I haven’t touched the plane in a month, but I have a really good reason…honest! First, I’ve been really busy at work, but what’s really killed all of my free time is that we bought a new plane! We’ve finally outgrown the Cessna Cardinal that has been our family plane for a number of years now. Even though the kids are still small, we’re basically right at gross weight with full fuel and baggage. It’s also pretty slow and has pretty anemic climb which is important around here. I’d been thinking about building an RV-10 after I finish the 7, but the ride in my buddy’s A36 Bonanza changed my mind. I ended up buying a 1/4 share of a 2001 turbo-normalized A36 Bonanza with really low time in fantastic shape. The search itself took quite a lot of time, but I’ve also been taking the Advanced Pilot Seminars course to learn to fly it lean-of-peak as well as the BPPP course to learn about how to fly the aircraft. I’ve also been reading books and articles in preparation for the transition training that starts next week.

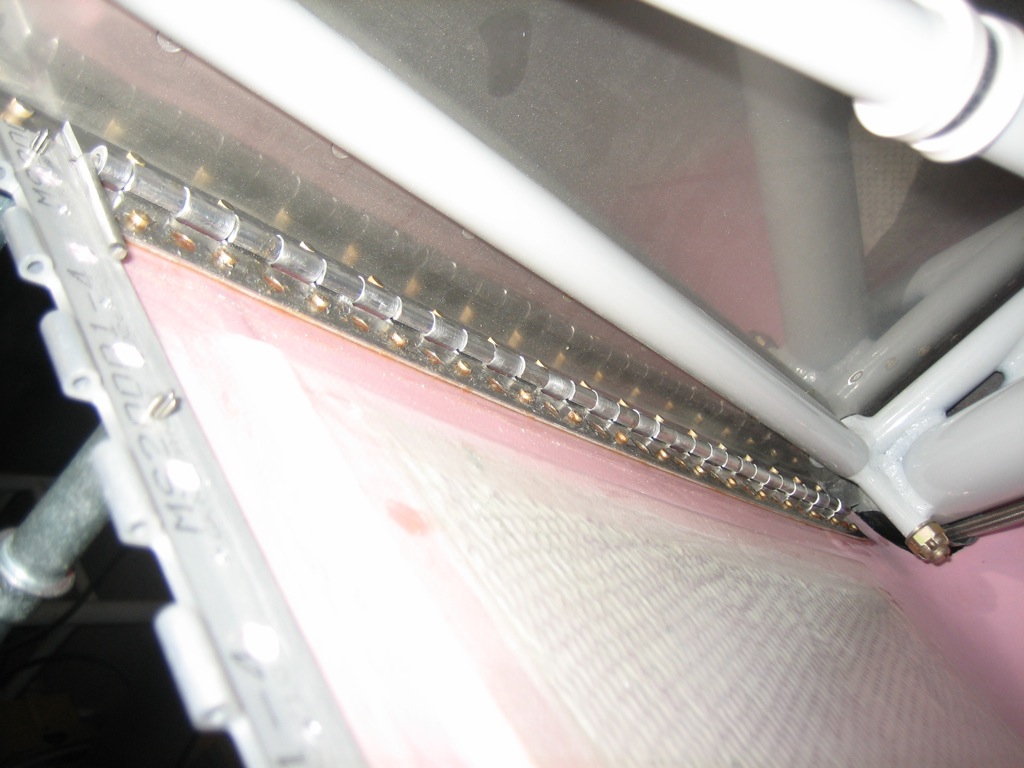

Anyway, a month is way too long, so I decided to use the long weekend to get restarted. I prepped the lower side hinges and riveted them to the cowl with some West Systems G/Flex epoxy which will stay more flexible than their 105 epoxy.

I used some AN426A rivets to avoid crushing the fiberglass. This is very slightly recessed from the side of the fuselage, but that’s perfect because I’m going to add a layer of lightweight cloth over these rivets and then a coat of dry micro so that it can be sanded perfectly flush with the fuselage.

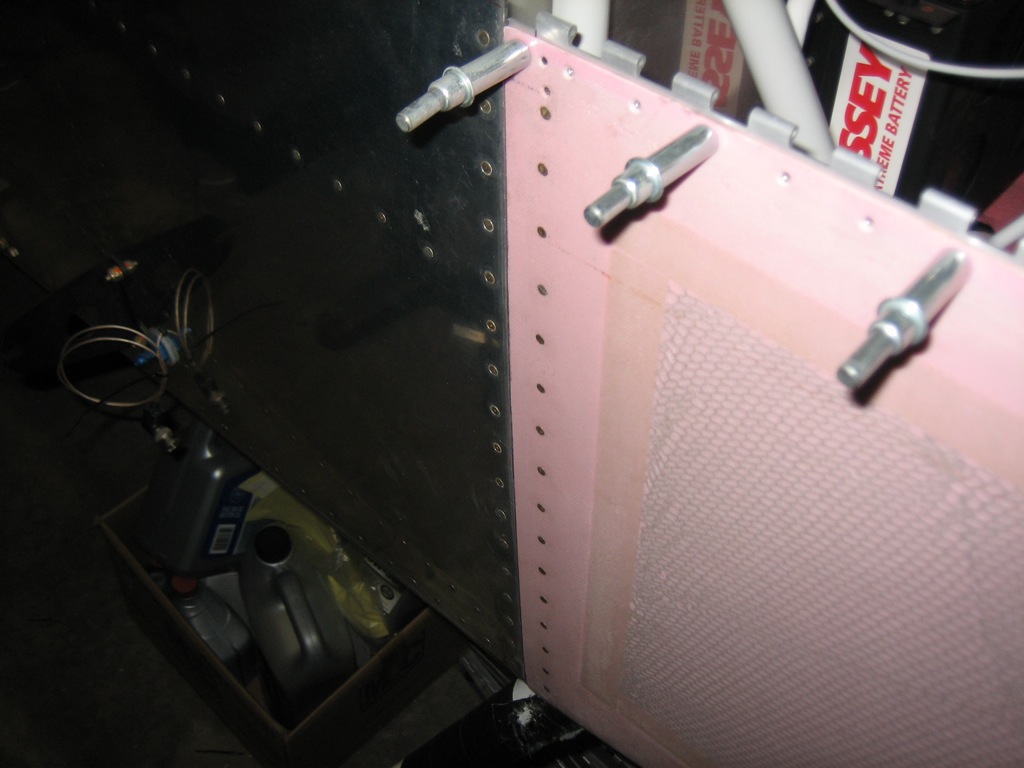

I also made a really rough cut in the side of the cowl to insert the hinge pins that attach the sides of the cowl together.

Here’s a wider shot to show where these pins stick through.