My engine shipped last friday and arrived at Apple’s loading dock this afternoon. The crate is bigger than I expected at about 3’x4′ and about 2.5′ tall. According to the shipping documents, it weighs 400lbs.

There was a little damage to the top of the crate near one end. Probably something that was placed on top of this crate that broke through. Hopefully there’s no damage to the components.

I rented a U-Haul pickup and the receiving guys loaded it into the back with their forklift.

Here’s the crate strapped in and ready for the ride to my house. My friend Josh from work helped me run this home and unload it with an engine hoist.

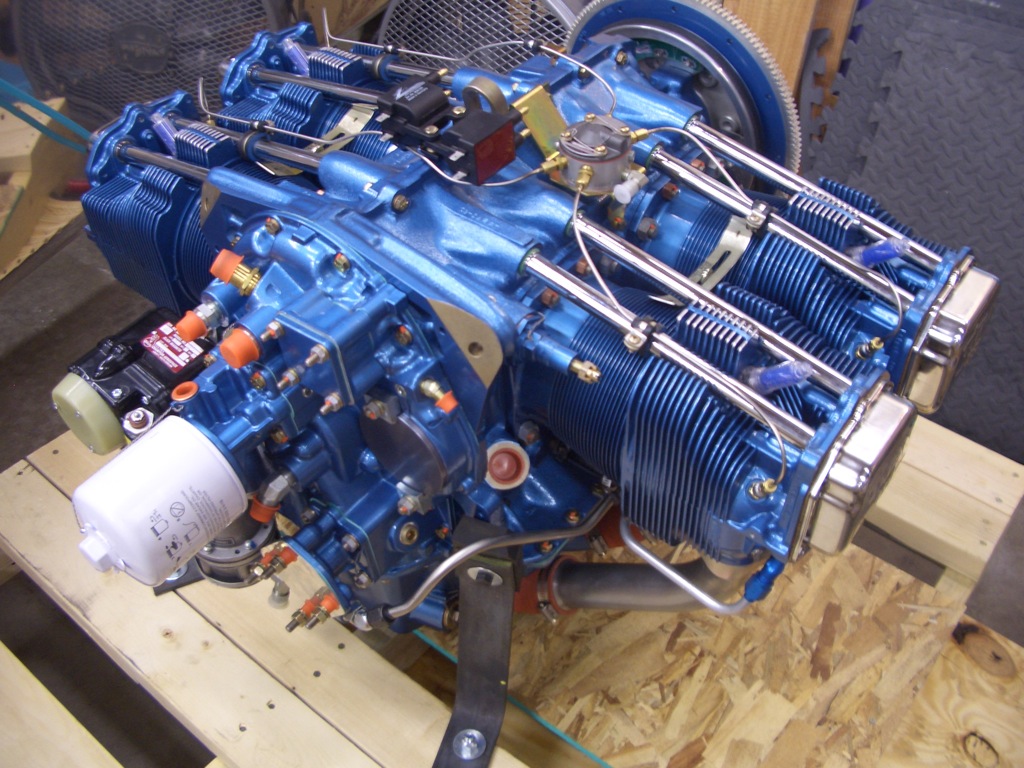

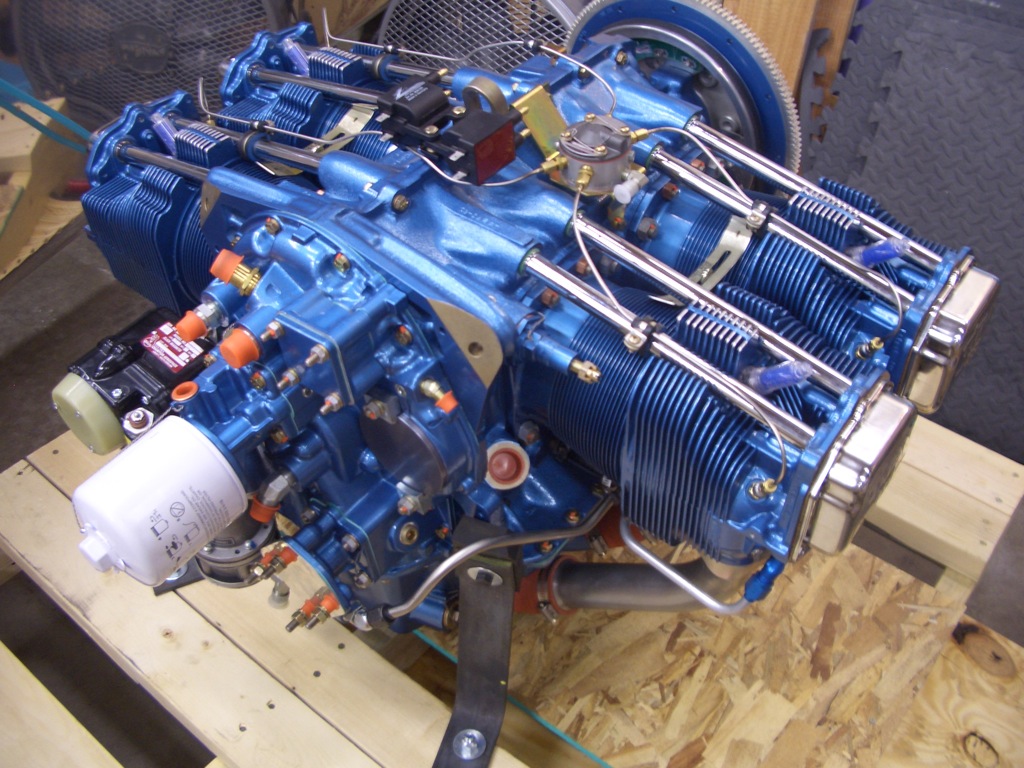

After work, I removed the crate (though the engine is still on the forklift pallet). The engine looks fantastic. It’s painted metallic blue (one of their stock colors) with chrome push rod tubes and valve covers. This is an Aero Sport Power IO-375 engine with a Superior cold air induction sump. It dyno’d at 196-198 hp on the test stand.

Aero Sport builds these from ECI components.

