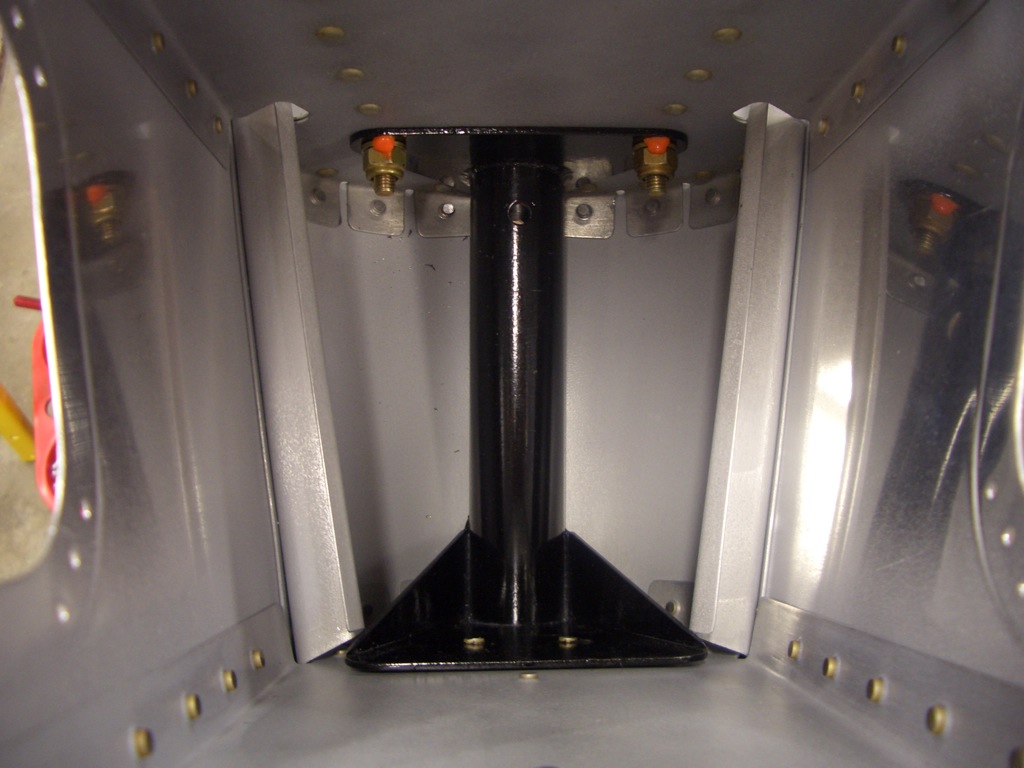

I received my Grove Aircraft master cylinders in the mail today. I decided to upgrade from the stock Matco master cylinders because people have had issues with them sticking. It appears that the issue can be addressed with external springs, but I don’t really like the way those look. Also, I heard such good things about the Grove cylinders that they seemed like the better choice. These have internal springs, so there should be no issue with them not extending fully when brake pressure is released.

