My fuselage was scheduled to ship next week some time, but on a fluke I checked my credit card online today and noticed I had been charged for the fuselage. I called Van’s to see if I could get an estimate on when it would ship and was told it had shipped yesterday. I called FedEx freight and they told me that it will be here tomorrow! Holy lack of notice Batman! If I hadn’t checked, I wonder when I would have found out.

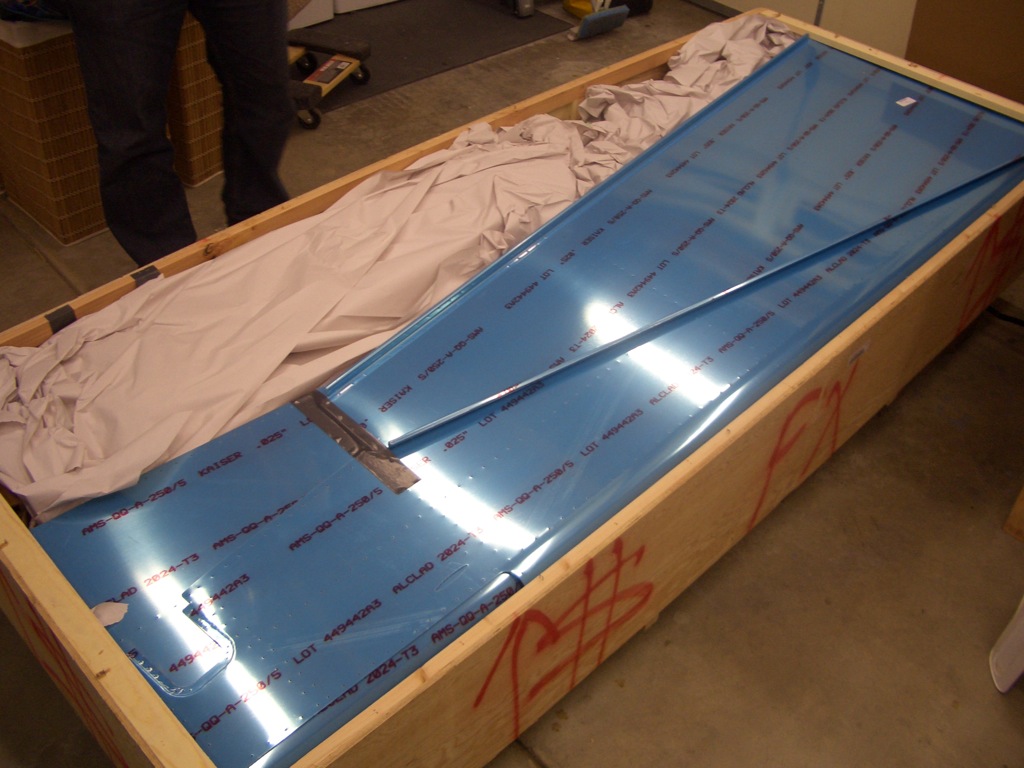

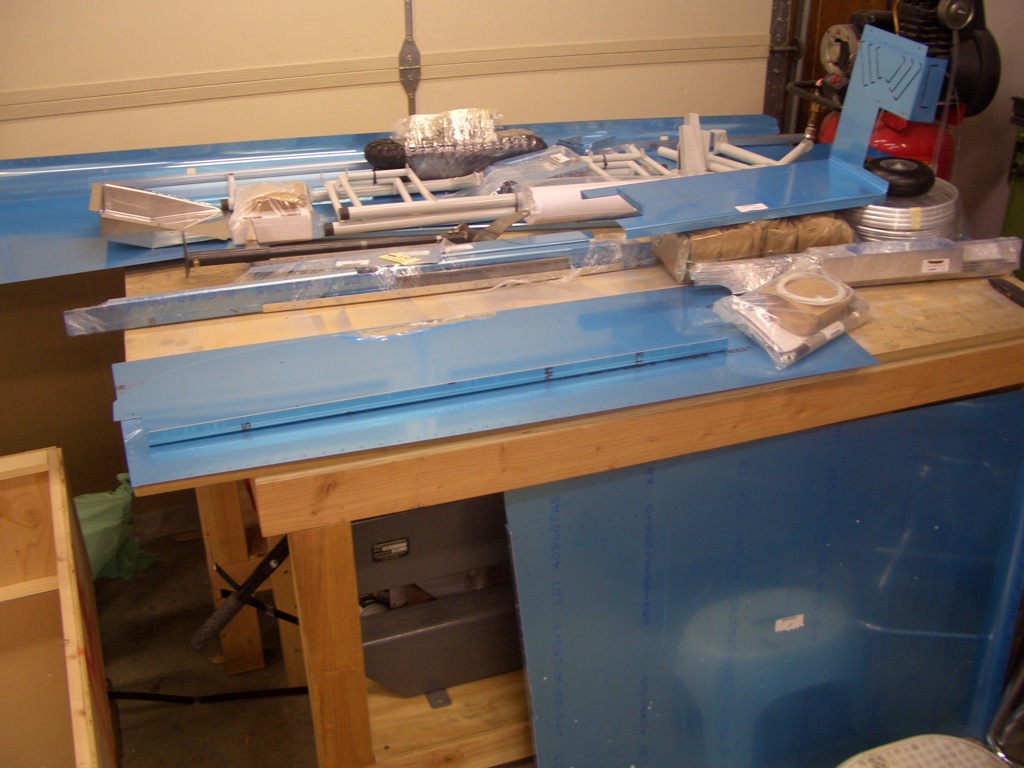

I didn’t do any work on the plane tonight, but I did spend a couple of hours cleaning up the garage and making room for the fuselage crate. The crate is pretty big (about 8′ long, 3.5′ wide and 1.5′ thick and it weighs over 300 lbs), so once I get it into the garage, I still need room to get around it and unpack it.