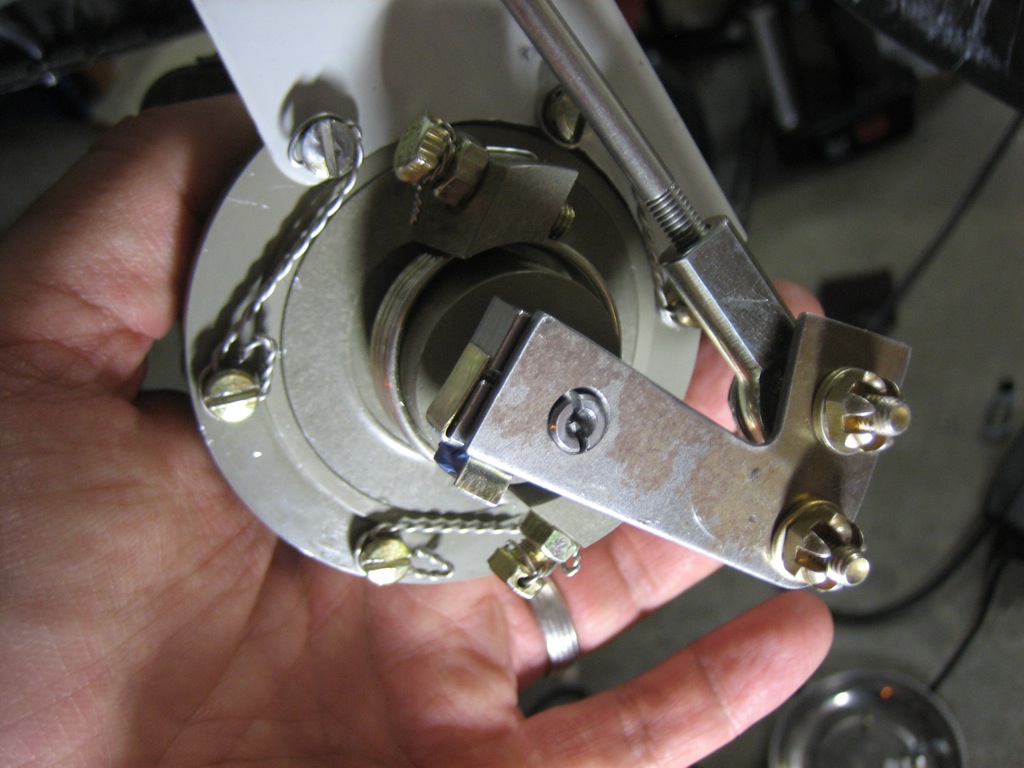

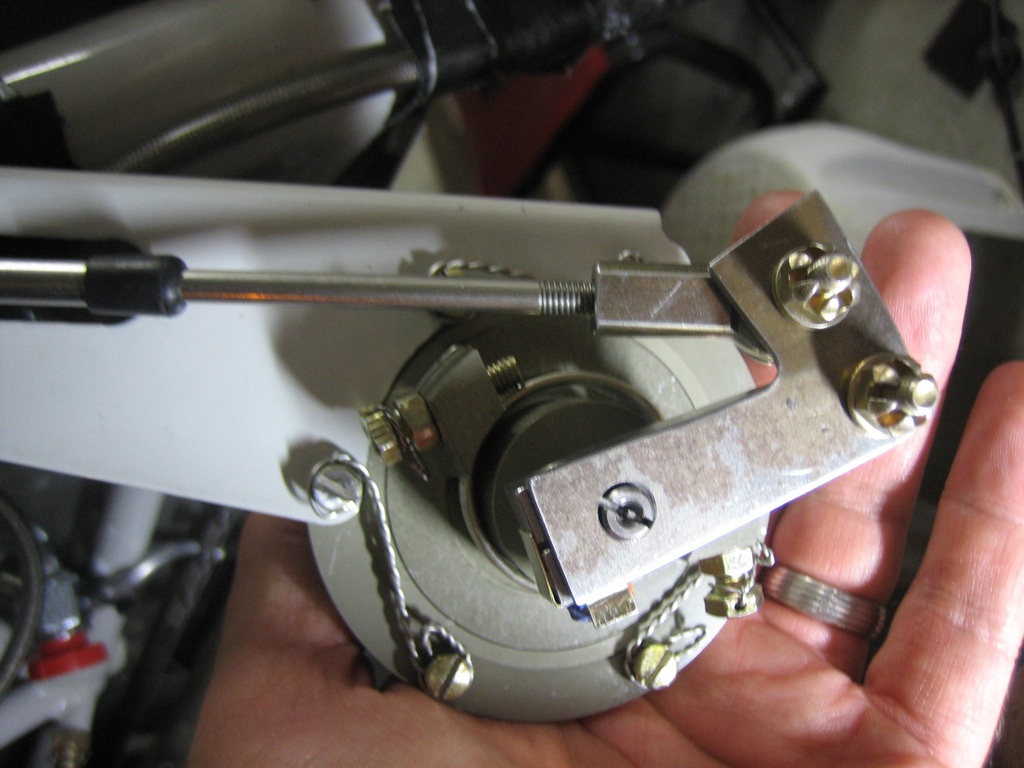

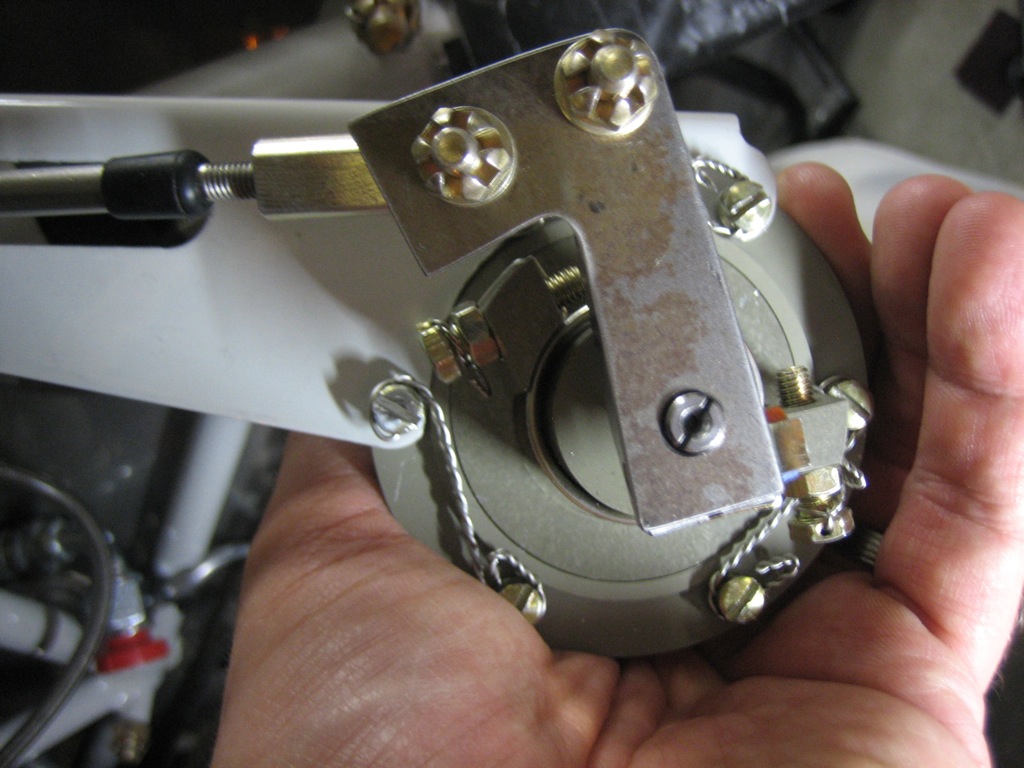

I’ve been trying to decide how I’m going to attach the prop governor control cable rod end bearing to the prop governor arm. The issue is that the rod end bearing has to be installed with various washers to allow the bearing to have some freedom of movement and some protection in case the bearing fails. This requires an AN3-11 bolt which is too long to insert from the front side of the arm (between the governor and the arm). Reversing the bolt and installing it from the aft side doesn’t work either because the bolt ends up hitting one of the screws around the perimeter of the governor head. Van’s specifies an AN3-10A bolt, but that’s still too long and I really