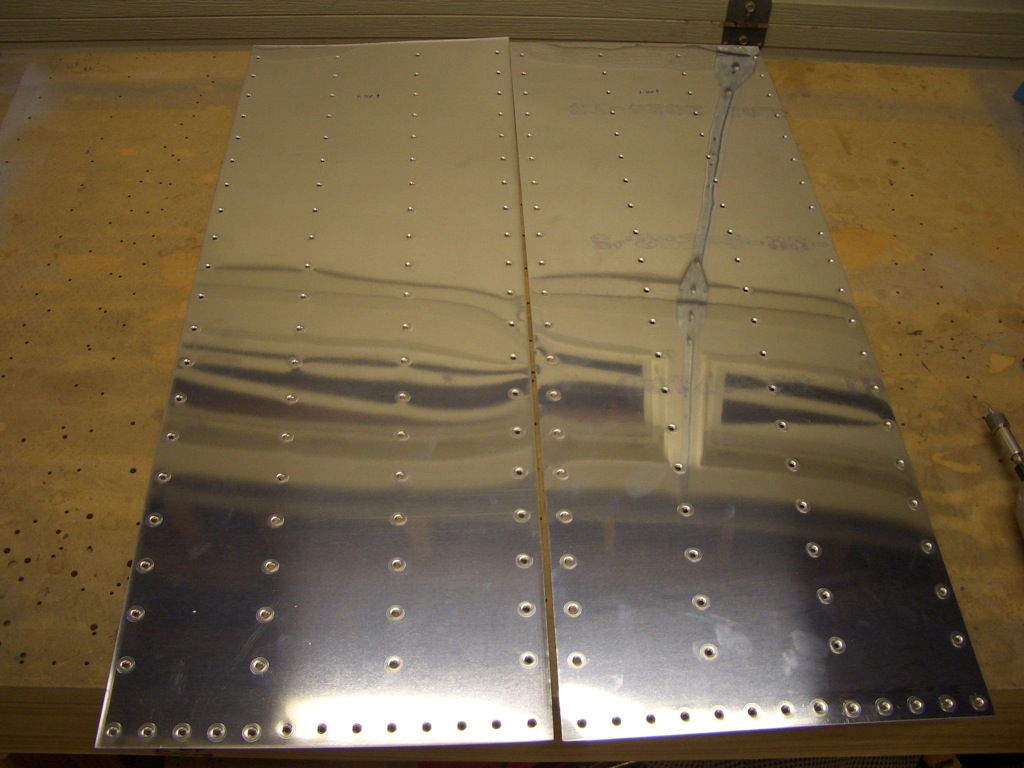

I finished deburring and dimpling the right wing’s rear spar and then started working on the leading edge to tank joint. If you recall from a week or so ago, the tank and leading edge skins aren’t perfectly flush along the joint. To fix this, I needed to shim out the outboard leading edge skin to be flush with the tank skin.

