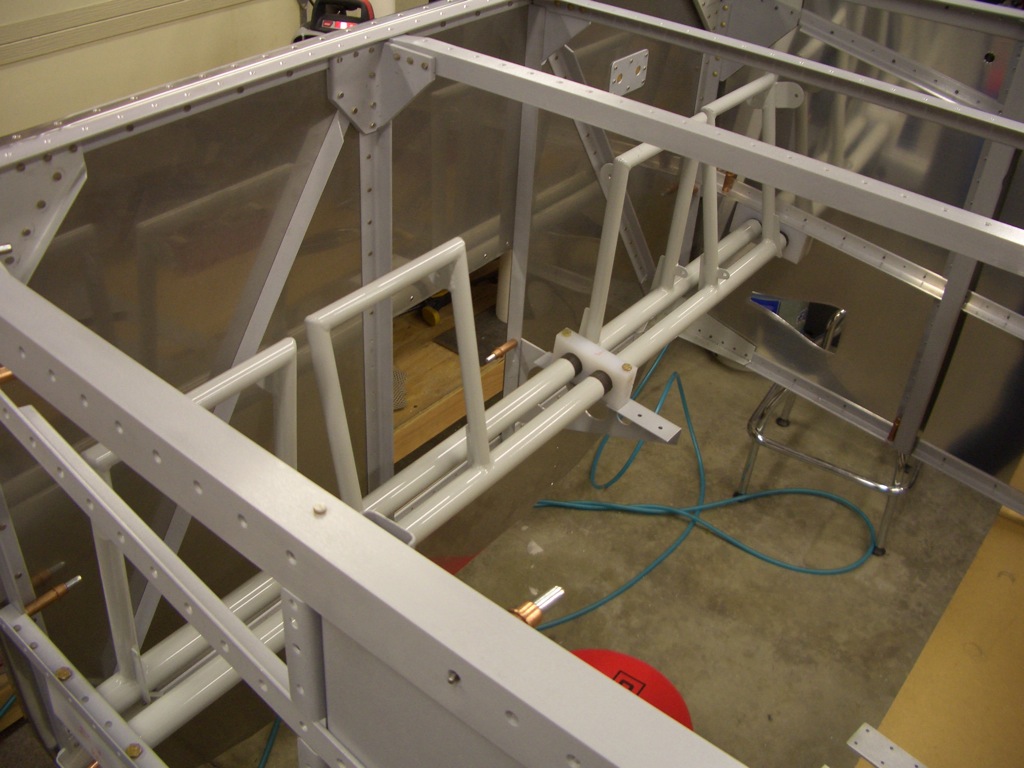

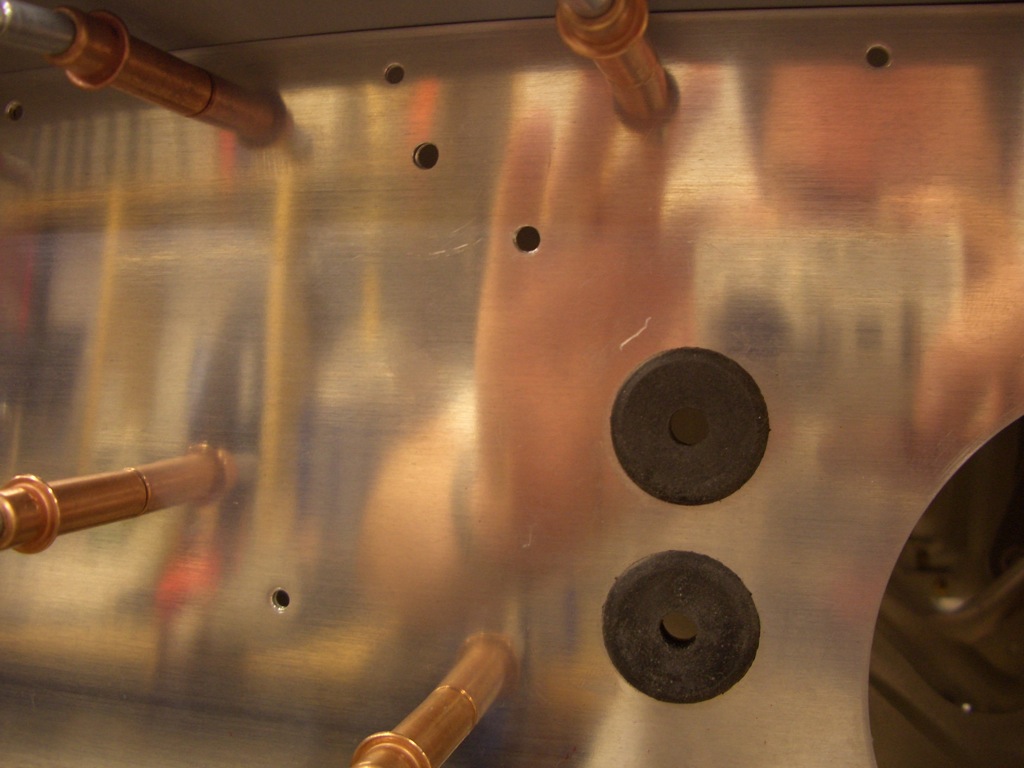

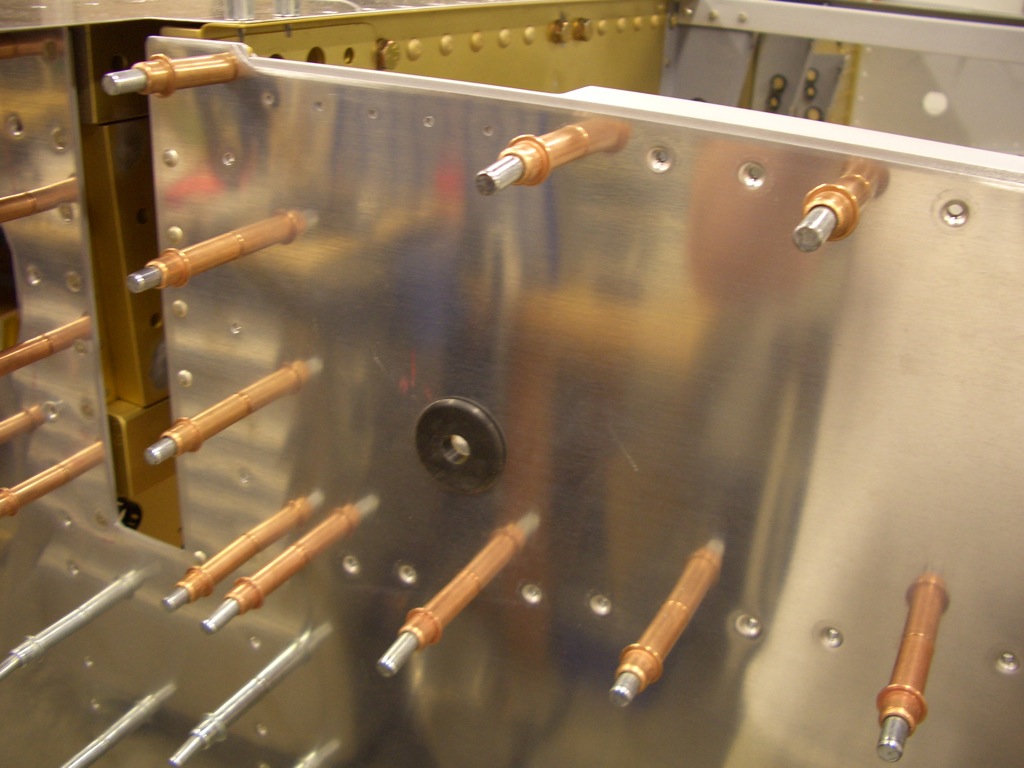

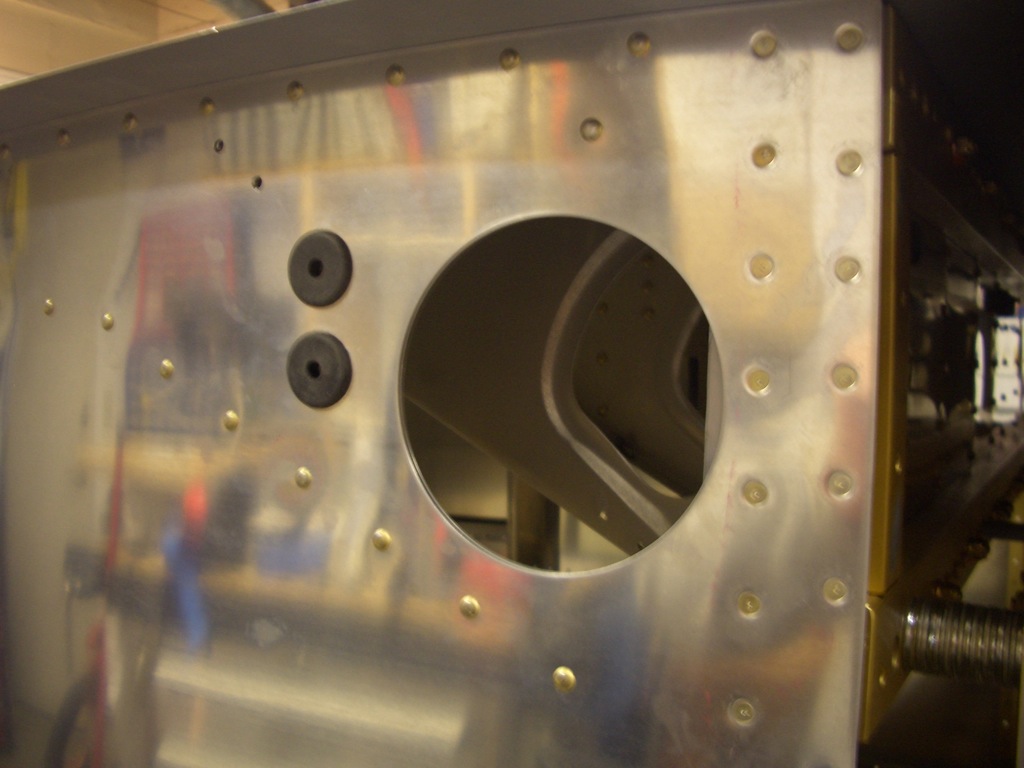