don’t think it’s a good idea to use a self-locking nut anywhere related to the engine control cables. I spoke with John DeJoris at Aircraft Propeller about this issue, and he suggested using one of their adaptor brackets. None of their stock ones looked like it would work, but it gave me a great idea how to make one. I fabricated this little bracket from some 16g sheet steel. It still needs to be cleaned up and powder coated, but this is how it will be installed. There is a 1/4″ hole that fits over the center shaft to prevent the bracket from shifting. It’s attached to the arm at the end with a short bolt and castellated nut. There is a flange that sticks out and has an extra hole for the bolt that attaches the control cable. This hole is positioned 1.5″ from the pivot point just like the hole in the arm, so the cable throw is identical. Since this offsets the attach point from the arm, I needed to turn the control head to allow the arm to be moved through the whole range. While this could probably have been done with the governor on the engine, I decided to pull it off and do the adjustment on the bench. I’m really glad I did too. It was pretty trivial to pull and replace, and it was far easier redoing all of this safety wire on the bench.

Here you can see that the bracket has a bend in it so that the rod end bearing doesn’t attach at such a steep angle (ignore the bearing alignment here; I hadn’t installed the jam nut to keep it from twisting).

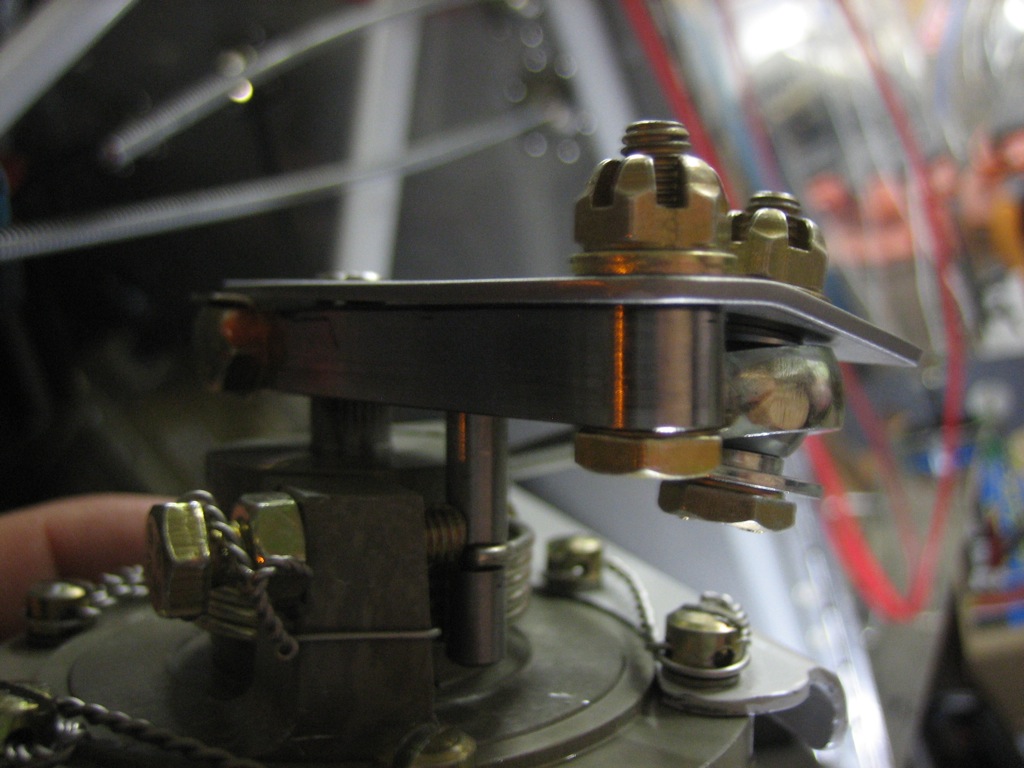

Here’s a good shot of how much better the bearing alignment is with that bend.

