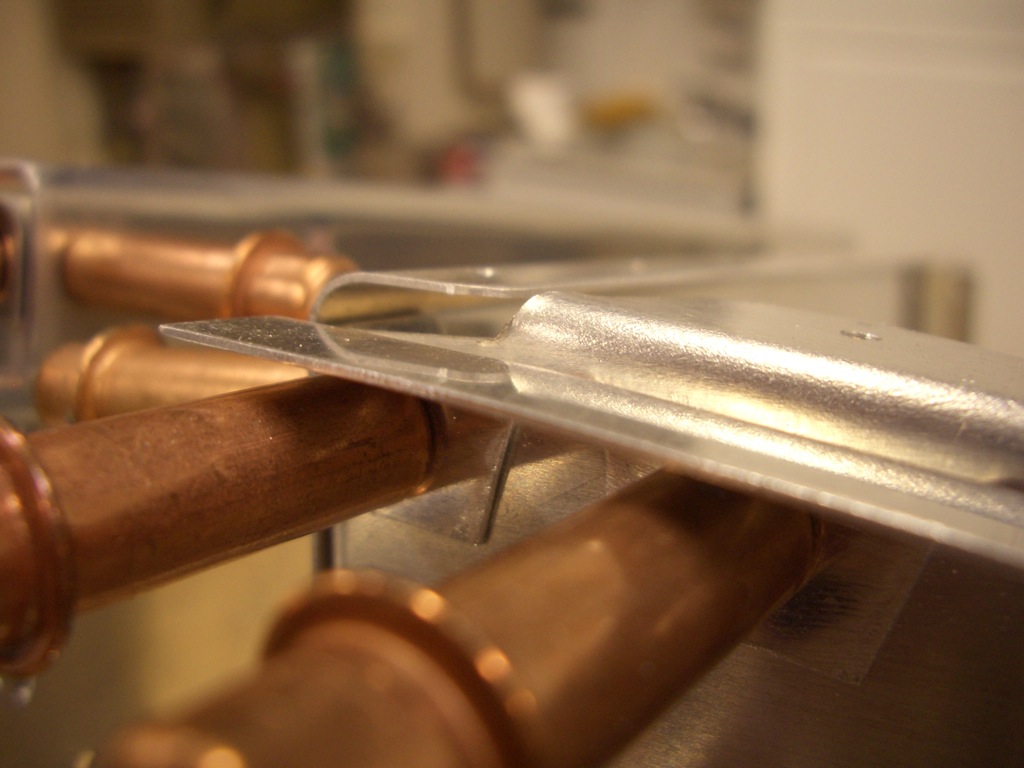

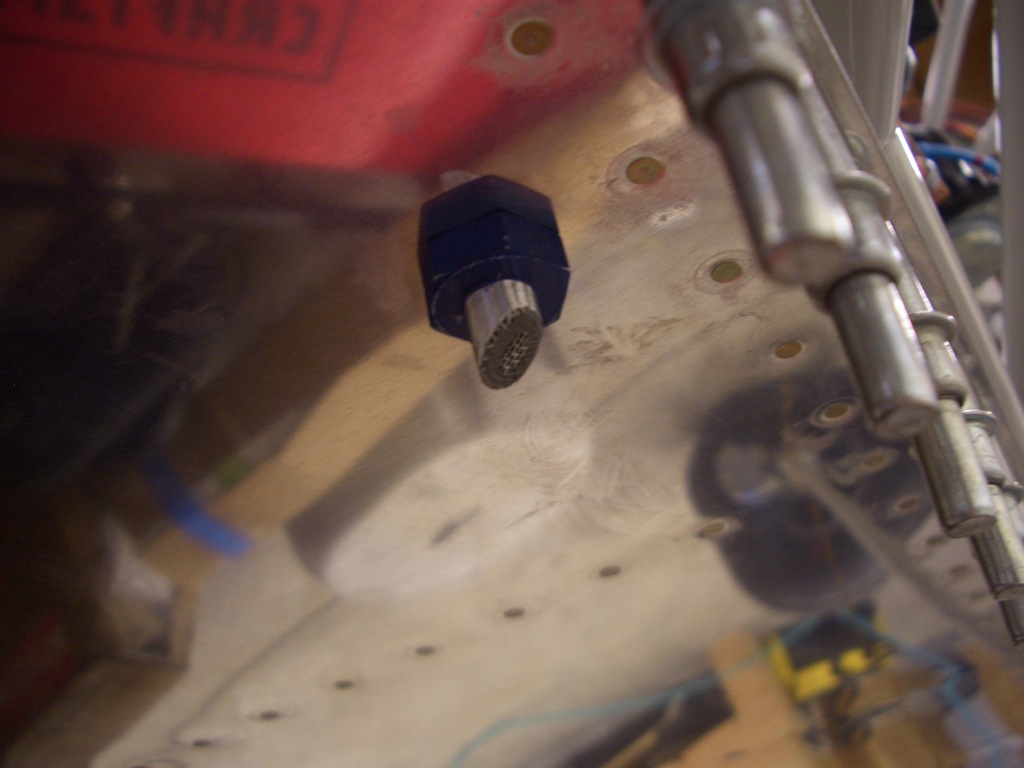

My order from Avery Tools showed up today. One of the items was a cover for the tach port. This is used for a tach cable if you have a mechanical tachometer. The Dynon will get its RPM information from the Light Speed Engineering electronic ignition box. I safety wired this, but it really can’t prevent this from unscrewing since the center part of the cap is separate from the outer part. At least it would prevent it from falling off though.

I don’t know if the high pressure fuel screen will need to be cleaned frequently or not. If so, I might want to find another place to safety wire this to so that it doesn’t run across the fitting.

My daughter was a big help with this. She kept pointing to parts on the engine and asking “what’s that?”

