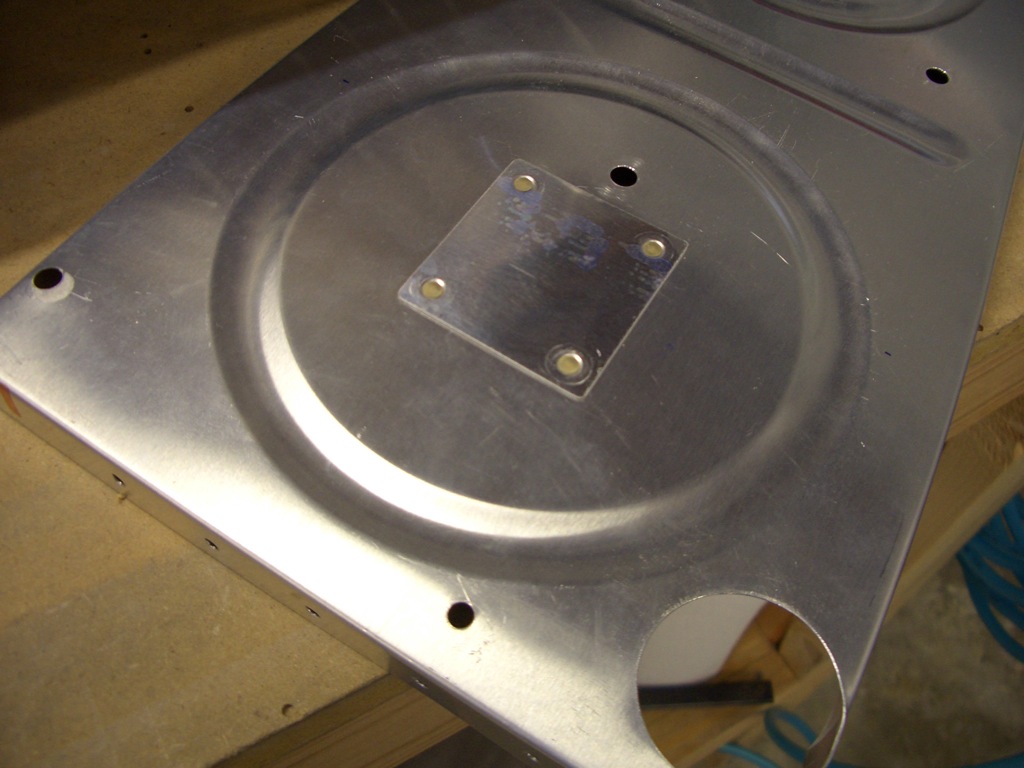

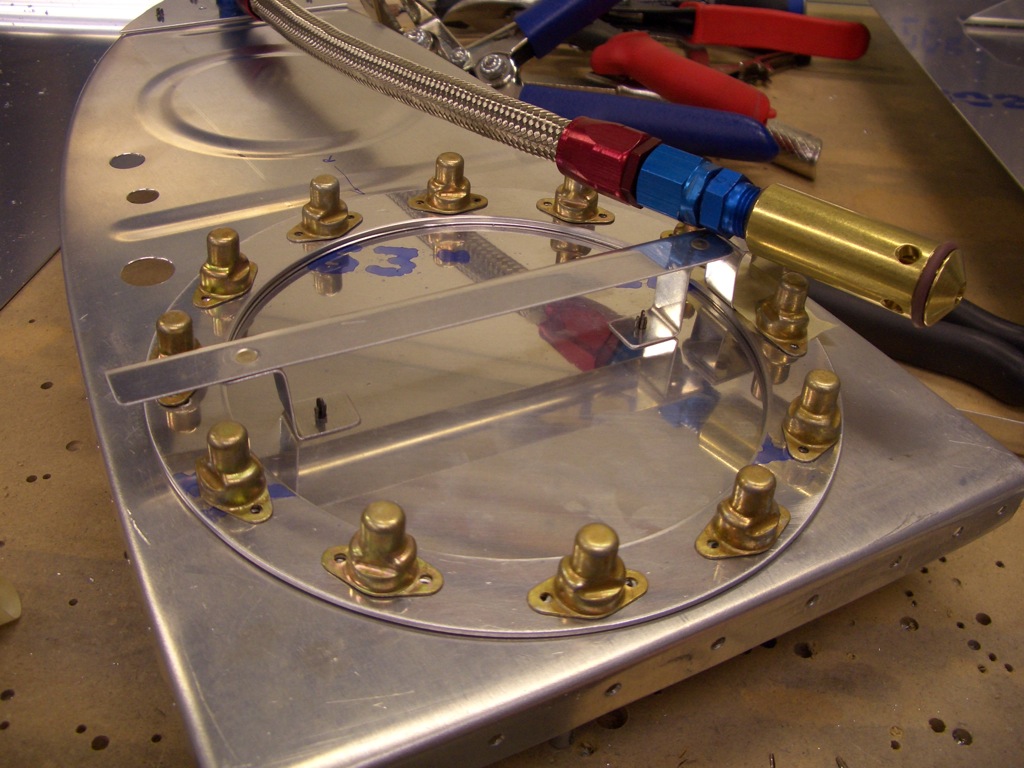

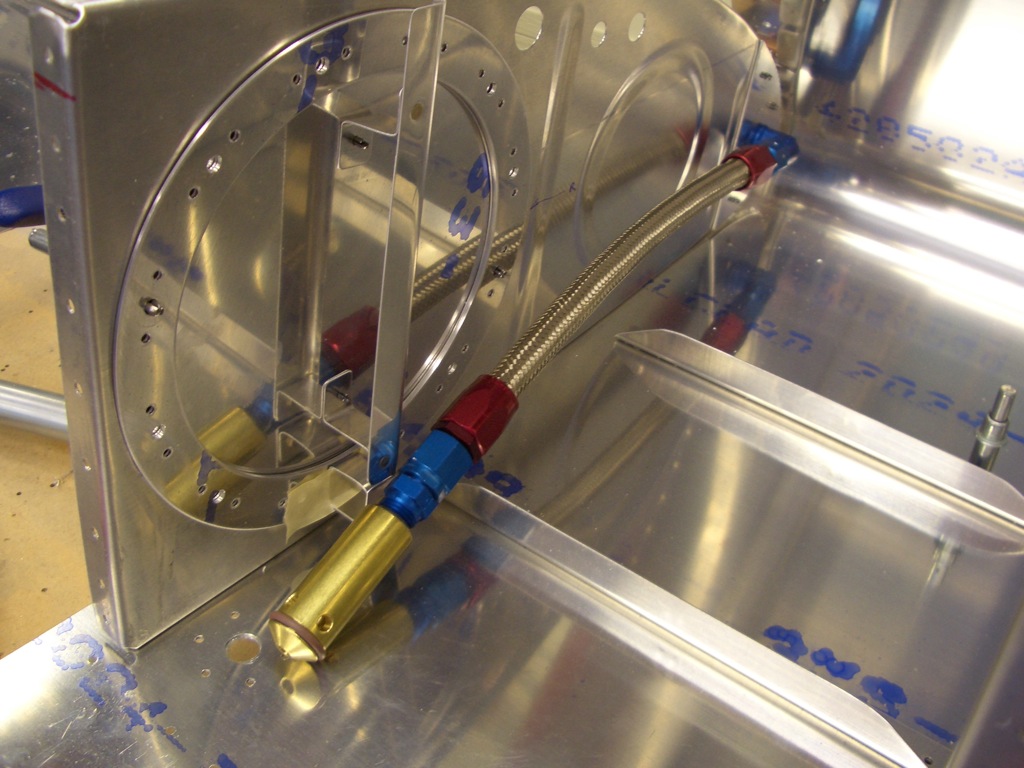