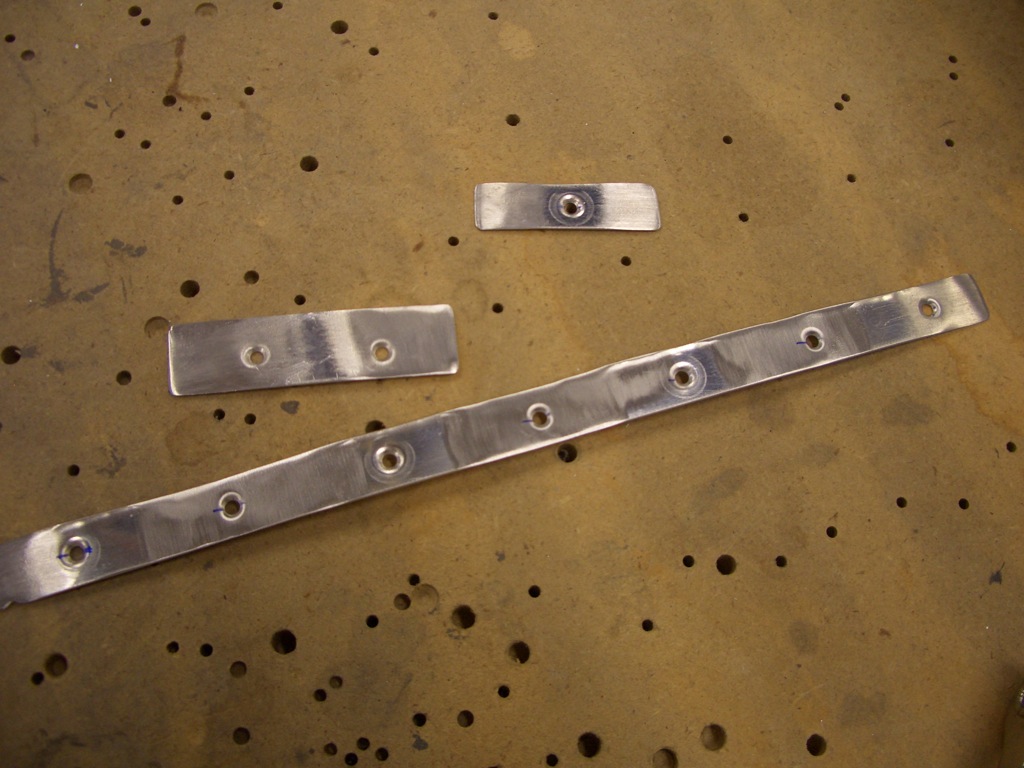

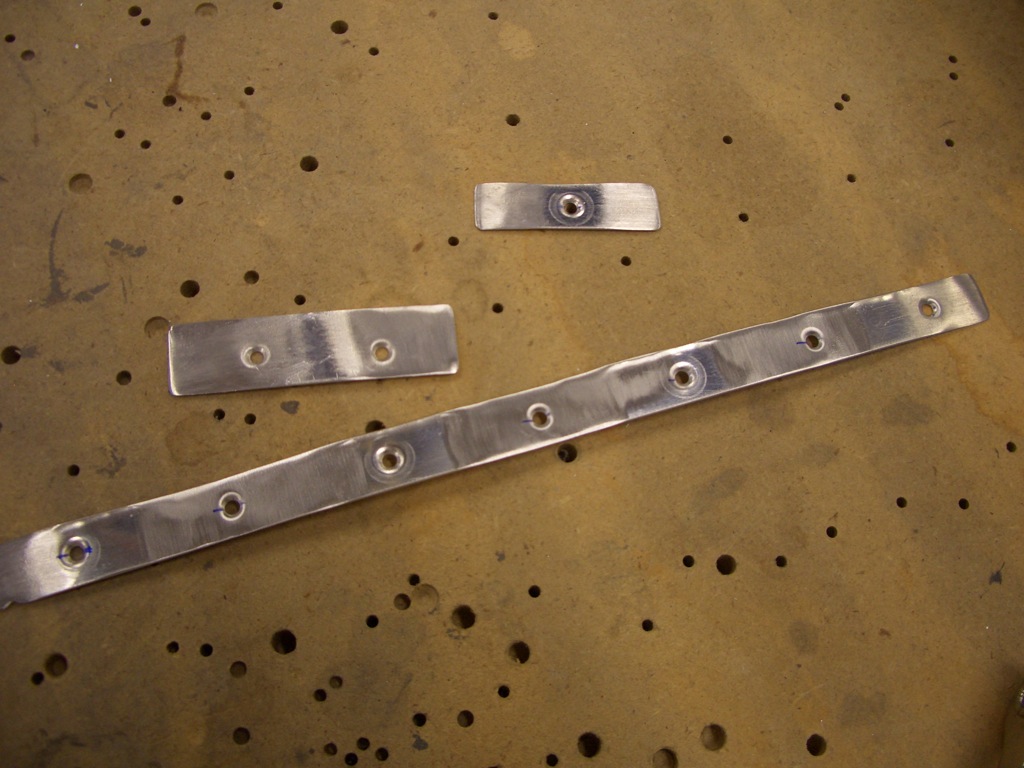

I took some measurements along the joint to see how much shimming needed to be done and then drilled out all of the rivets on the inboard rib of the outboard leading edge section (the one containing the tank splice plate). Next, I fabricated a few shims shown below for one side of one of the joints. If you click the picture to zoom in, you can see that parts of the shims have been run against the scotchbrite wheel to vary the thickness along the shim.