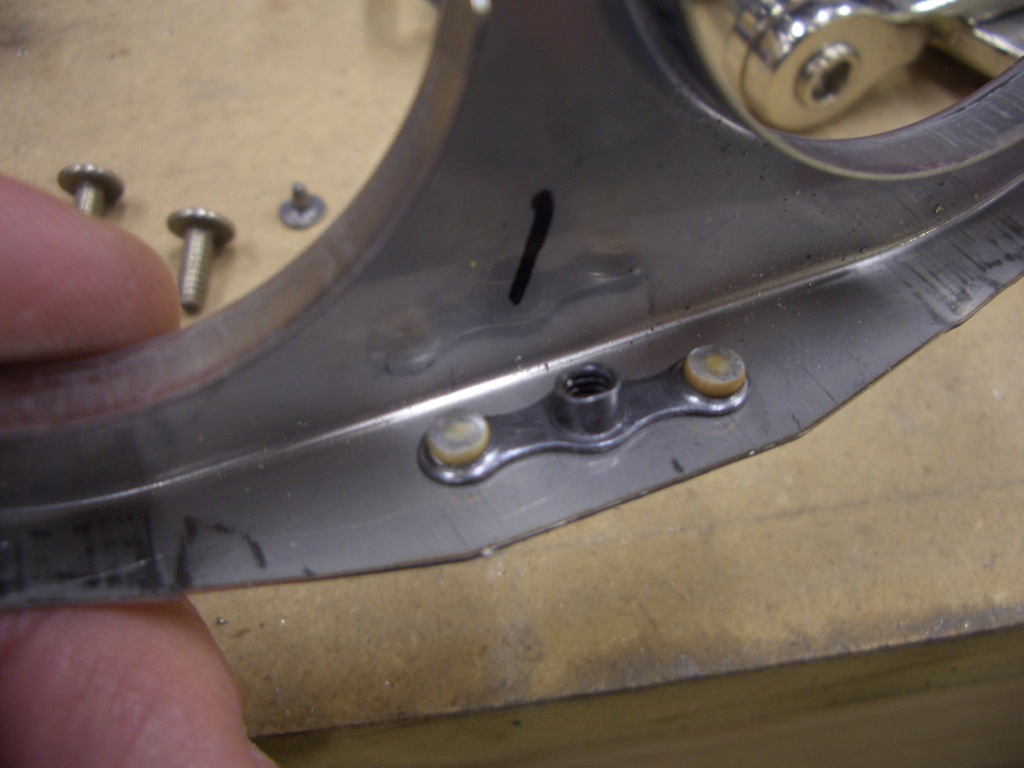

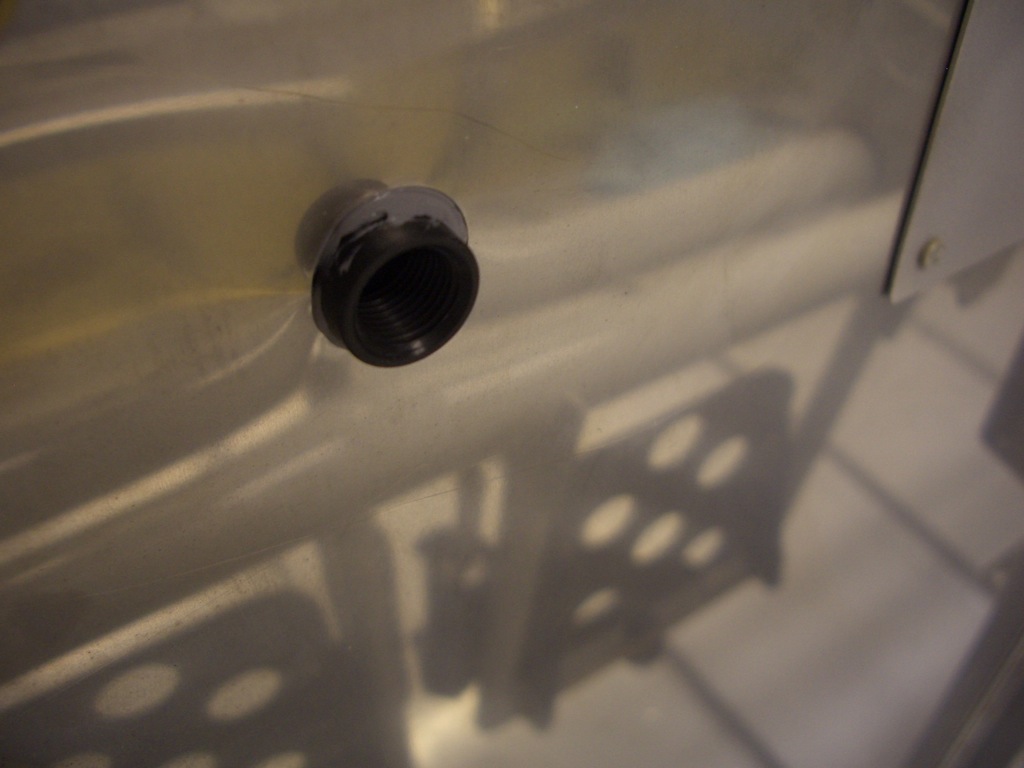

I also removed the regular 45º fuel outlet fitting and installed a 90º tee fitting. The bottom silver part of the fitting will connect to the fuel injection system. The black fitting has a restrictor inside and will tie into the fuel pressure transducer.

