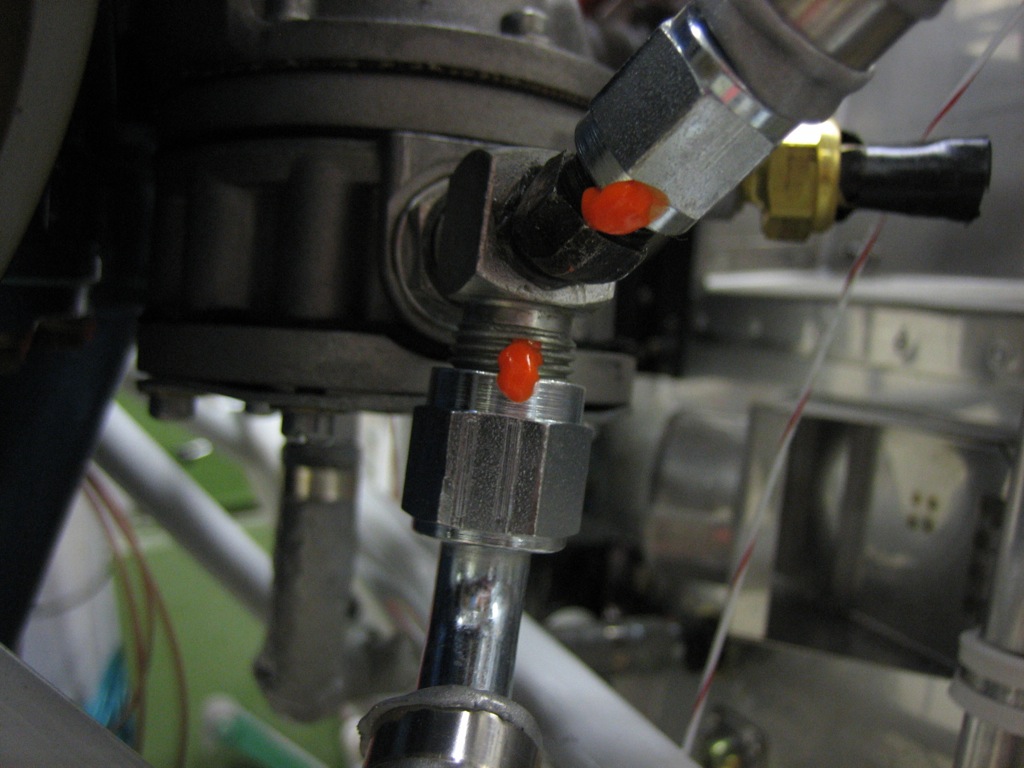

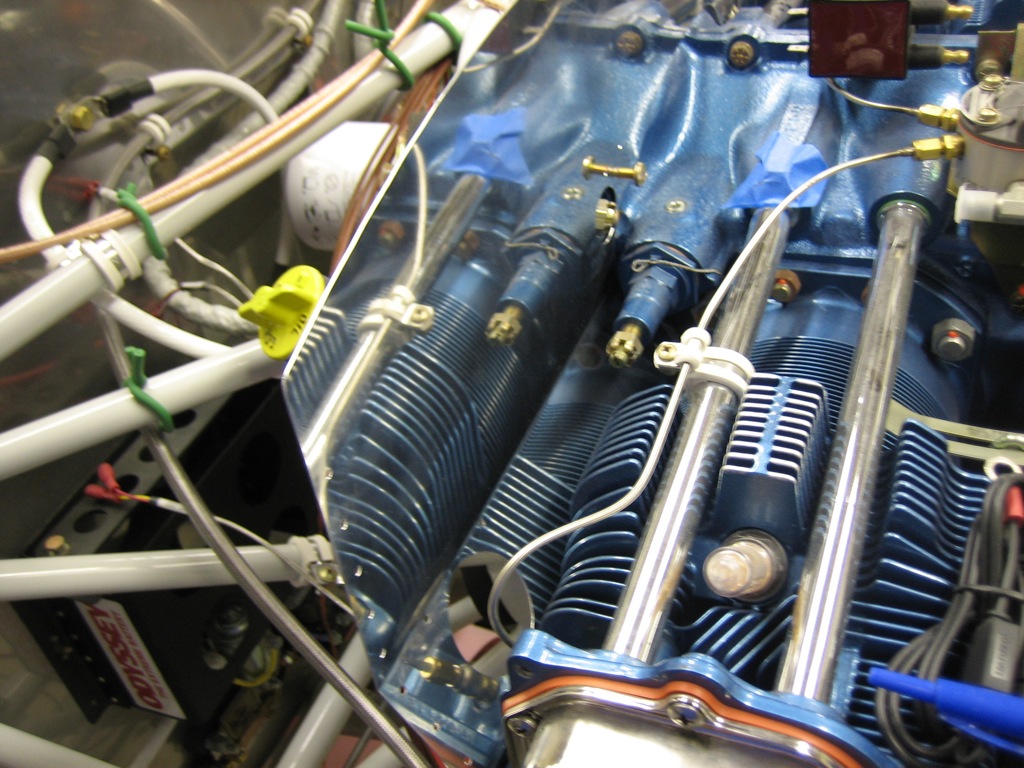

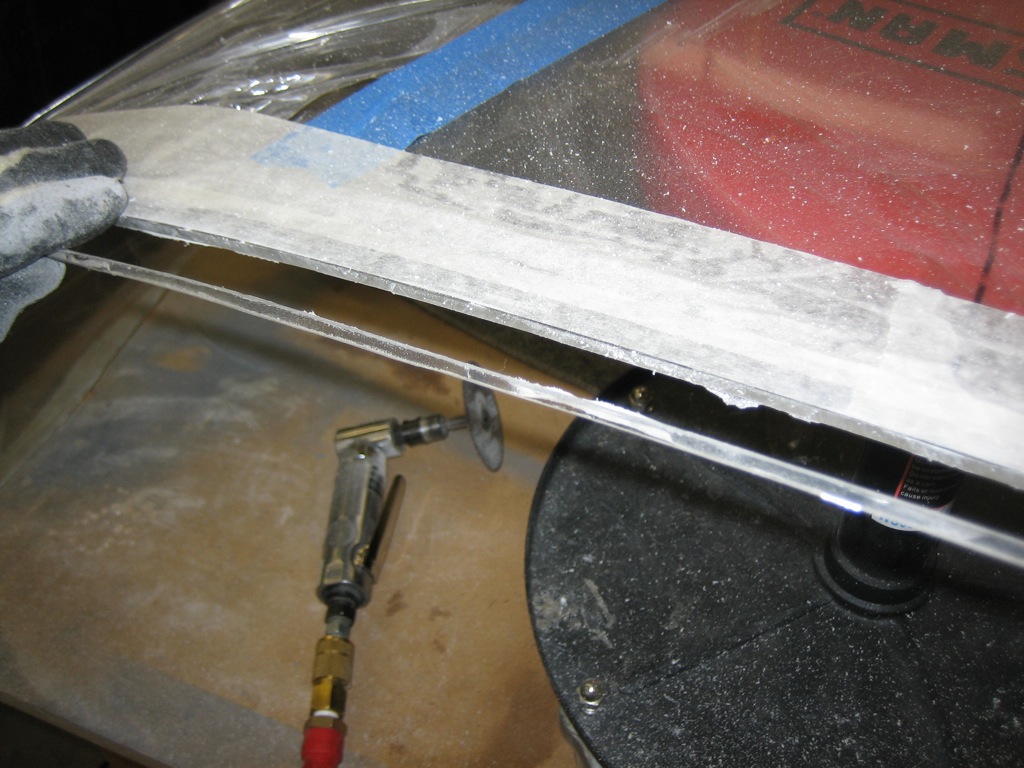

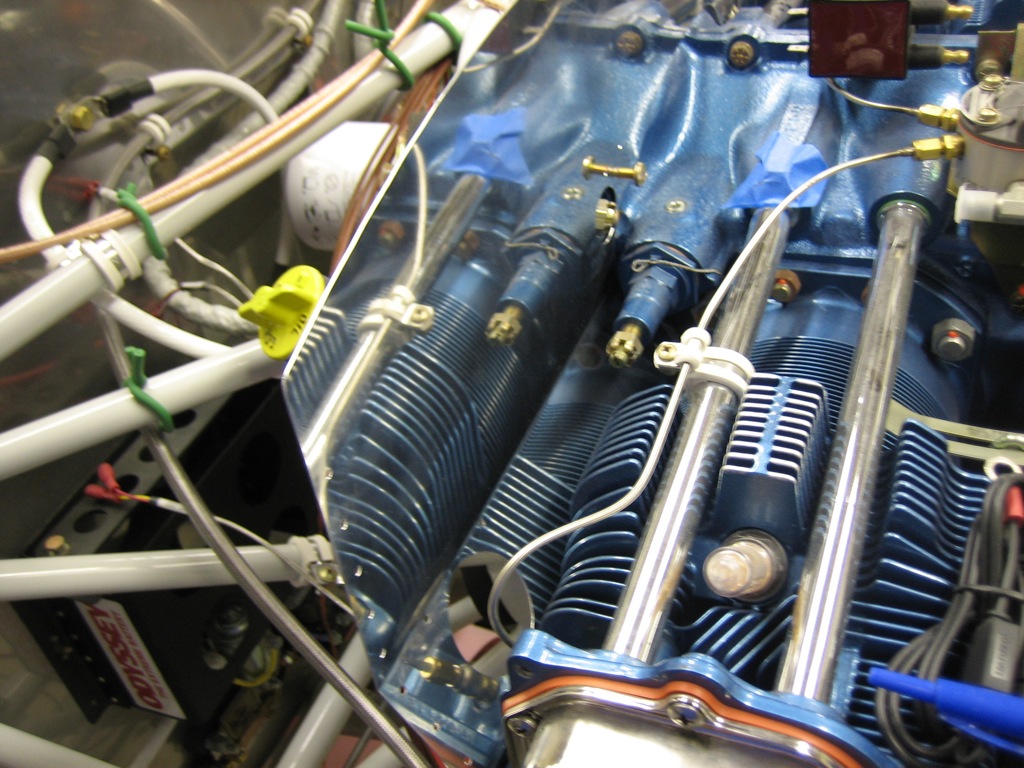

I’m waiting on some sheet stock from Aircraft Spruce to make the canopy side skins (I can’t use the stock included in the kit because I moved the joint line forward to line up with the longeron bend and it isn’t long enough). I decided to pick back up on the baffles since I like to have multiple parts of the aircraft under construction simultaneously. I managed to get the whole rear wall and left side wall rough fit. Here’s a view of the rear wall on the right side. This piece required quite a bit of trimming to fit around the upper engine mount bolt.