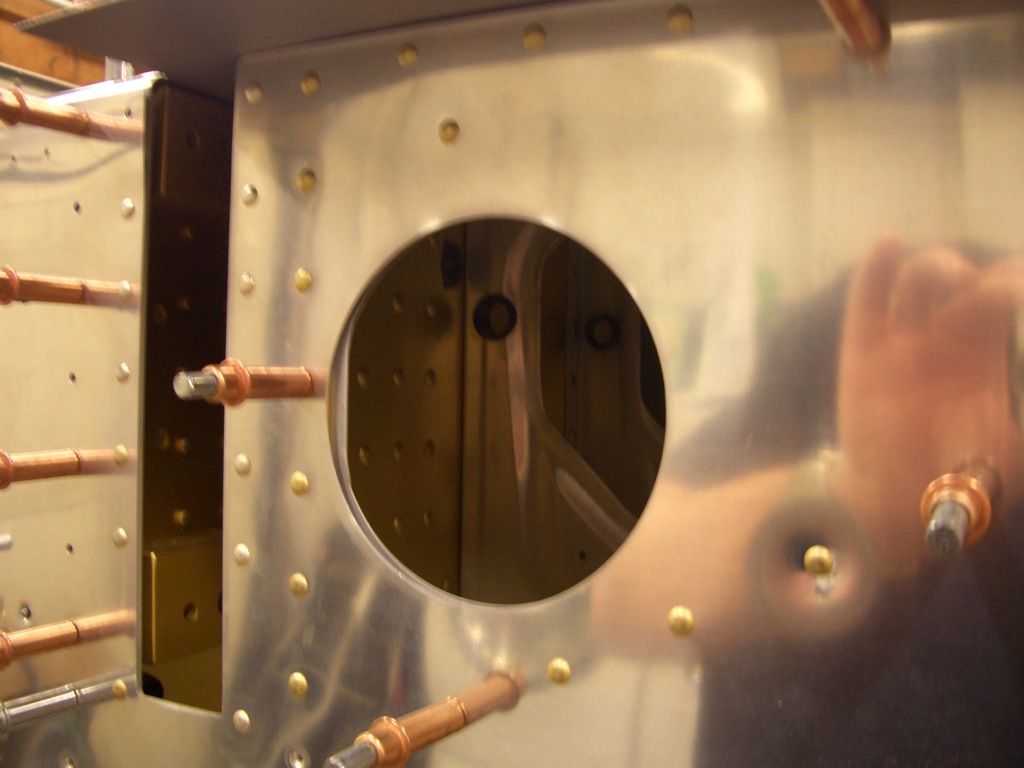

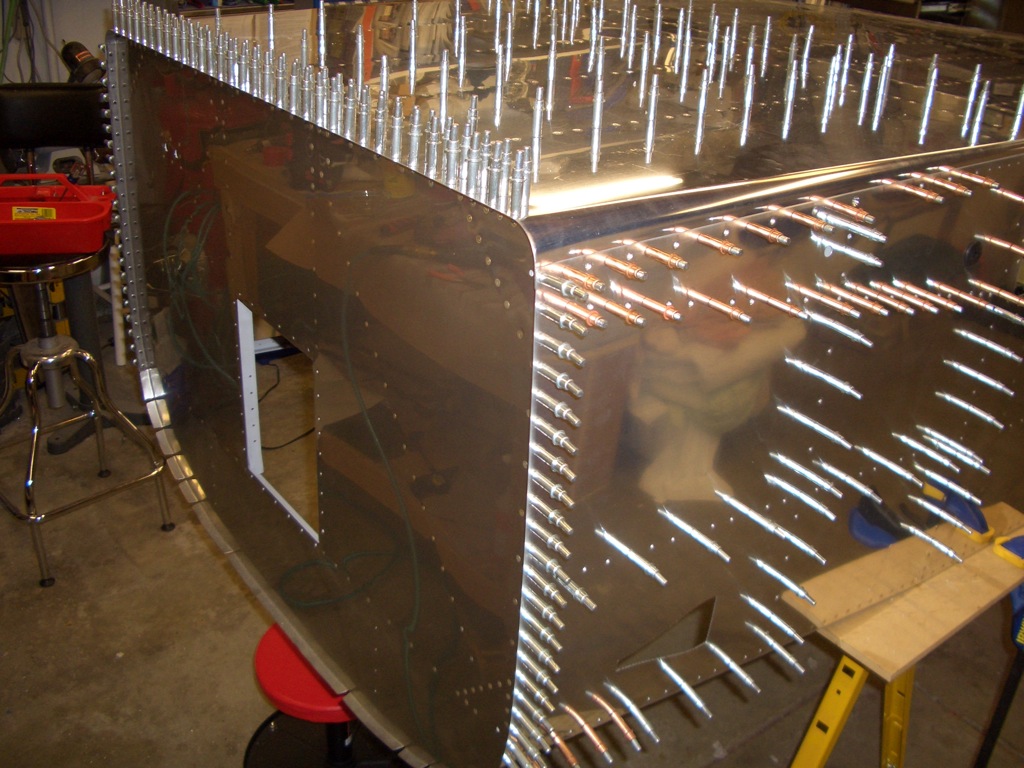

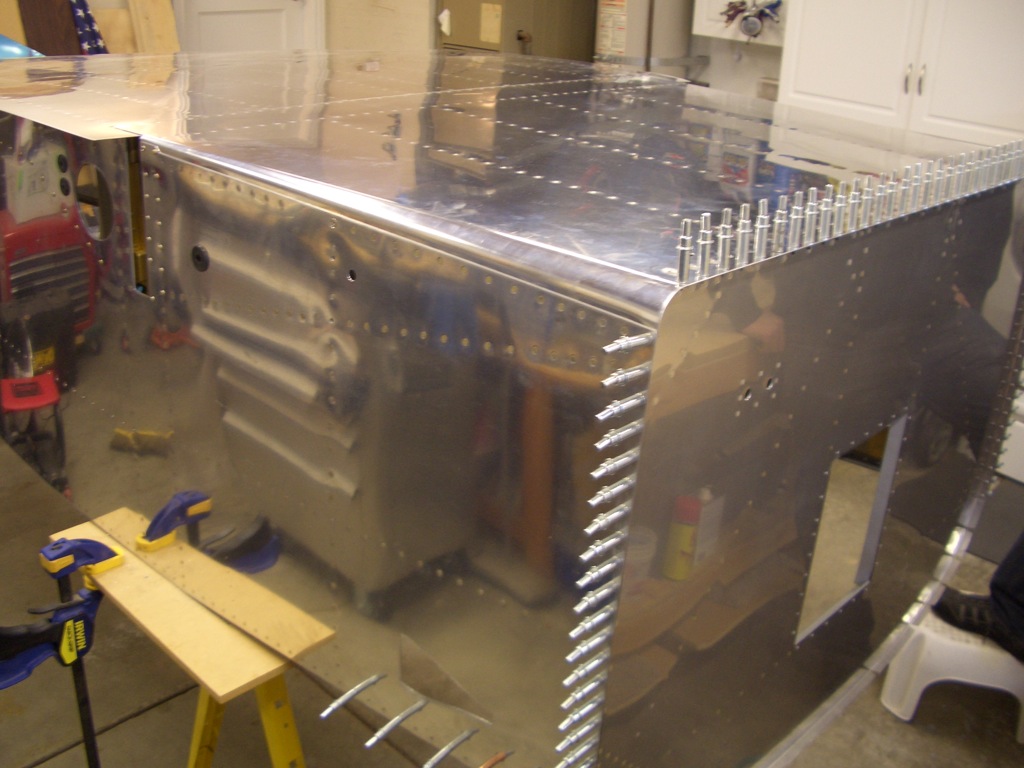