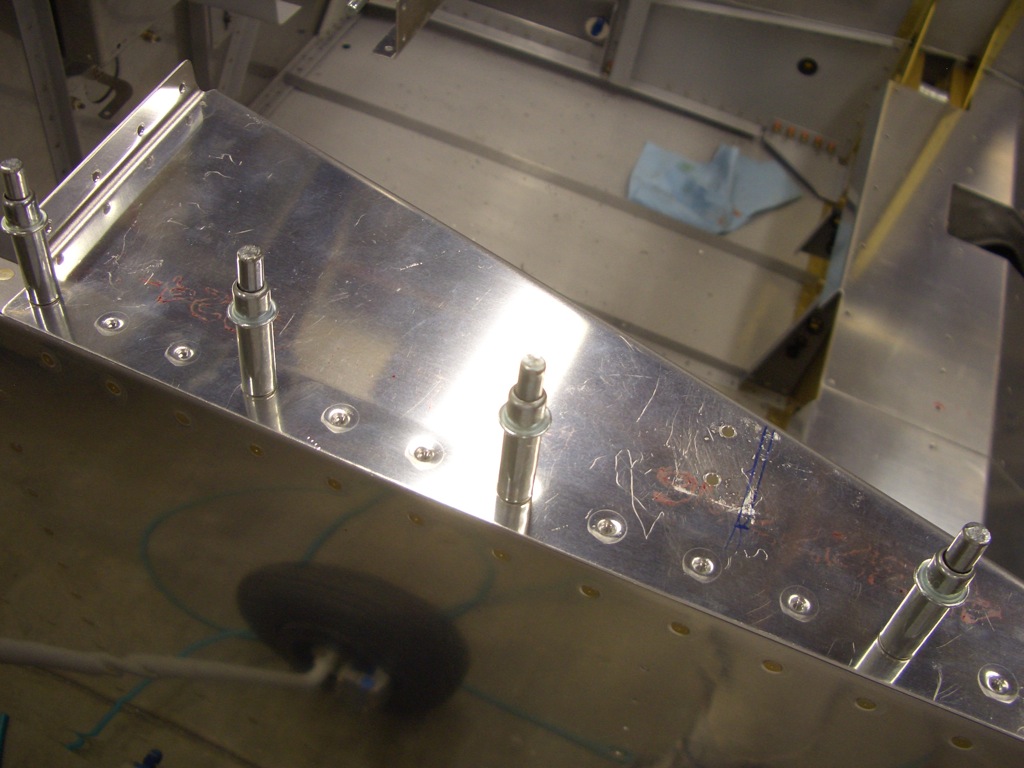

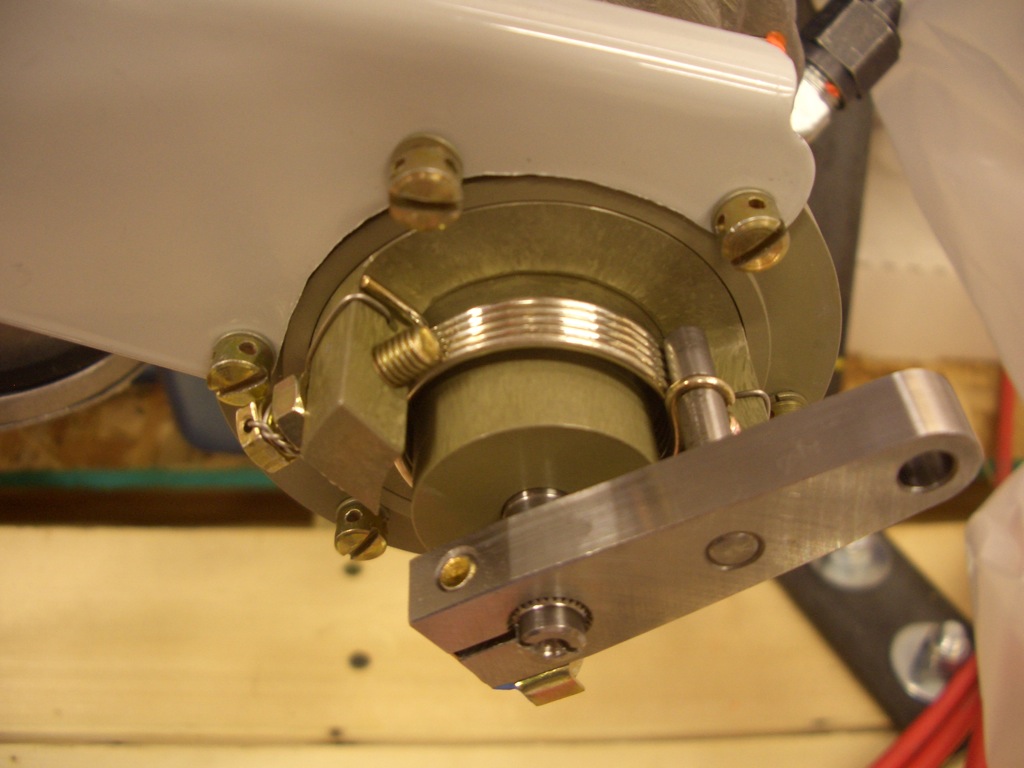

I also got an order from Van’s that included the prop governor cable bracket. After some grinding of the inner radius and elongating a couple of the holes slightly, it fits quite well. I had to cut off the safety wire for all six screw holding this ring on so that I could rotate the head and control arm. I can’t determine the final position of the control head until my prop cable shows up next week.

Here’s the entire bracket. The cable housing attaches to a hole on the left side and the cable passes through the slot in the bracket.

I also got an order from Aircraft Spruce that included some steel fittings to replace the aluminum ones I had installed for the brake lines. I’m trying to use steel fittings for all firewall penetrations if possible.