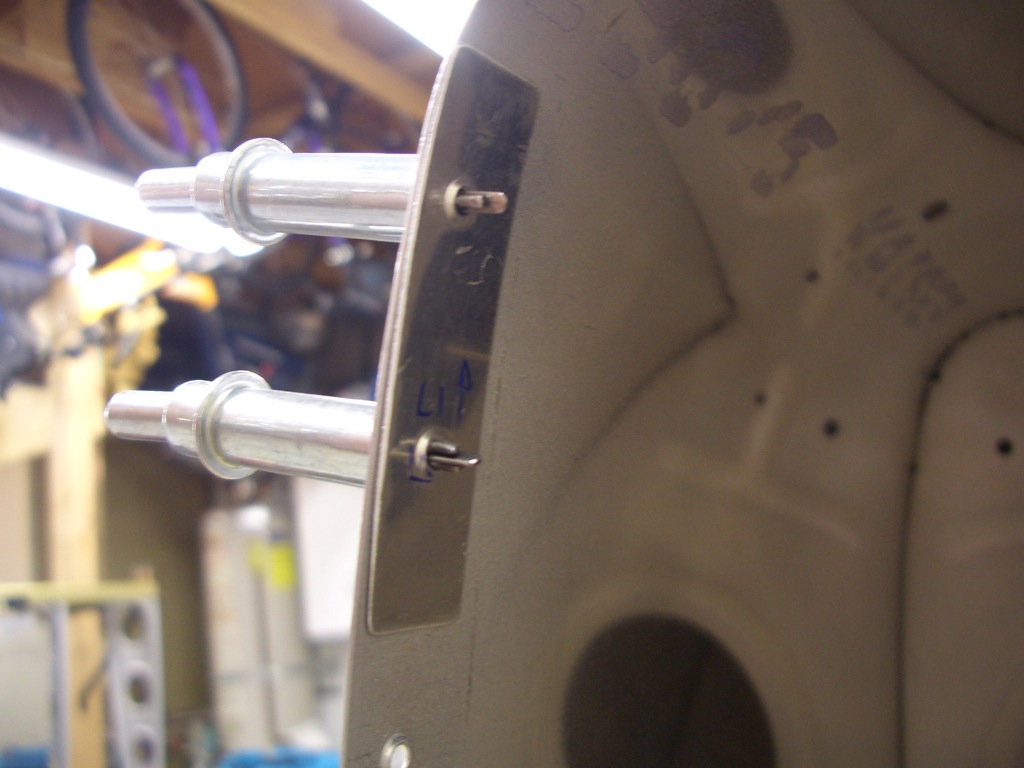

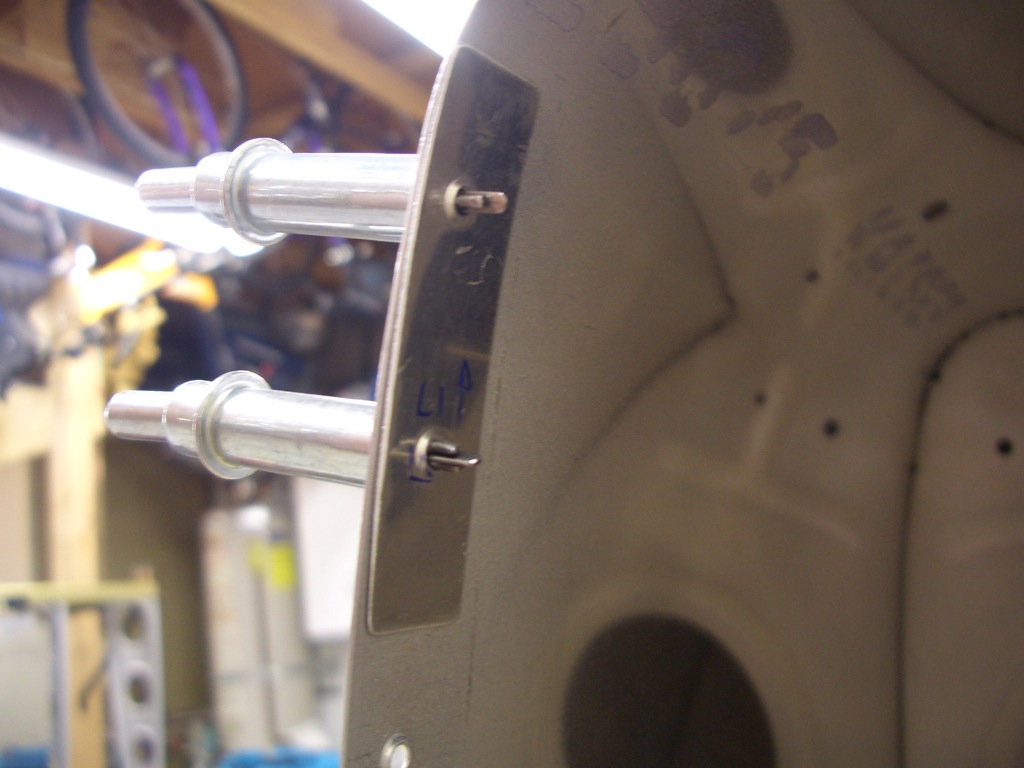

Here you can see one of the shims in place on the inside of the outboard leading edge skin. These still need some fine tuning and will need to be primed before they’re installed. These shims are only for the bottom side of the right wing, so there are quite a few more shims to be fabricated before I can rivet this all back together and install the leading edges on the wings.