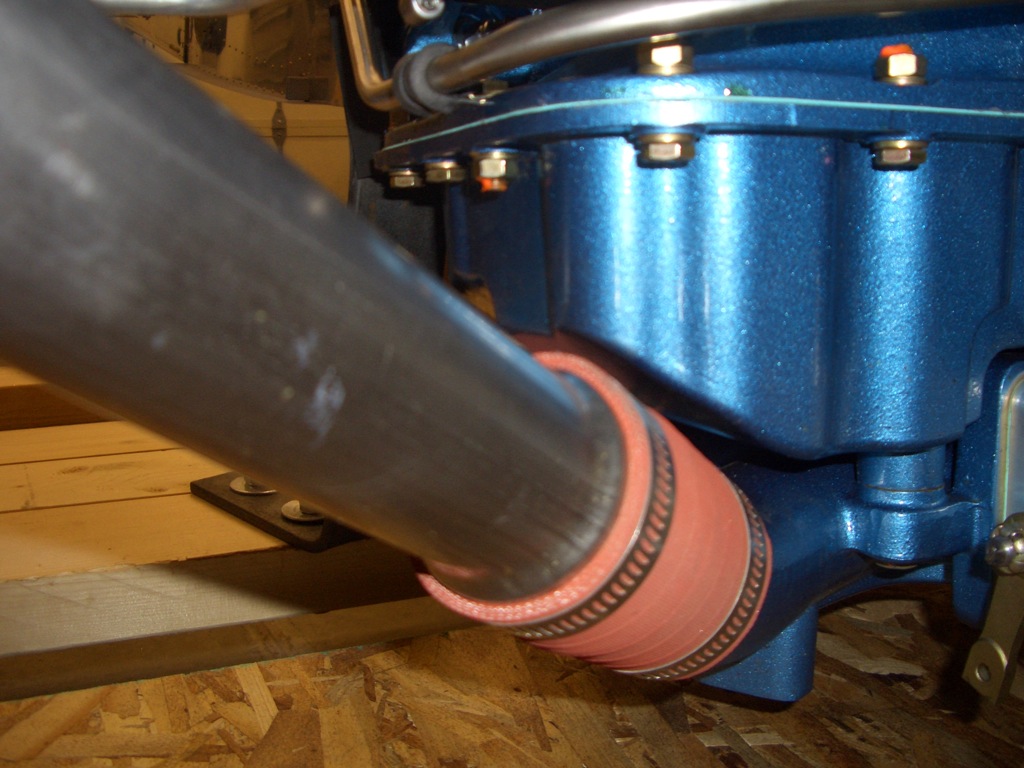

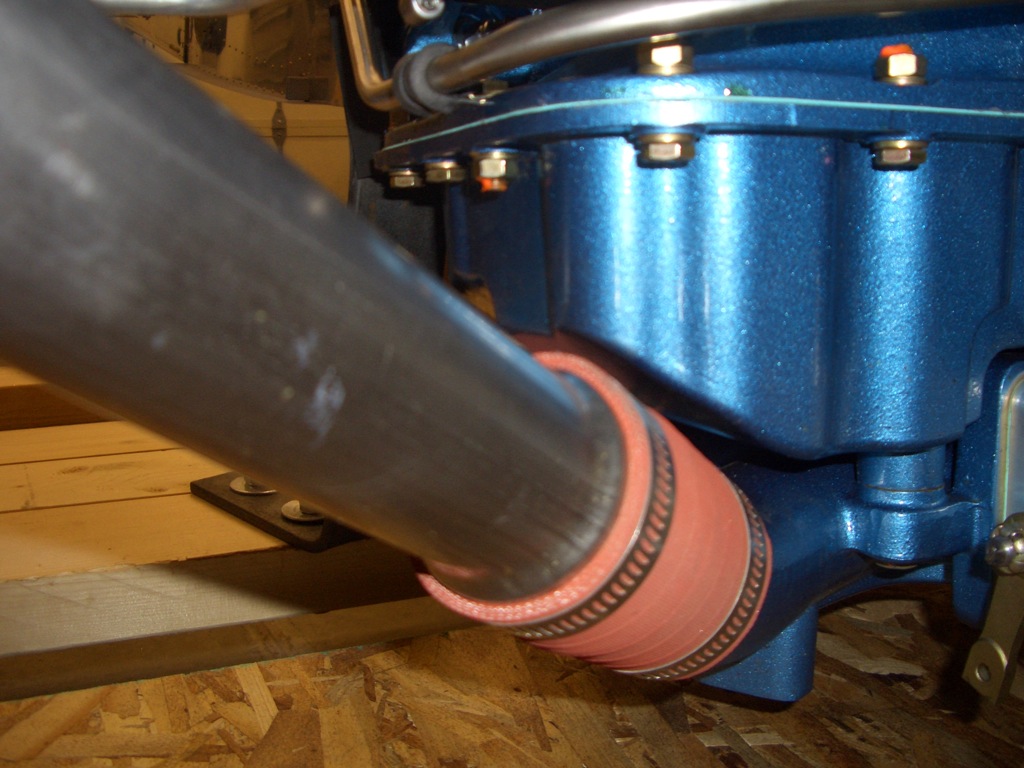

Here’s the Superior cold air sump. You can sort of see that the intake tubes don’t run through the oil pan which keeps the intake air cooler than traditional sumps. The intake tubes are stainless steel (just like the exhaust pipes will be).

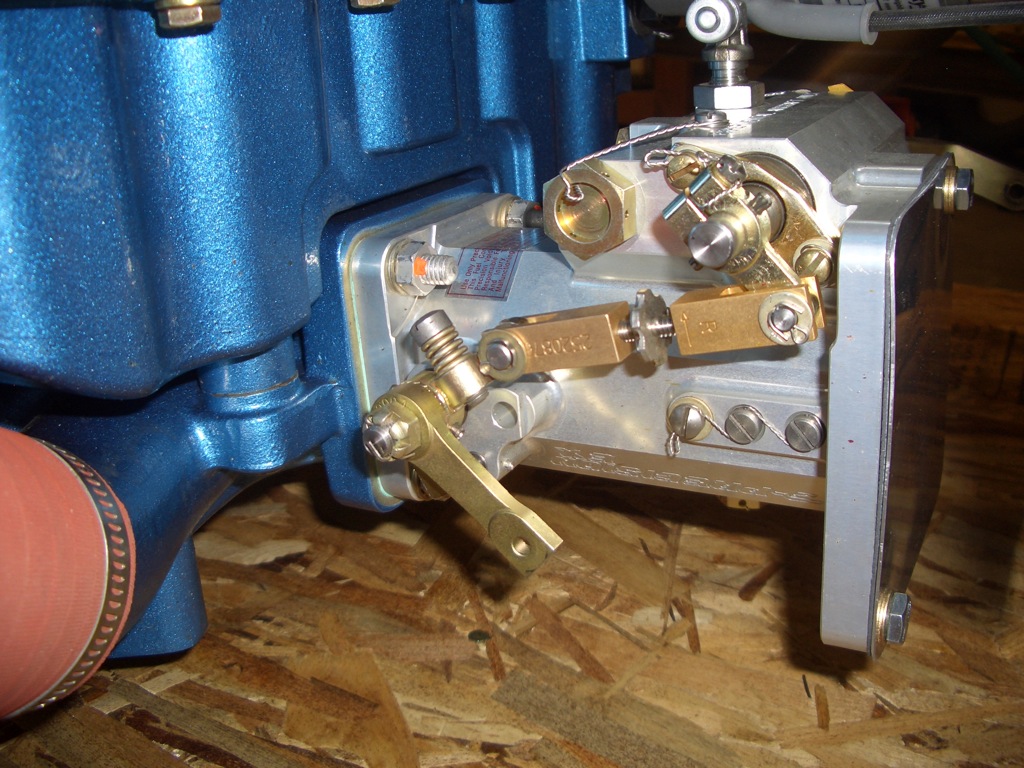

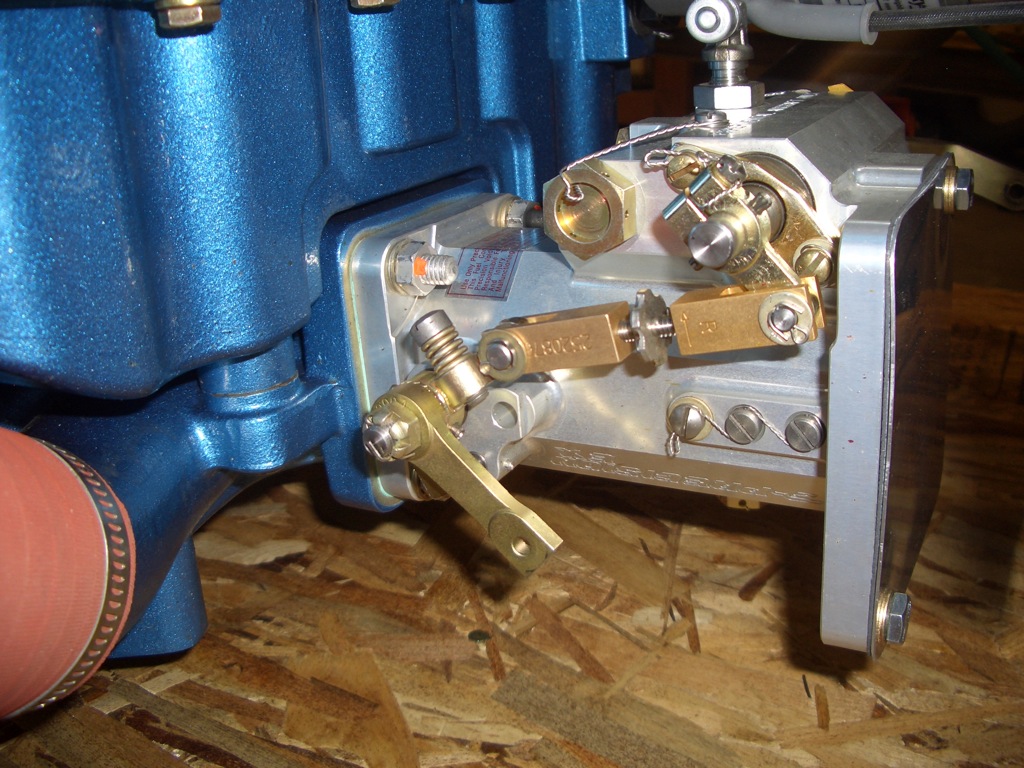

This is the Silver Hawk EX fuel injection servo. Intake air will come through the opening covered by the plate on the right.

