Work has kept me busy the last couple of weeks, but I wanted to give the plane a thorough inspection after the trip. While I was doing the inspection, I upgraded the SkyView system with the version 11 software that was announced at the show. It included a new very-high resolution database, so it took quite a while to load.

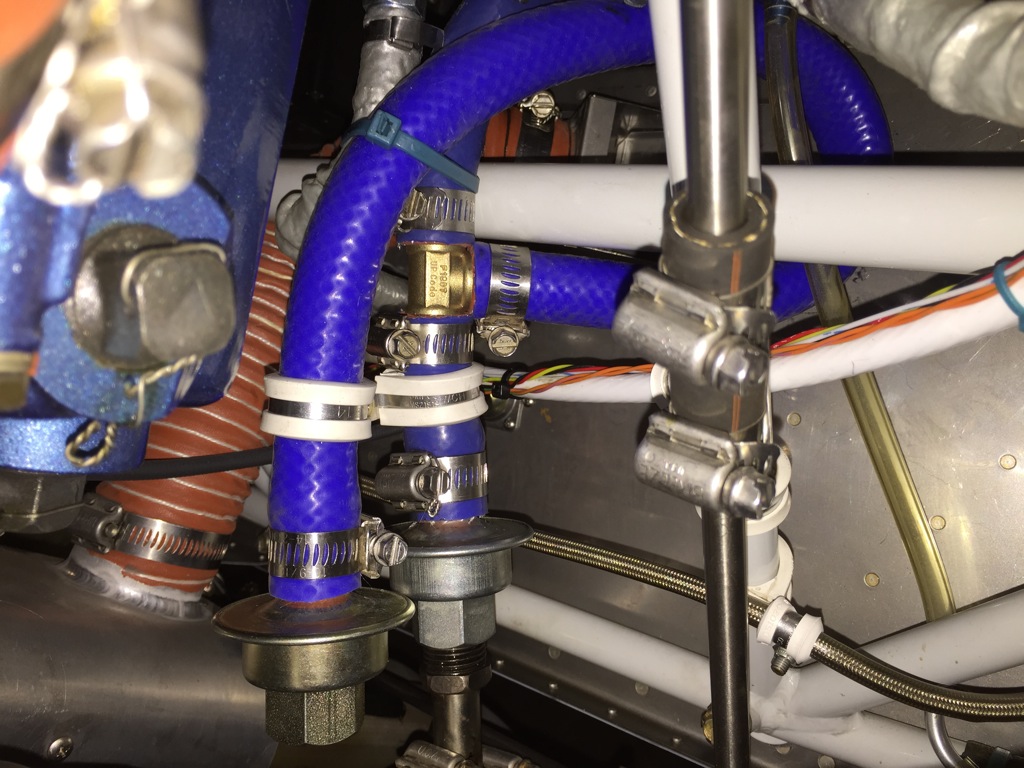

I gave the engine compartment a thorough inspection. There were no surprises, and everything looks great.

One of the tabs on the upper gear leg fairing broke off. This allowed the clamp to loosen and the gear leg fairing to slide down a bit.