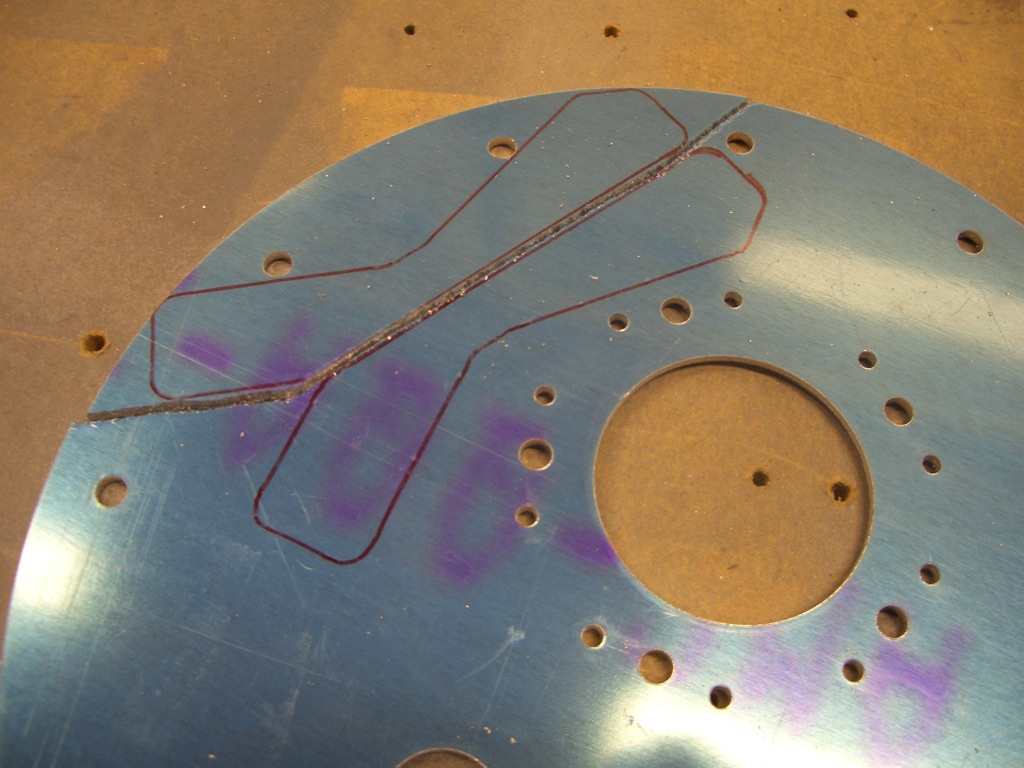

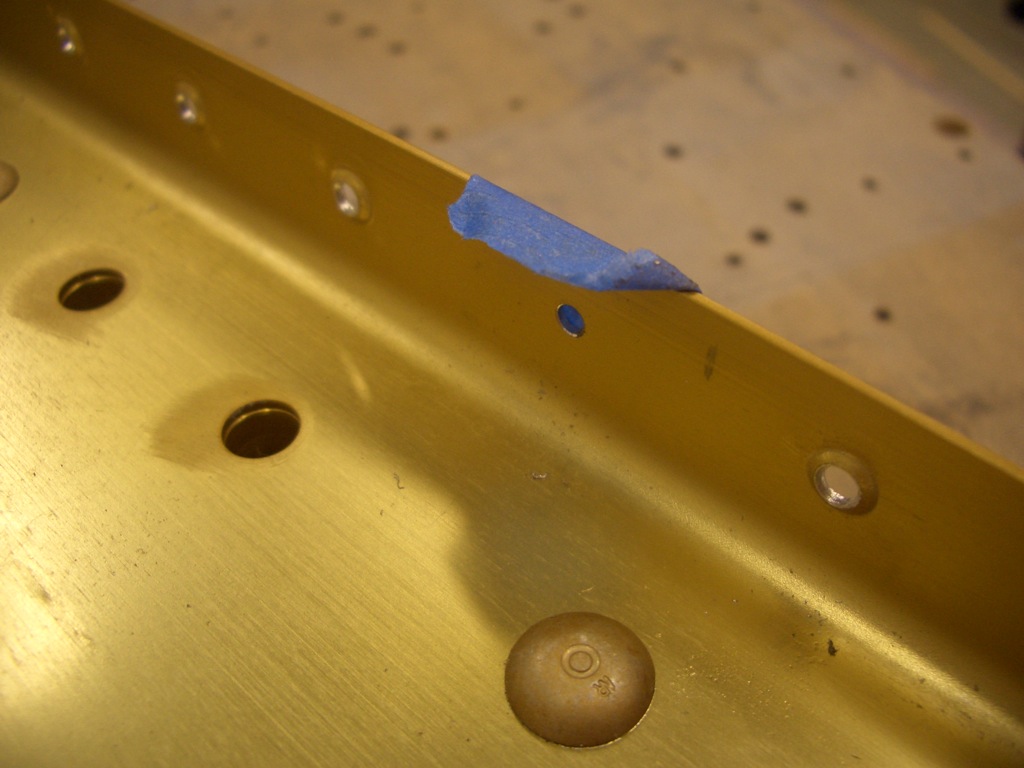

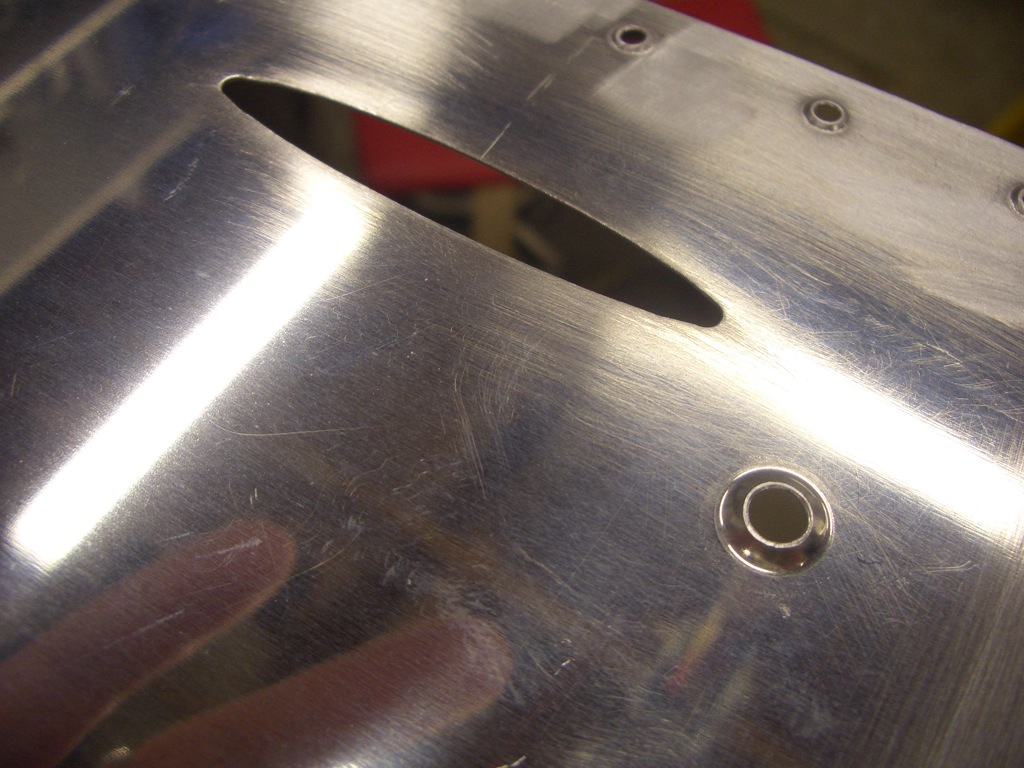

Before reassembling the tailcone, I took care of one additional task that would be tough if I waited until later. I drilled the holes next to the rudder cable exit holes out to #19 and dimpled for a #8 screw. This will be used to attach an adel clamp to hold the rudder cable guide.

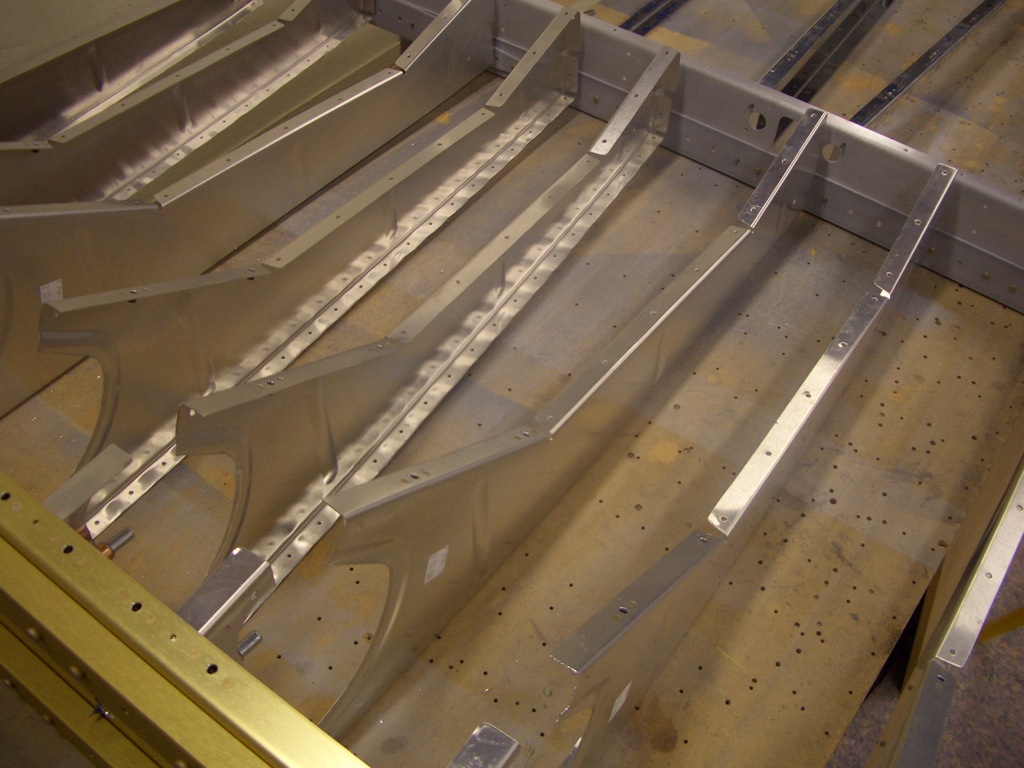

I primed all of the bulkhead and stringer seams since these got somewhat scratched up during the drilling.

