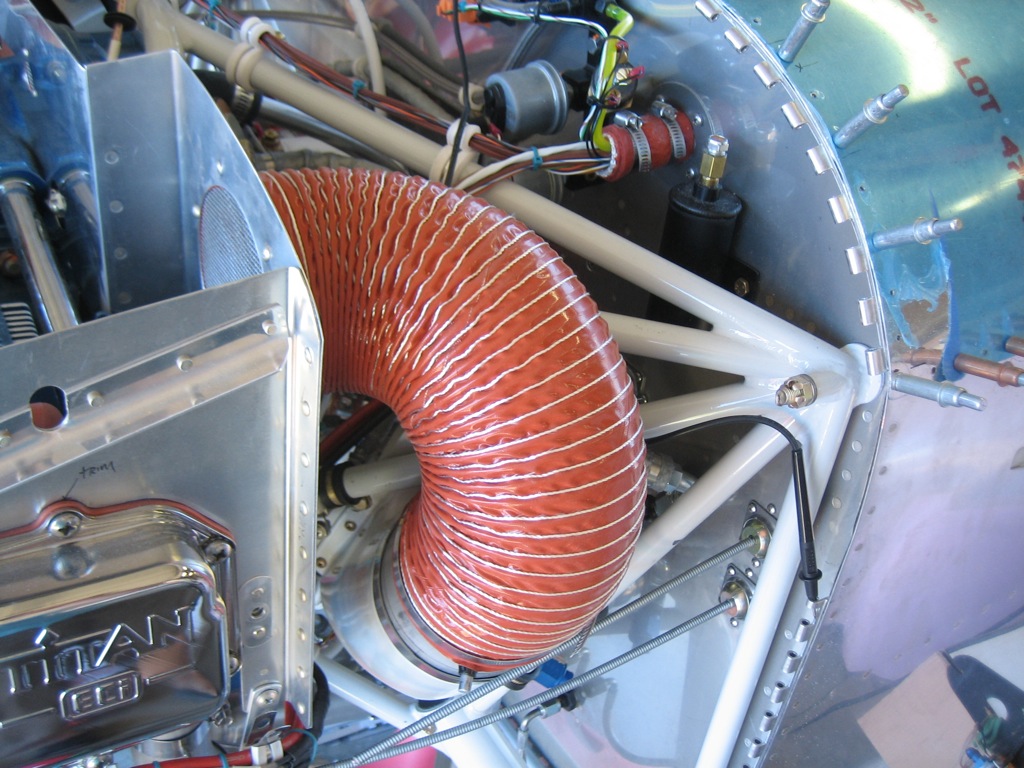

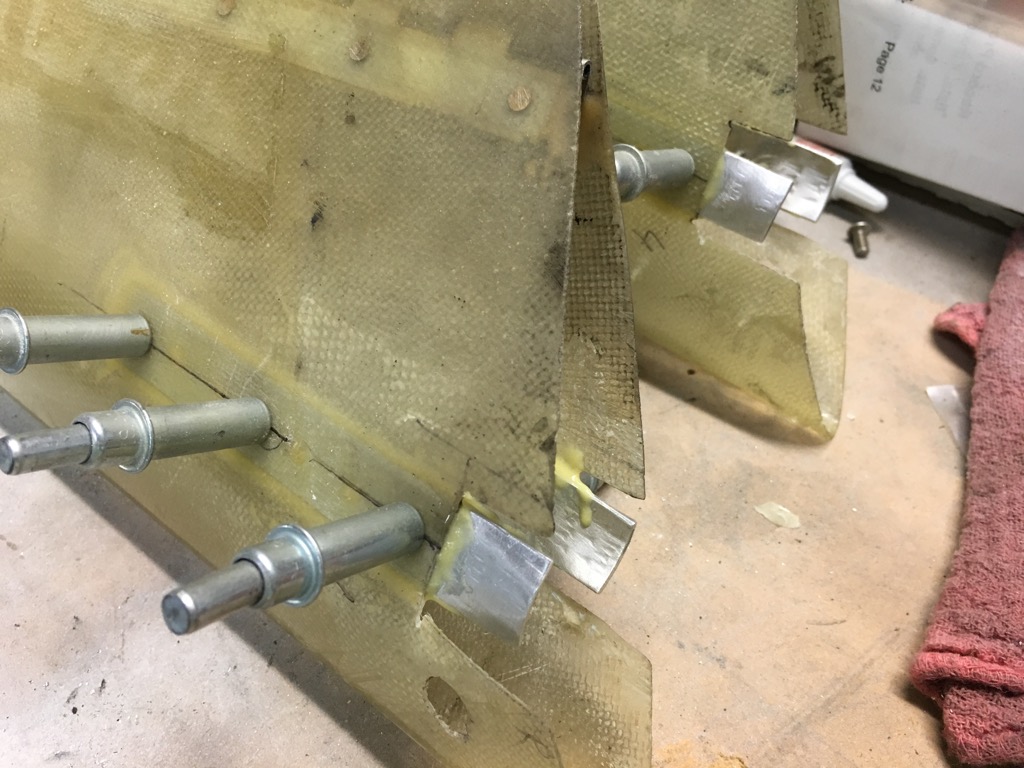

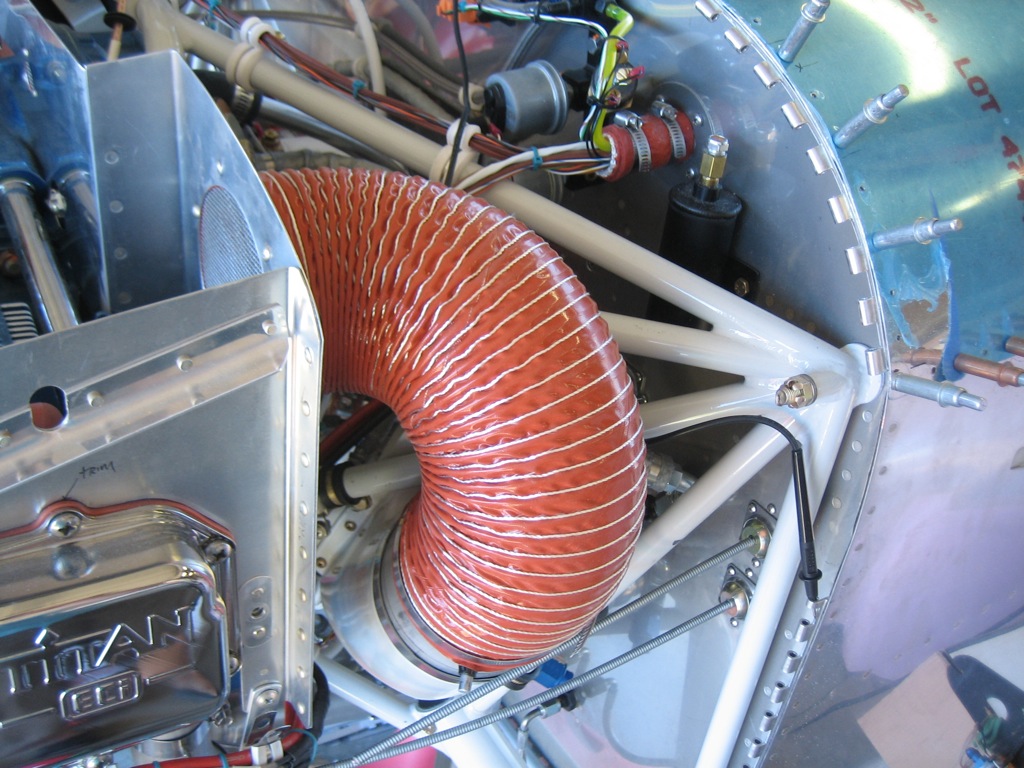

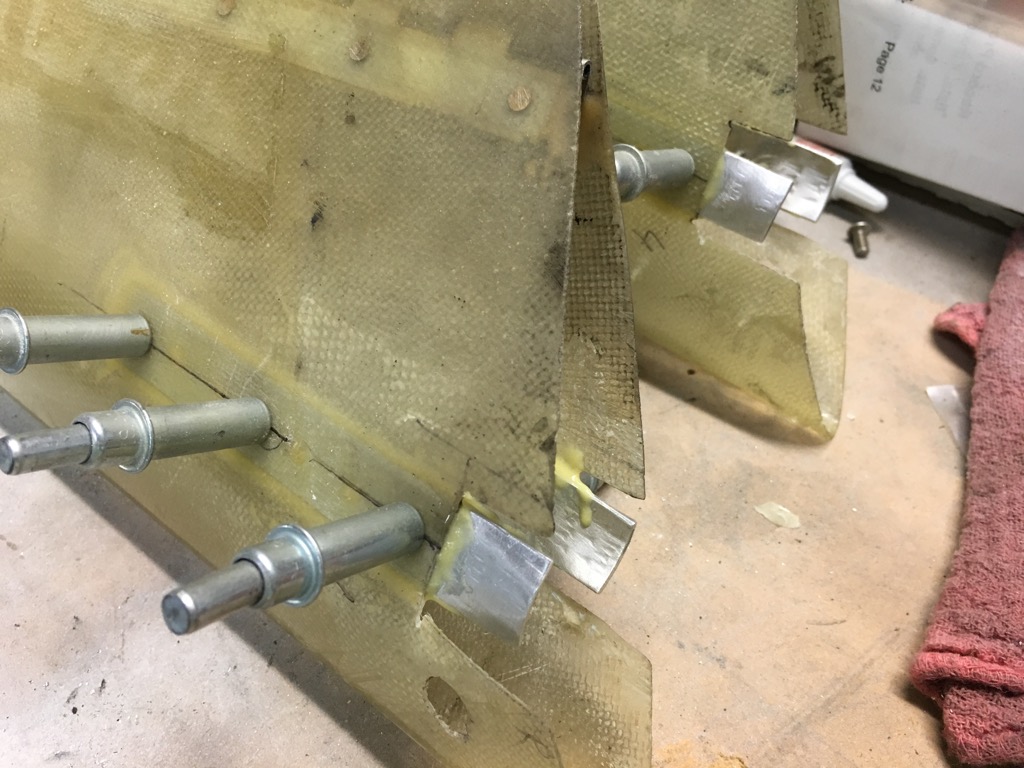