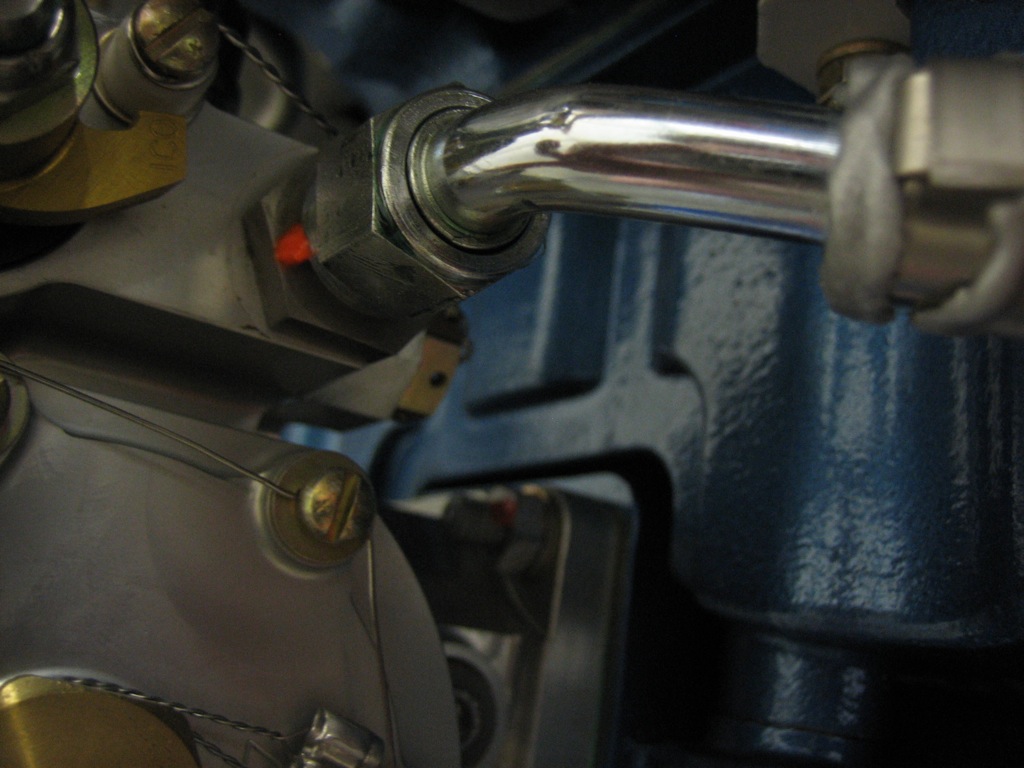

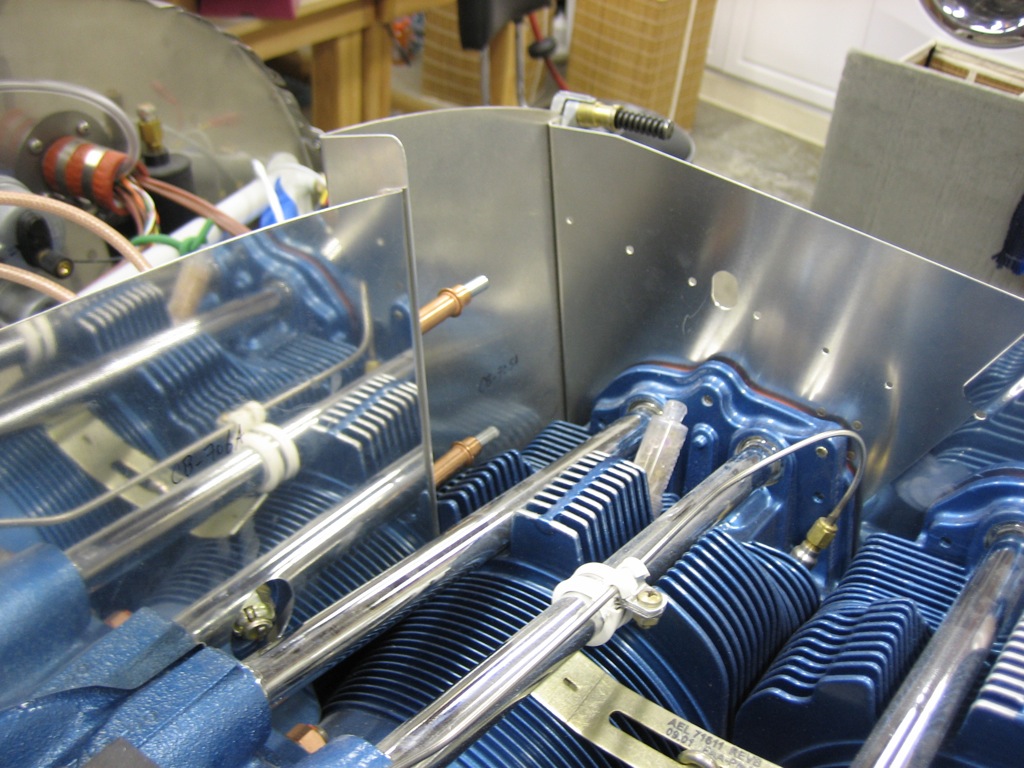

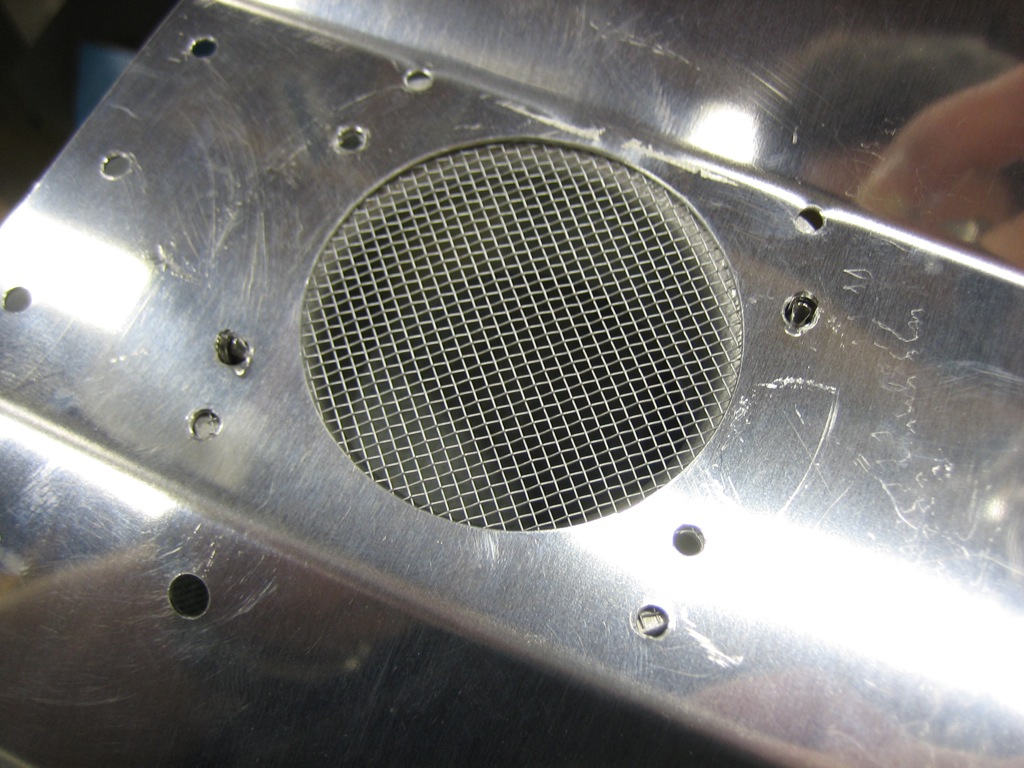

Here’s a view of the left rear wall. The recessed portion will eventually contain a hole for the oil cooler.

