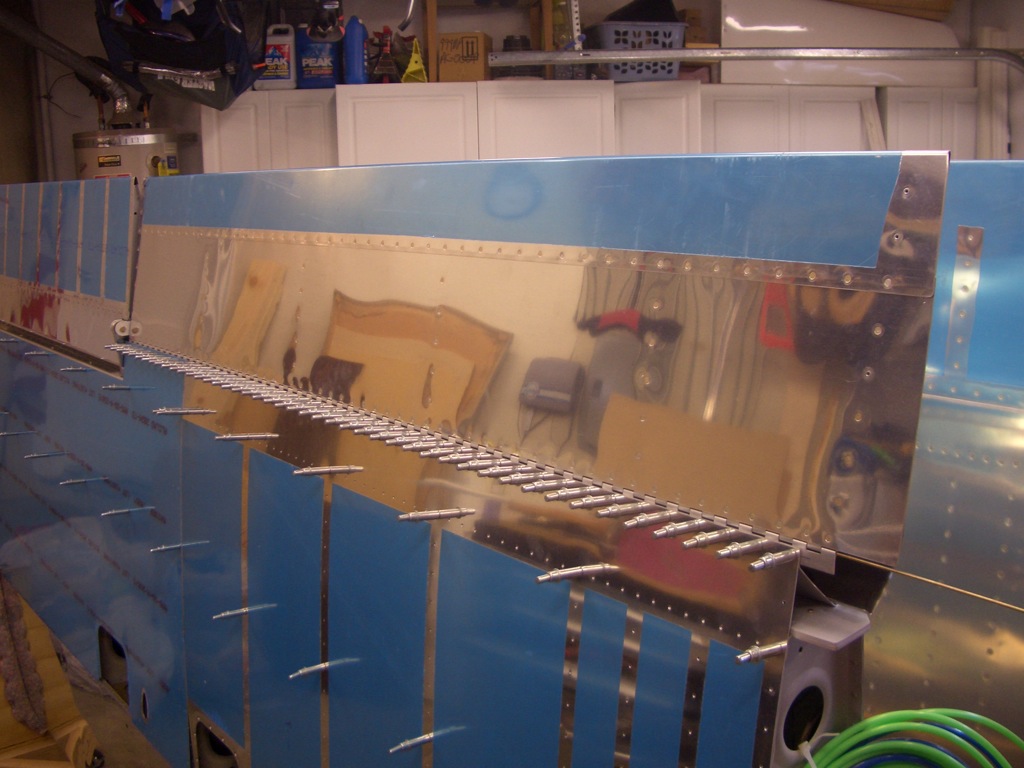

I got up this morning and drilled the left flap before work. This side didn’t end up quite as good as the right side (the flap trailing edge ended up about 1/64″ below the aileron trailing edge as it’s standing vertically like this). I looked around at a bunch of builders websites and this is apparently a really common problem and 1/64″ is actually better than most. I don’t think I’m going to replace the hinge since it could easily end up worse. I may be able to tweak a few things to make it just about disappear when finally riveted together.