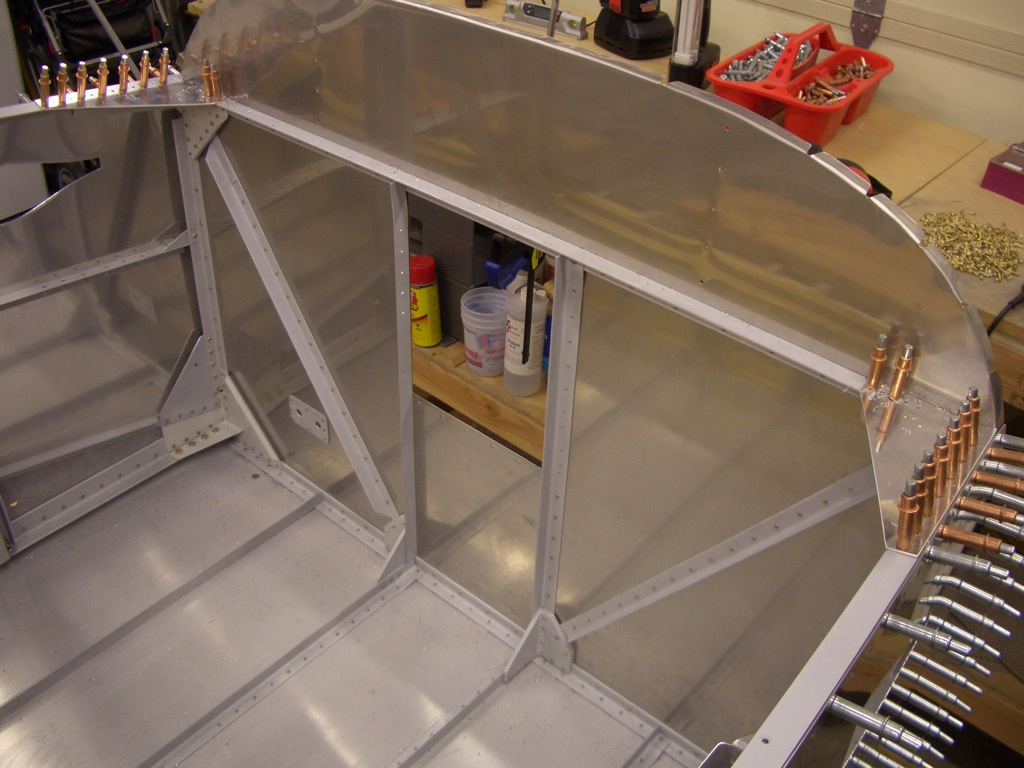

Andre stopped by today to help me finish up the riveting on the forward fuselage. We didn’t get any pictures during the process, but here is the finished result. The holes along the firewall will wait until they’re match drilled to the hinges that are used to attach the cowling.