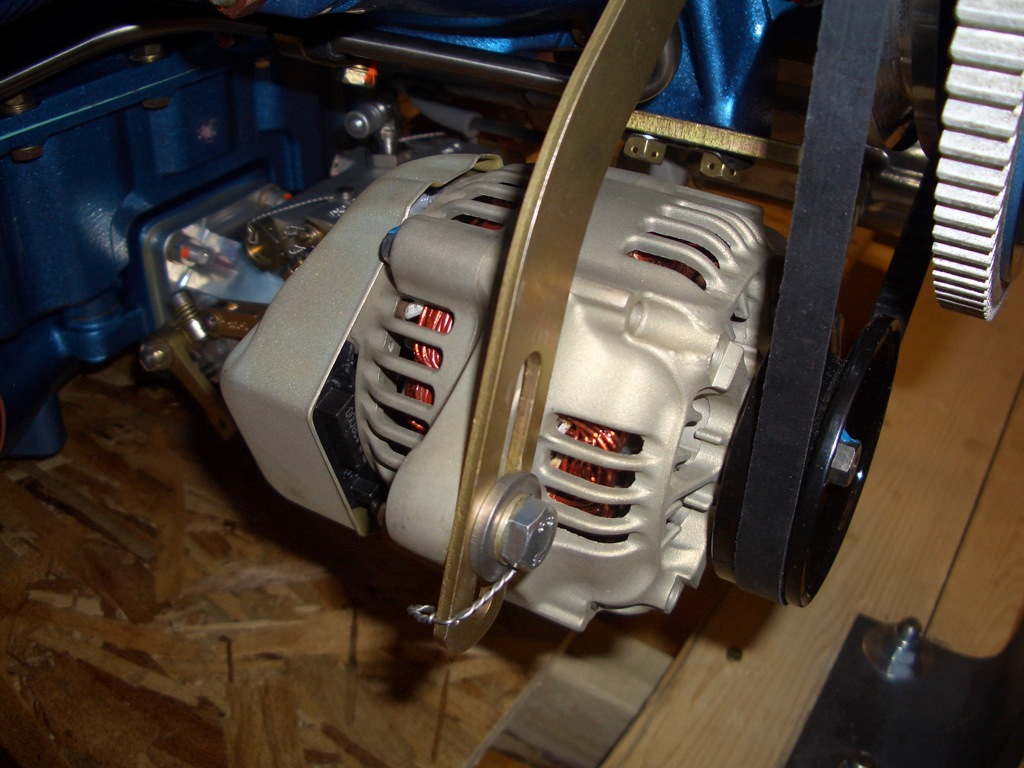

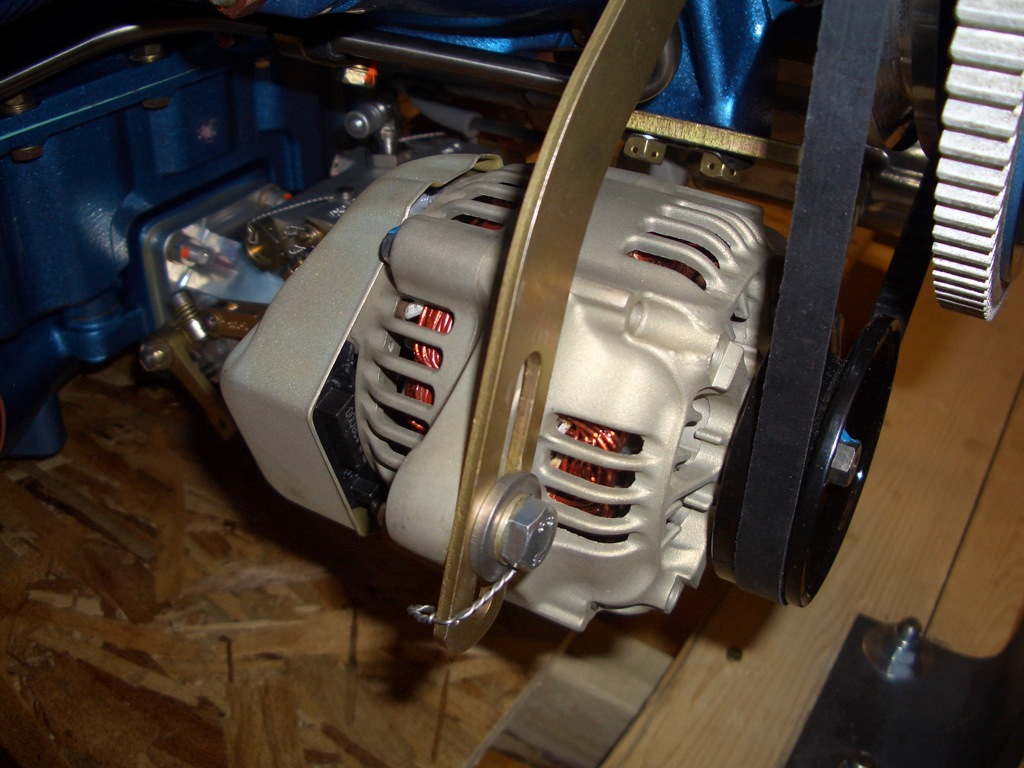

I also ordered a B&C Products 40 amp alternator that was preinstalled.

Traditional aircraft engine run dual magnetos for the ignition system. I’m using an electronic ignition for one set of spark plugs, but I’m using a traditional mag for the other set. This provides two independent ignition systems, one of which is not dependent on the electrical system.

