Wow, over two weeks since I’ve touched the project. I’ve been out of town for most of that time on various trips as well as planning for our imminent bathroom remodel. I did get some flying in though; my dad and I flew my Cardinal down to TX for a funeral. Roughly 24 hours of flying over two days; fun, but very exhausting.

I received another shipment of hoses from Bonaco today. I haven’t written anything about my experiences with them, but I’ve had no end of trouble getting correct hoses from them. Brett has always been great to work with and has always corrected any problems, but I’m simply astonished at the number of problems I’ve encountered. Not a single order has come in correct the first time, and one hose took three tries for them to make it correctly. Brett offered the most recent batch of hoses for free in an attempt to make up for all of the problems, but even this order had problems.

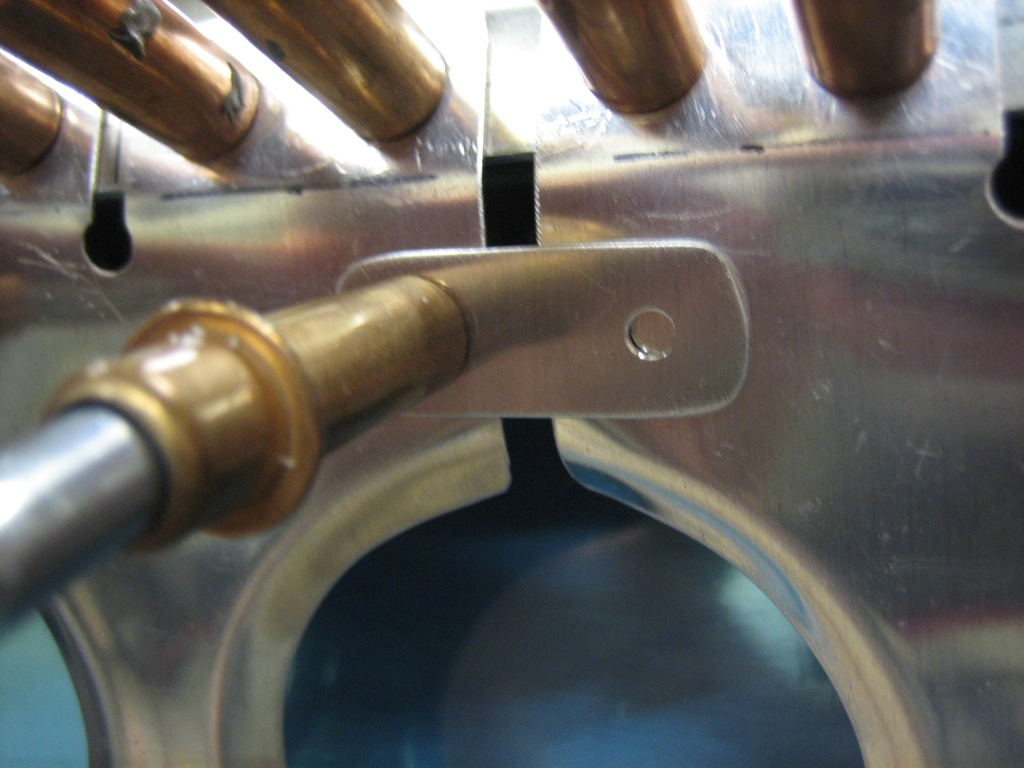