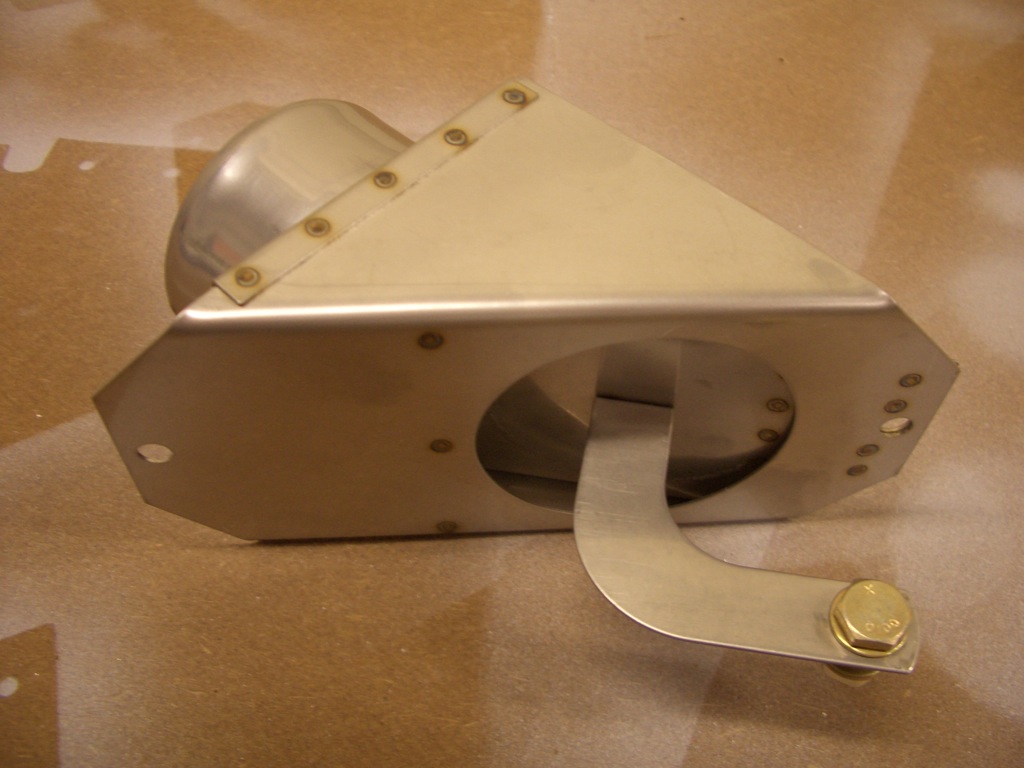

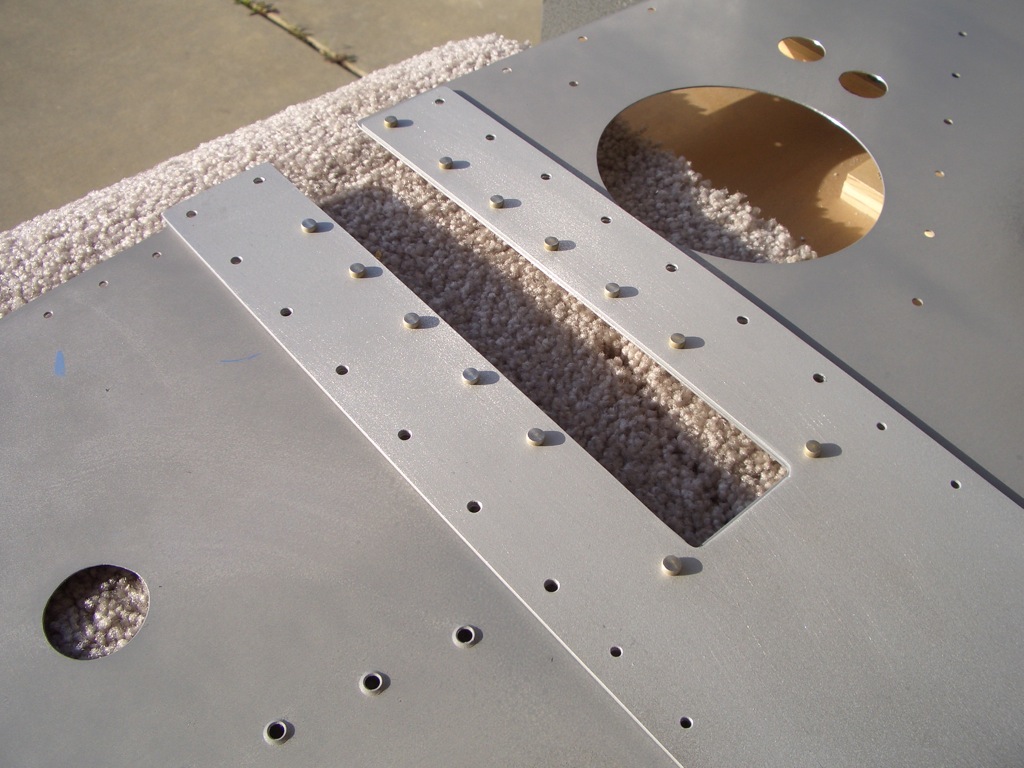

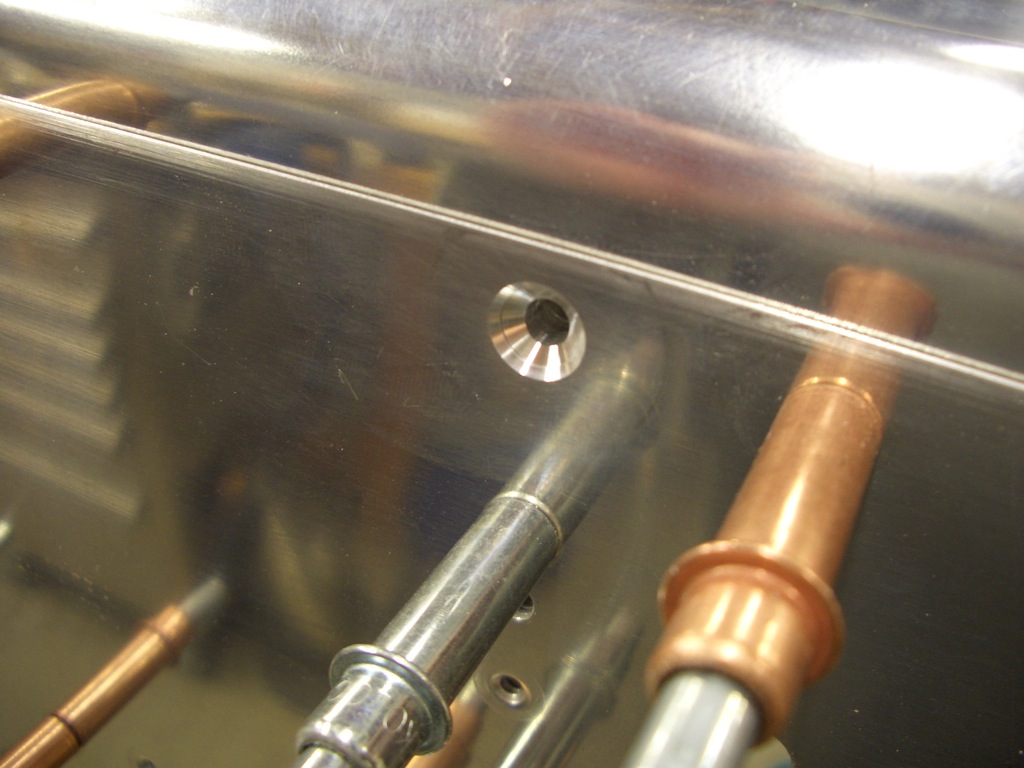

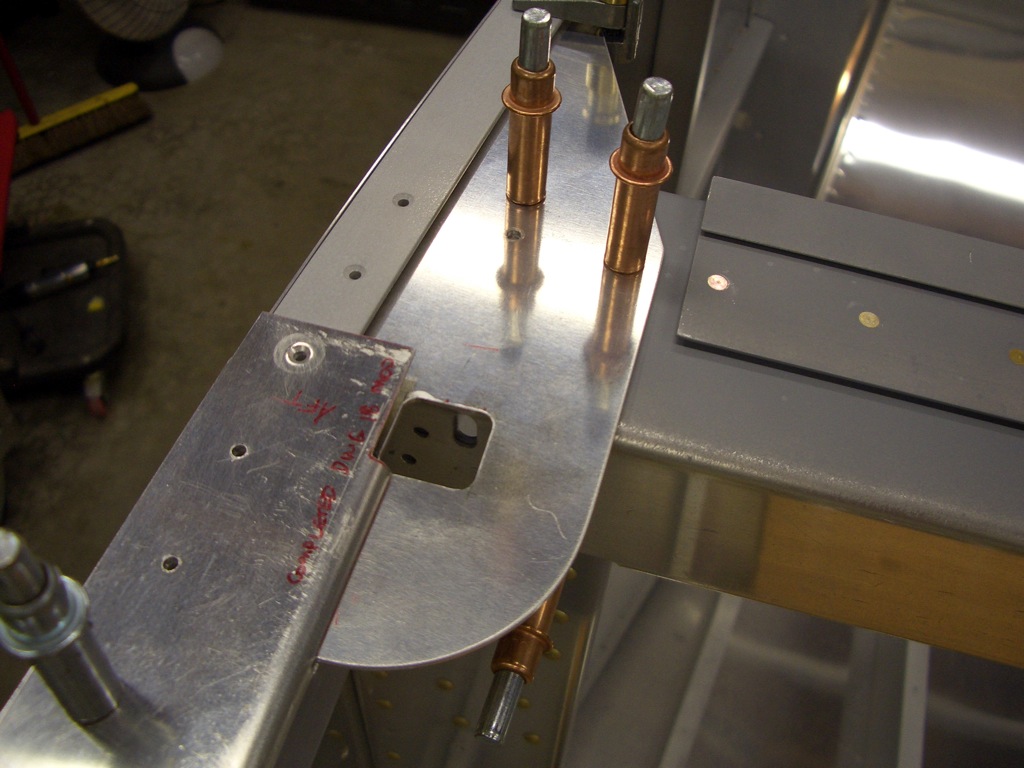

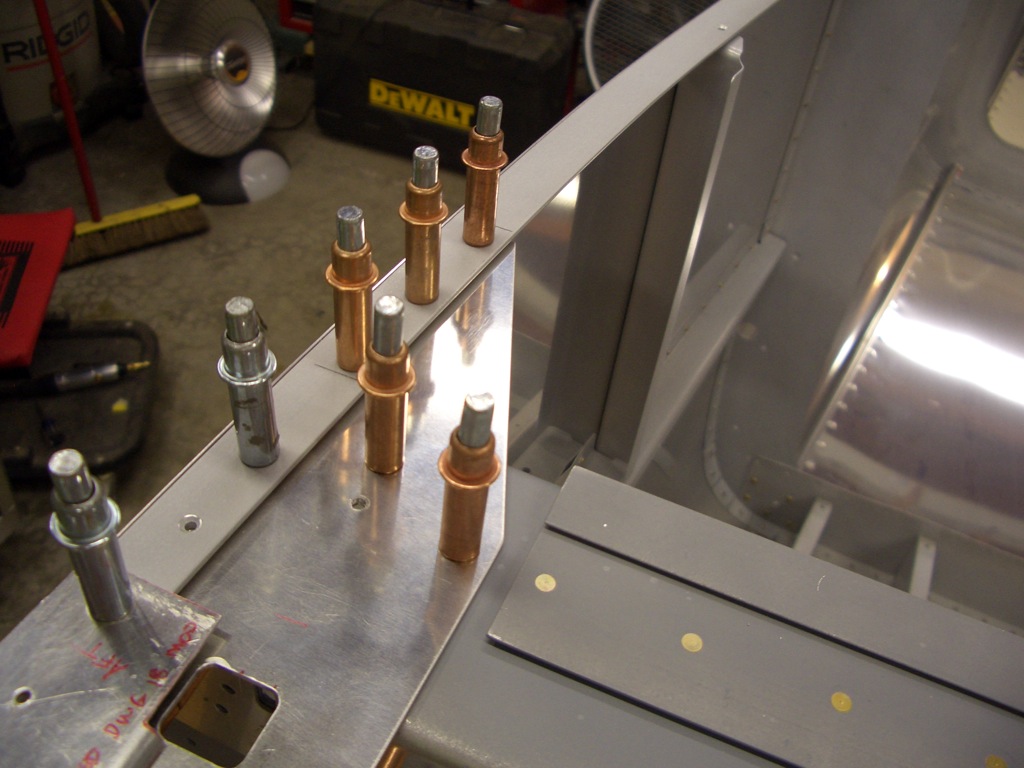

Some of the holes where the fuel tank brackets