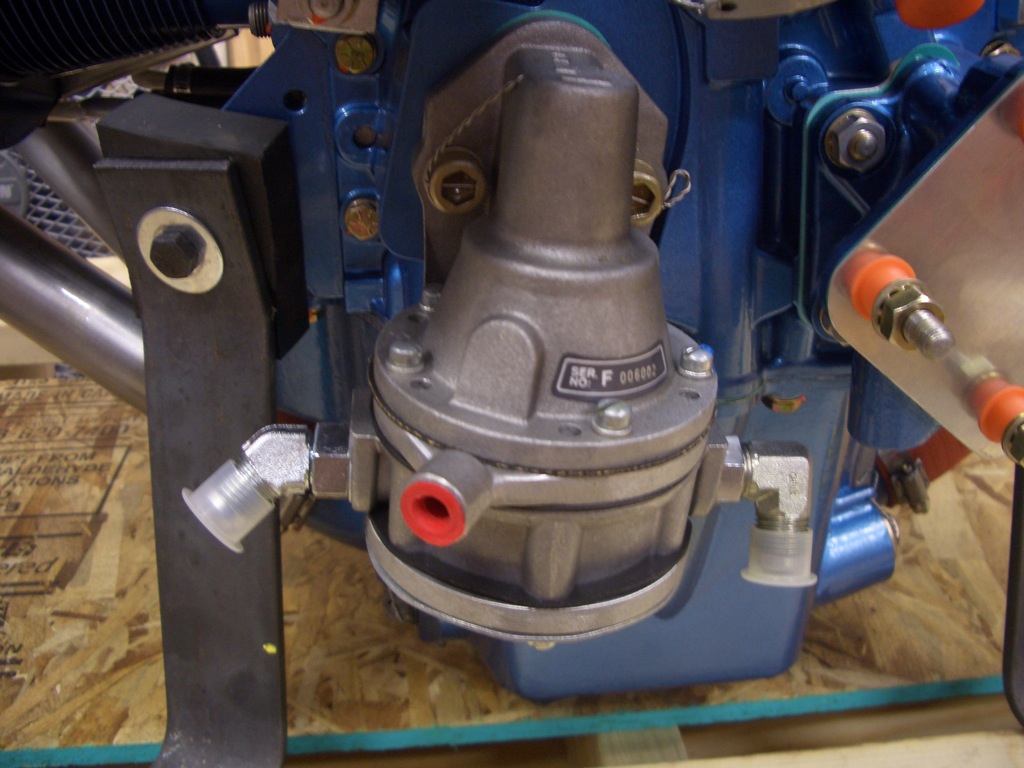

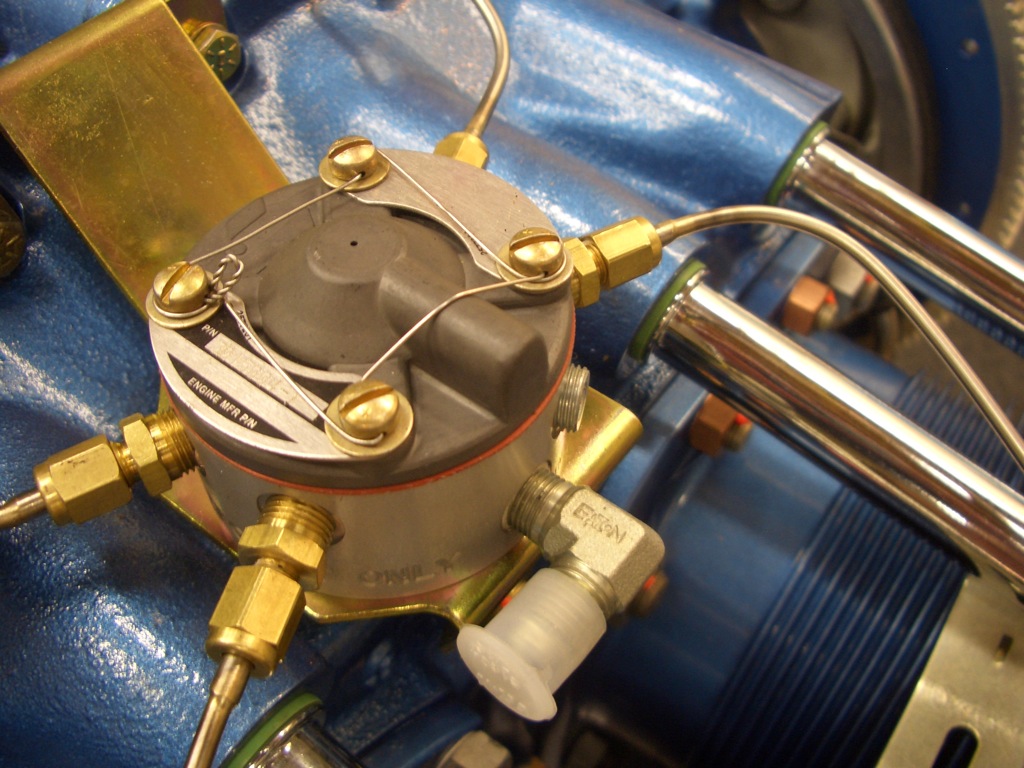

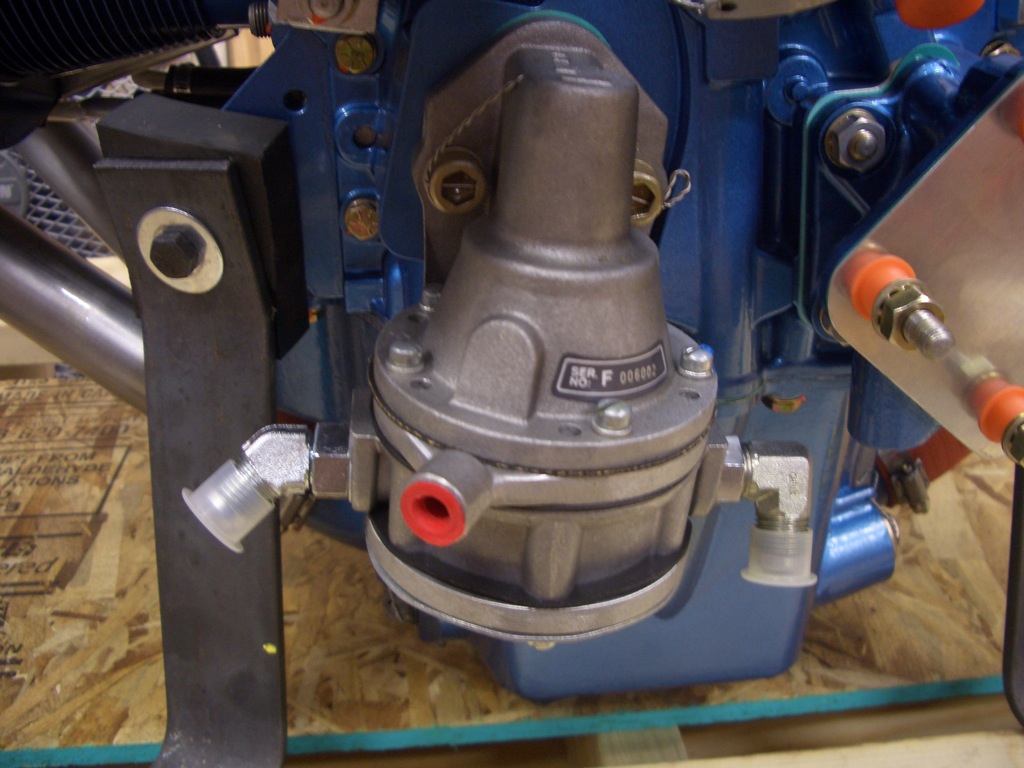

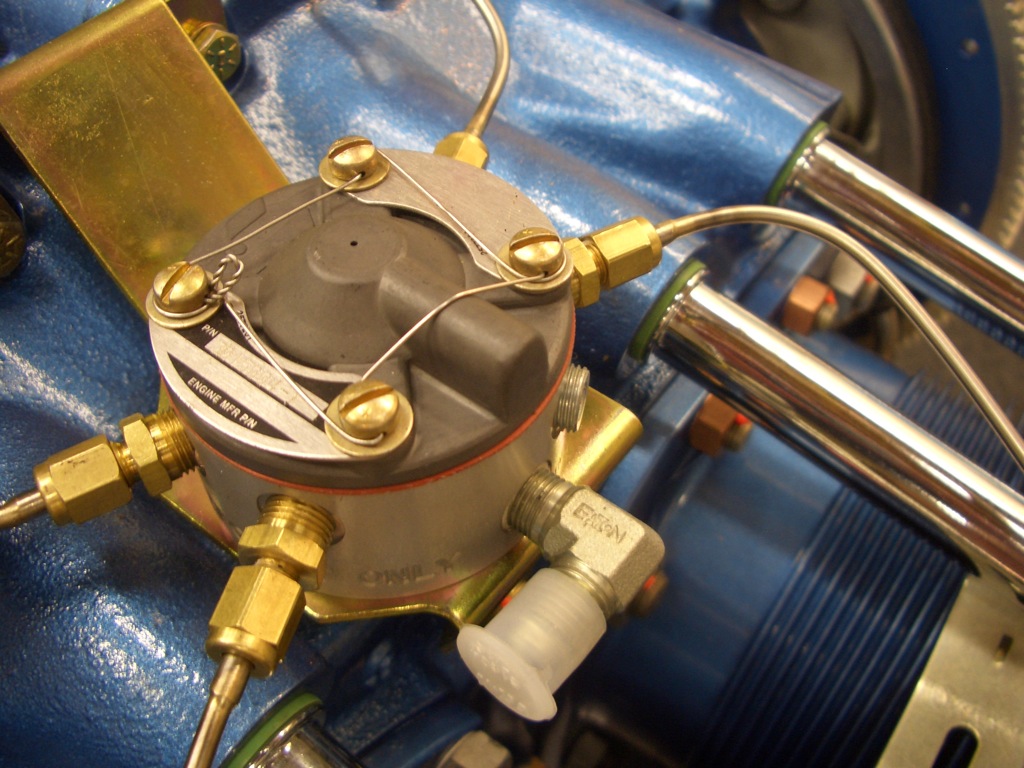

This is the mechanical fuel pump. The fuel first passes through an electric fuel pump in the cabin. This provides fuel delivery redundancy in case the mechanical pump fails.