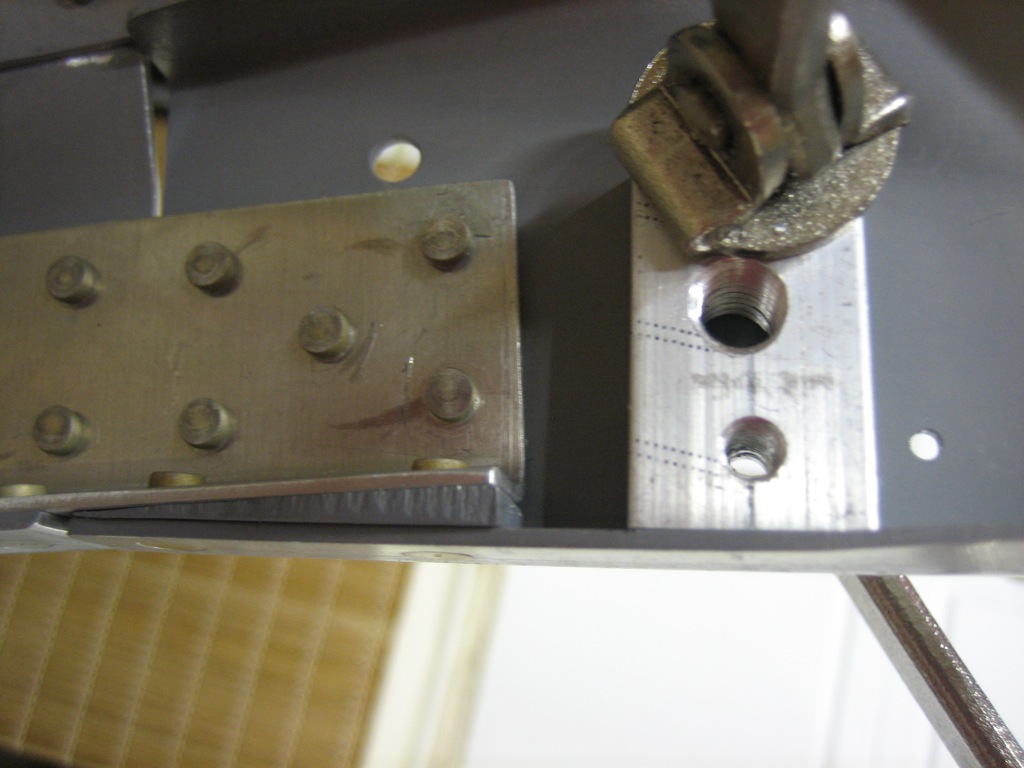

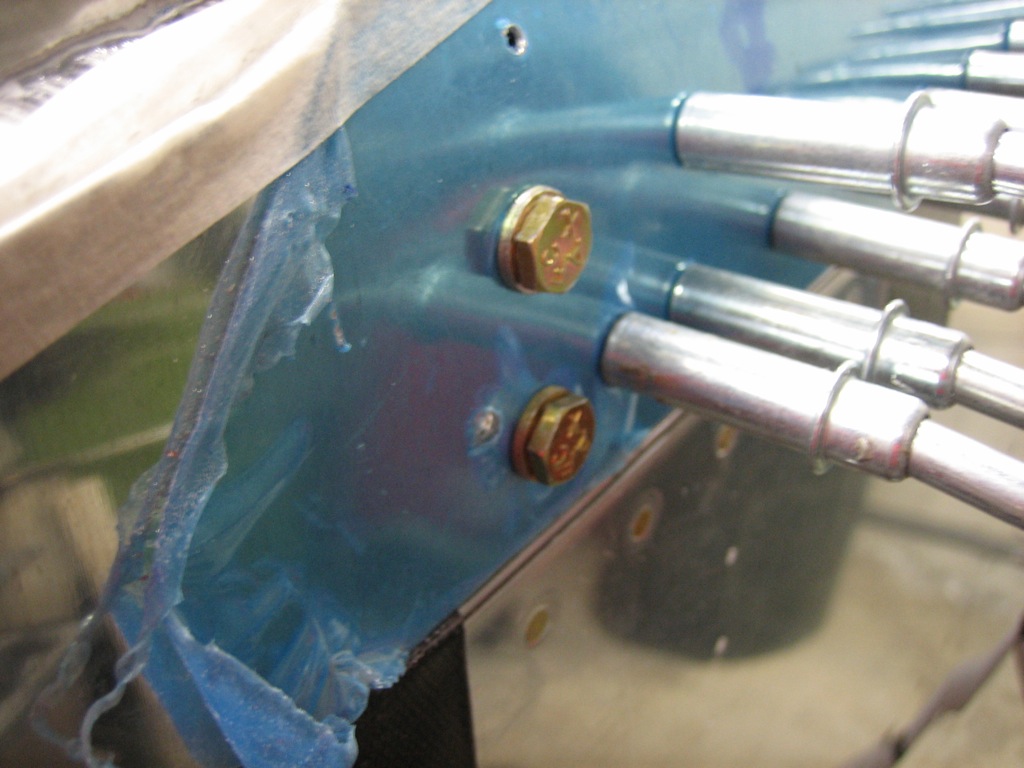

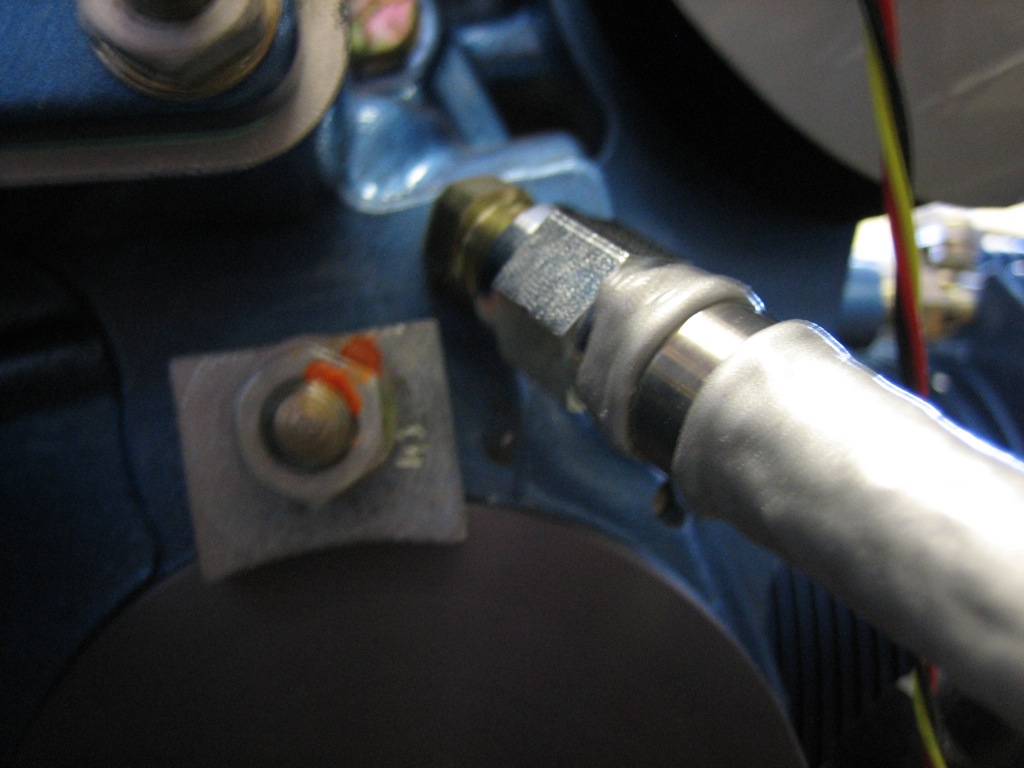

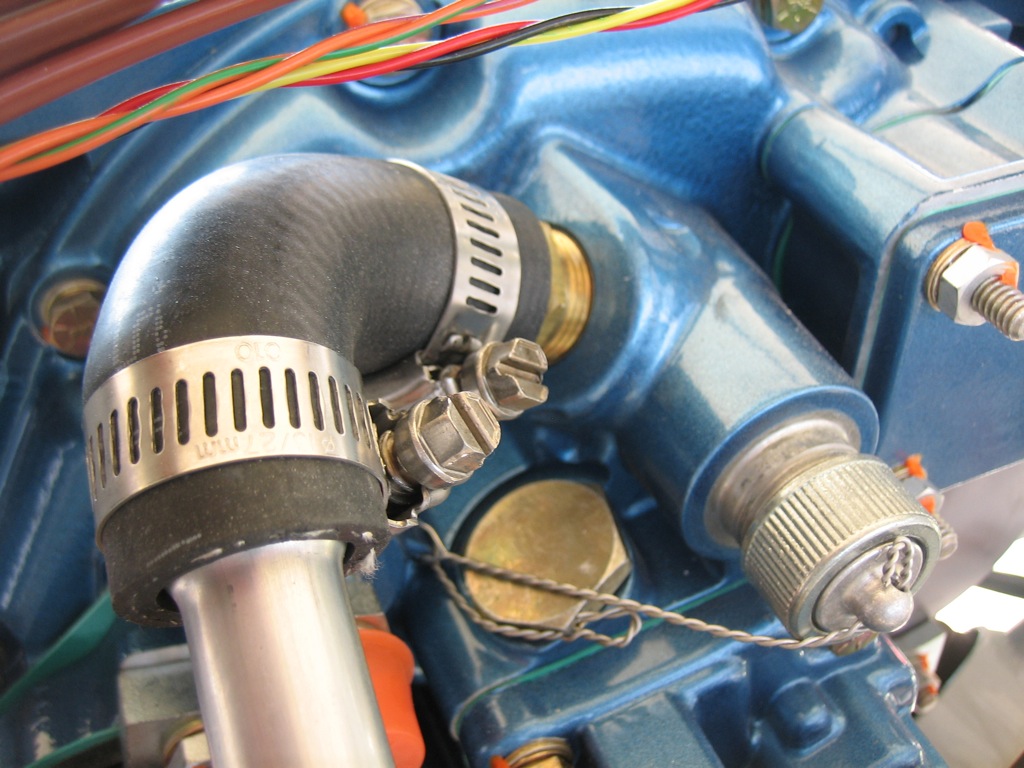

First up is the manifold pressure hose. This was supposed to have aluminum fittings, but as you can see, they messed up and installed steel fittings. I installed it anyway to see if the length and routing is acceptable. It’s a little long, so I may order a replacement that fits better and has aluminum fittings.