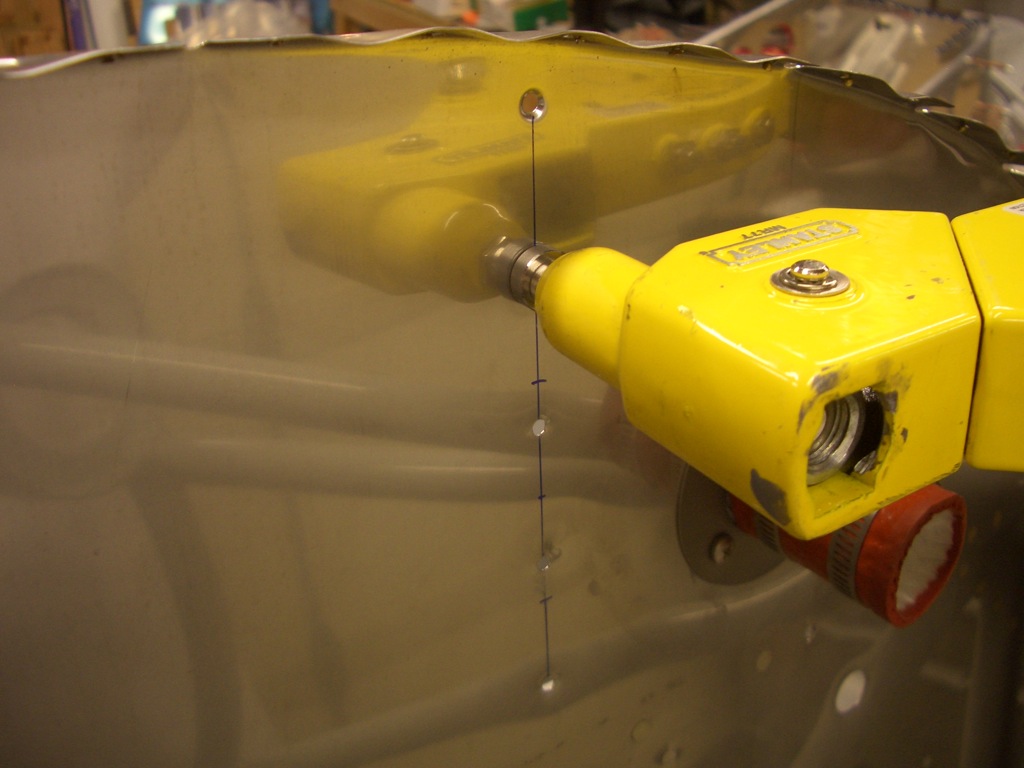

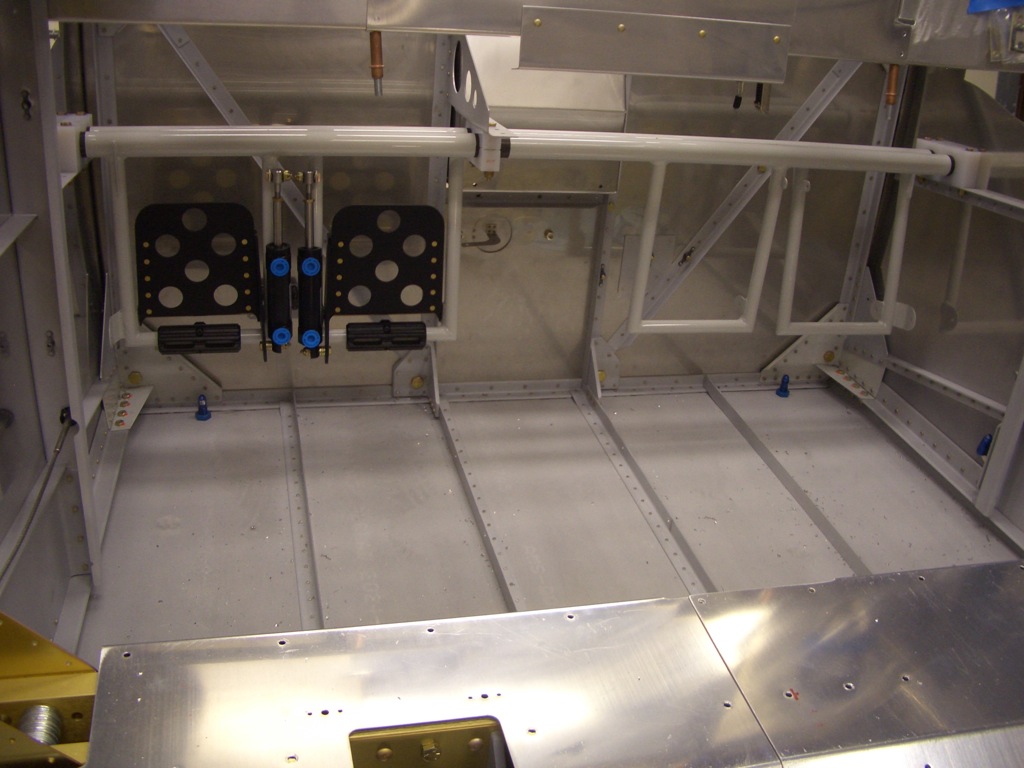

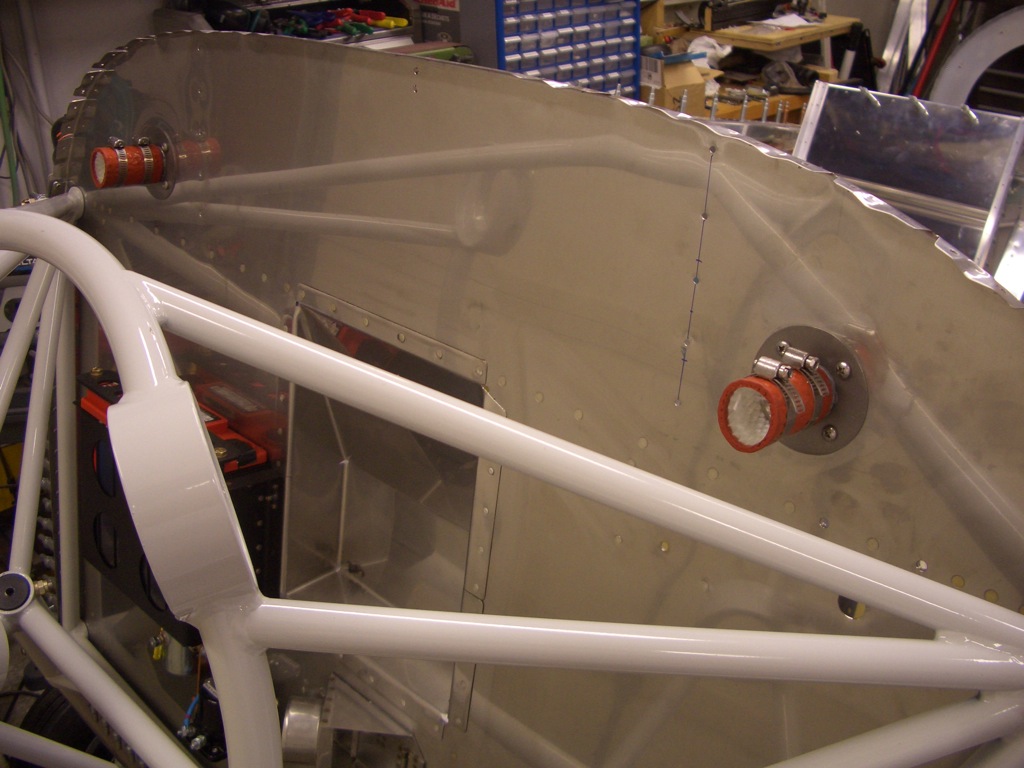

My order from Avery Tools included a couple of firewall pass-throughs from SafeAir1. These have a stainless steel tube with a spun flange so there are no sharp edges. I installed them