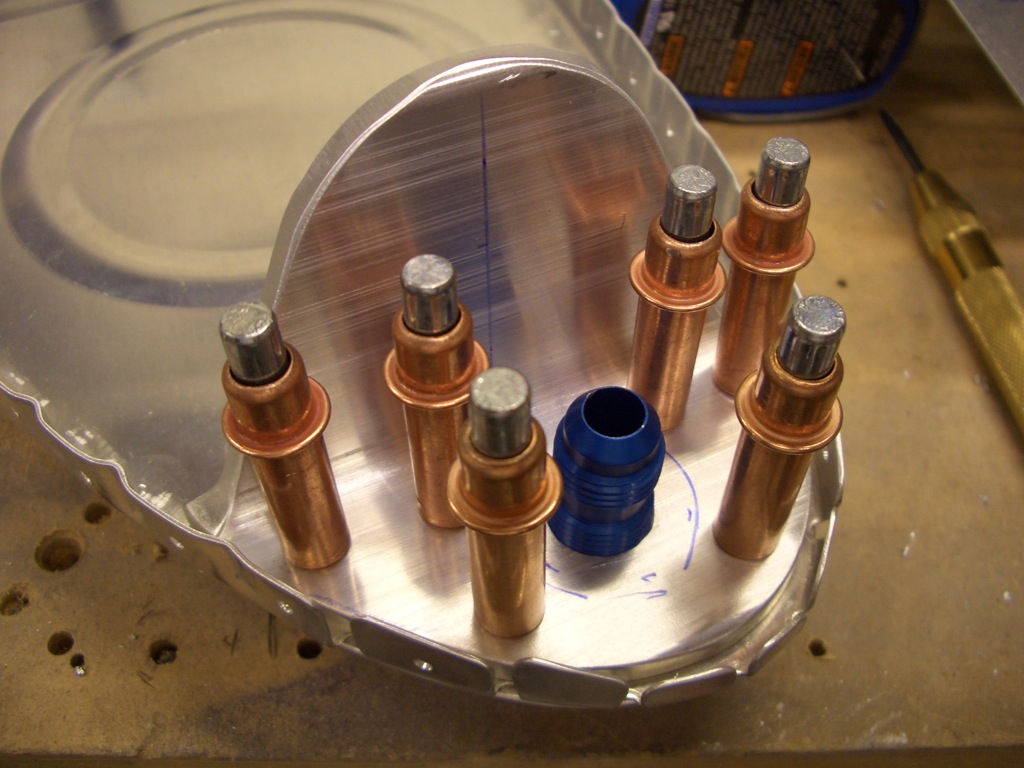

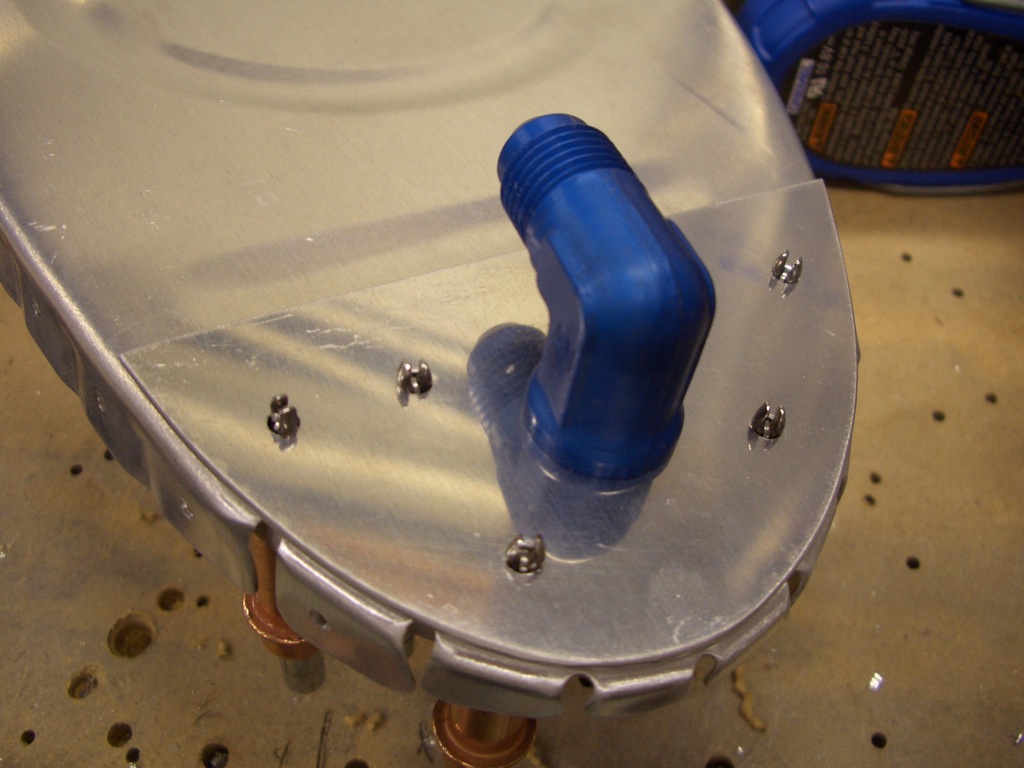

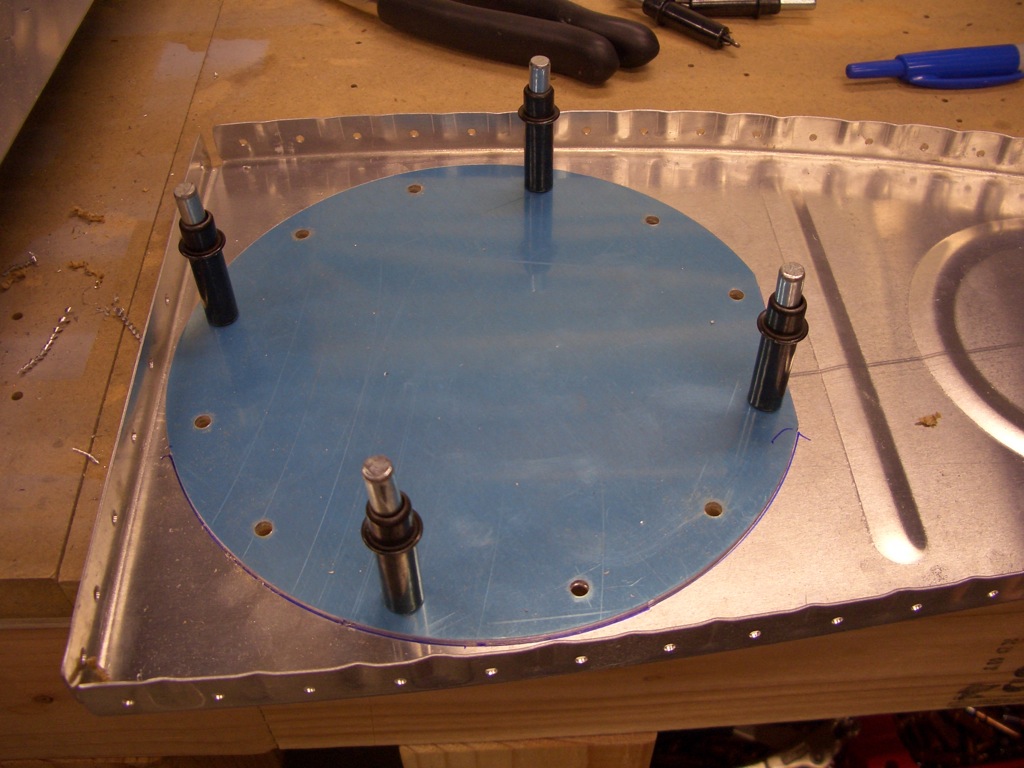

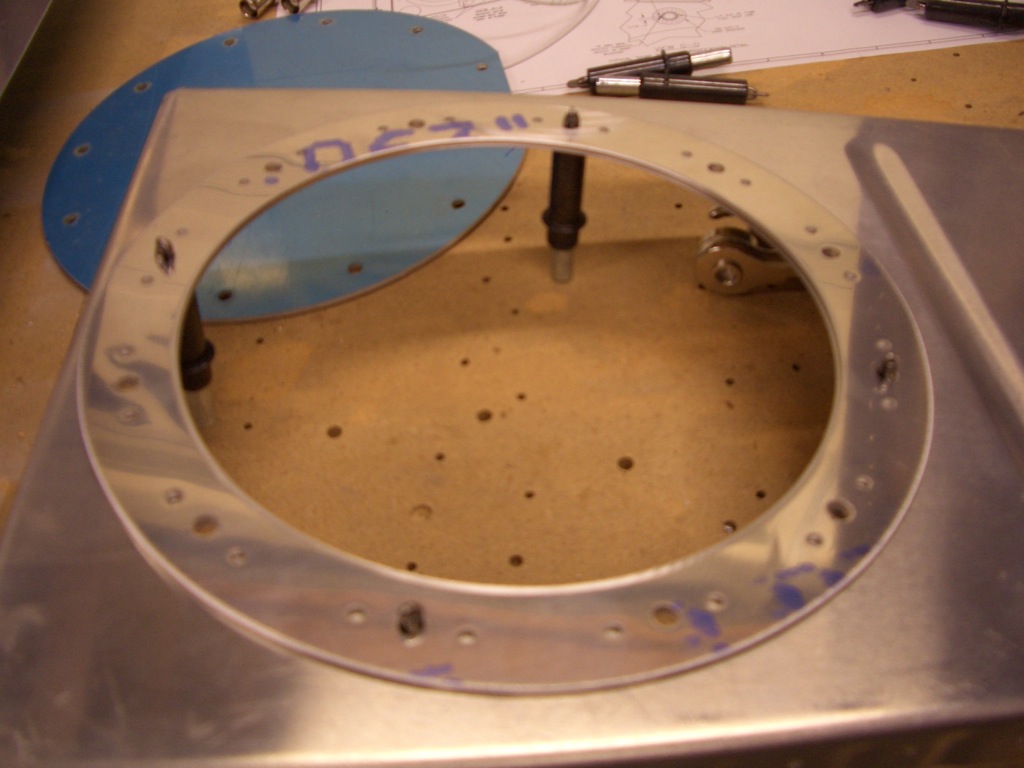