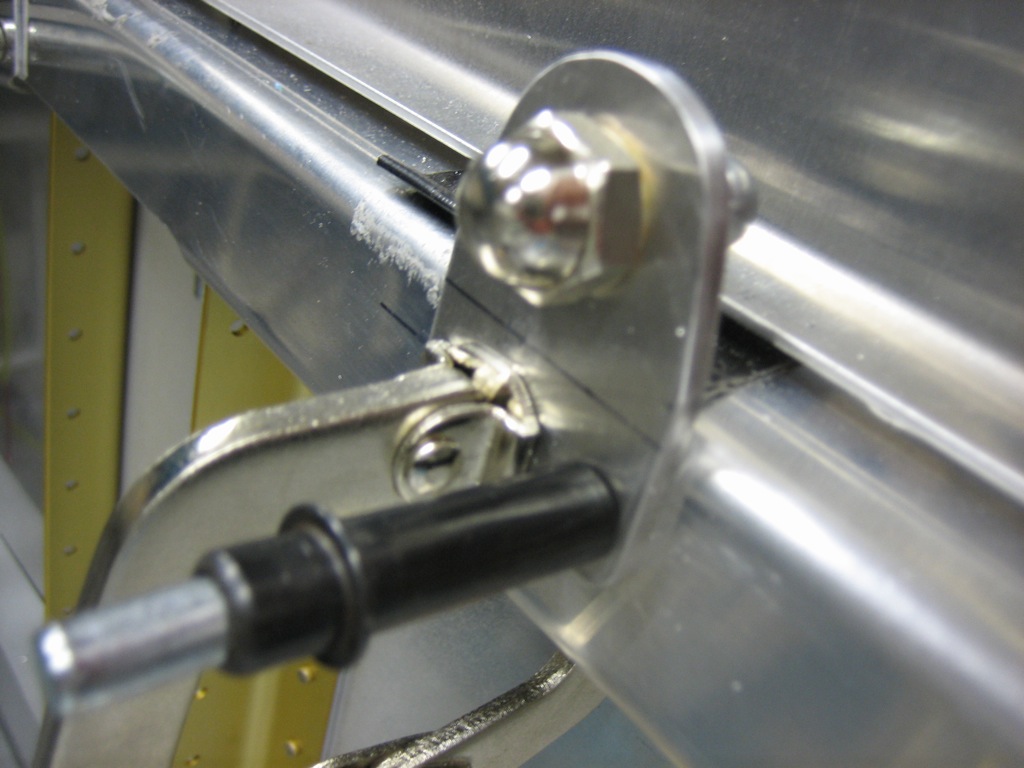

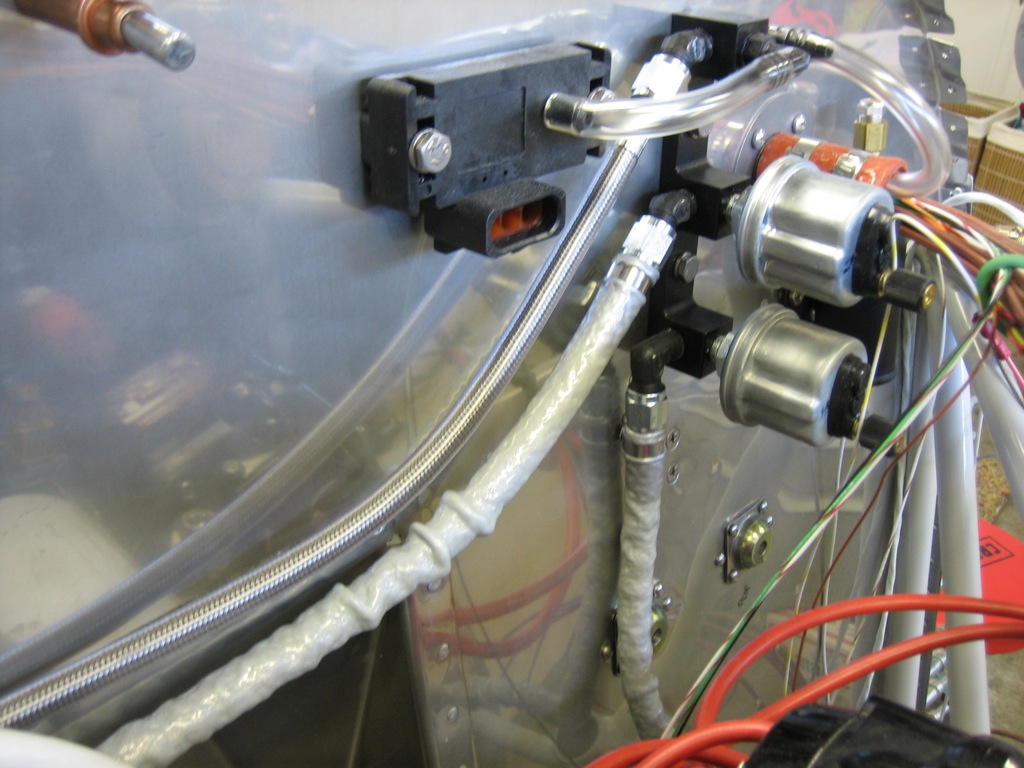

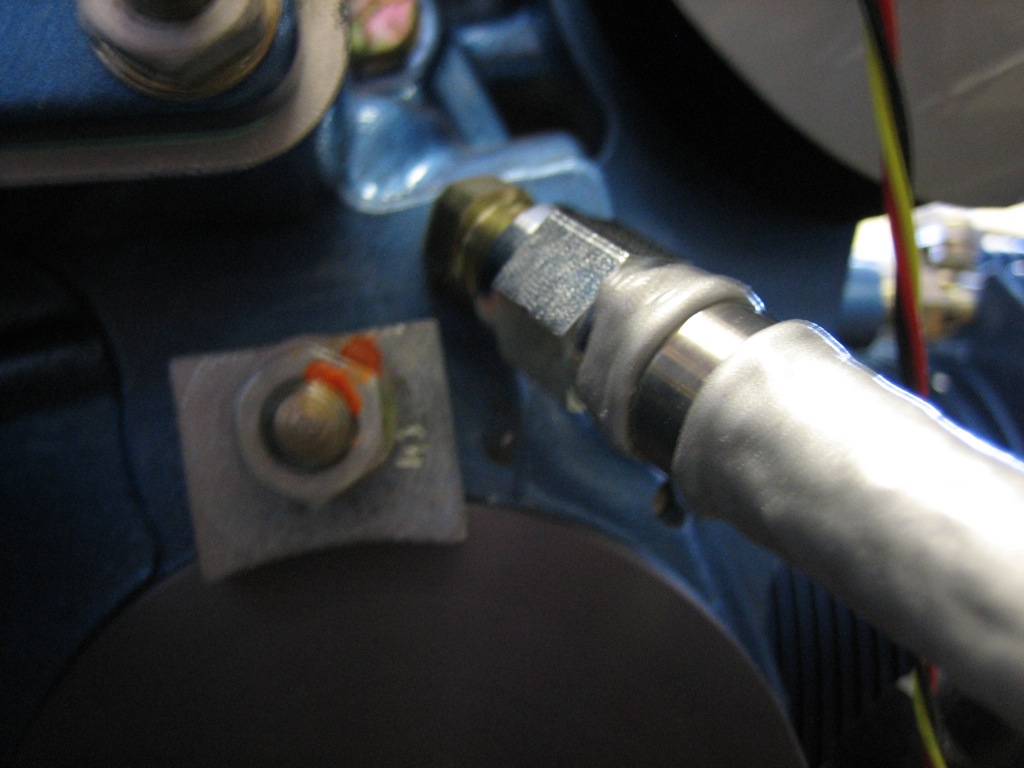

I also received the oil pressure hose. This screws into a restrictor fitting on the accessory case and connects to the pressure transducer manifold.

