pump to the other end of the aluminum tubing.