attach can’t be reached with any of my regular bucking bars, so I taped a hunk of steel to one of my long rivet sets and used the rightmost end to buck the rivets.

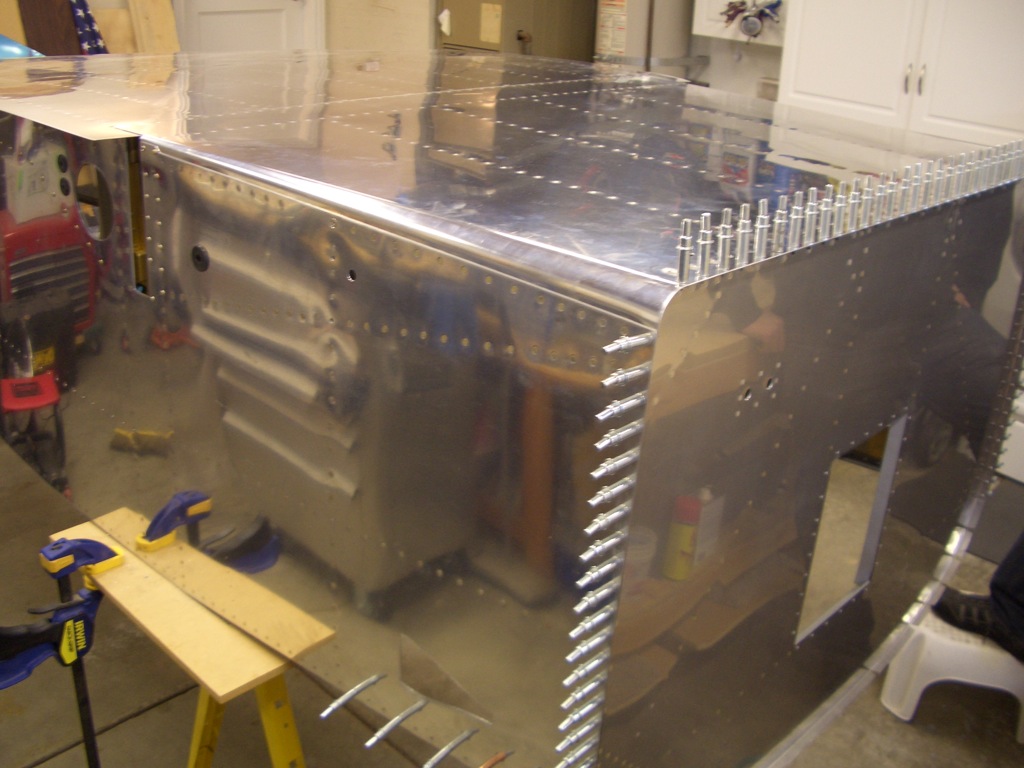

Jenn came out and helped Andre and I flip the fuselage.

Jenn took a shot of me checking out the pilot’s seat.

Andre and I checkout out how roomy the cockpit is.

Here you can see that I’m using two low saw horses under the front part of the fuselage so that it is nice and stable when climbing in and out.