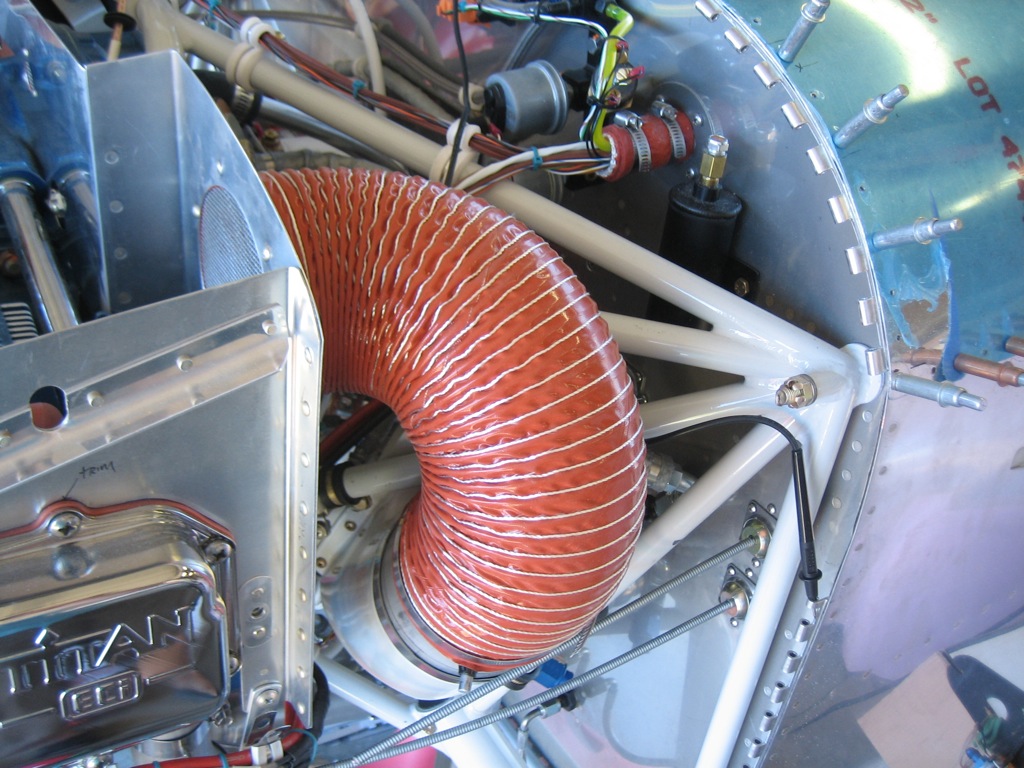

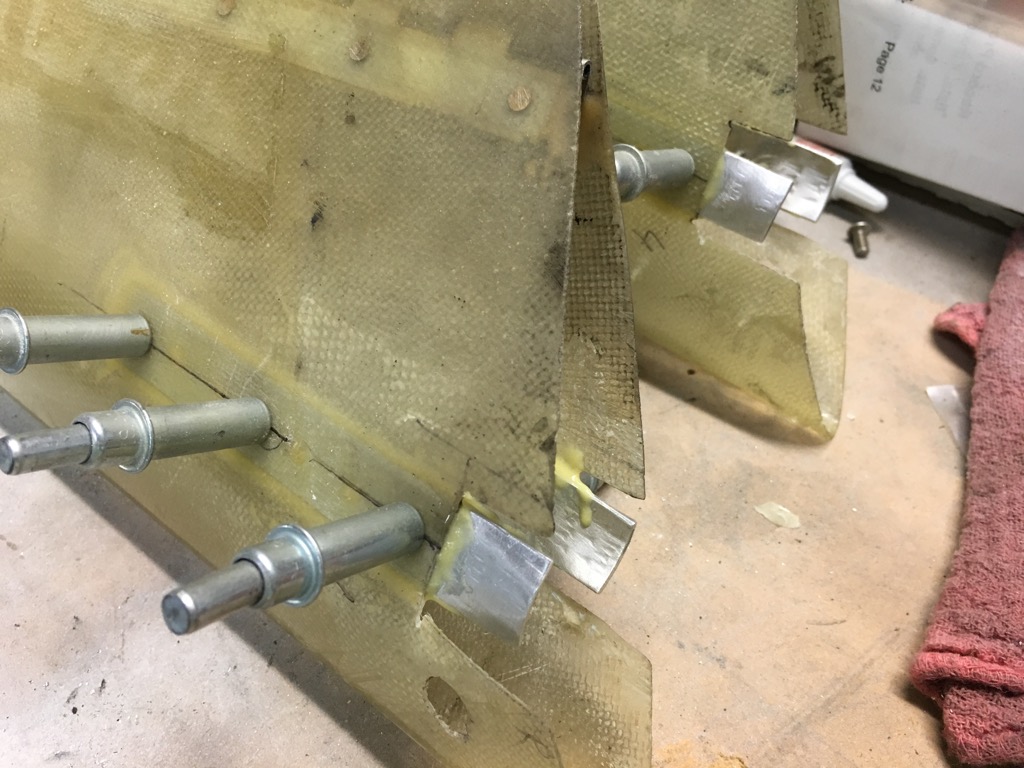

With the epoxy cured on the oil cooler SCAT tube flange, I reinstalled the baffles to test fit the SCAT tube.