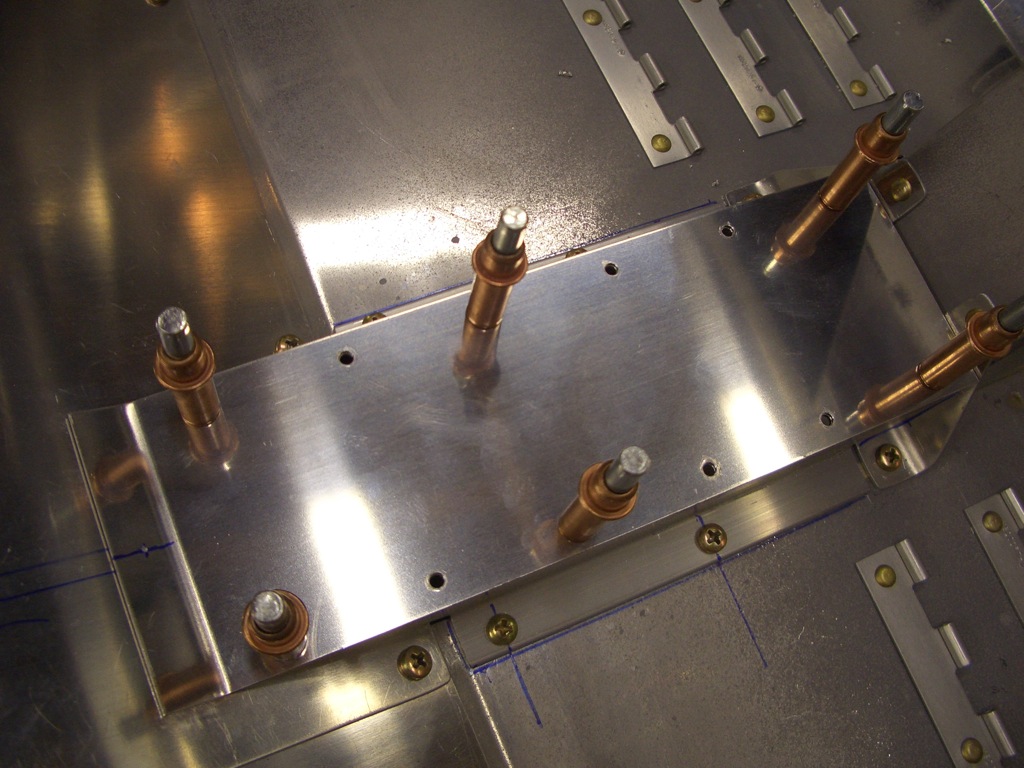

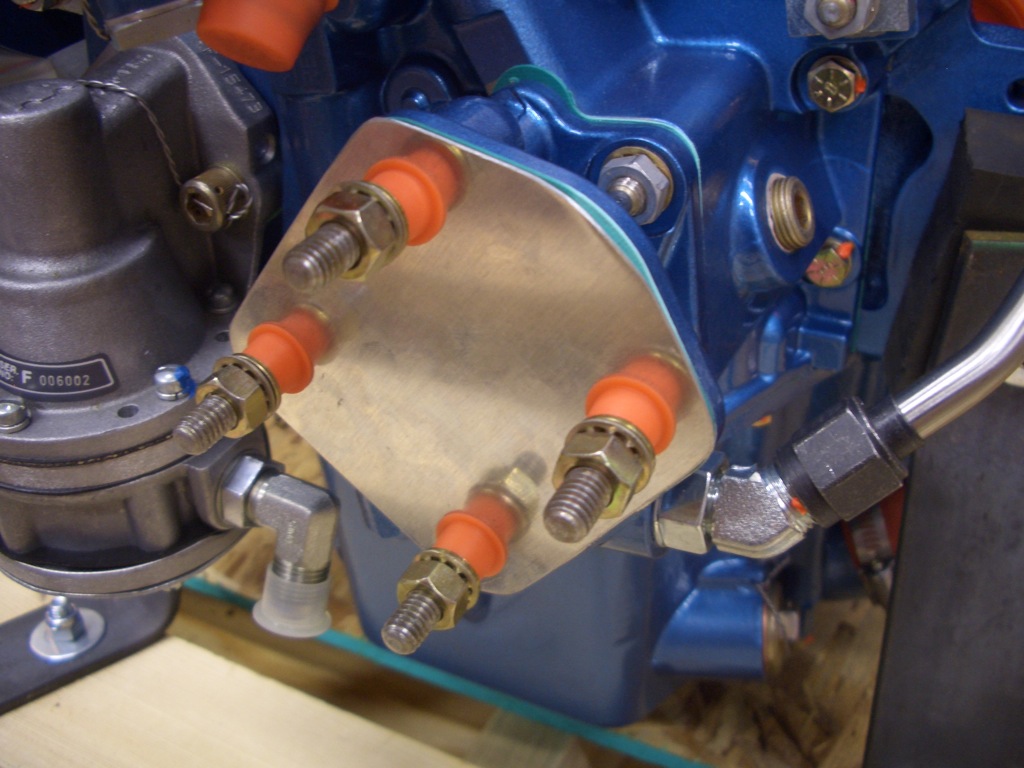

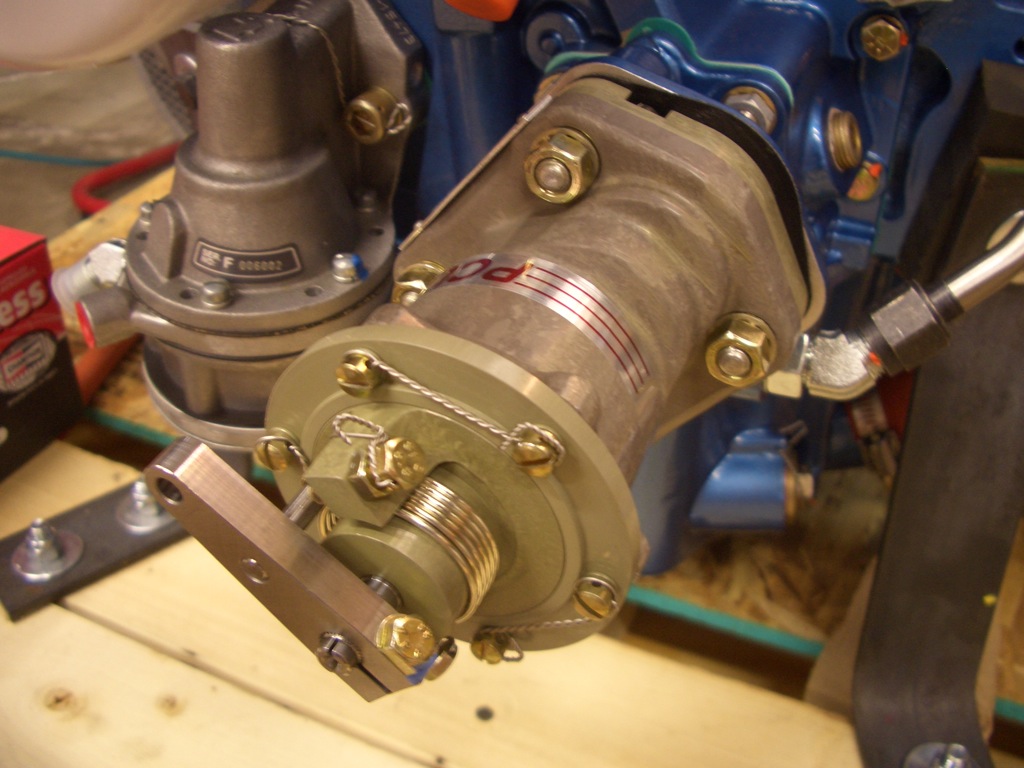

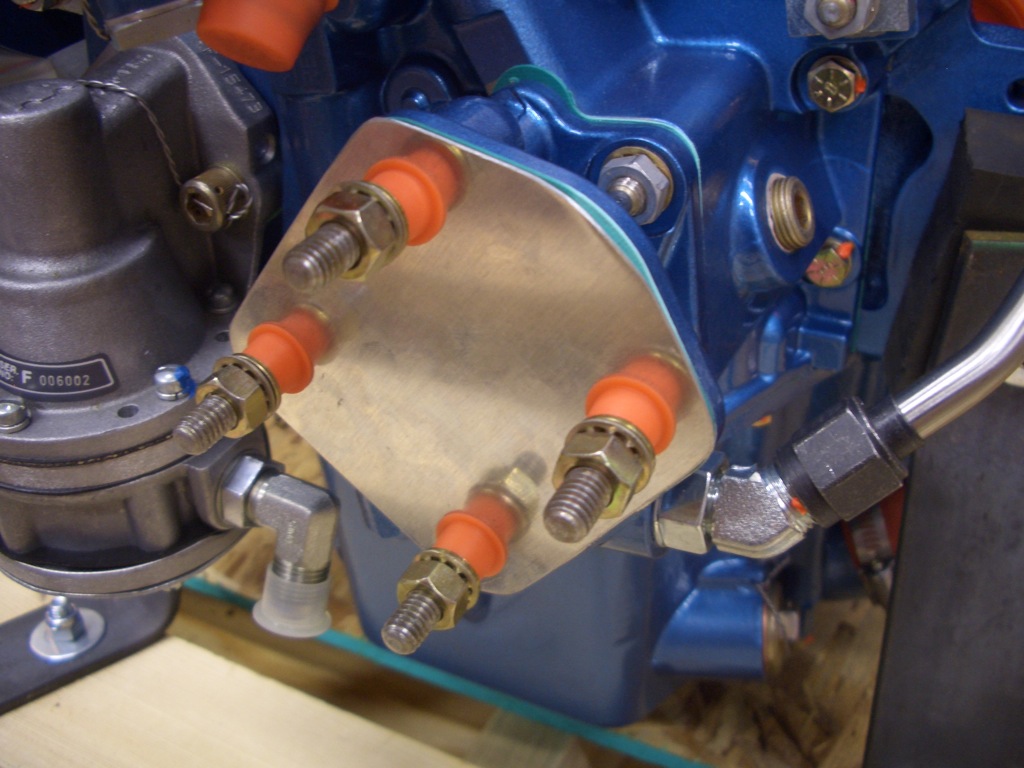

This is where the propeller governor will mount. Fortunately, the studs are already installed, since I’ve heard these can be a pain to put in.