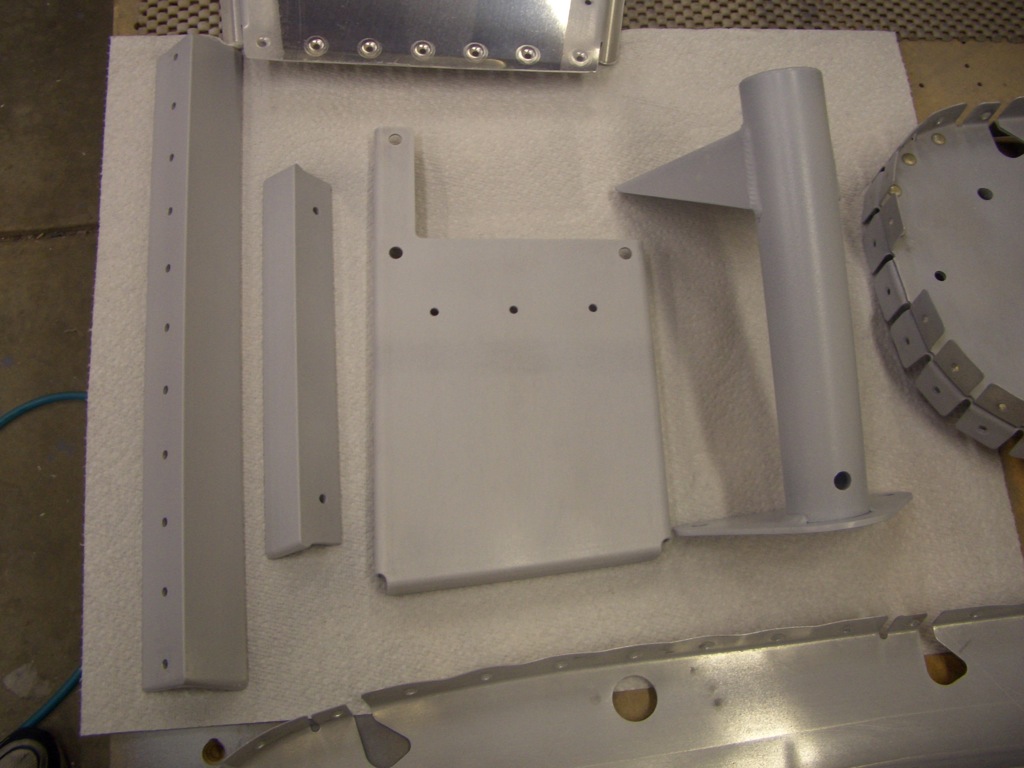

I also primed the rest of the components for the tailcone.

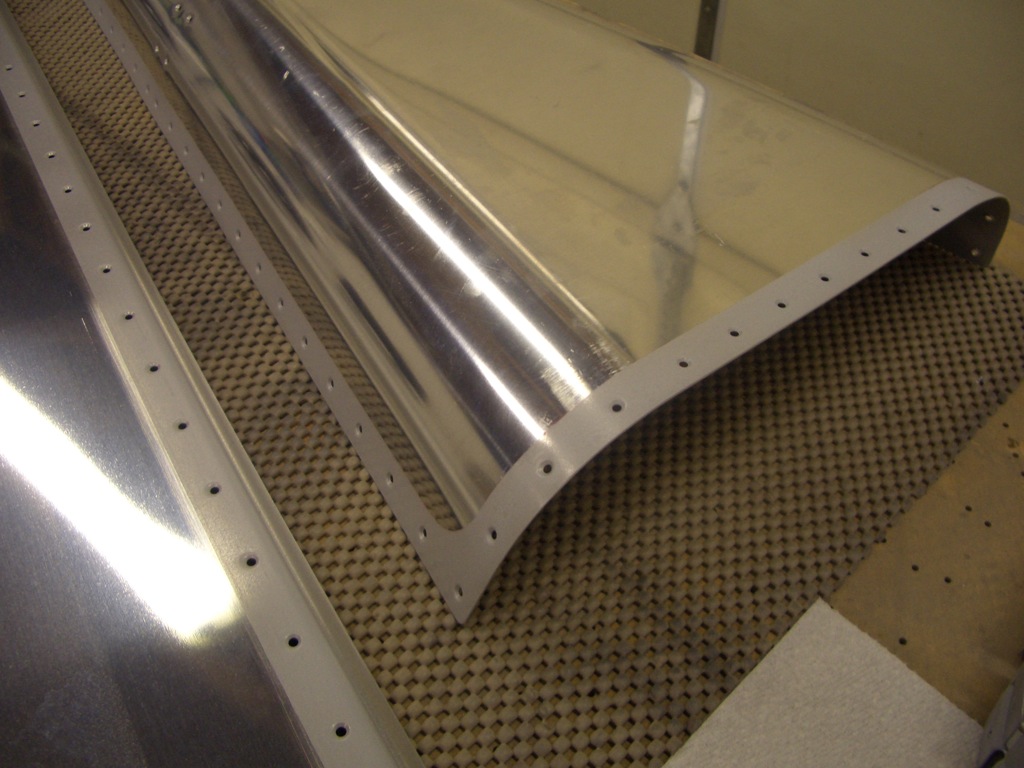

Since these are the lowest seams in the fuselage, I wanted to prime the overlap areas in case any water gets trapped there. I also primed the entire inside of the tail skin.