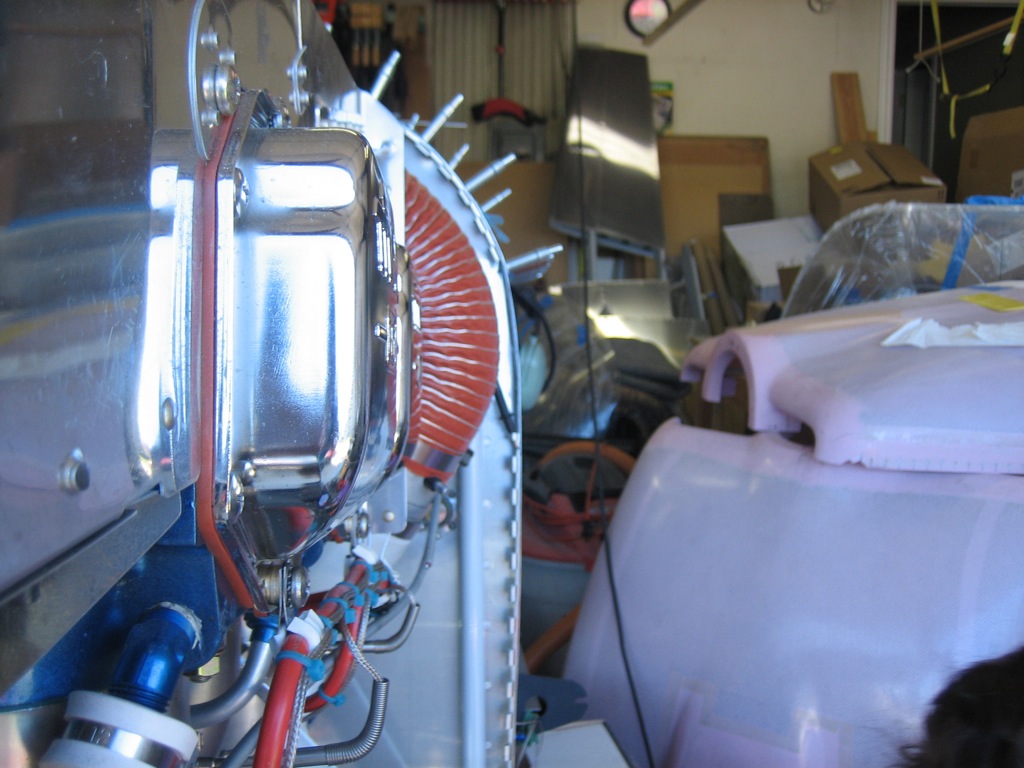

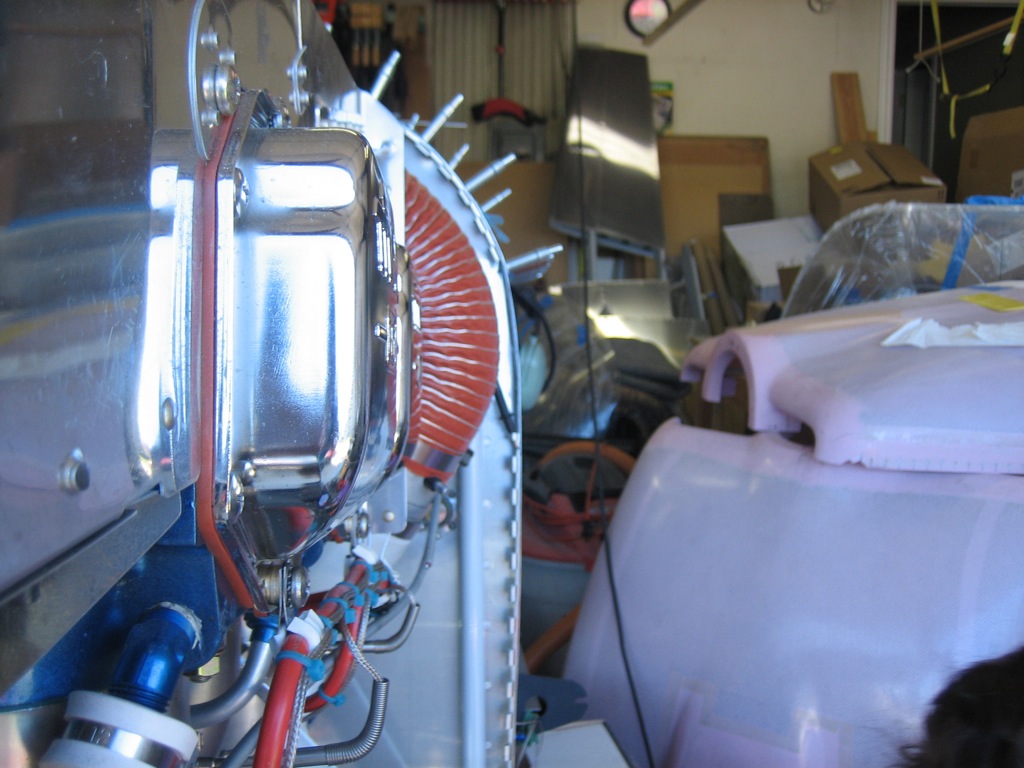

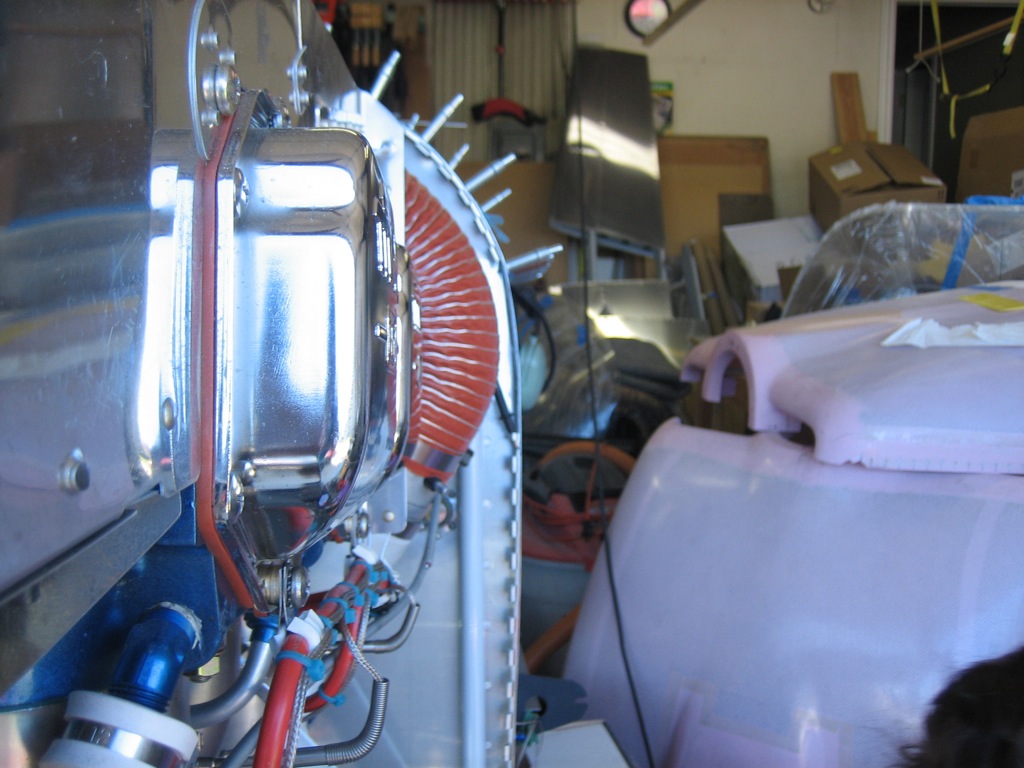

As you can see, the SCAT tube is well inside the cowling. I should have at least 1/2″ of clearance.