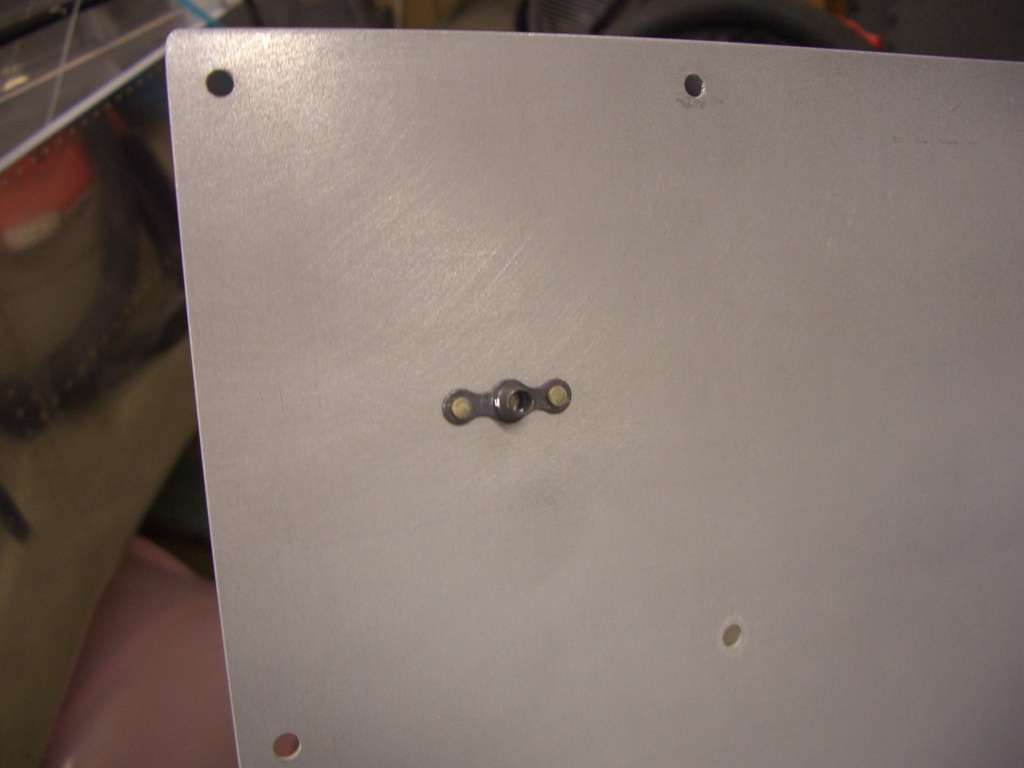

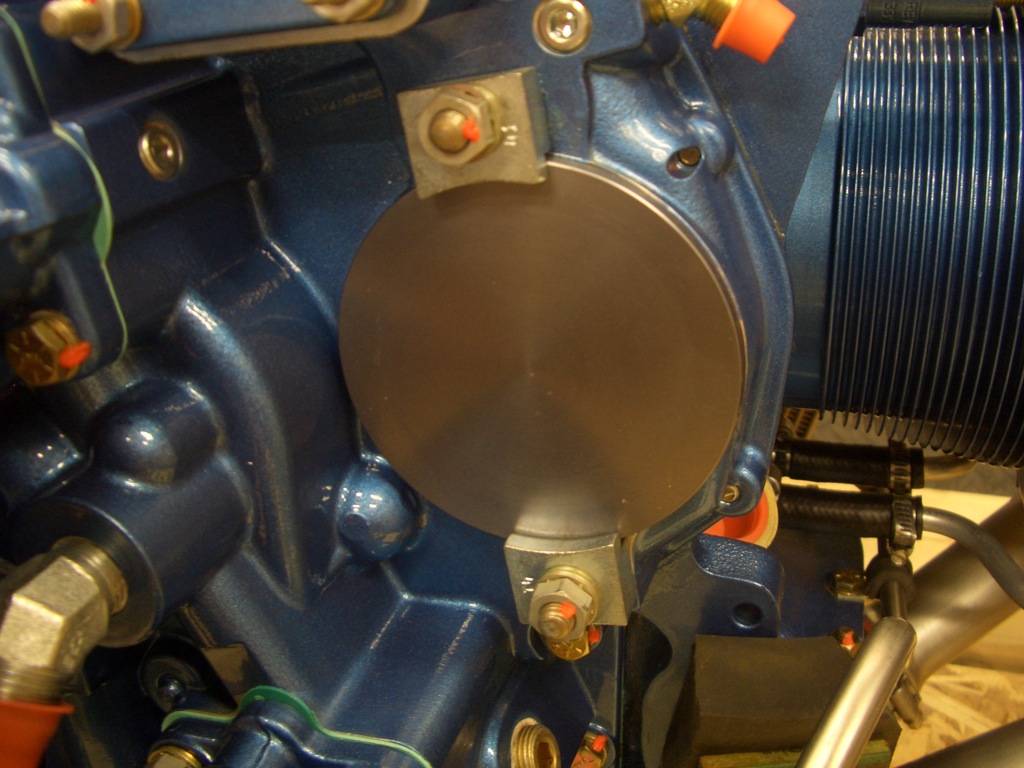

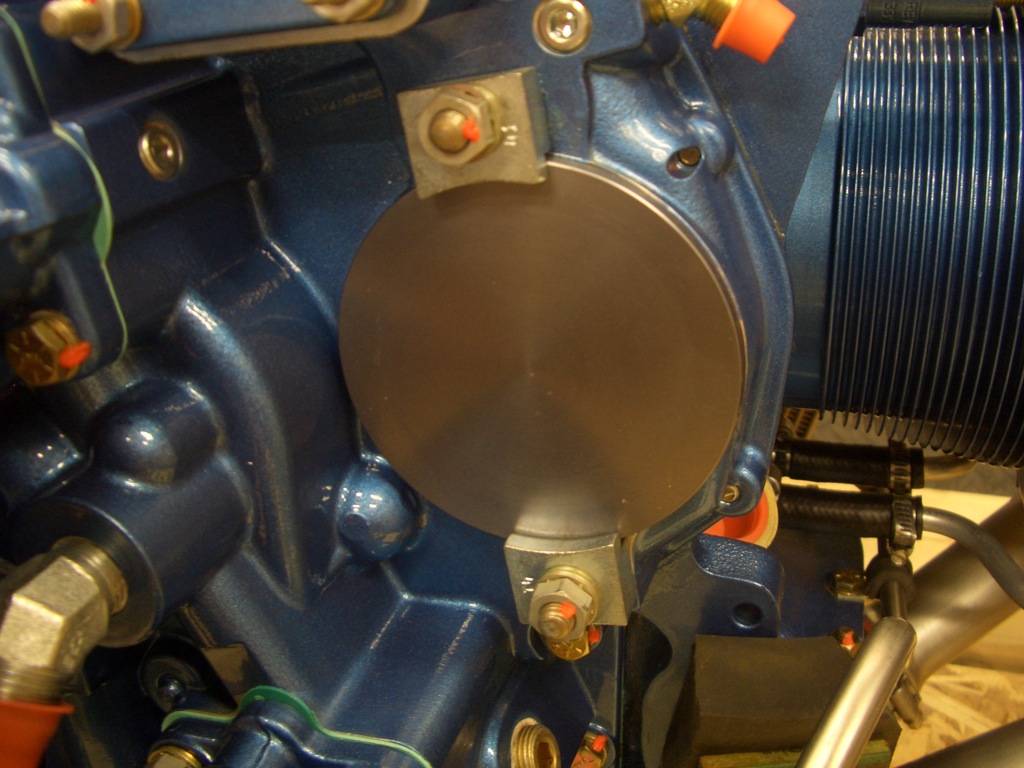

This is where the other magneto would mount if I were using dual magnetos. Since I’m using an electronic ignition with a direct crank sensor, this is unused. I may install a B&C Products SD-8 standby alternator here at some point.

The oil filter mounts on the back of the engine.

Here is the fuel distribution spider mounted to the top of the engine. There are stainless steel lines from here to each of the cylinders.