with some 2000º fireproof sealant and then installed the outer fire sleeve and clamps.

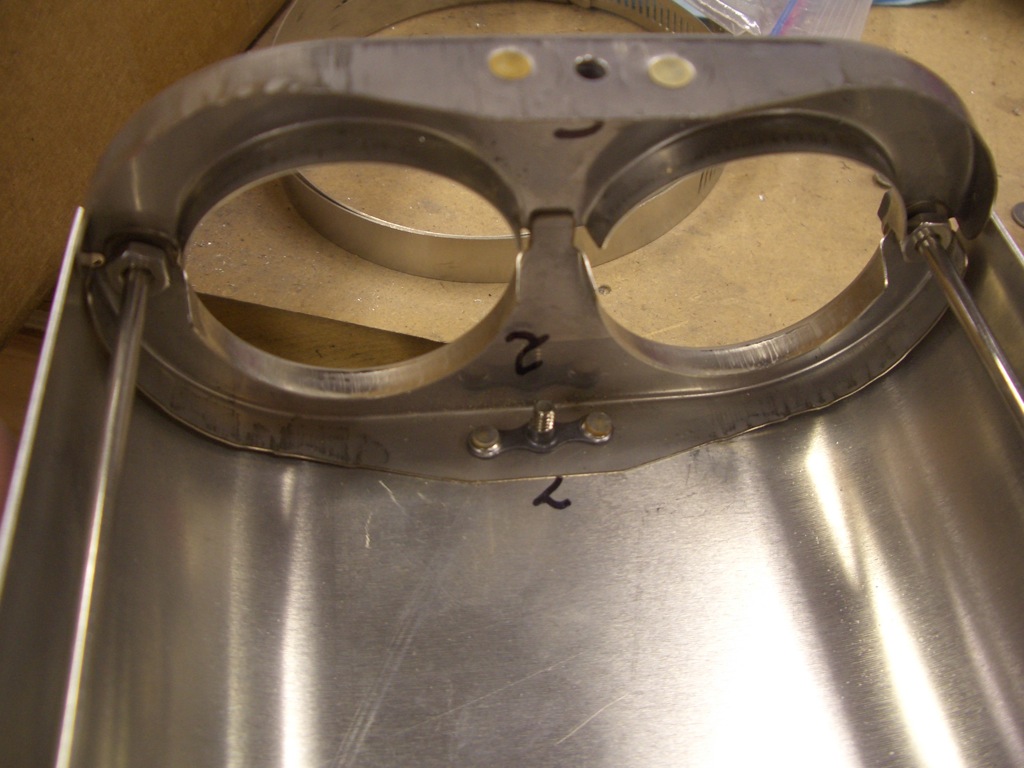

Here you can see through the pass-through. These each provide a 1″ opening for all of the wires that need to penetrate the firewall. I’ll use the one on the right side for all of the large power wires and the one of the left for all of the engine sensors. After the wires are installed, they’re wrapped tight with another piece of fire sleeving and some silicone tape and then pushed into the tube. The outer piece of fire sleeve is then slipped in place and the clamps are tightened.