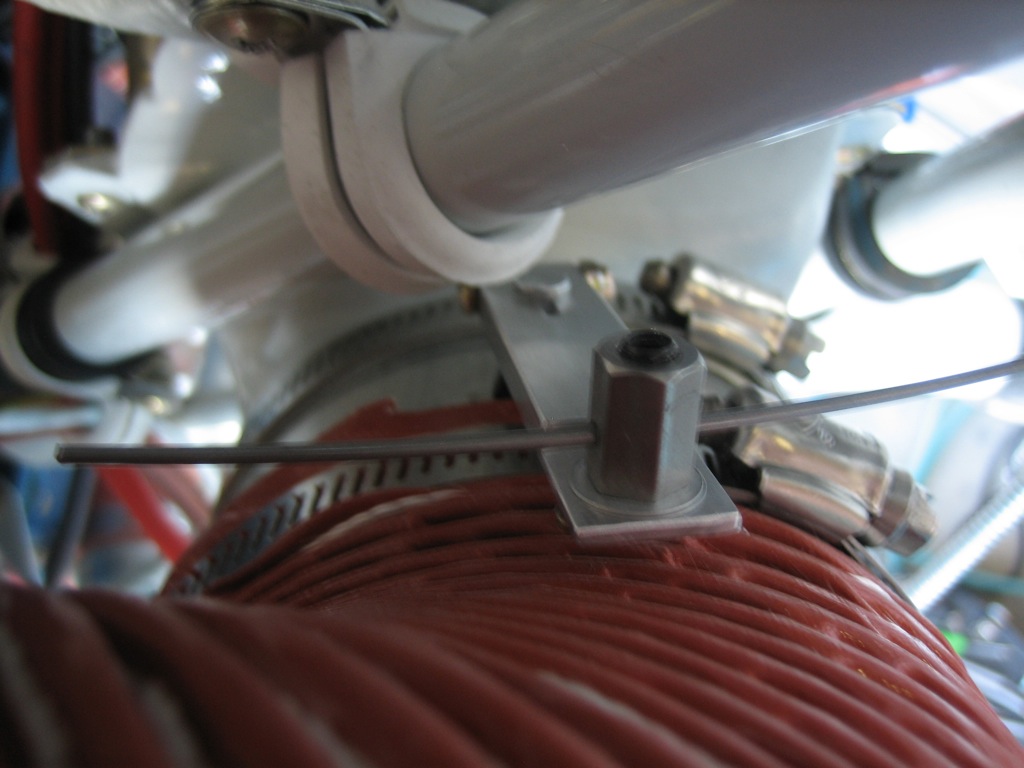

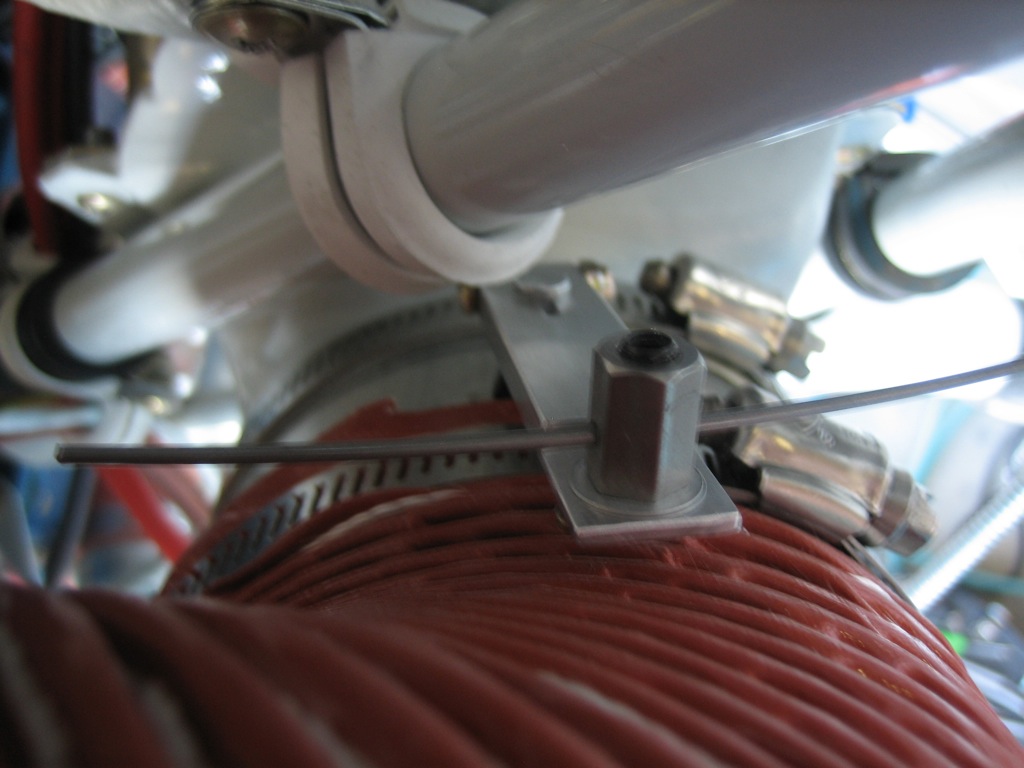

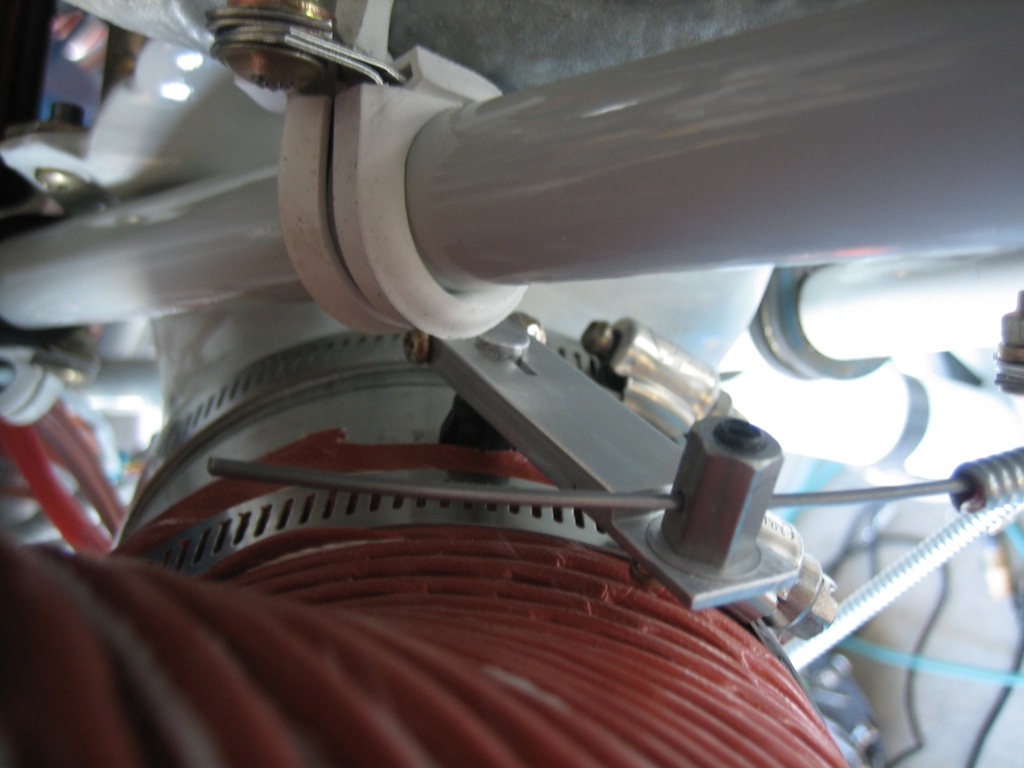

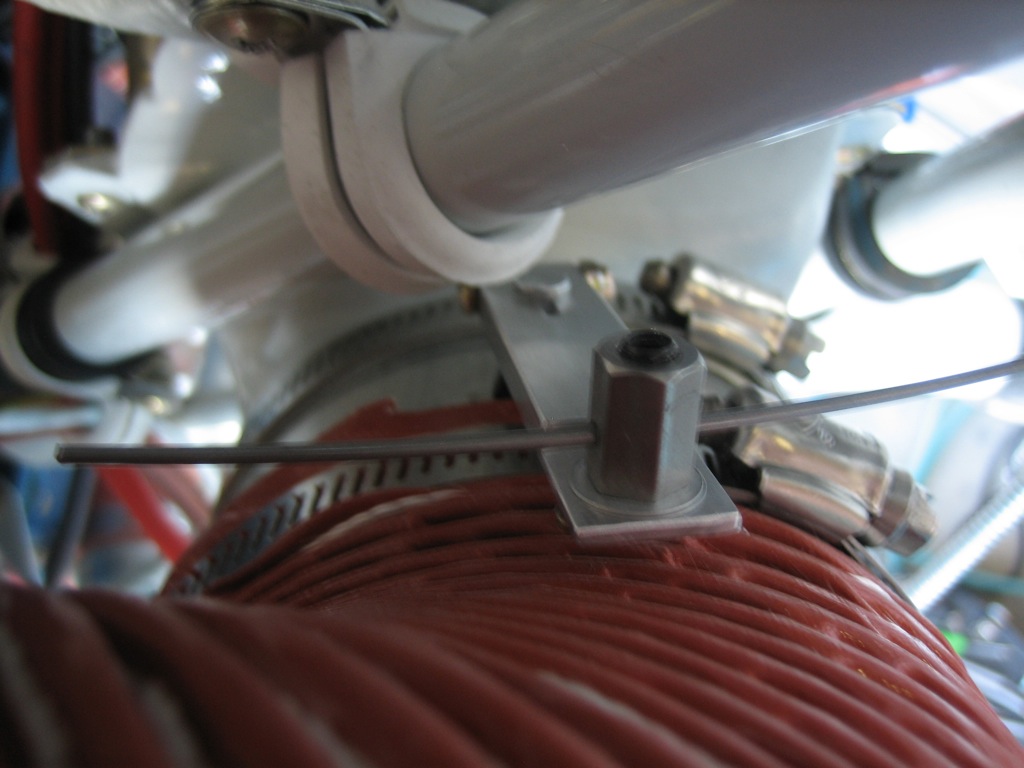

