Even though there is work left to do on the wings, I was excited to get started on the fuselage. First up is to fabricate the firewall. There are several parts that have to be fabricated from rough stock. These are fabricated from some beefy 0.187″ thick angle stock.

This stiffener is fabricated from some 0.063″ angle stock.

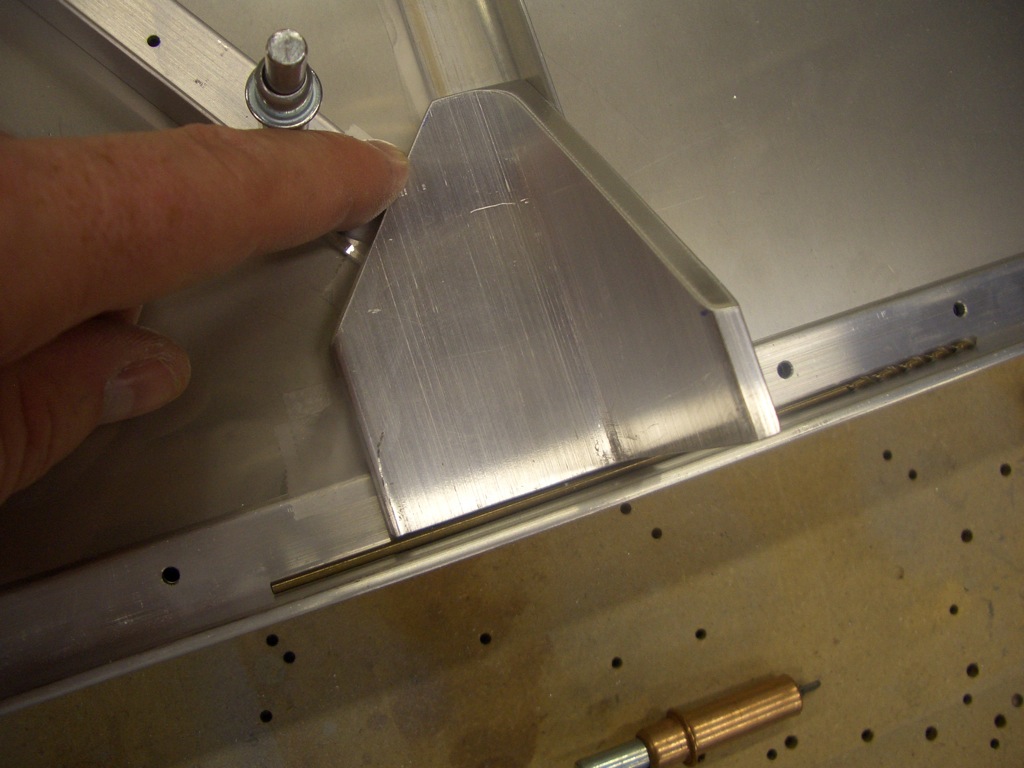

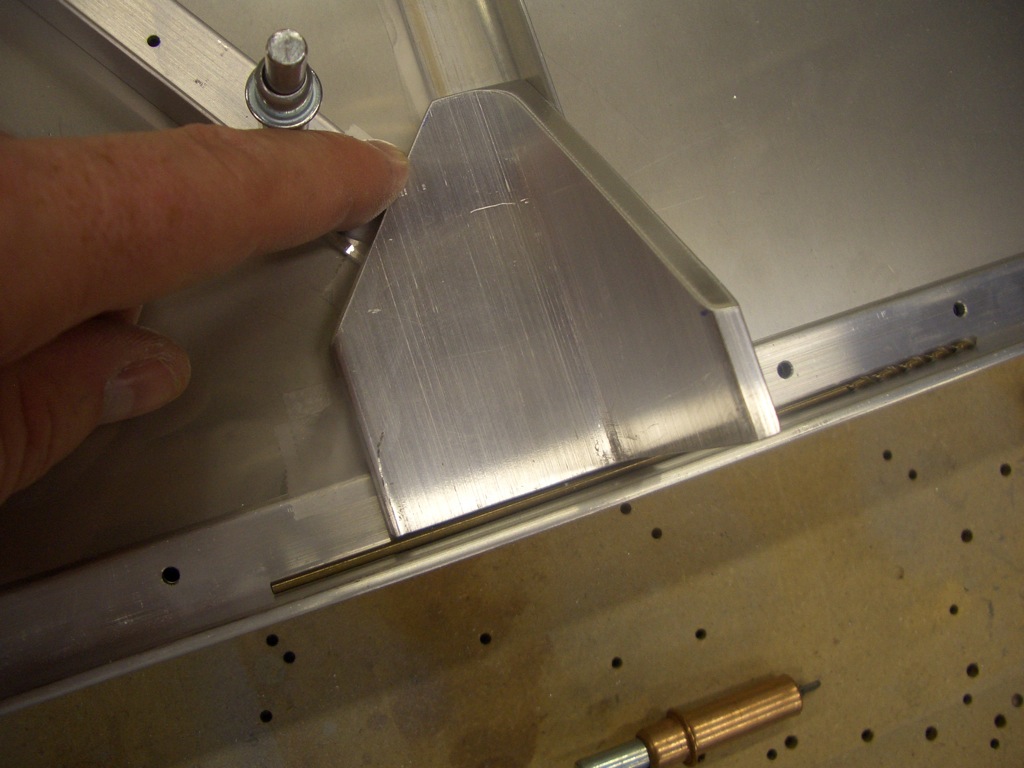

These attach angles tie together the lower firewall stiffener, two upper firewall stiffeners and later the forward floor stiffeners of the fuselage. These need to be spaced 3/32″ from the flange of the lower stiffener. The easiest way to do this is to use a #40 drill bit to position the angle. Behind the angle are a couple of shims that are scotch taped in place so that all of these can be drilled together to the firewall.