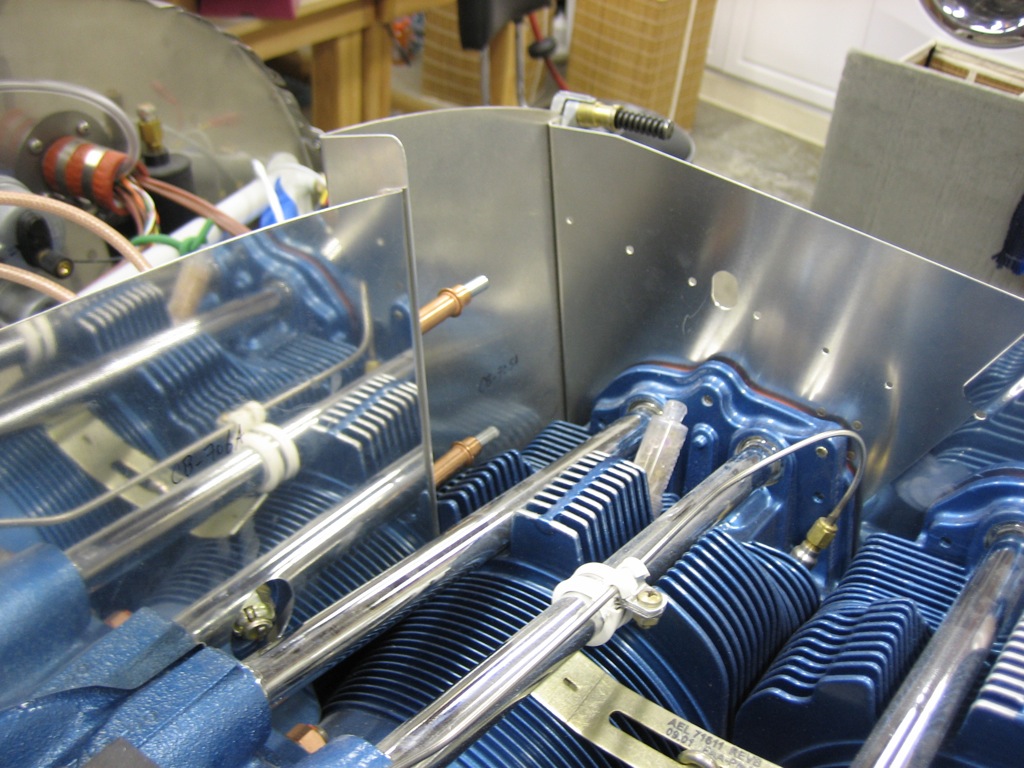

And here are the pieces that make up the left side wall. You can see here that small doublers are riveted on where the screws attach the baffles to the cylinders.