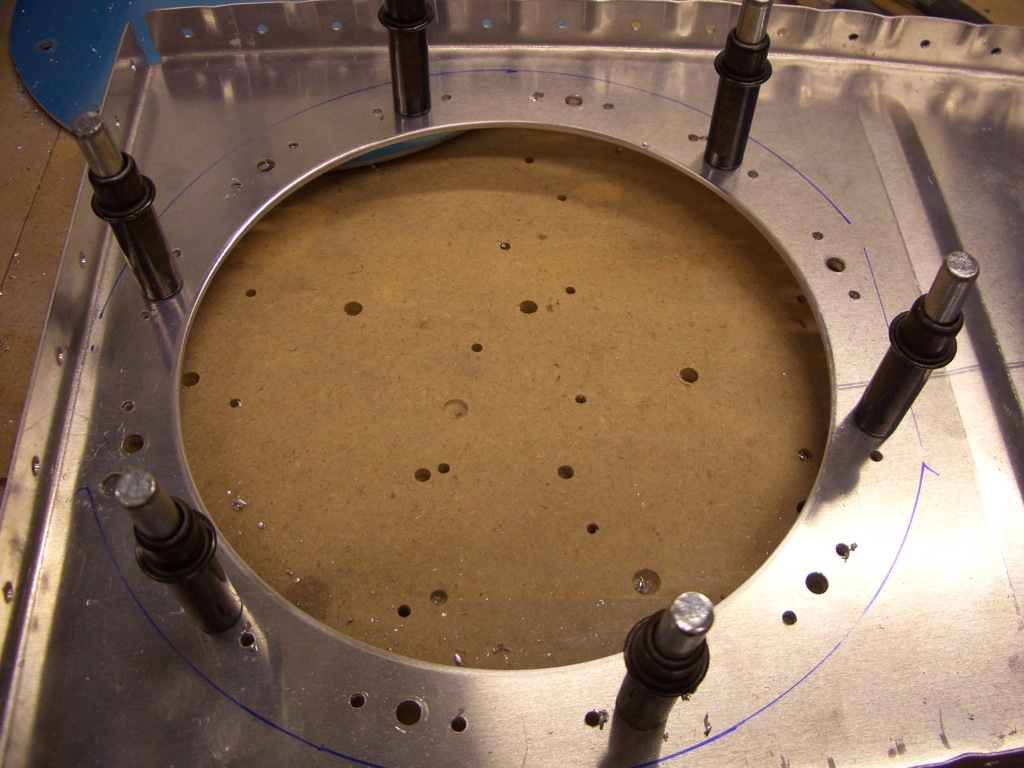

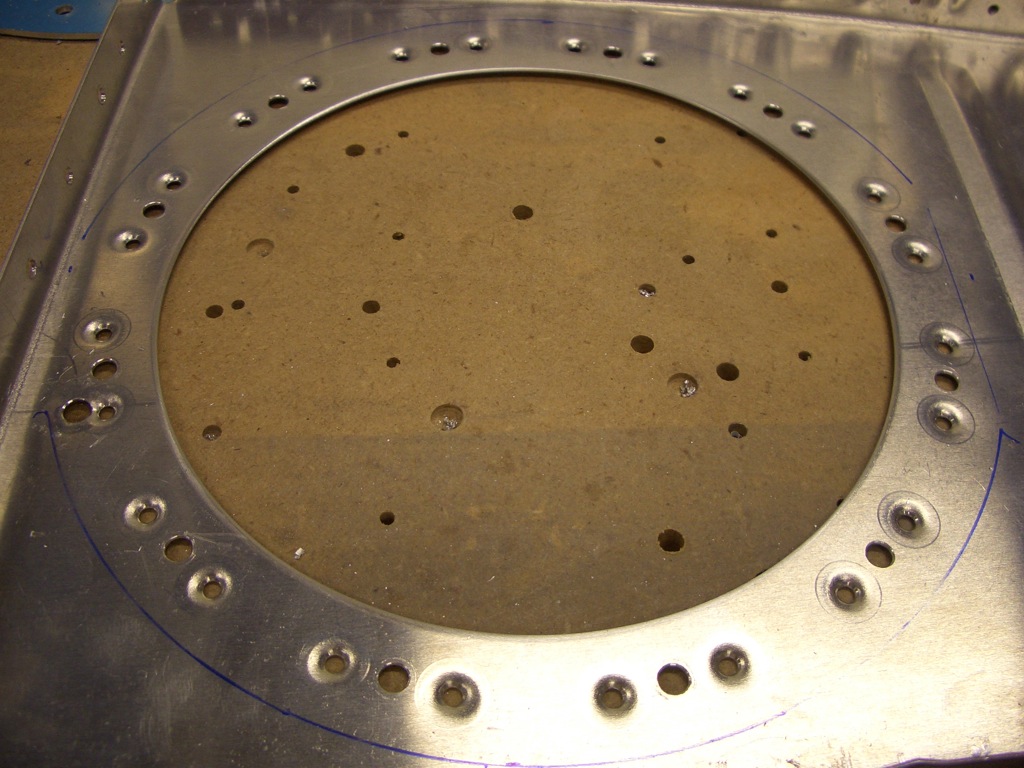

I made two-part anti-hangup guides to prevent the flop tubes from getting hung up on the nutplates surrounding the access plates. The plans call for a single piece guide that rivets across the opening. The problem with this is that it severely impedes access to the interior of the tank if I ever need to open it up for some reason. Most of this two-part guide is attached to the access plate and comes off with the plate, providing unimpeded access to the interior of the tank.