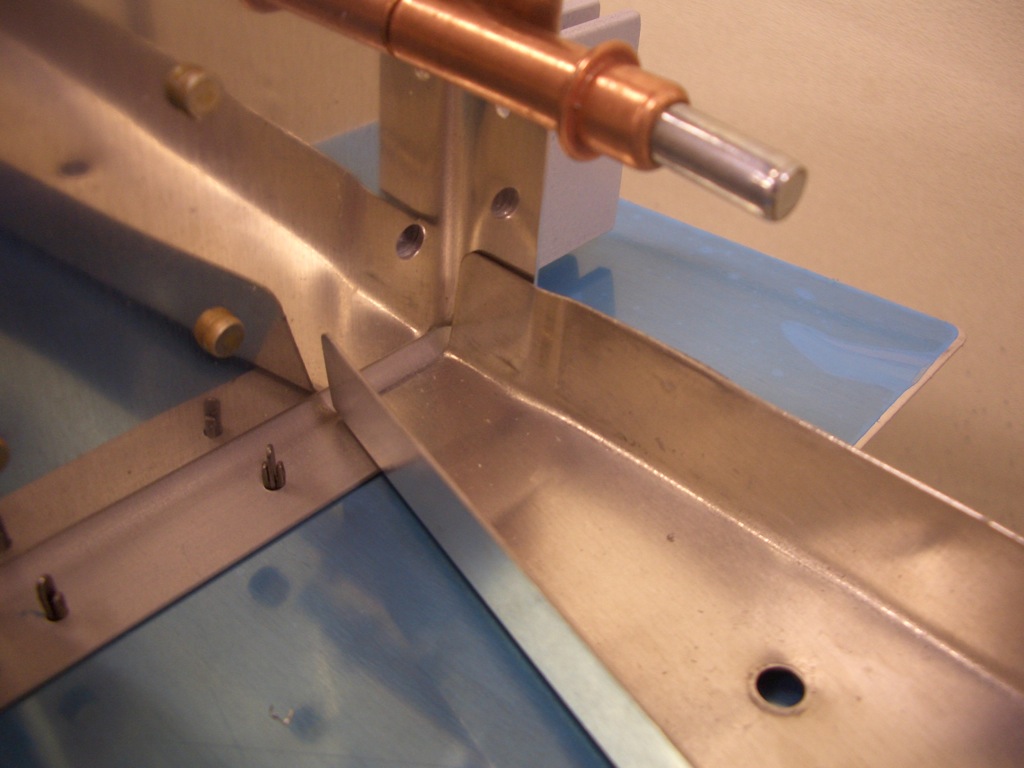

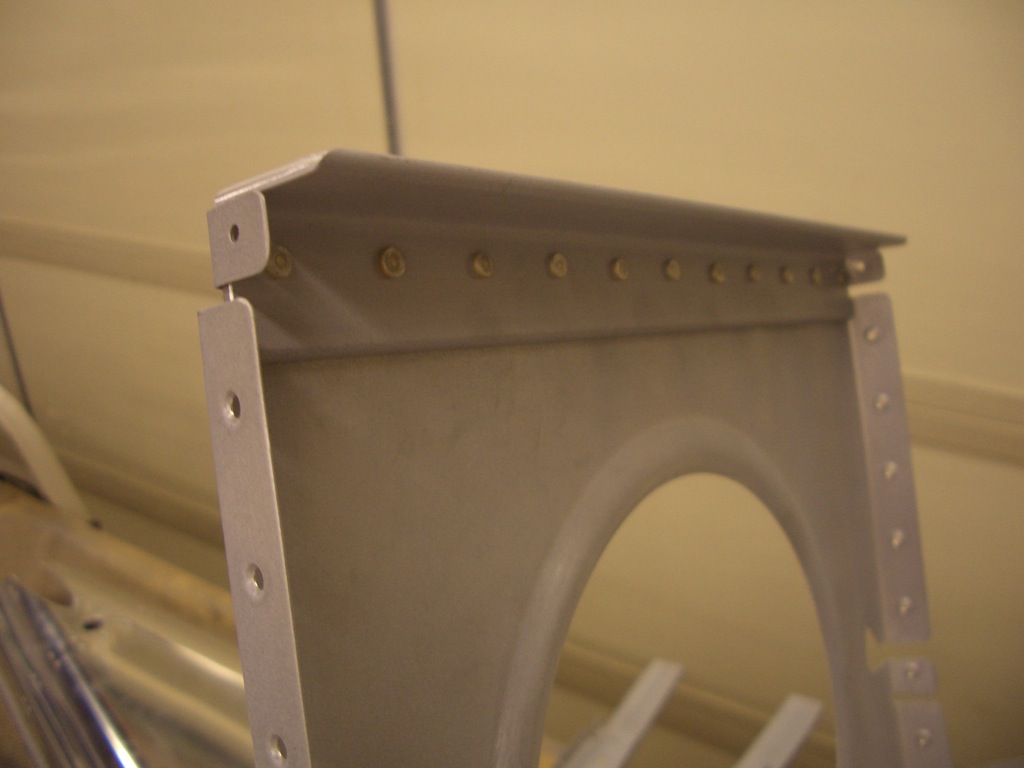

The top angle can now be riveted to the F-710 bulkhead.