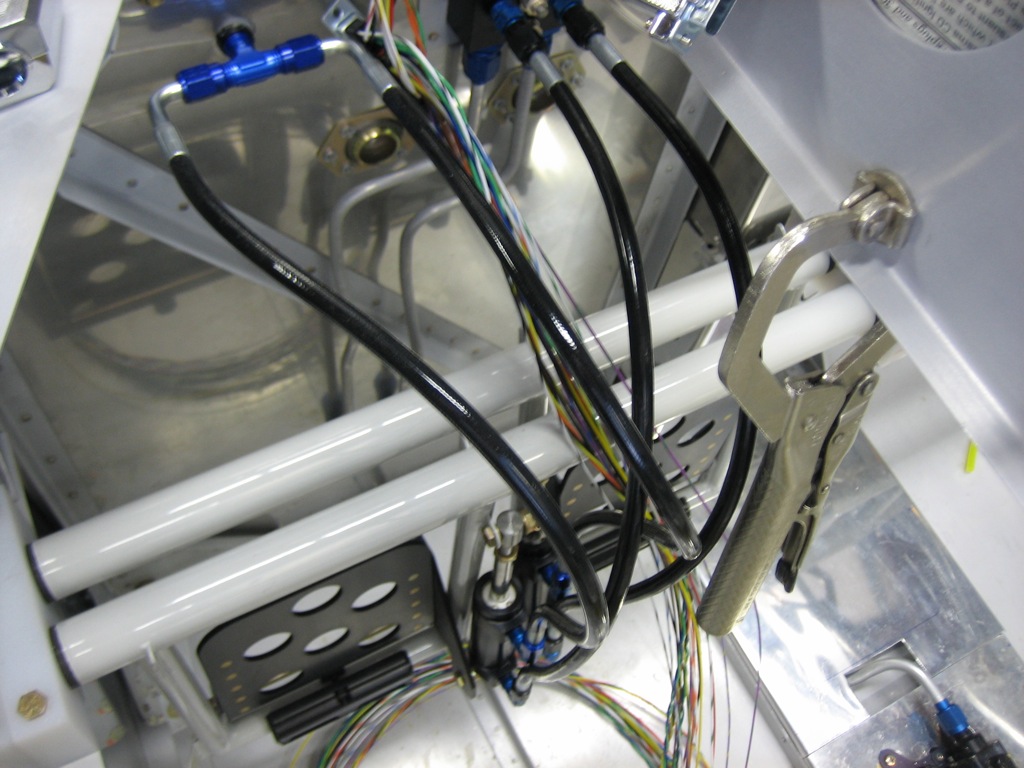

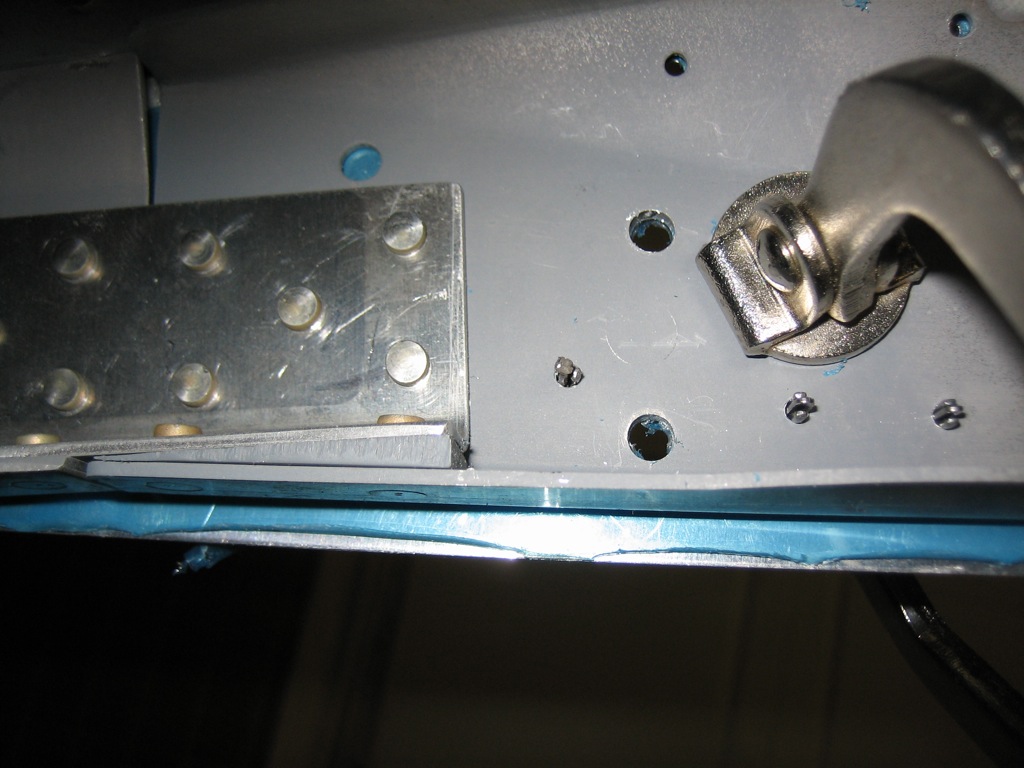

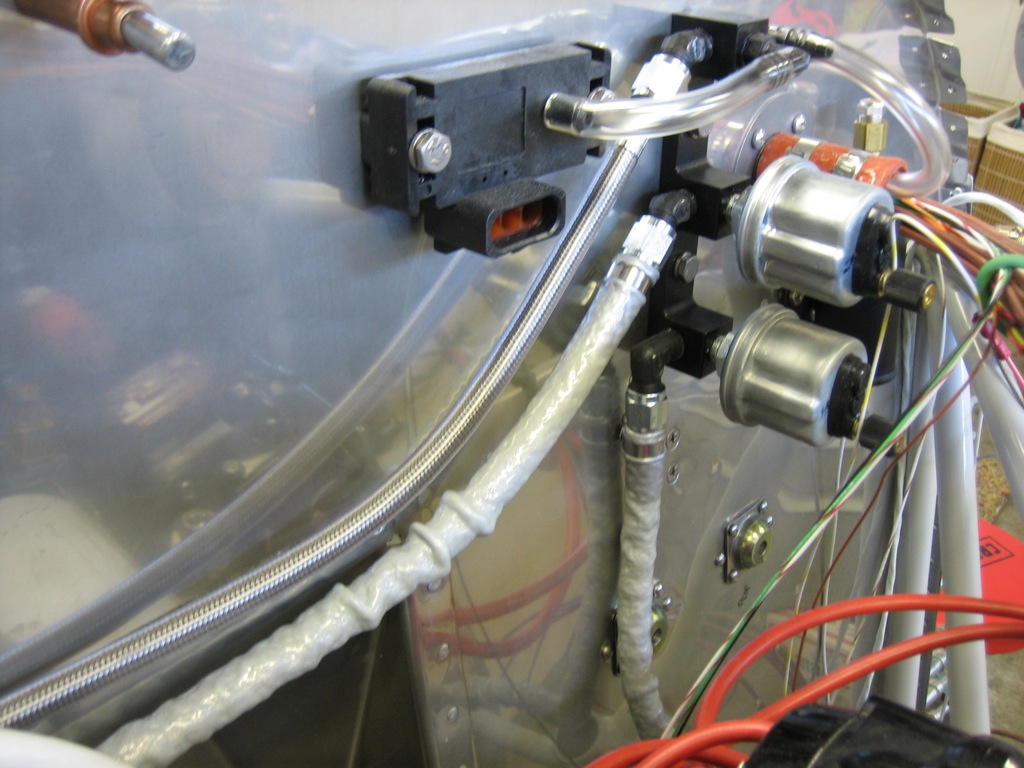

Here are where these hoses connect to the manifold. The top line (without the firesleeve) is the manifold pressure hose. The middle hose is the oil pressure line. The bottom line which goes straight down is the fuel pressure hose.

Here’s the other end of the fuel pressure line. The angle fitting needs to be replaced with a restrictor fitting, but I’ll wait until I have a few more things to order before ordering that.