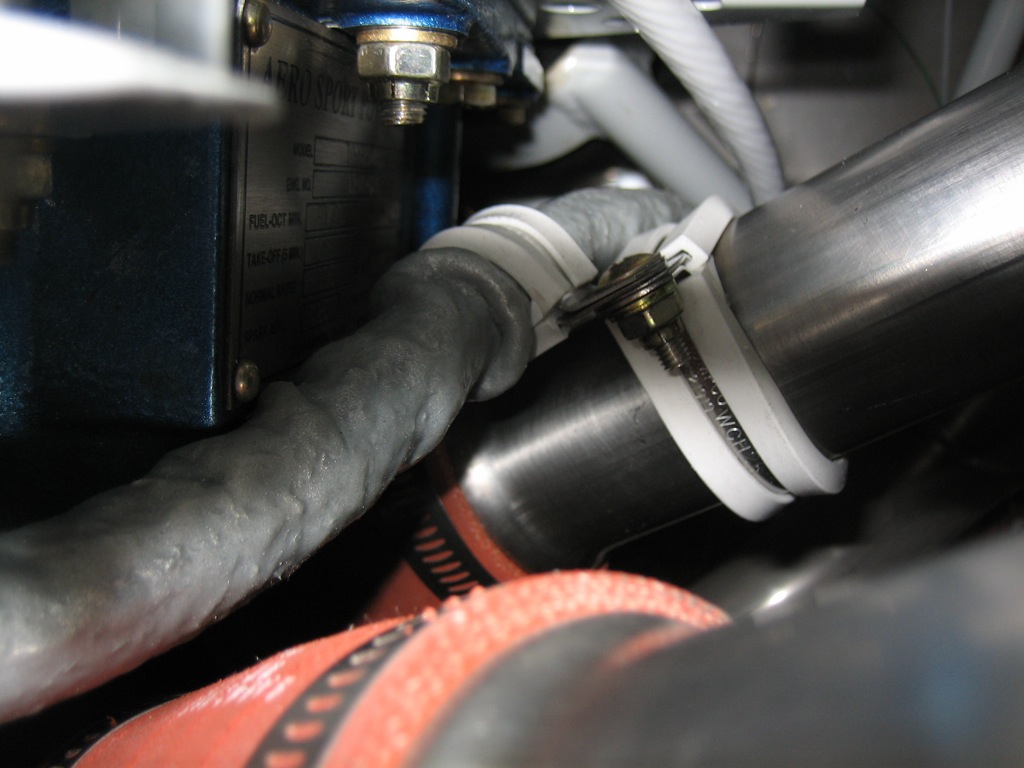

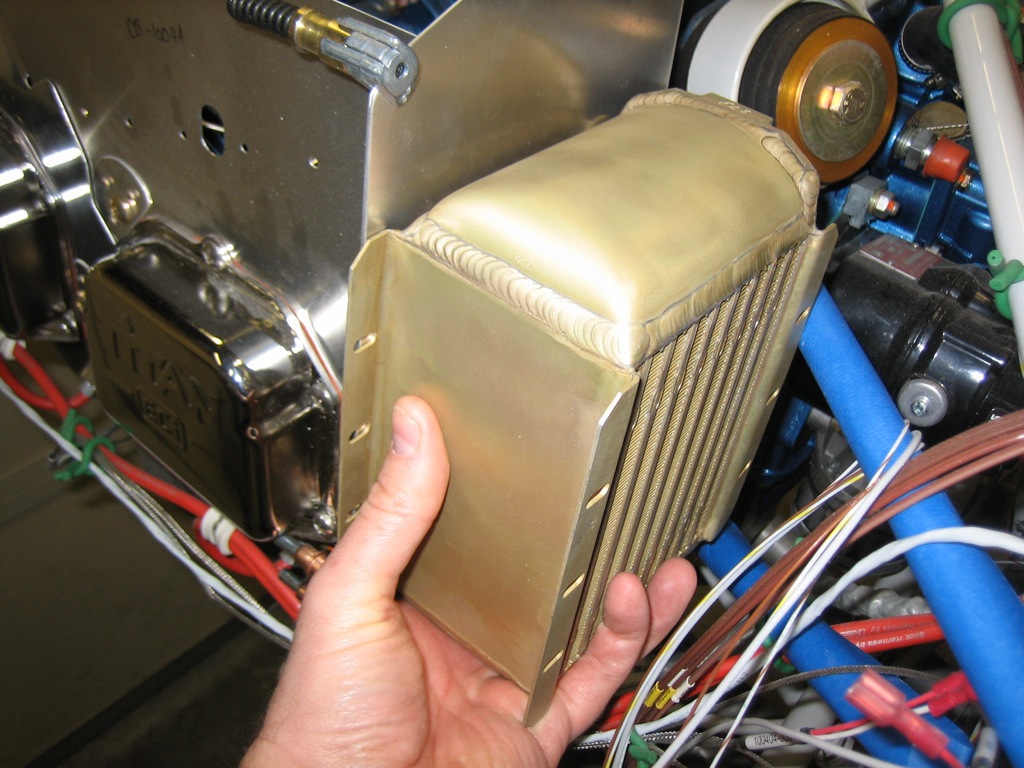

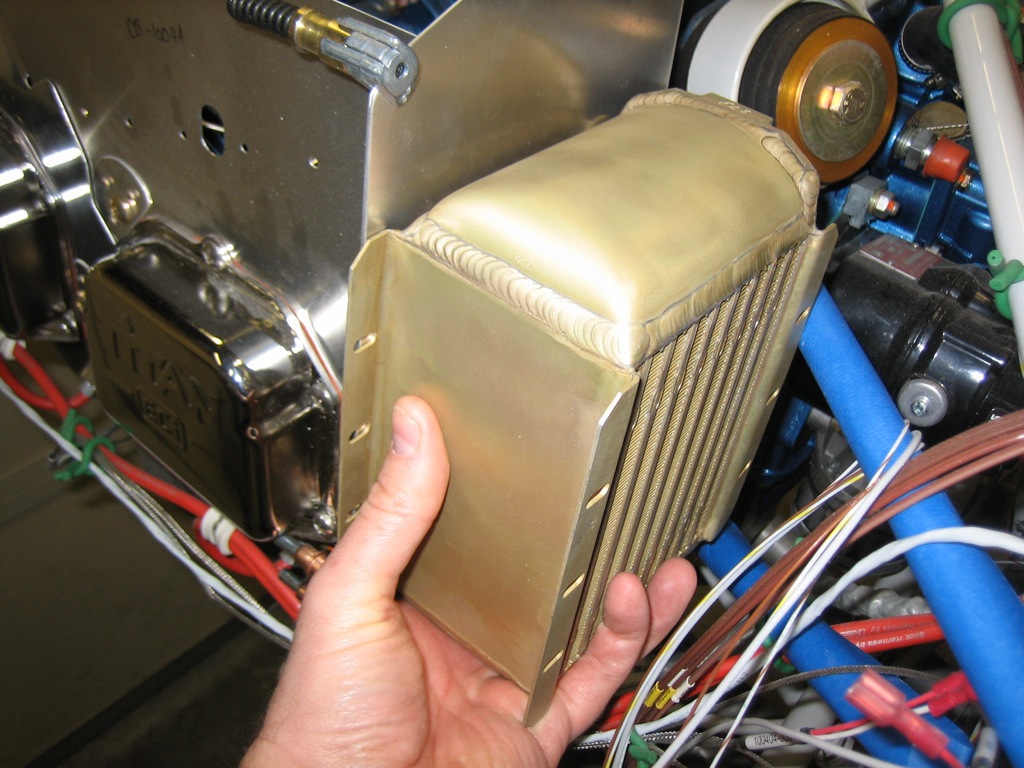

Here’s roughly where the oil cooler will be mounted. Since I’ve installed an IO-375, Bart at Aerosport recommended I install the Stewart Warner 10599R instead of the more common 8432R. This is over 1″ wider than the 8432, so the fit is snug. Even with the oil cooler touching the engine mount (I will eventually cut away a notch to give some clearance), the flange sticks past the edge of the baffles.