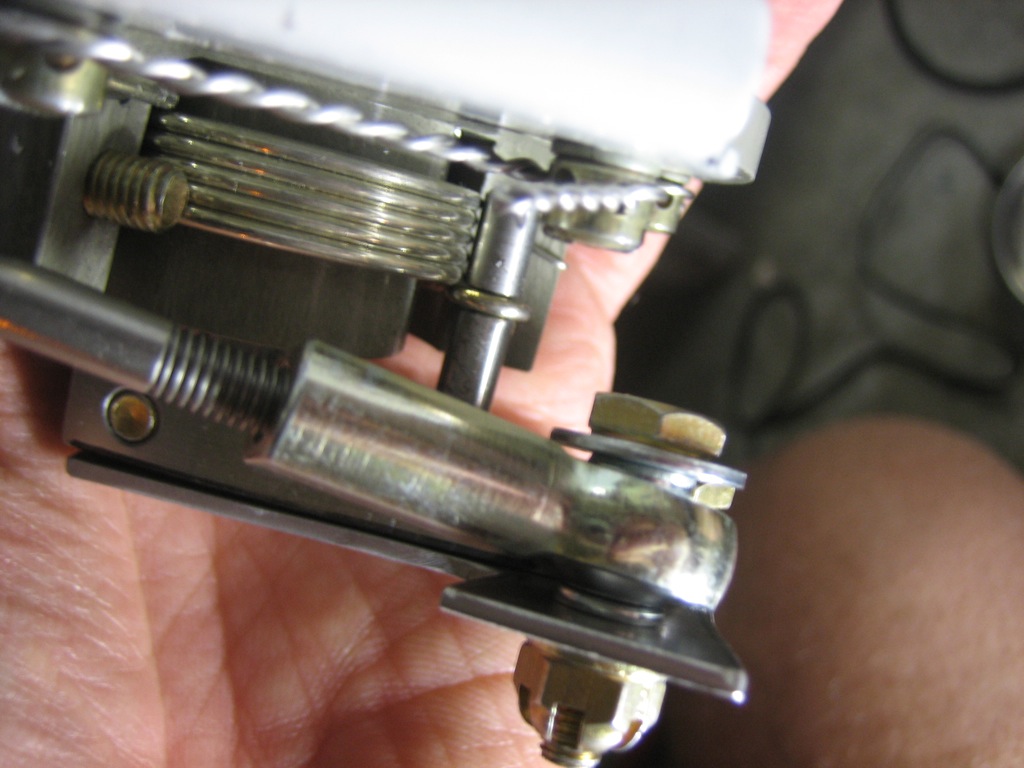

Here’s the control arm at the fine pitch stop. You can see the arm is a lot farther around (clockwise) than would work if the cable attached directly to the arm.

Here’s the control arm at the coarse pitch stop. You can tell from the last picture and this one that the overall throw is biased towards the fine pitch stop. This works beautifully because you’re pulling against a spring as you move towards the coarse pitch stop, but you’re gaining mechanical advantage as you pull because the cable and arm become more perpendicular. This means that the pull feels pretty linear. When I had the throw more evenly spread, the control cable required a fairly hard pull near the end to get the arm near the coarse pitch stop because you lost mechanical advantage and the spring force was the strongest.

After getting everything adjusted, I reinstalled the governor with new washers and lock washers, and then torqued/sealed the attach nuts.

Here’s the finished bracket. All it needs now is some cleanup and powder coating.