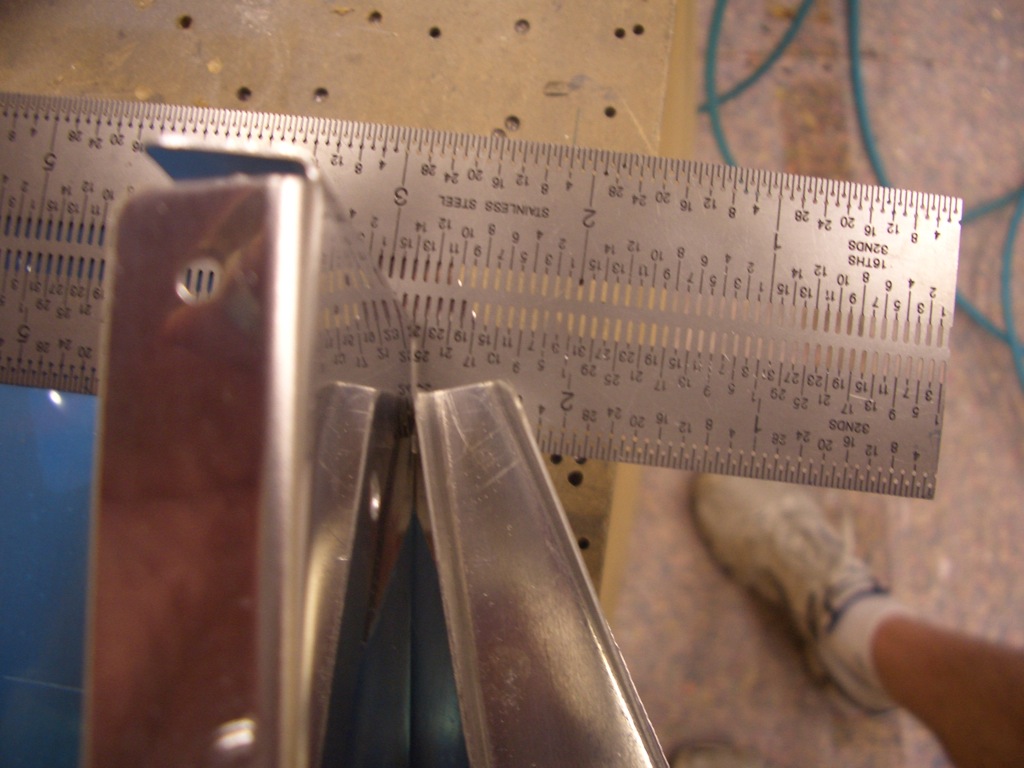

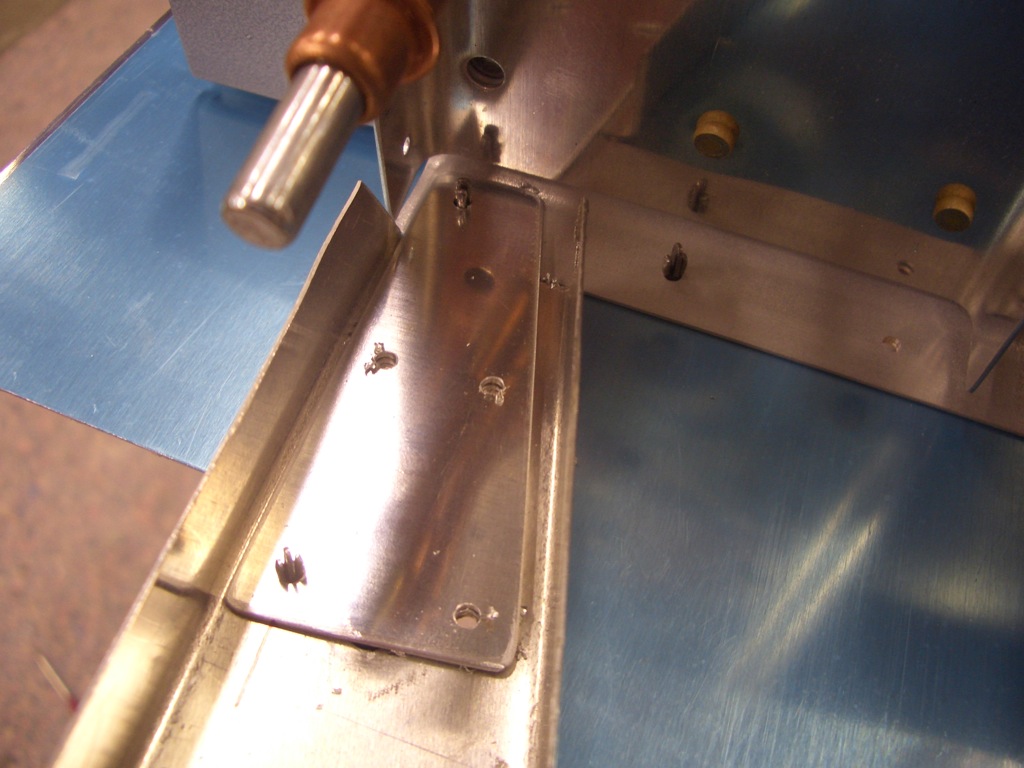

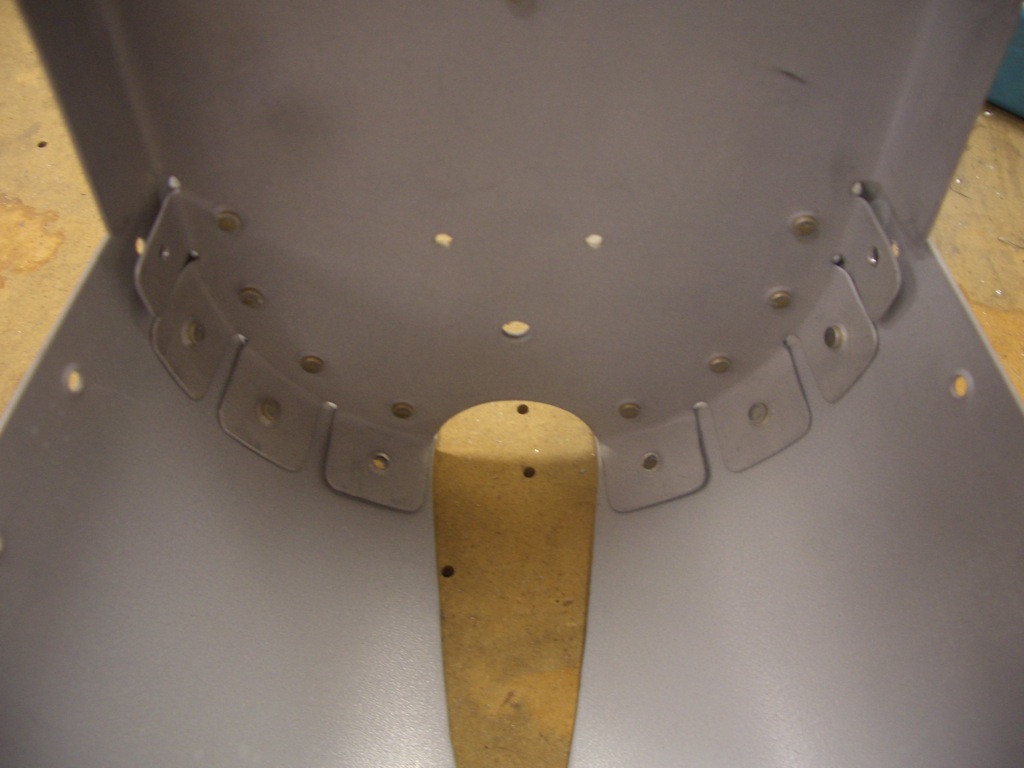

And F-712 can be riveted to the tail skin. These rivets were a little tricky to set, and I ended up drilling out two of them and replacing them. Since these flanges have an acute angle to the web, using the 4″ no-hole yoke with its thin nose made these easier.