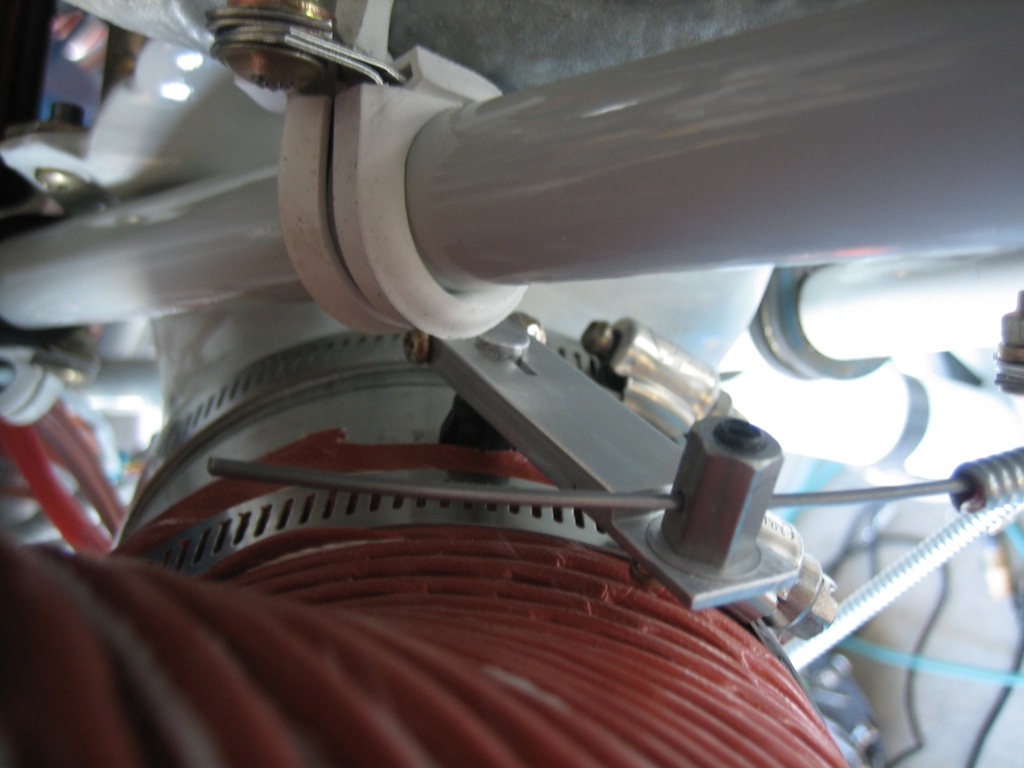

I fabricated a longer control arm and then anchored the control cable to the nearby engine mount tube.