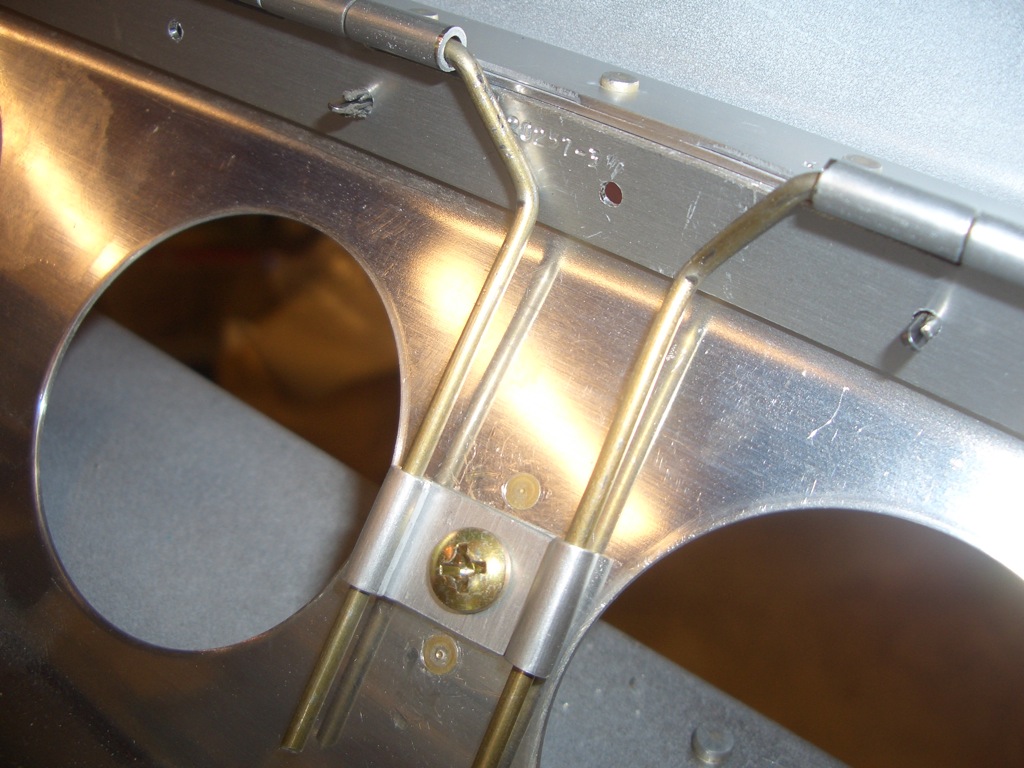

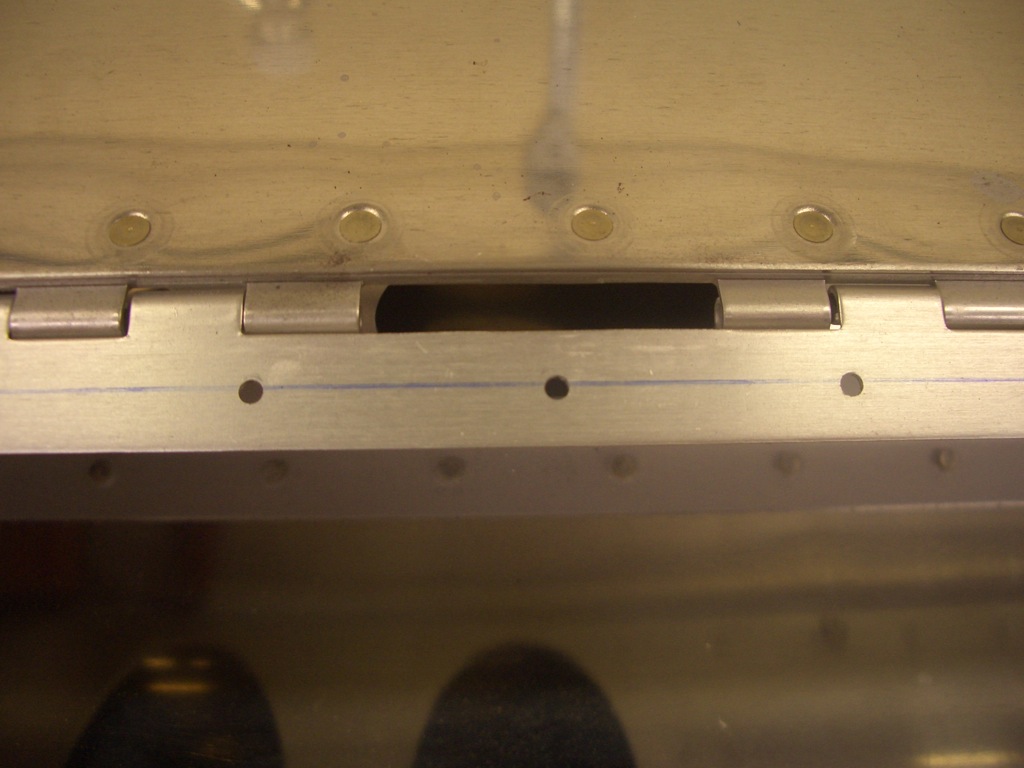

Van’s offers a couple of suggestions for securing the flap hinge pin. The first is to drill a hole in the inboard aileron bracket that’s intentionally slightly out of alignment with the hinge pin. The hinge pin is then inserted through this hole and the misalignment prevents the pin from sliding back out. The other suggestion (which most builders including me go with) is to remove several of the hinge loops near the center of the hinge and then secure the hinge pins against the flap brace. Here I’ve removed one loop on the flap side and two on the wing side. You can also see here how close the rivet holes ended up to my line drawn at 1/4″ from the lower edge.

I drilled the flap brace for the #8 nutplate and riveted it on with a couple of oops rivets.

Here you can see how the hinge pins are secured. The bends in the hinge pins prevent the pins from migrating toward the ends of the flaps and interfering with either the ailerons or the fuselage. The clip (which I made by cutting a couple of loops off of some extra hinge material) will keep the hinge pin from migrating inboard. I’ll cut off the extra pin material that’s sticking out beyond the clip the next time I have the flap off of the wing.