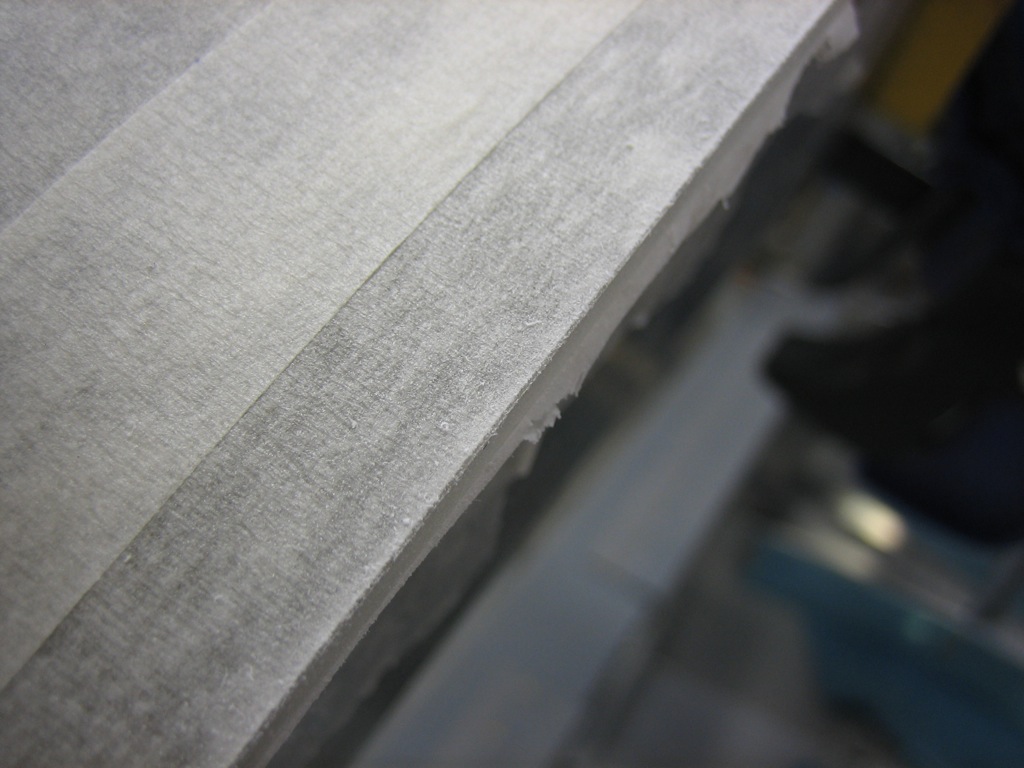

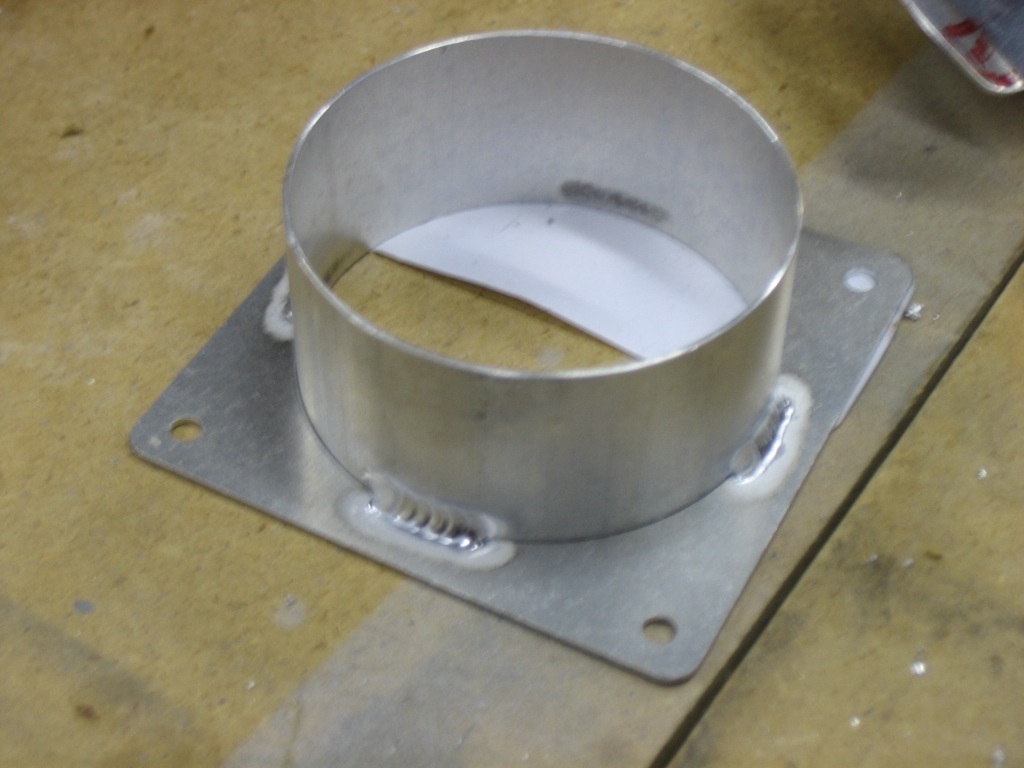

Here’s a look from the front side showing that the mounting holes in the oil cooler stick past the edge of the baffles. I will need to fabricate a mounting bracket to support this. I’m not ready to do anything on it yet though since the plans recommend waiting until the baffle seals are installed and then positioning the oil cooler as high as possible. There is also still a small chance that I’ll mount the oil cooler on the firewall.