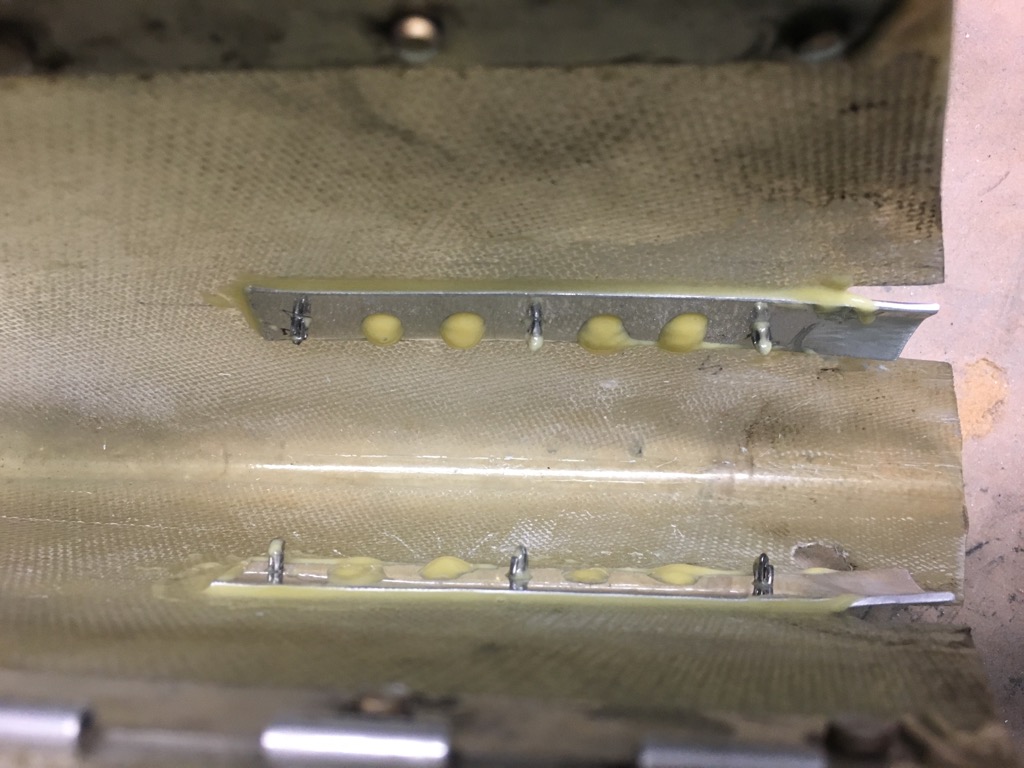

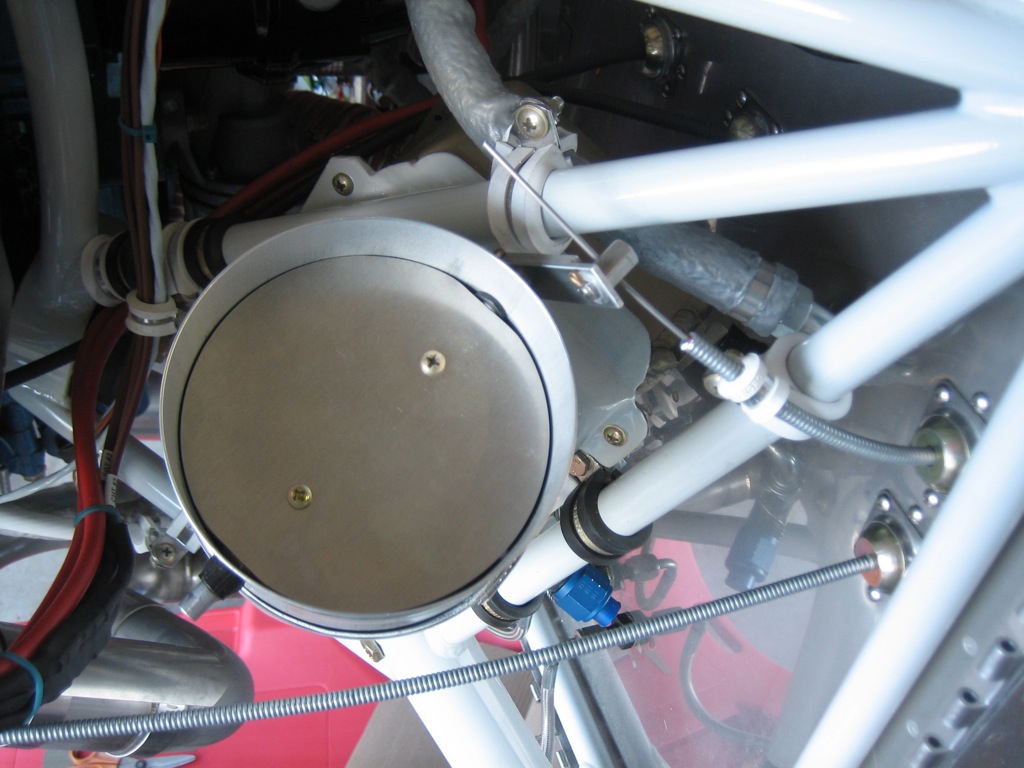

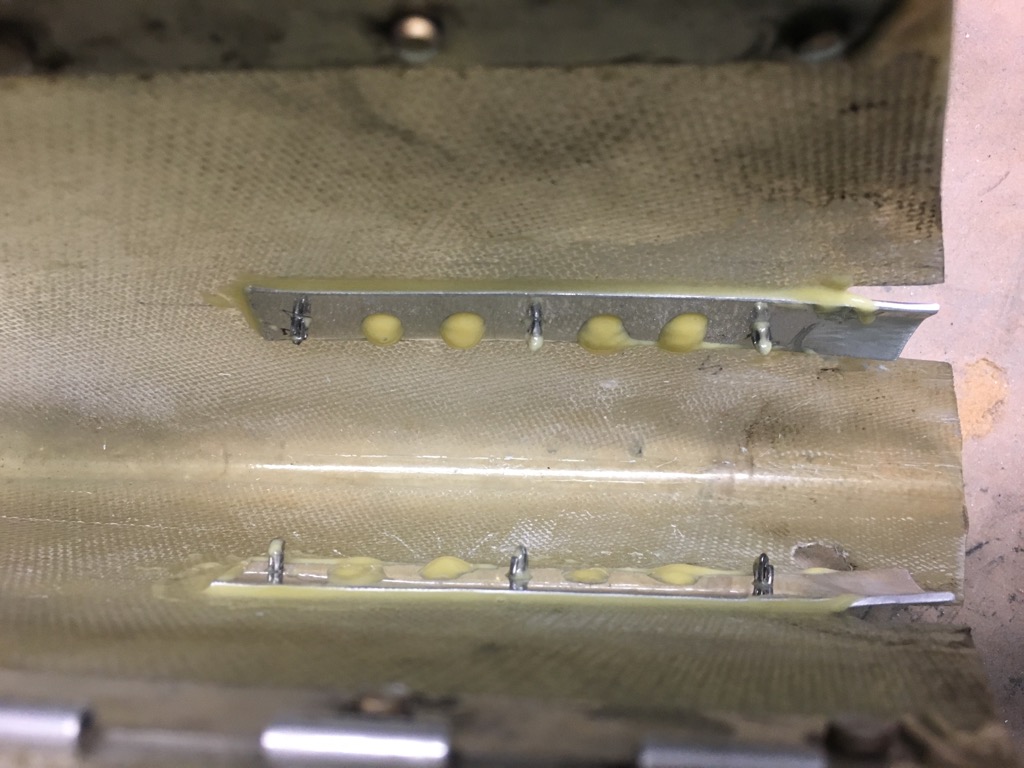

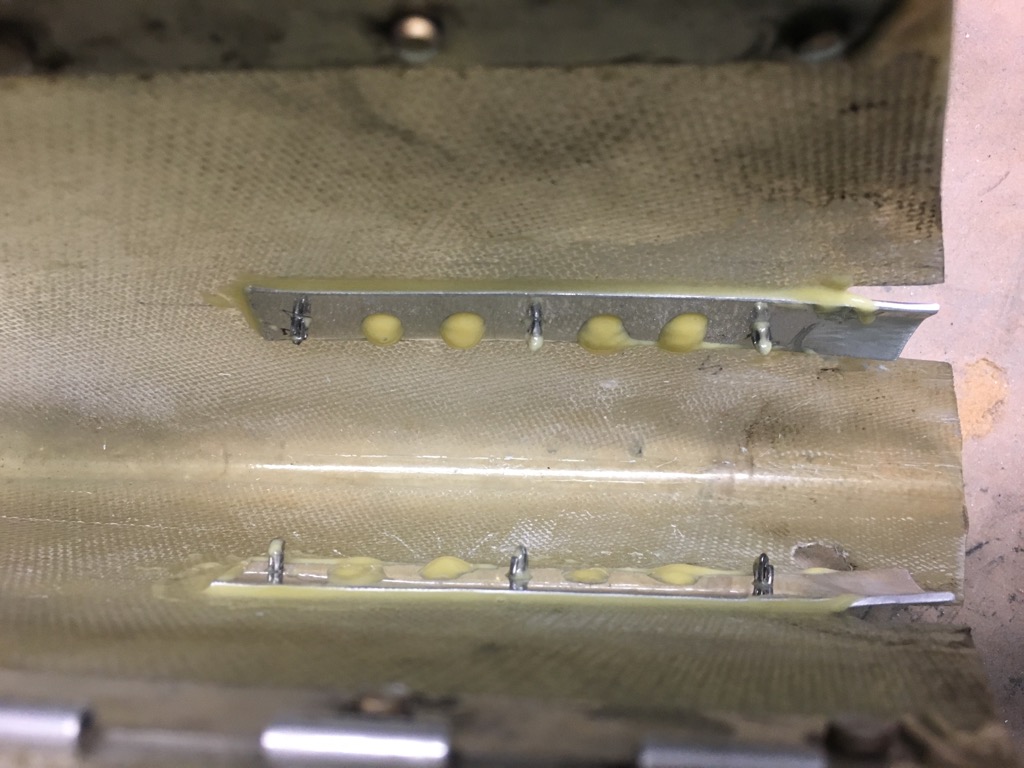

Here’s the control arm I fabricated. I cut it from some 1/4″ stock and machined it down to 3/16″ thick and notched the closed end for the b-nut. The far end has a 1/4″ hole and a slot so that it can be clamped to the rod.