Using plenty of boelube, these are match drilled using the firewall as a guide.

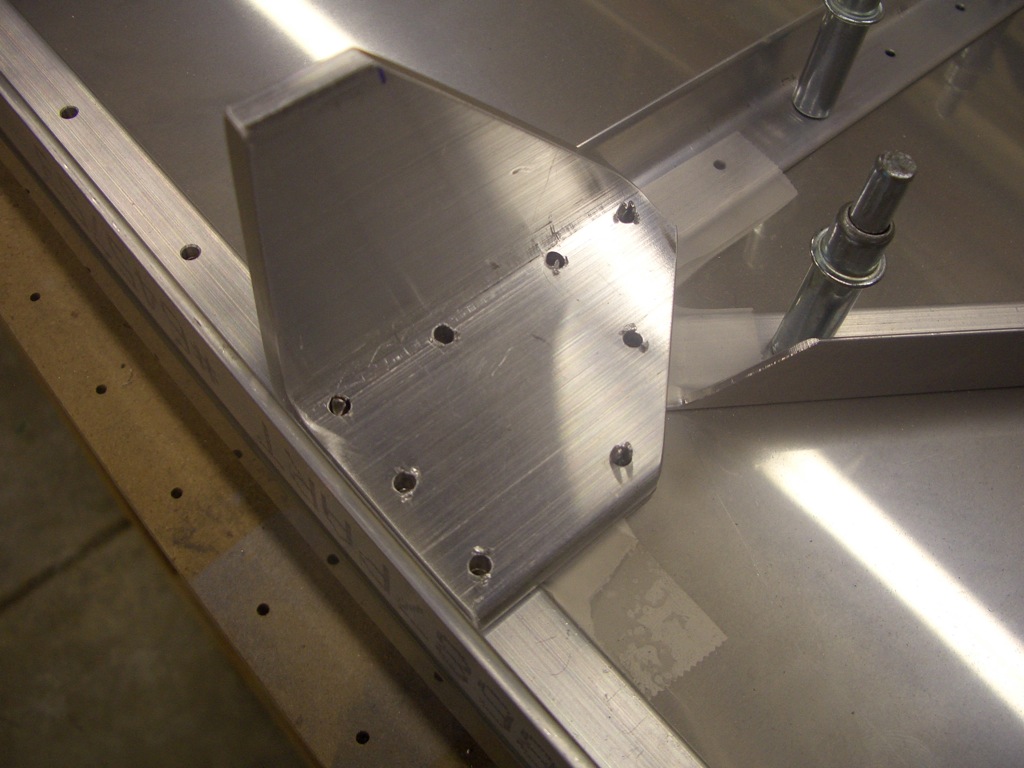

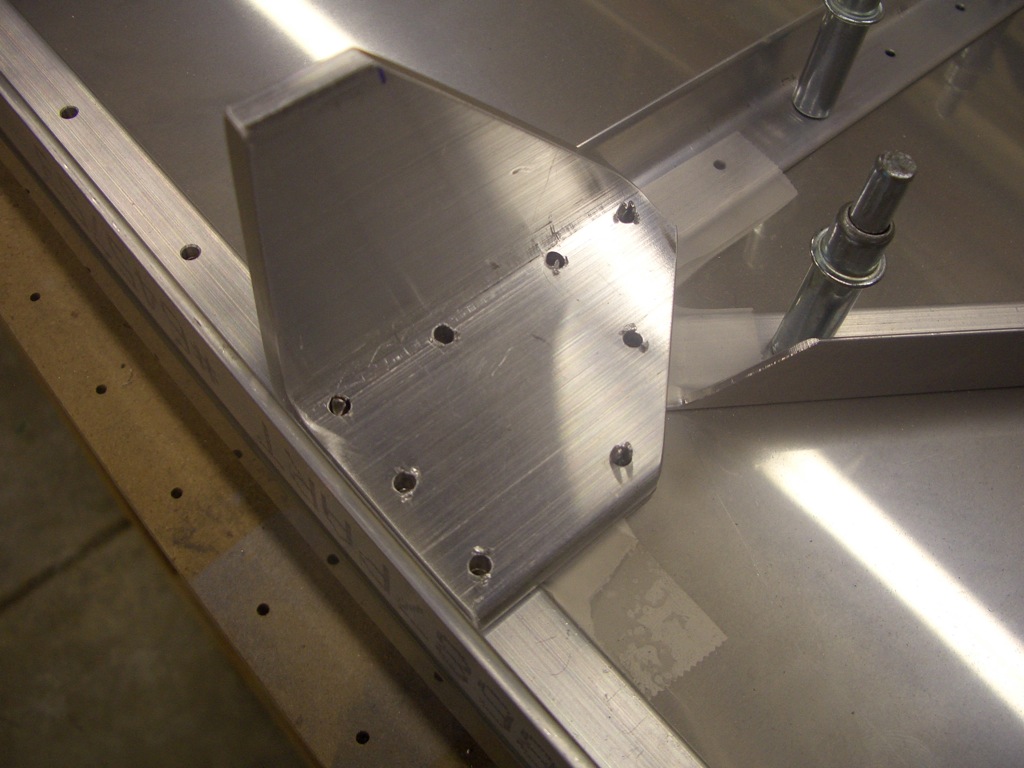

After fabricating a couple of additional stiffeners, I clecoed all of the stiffeners and weldments to the firewall. The four gray brackets in each corner are powder coated steel weldments that will eventually tie the fuselage longerons directly to the engine mount through some beefy bolts.