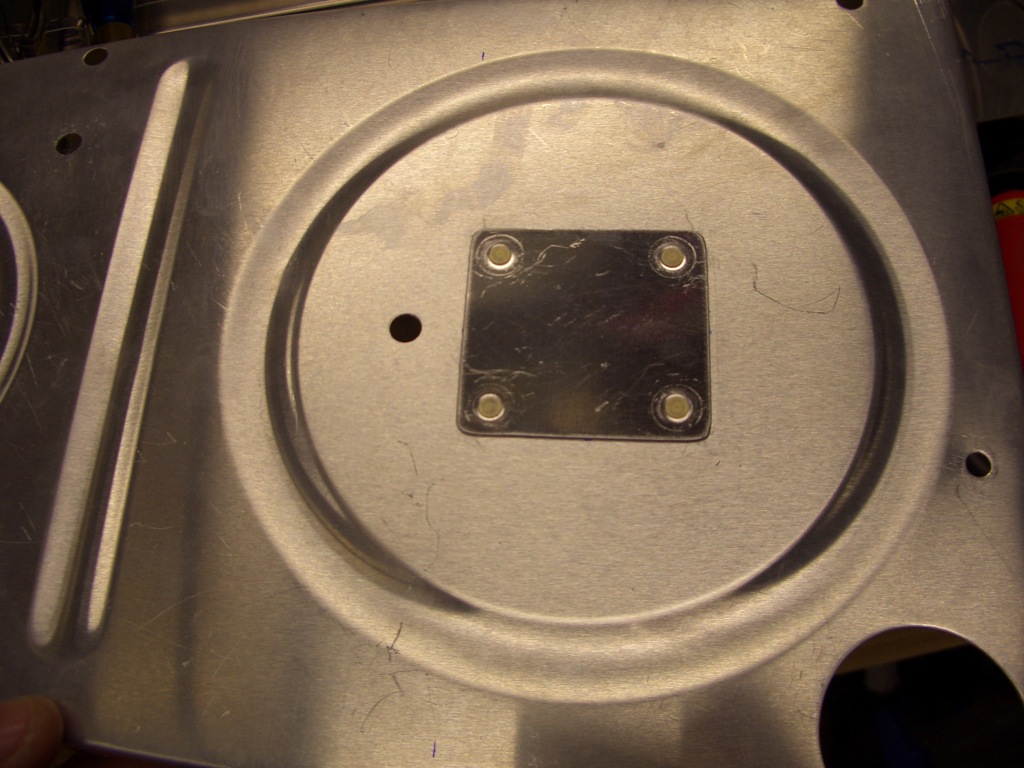

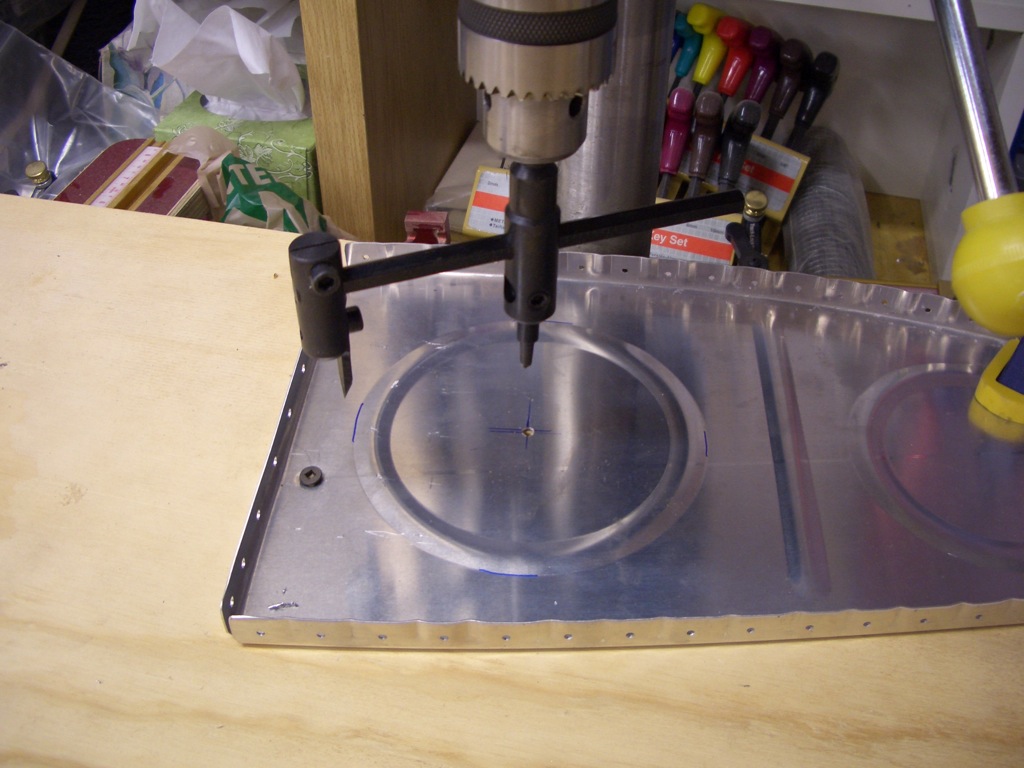

I also riveted covers over the large holes in the second ribs to keep fuel in the inboard bays during knife edge flight.