The longer arm gives me about 2″ of throw on the cockpit control which should give me plenty of precision for fine tuning the oil temperature

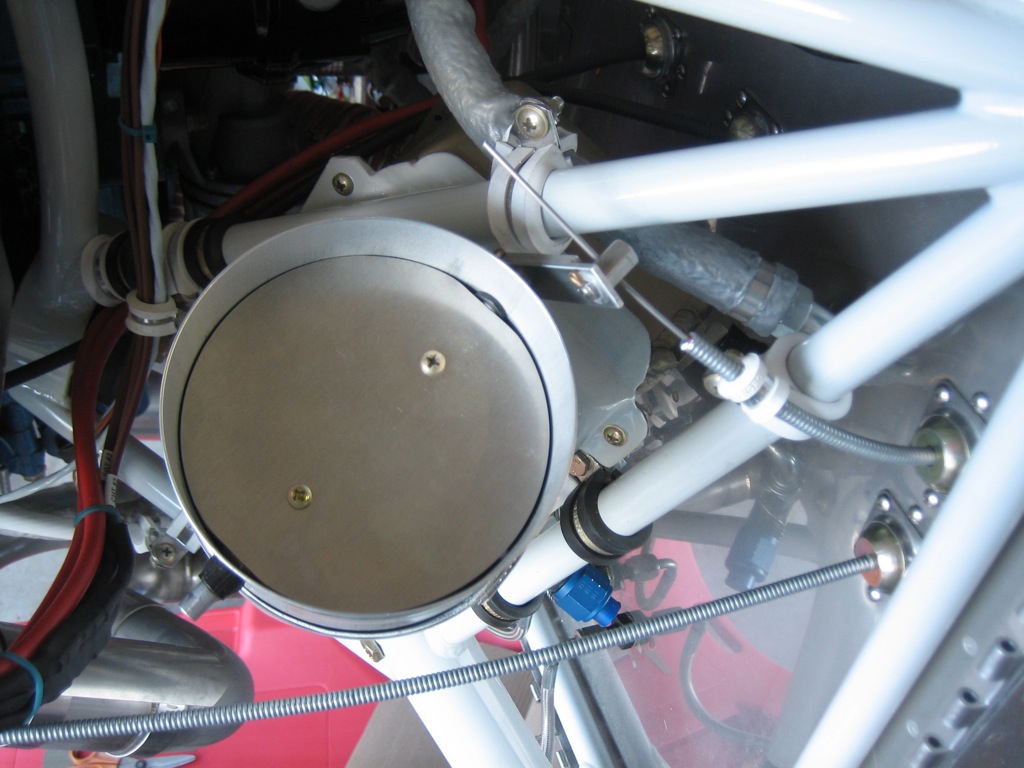

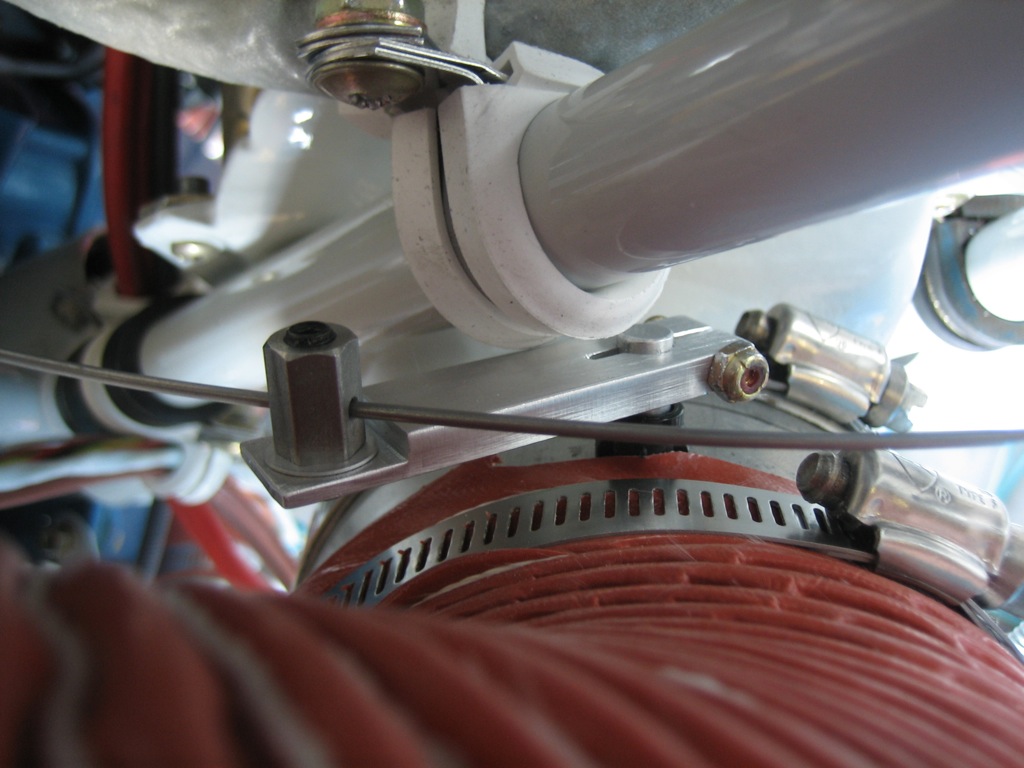

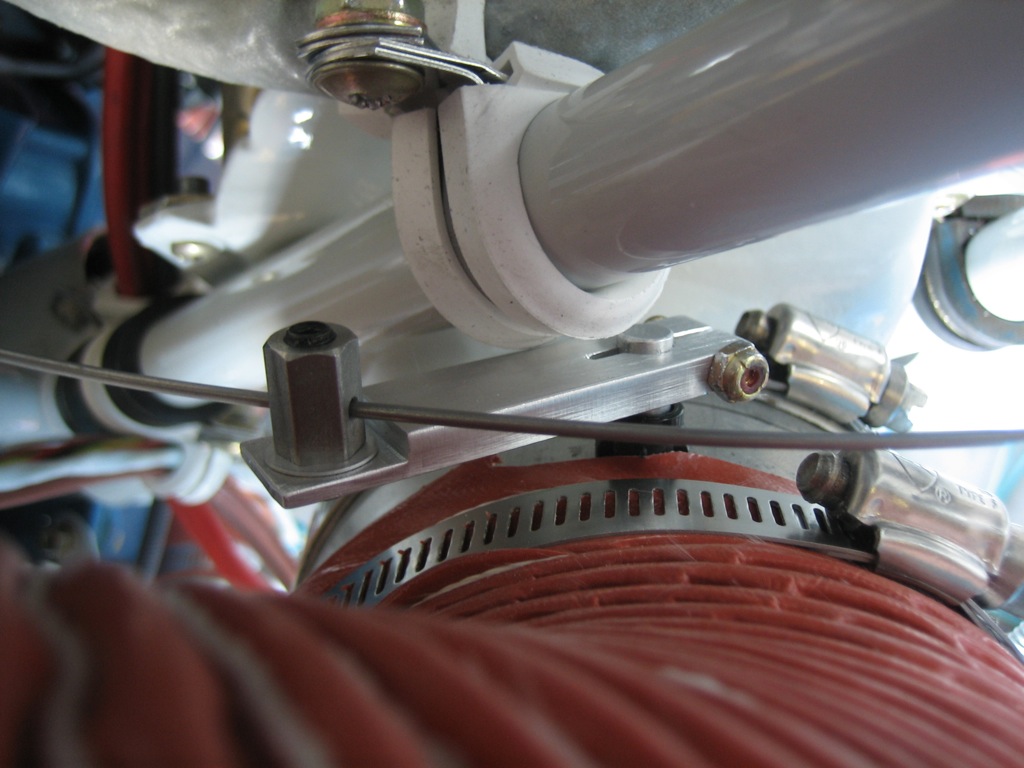

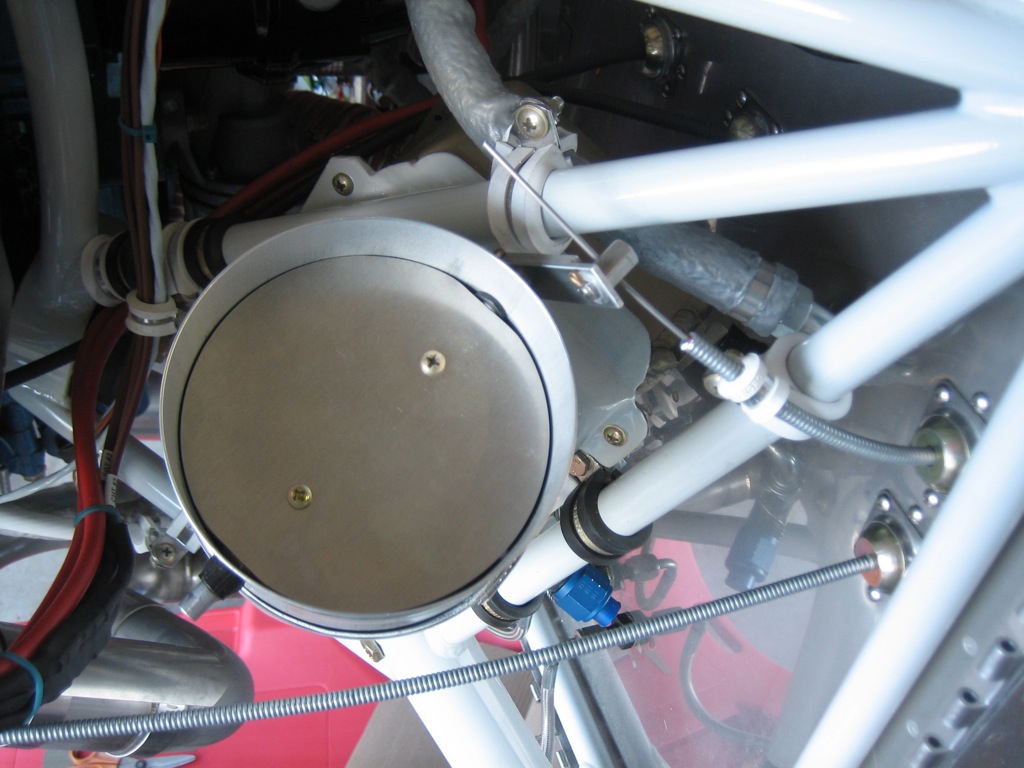

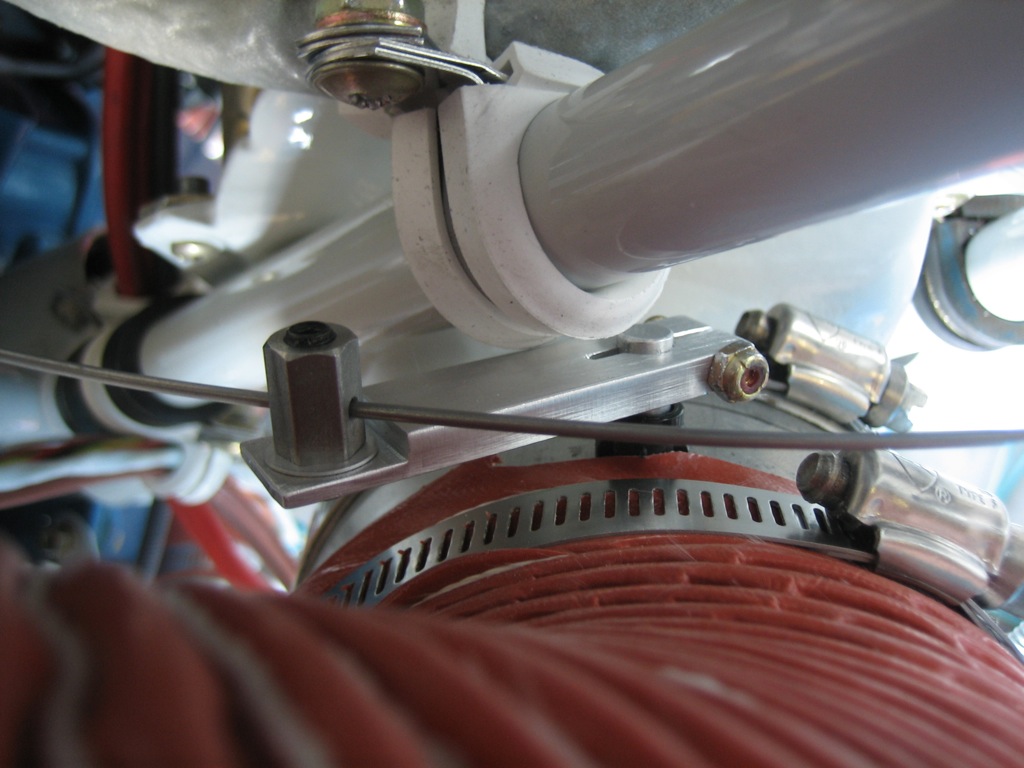

Here’s what the butterfly valve looks like when the control cable is pushed