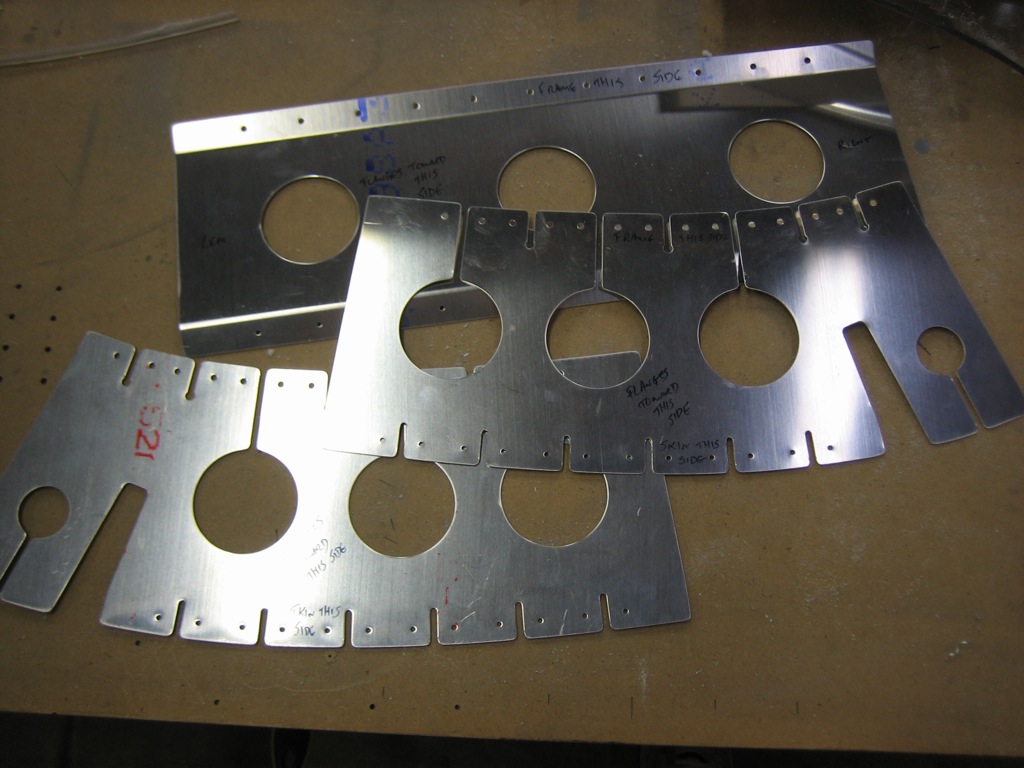

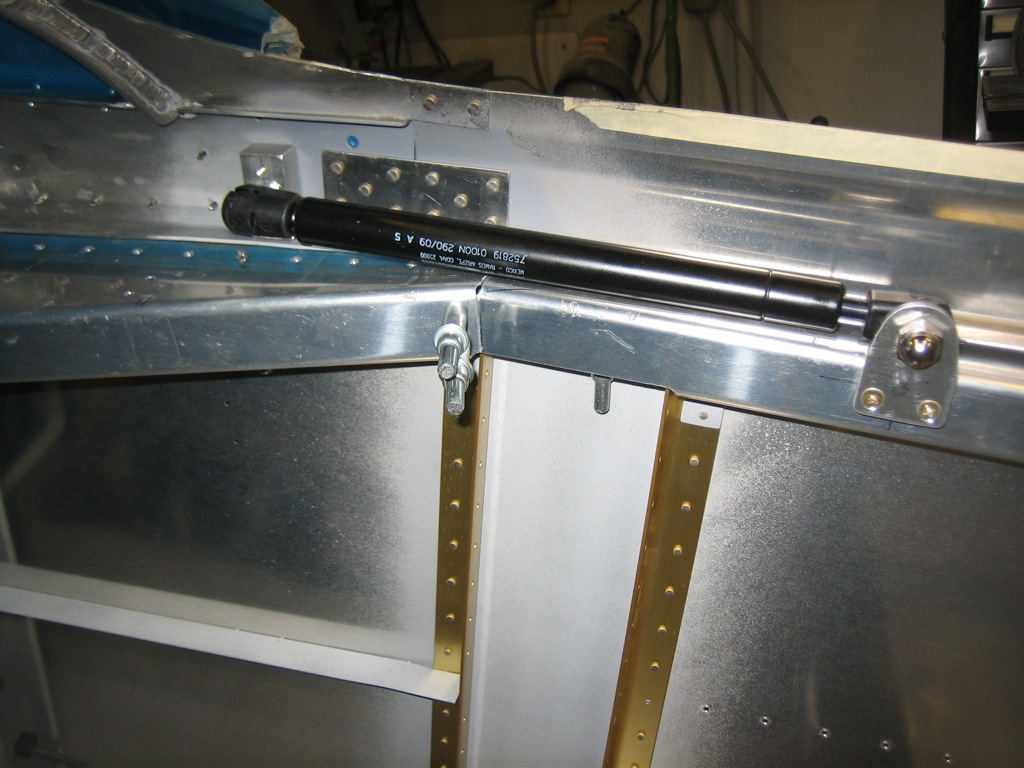

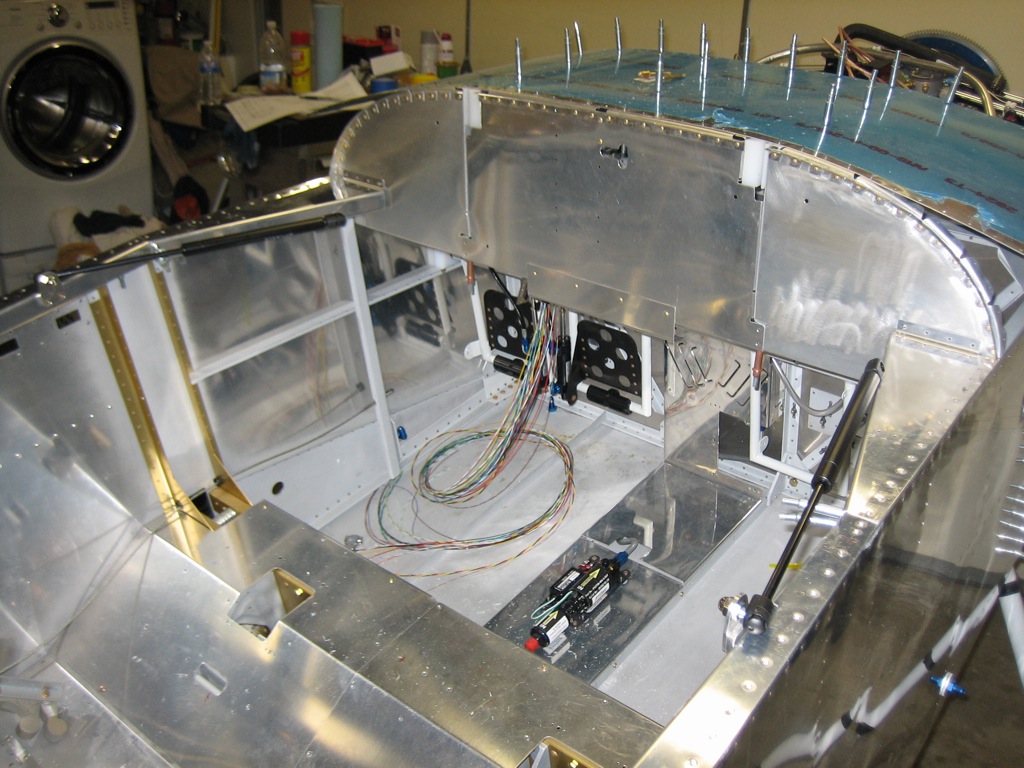

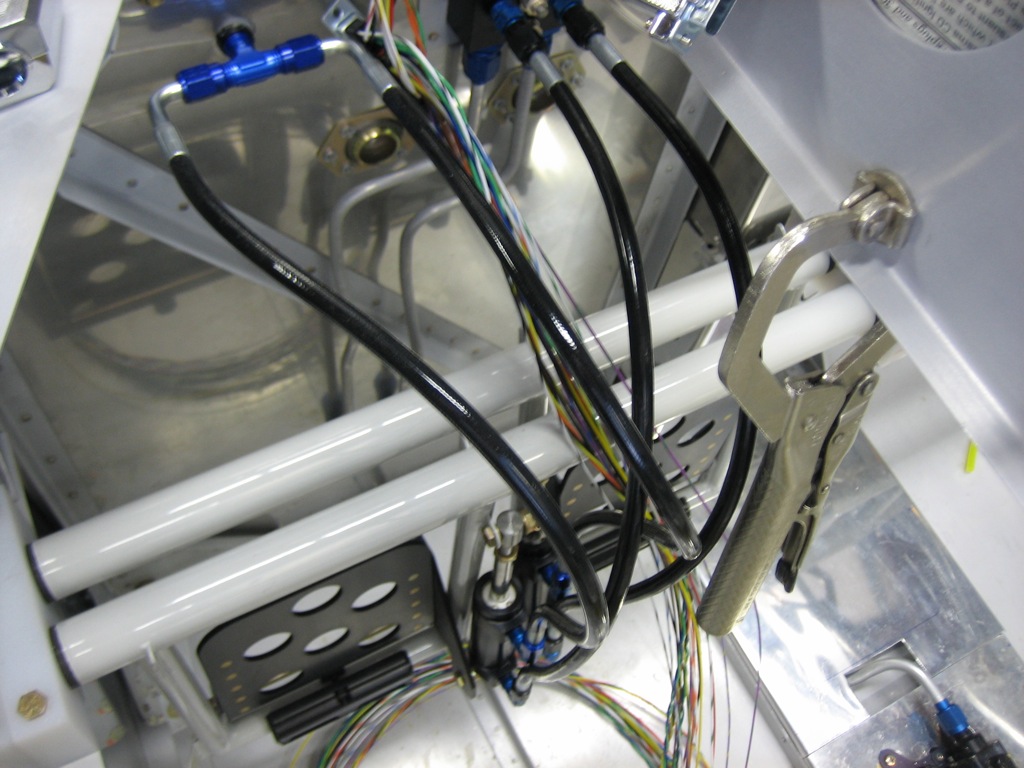

I also received the final two brake lines. These were also not made correctly; I ordered these with blue fittings, but they came in black. I may swap out the other ones for black fittings and re-anodize the fittings that thread into the master cylinders anyway, so I’m not concerned about this mistake.