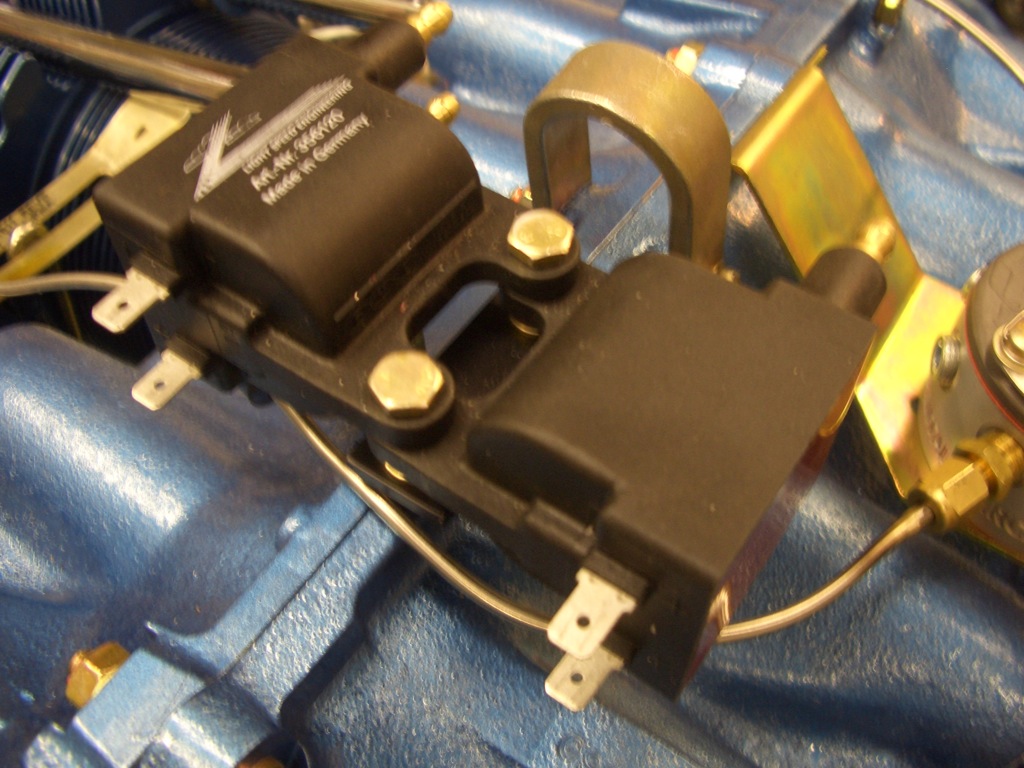

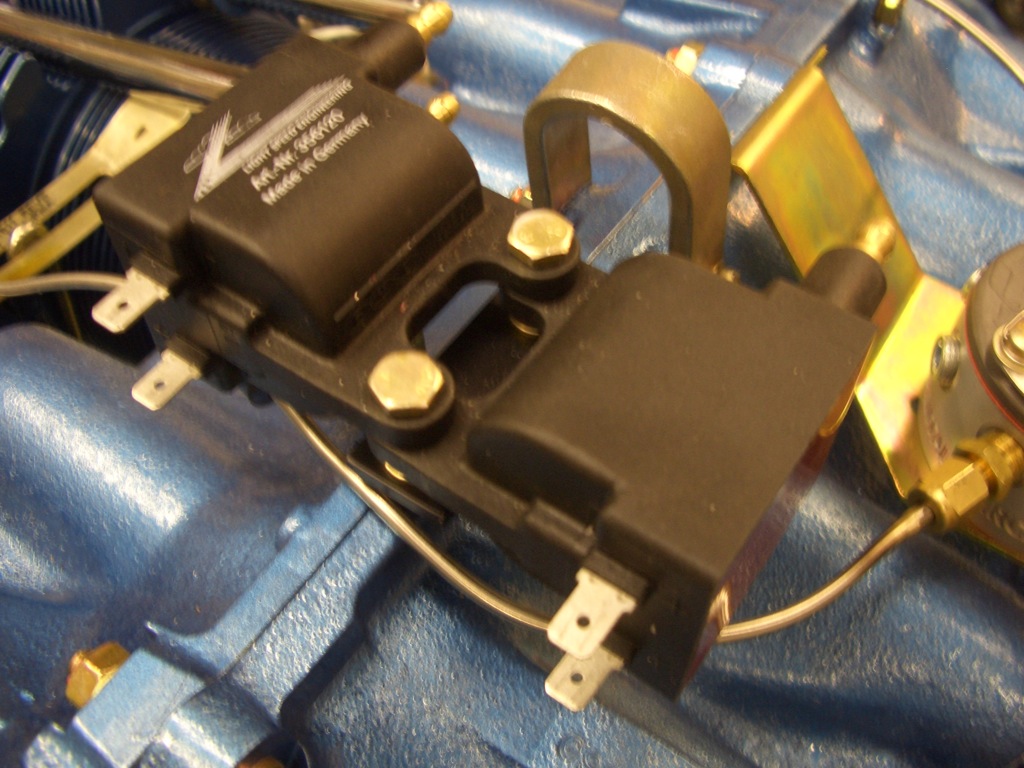

These are the ignition coils for the electronic ignition. These will fire the top spark plugs while the magneto will fire the bottom plugs.

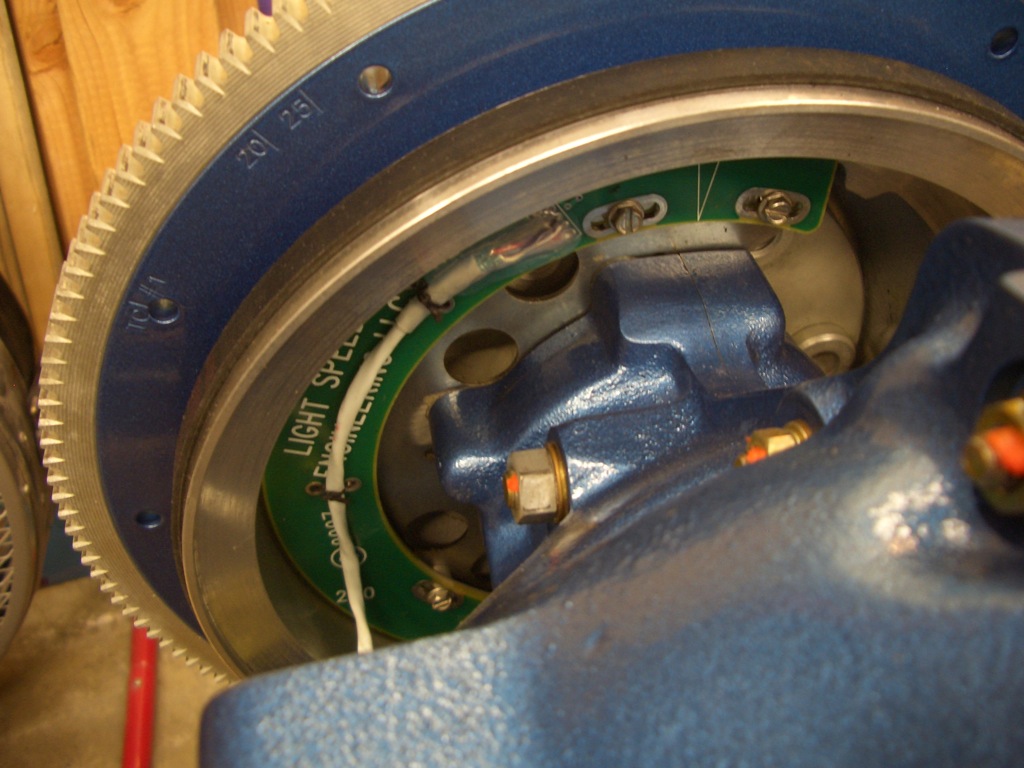

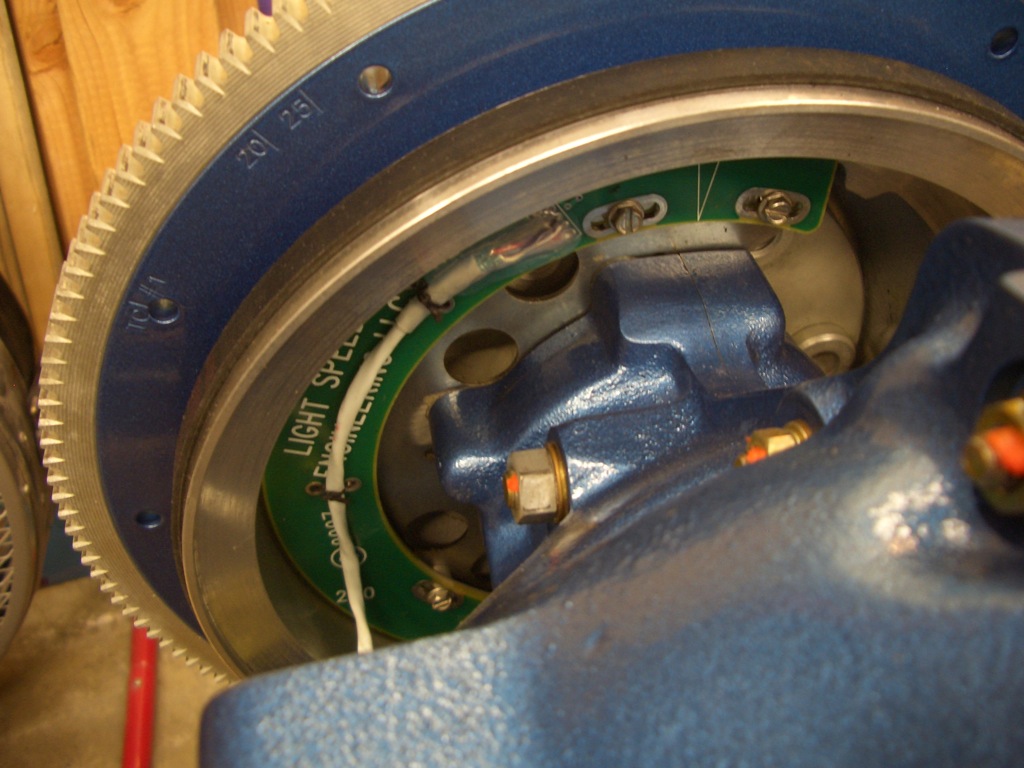

The electronic ignition detects the crank position using this crank sensor mounted inside the flywheel. There are tiny magnets installed into the flywheel that pass by sensors on this circuit board.