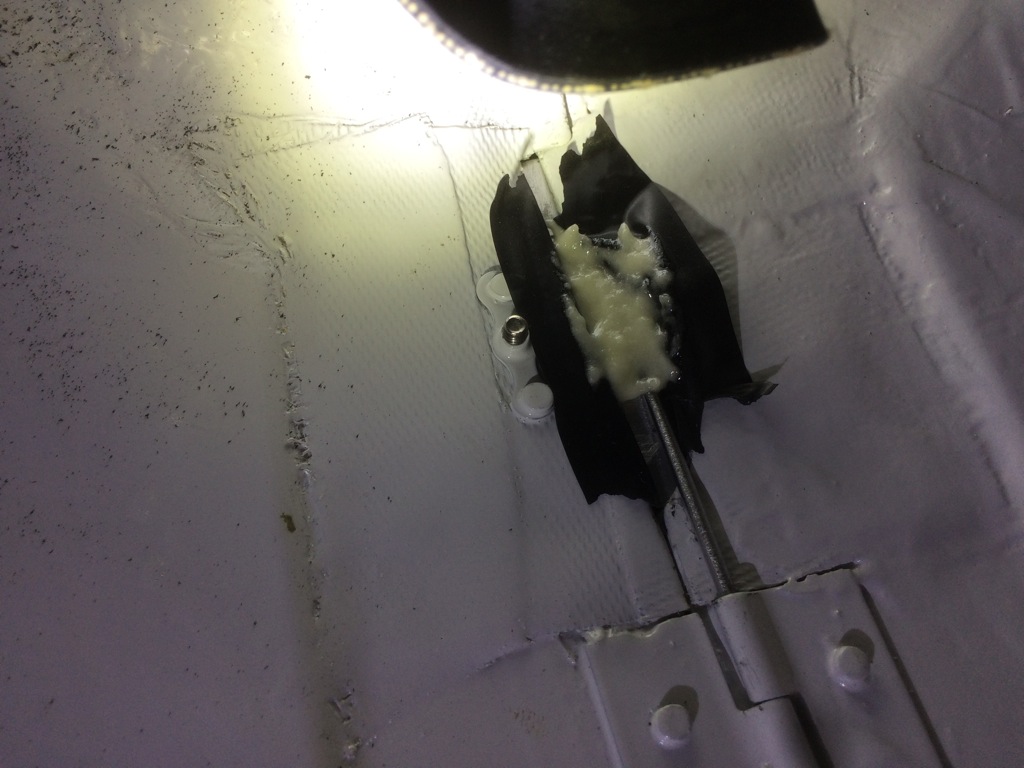

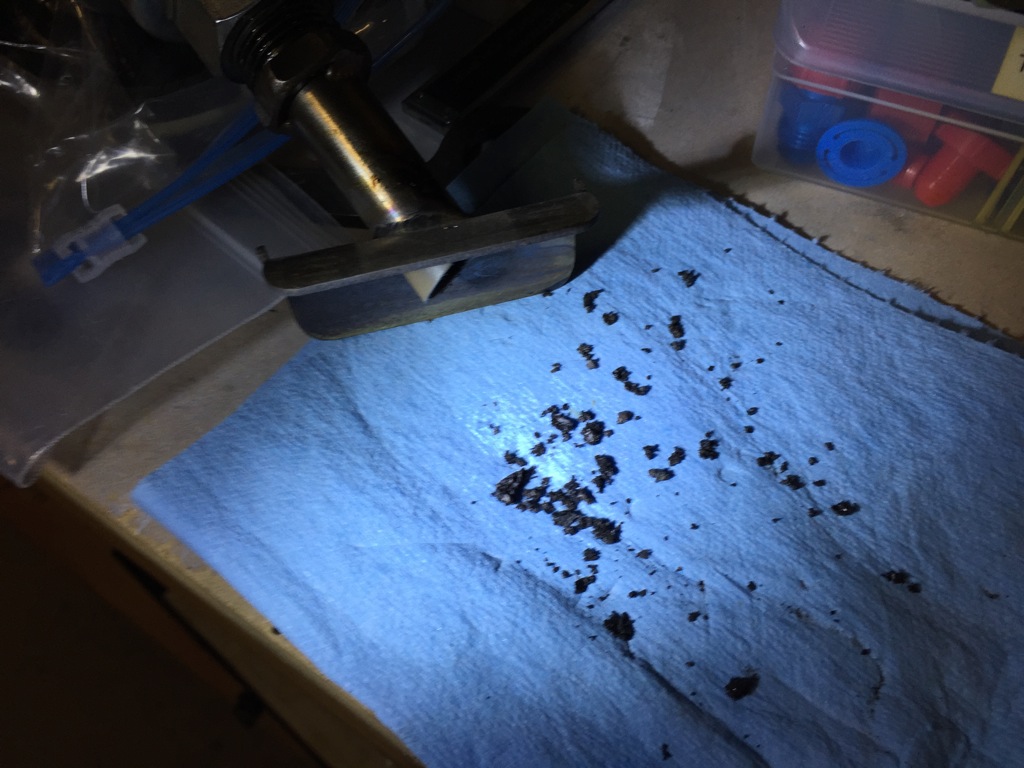

The side cowl hinge pin also broke loose from the hinge pin cover. I cleaned out the old JB Weld and mixed up some epoxy/flox. After applying some electrical tape around the opening to prevent the epoxy from adhering, I applied the epoxy. After it cured, I popped it off and cleaned up the excess. This seems quite a bit stronger than the JB Weld, so hopefully it will hold up. Other than these couple of issues, there were no faults on the plane.