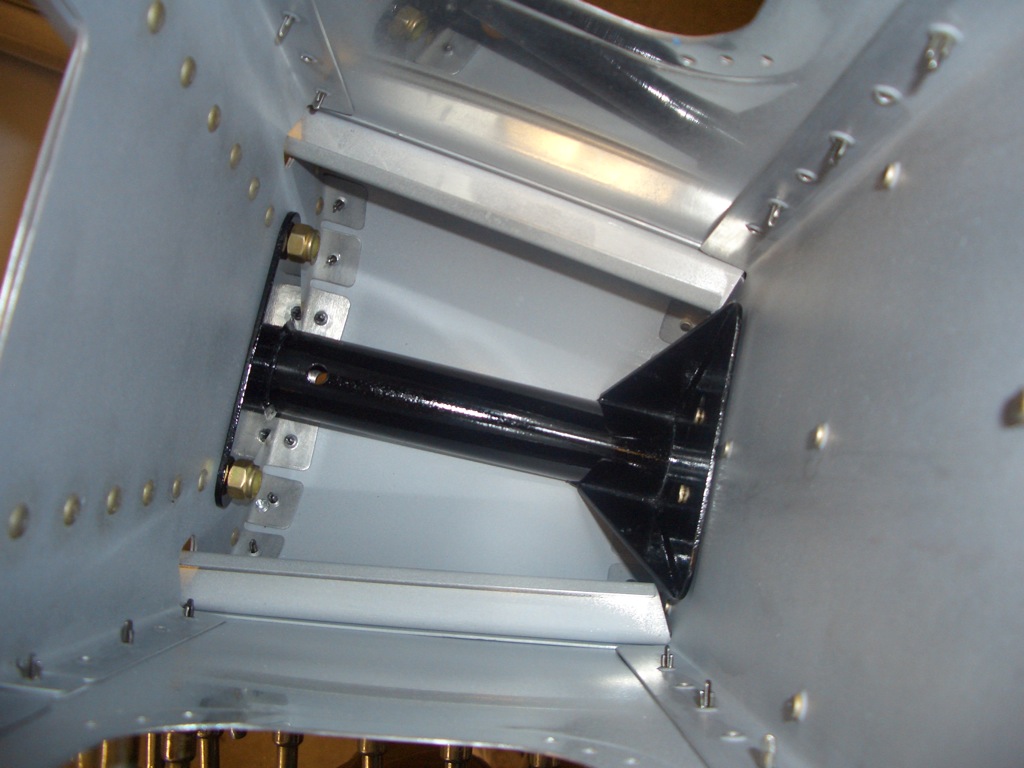

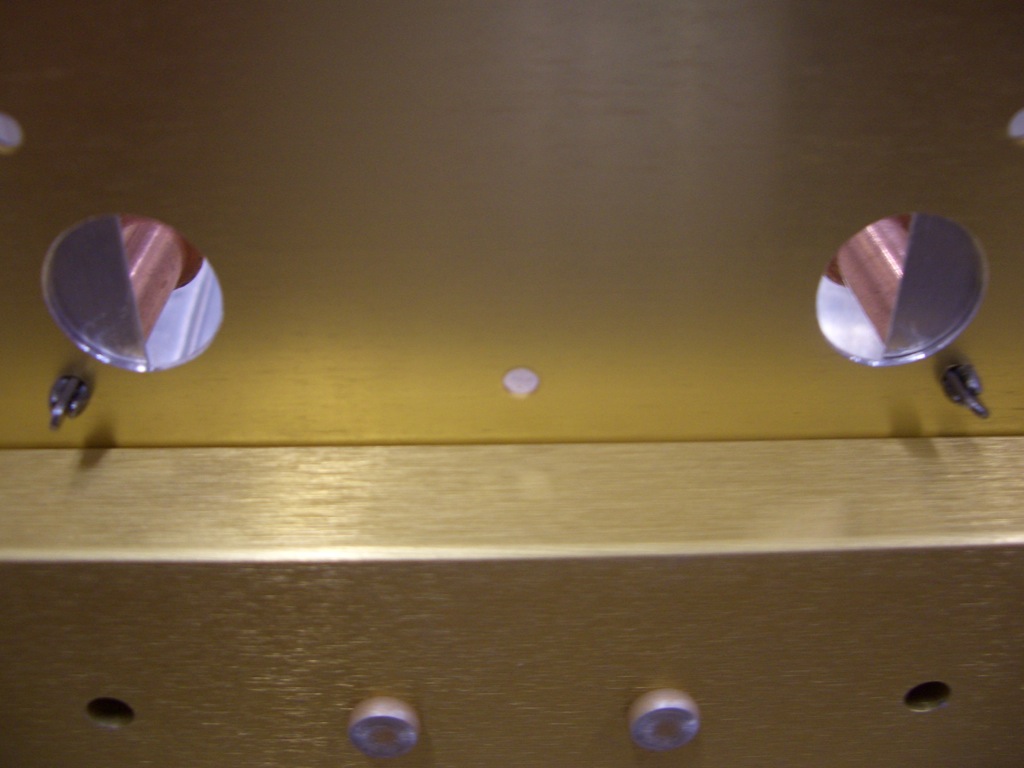

Here are the rivets on the other side of F-712 (remember that it is a double bulkhead). The only ones that couldn’t be squeezed were the two lowest ones just next to the mouse hole. It’s too late to fire up the rivet gun tonight, so this will have to wait. I’m not ready to rivet the tail spring mount in place yet anyway since I want to give it a top coat of paint and the primer needs to dry for 24 hours.

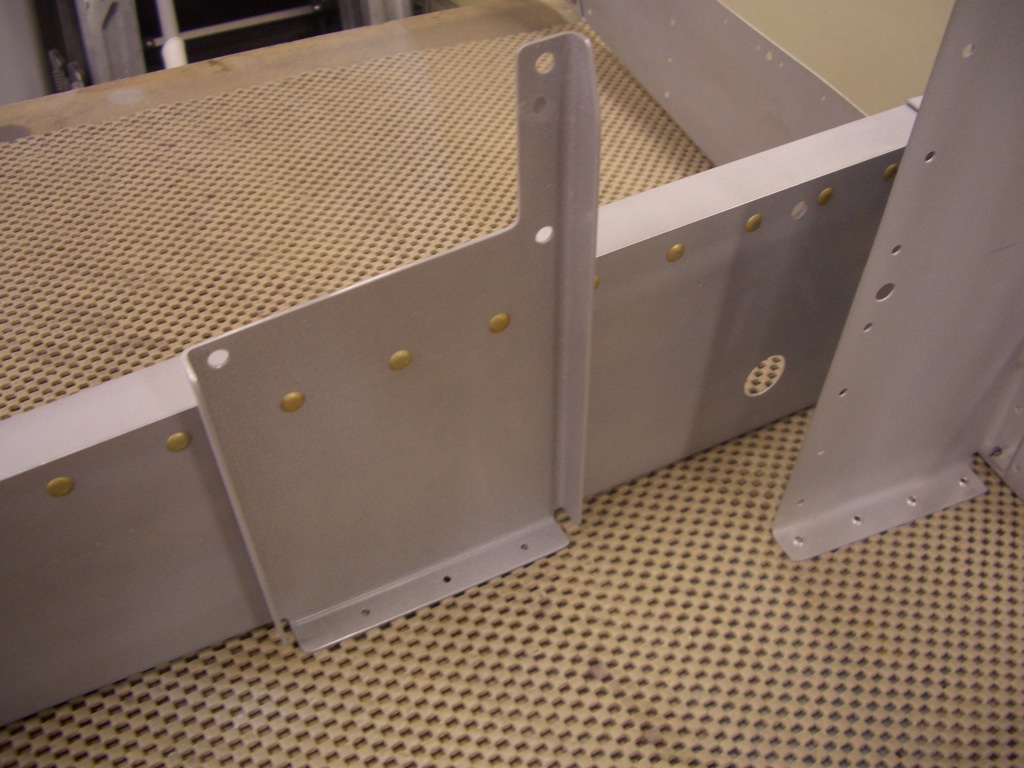

I went ahead and riveted the autopilot pitch servo mounting bracket to the rib using some AN470AD4-5 rivets. Apparently, I had forgotten to dimple the holes in the bottom of this rib, so I did that now as well.