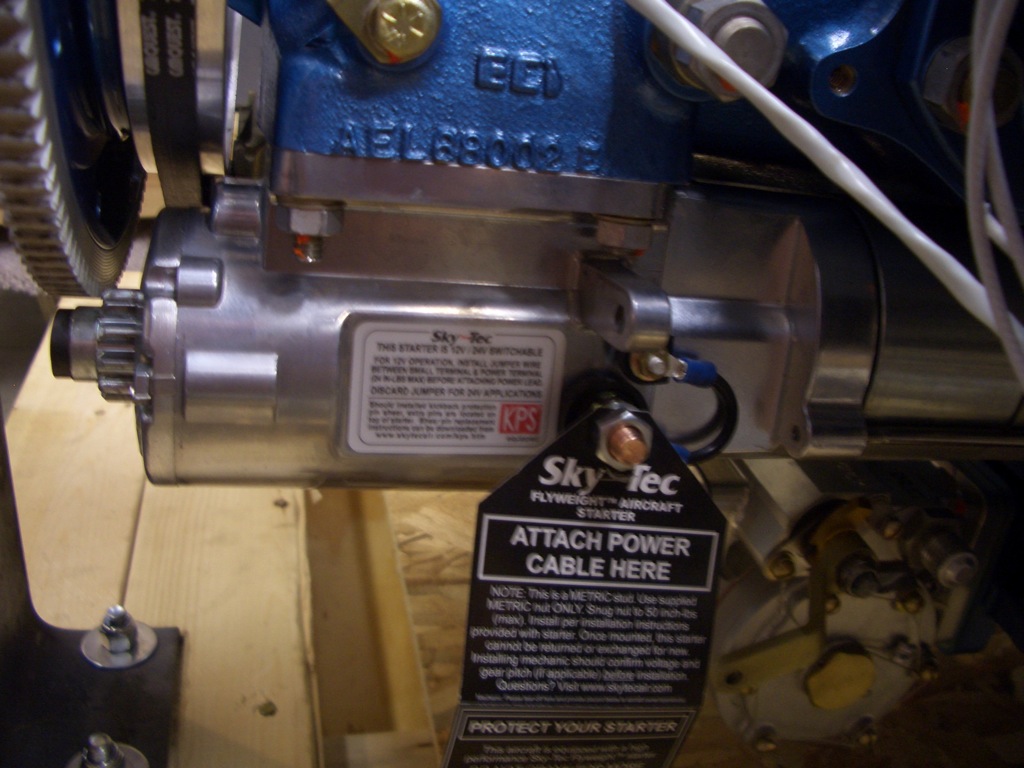

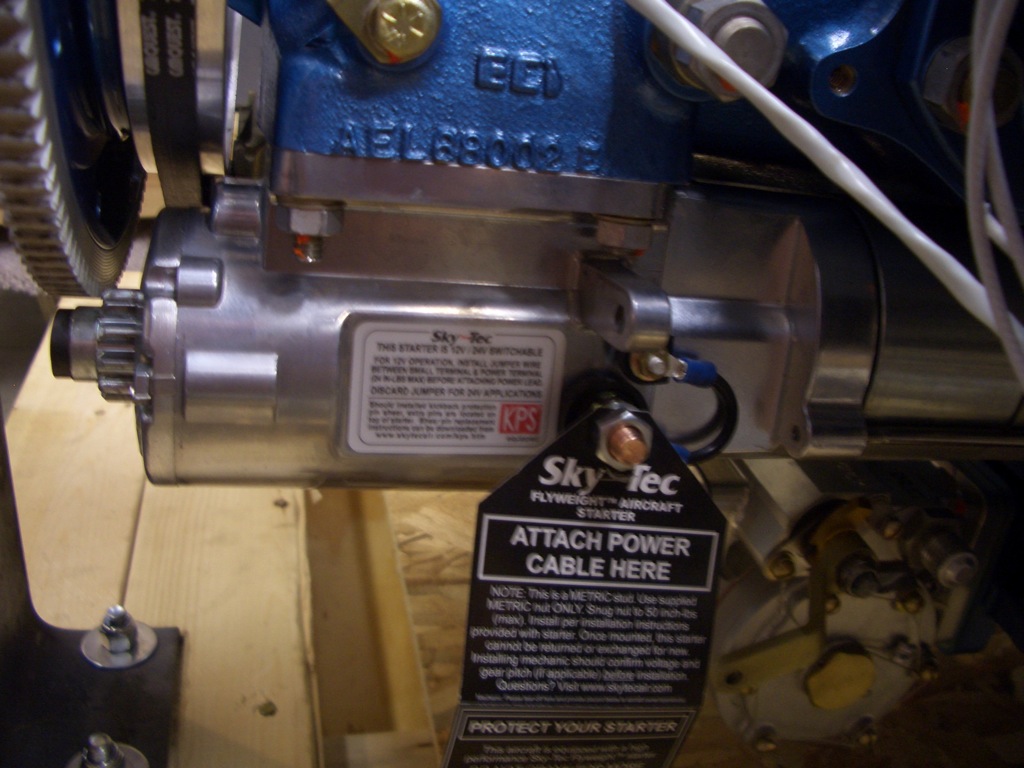

Aero Sport engines come with a Sky Tec Light Weight Inline starter. Early versions of Sky Tec starters suffered from quality problems, but the company created new clean sheet designs that are very high quality. I haven’t heard of anyone having issues with any of the newer model Sky Tec starters.

The B&C alternator requires an external voltage regulator. This has a built-in crowbar over voltage protection feature to nearly instantly take the alternator off-line if it starts to go over voltage.

The crate also included new aviation spark plugs for the bottom set.

There are also some fittings that presumably need to be installed somewhere.

Here are the spark plug wires for the magneto.

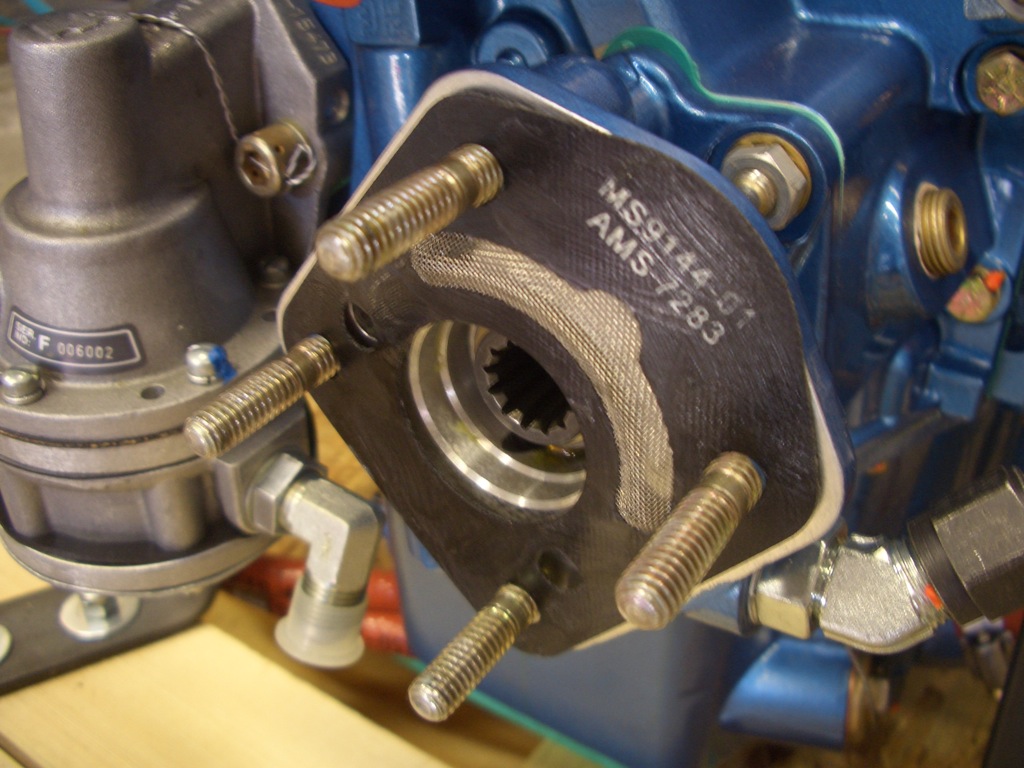

This is the propeller governor gasket with a stainless steel screen to keep debris out of the governor.

Aero Sport kindly included a small bottle of touch up paint for the inevitable scratches that I’ll get on the engine before it’s ready for flight.

The crate also included a couple of firesleeved oil hoses. I’ll need to figure out what these are for.

Aero Sport also included a Lycoming operator’s manual.

They also sent a couple of t-shirts which was super nice of them.

There is also a packet of info from Aero Sport that includes an engine log.

Here’s the brain box for the Lightspeed ignition. This will mount behind the firewall to keep it away from the heat and from engine cleaners and water.

The box from Lightspeed also includes a set of automotive plugs, adaptors, spark plug wires, etc. for hooking up the electronic ignition.