all the way in. I’ll trim and bend the end of the control cable when I’m sure it’s on for good.

With the SCAT tube back in place, there’s plenty of clearance in the full open position.

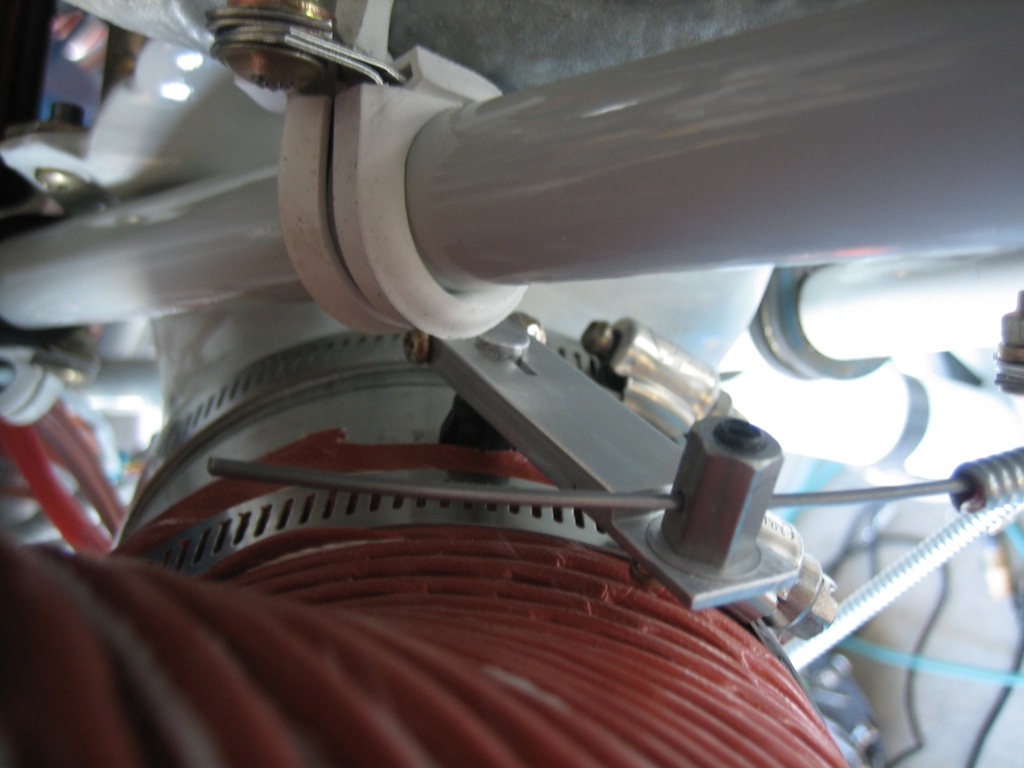

…and in the full closed position.

In the middle, there’s about 1/4″ of clearance between the control arm and the SCAT tube. I might end up adding a bend in the control arm to increase this a bit.