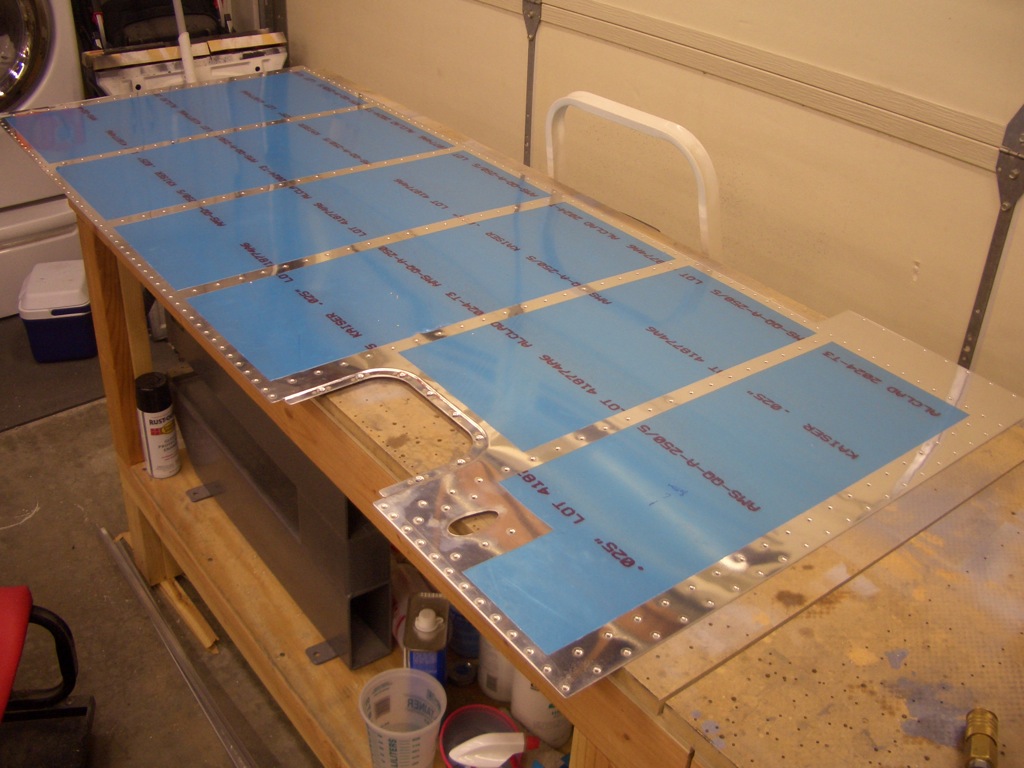

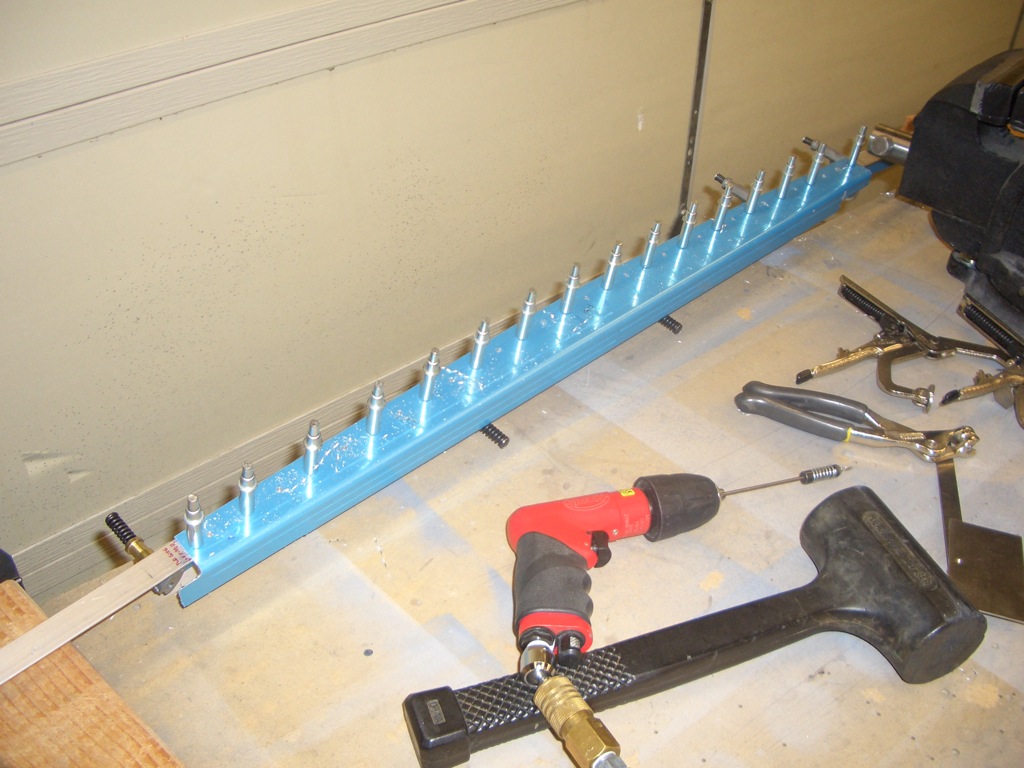

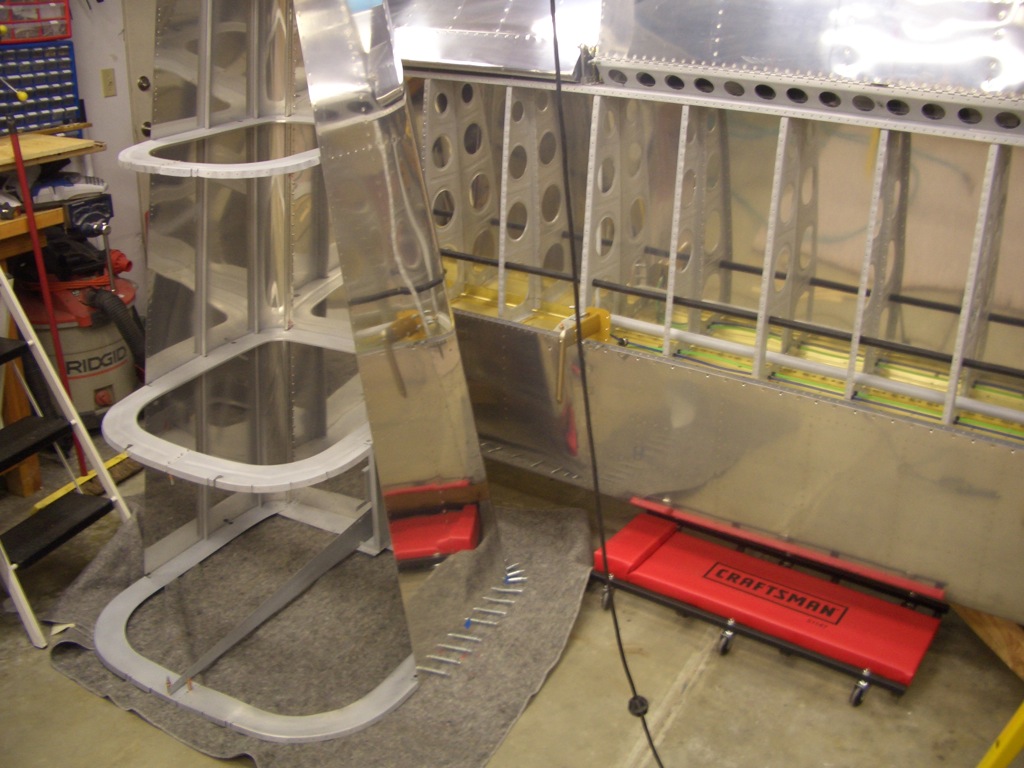

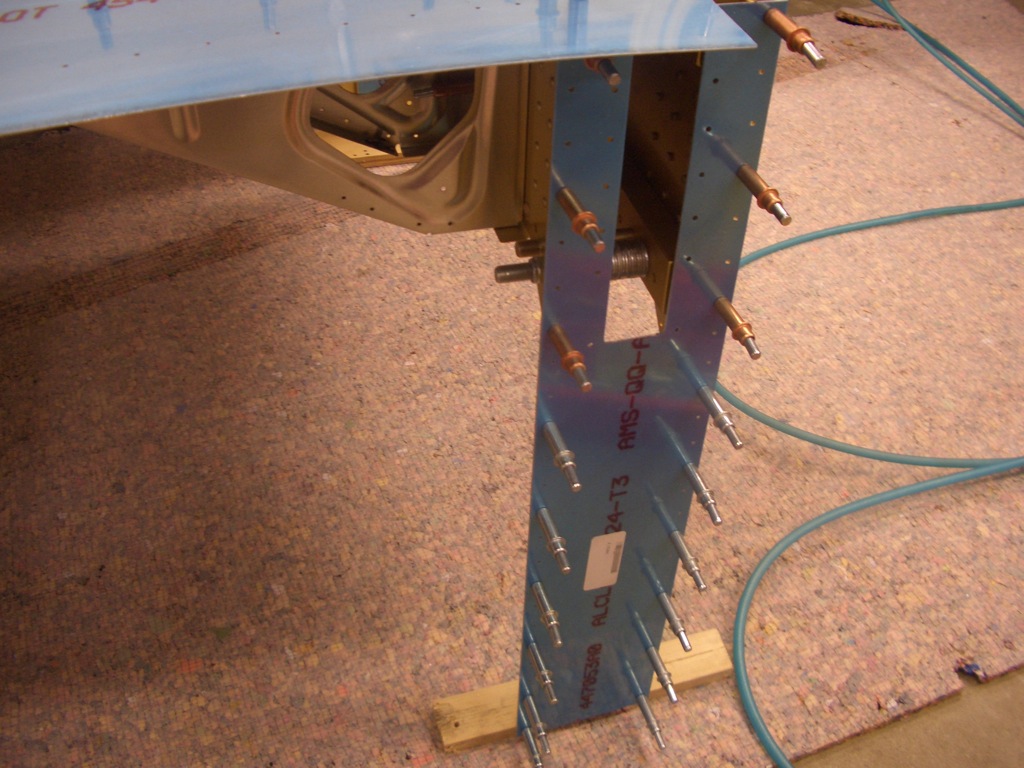

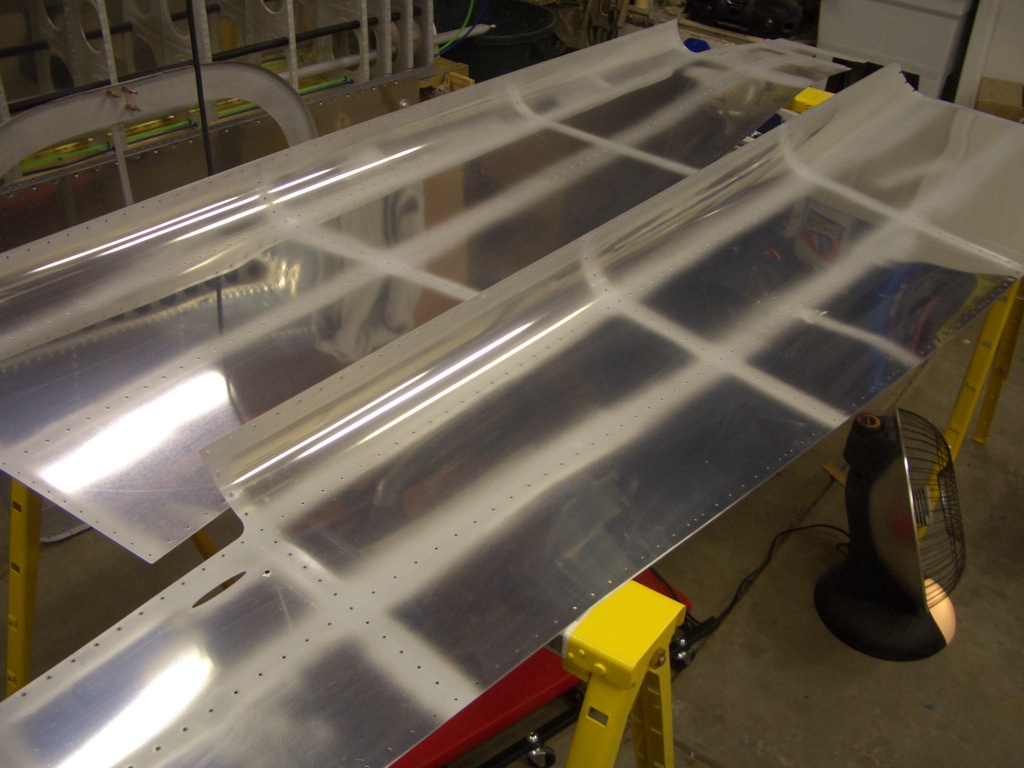

Finally, I got started clecoing the tailcone together. It was at this point that I noticed that I forgot to prime the stringers, so I had to stop for the night. I’ll do those tomorrow and then the tailcone can be fully clecoed together and riveting can begin.