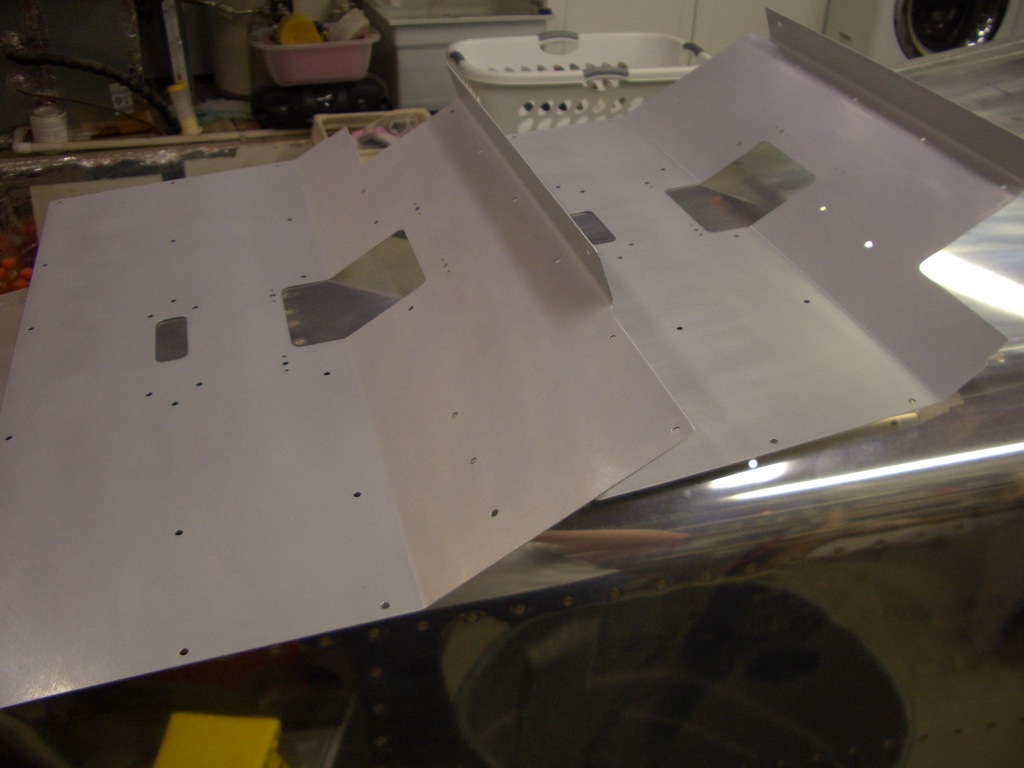

After Andre took off, I installed the AN3 bolts through the lower engine mounts and lower longerons. I probably should have done this before riveting on the bottom skin since I couldn’t get a torque wrench on these. I had to calibrate my hand and do these by feel.

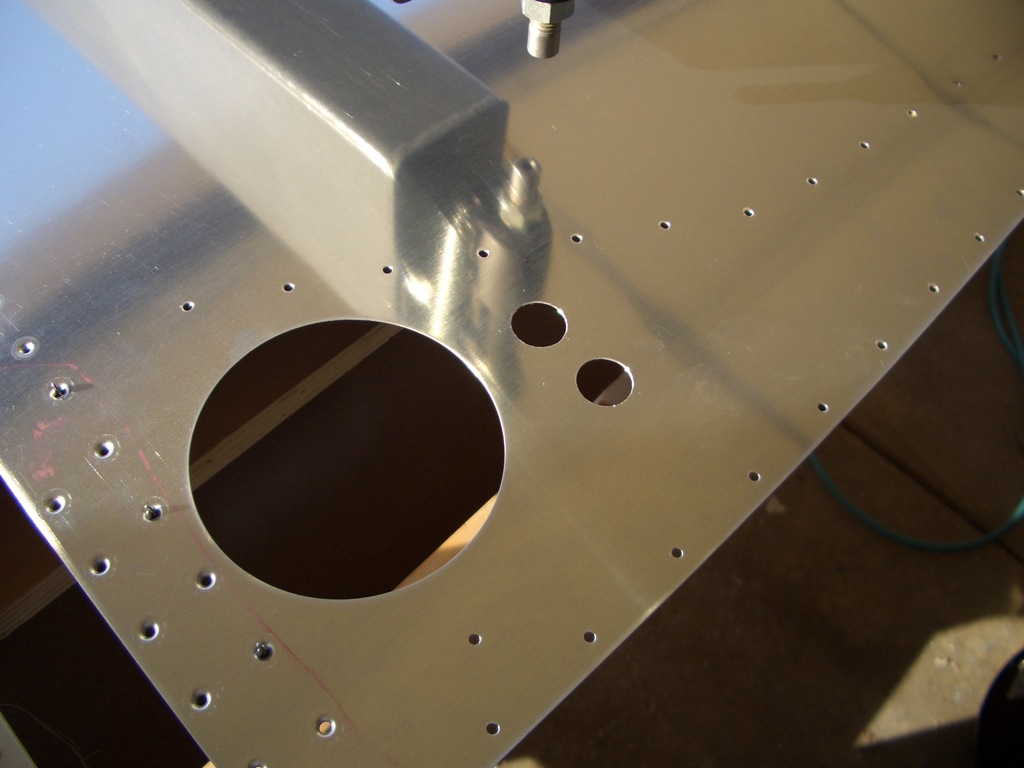

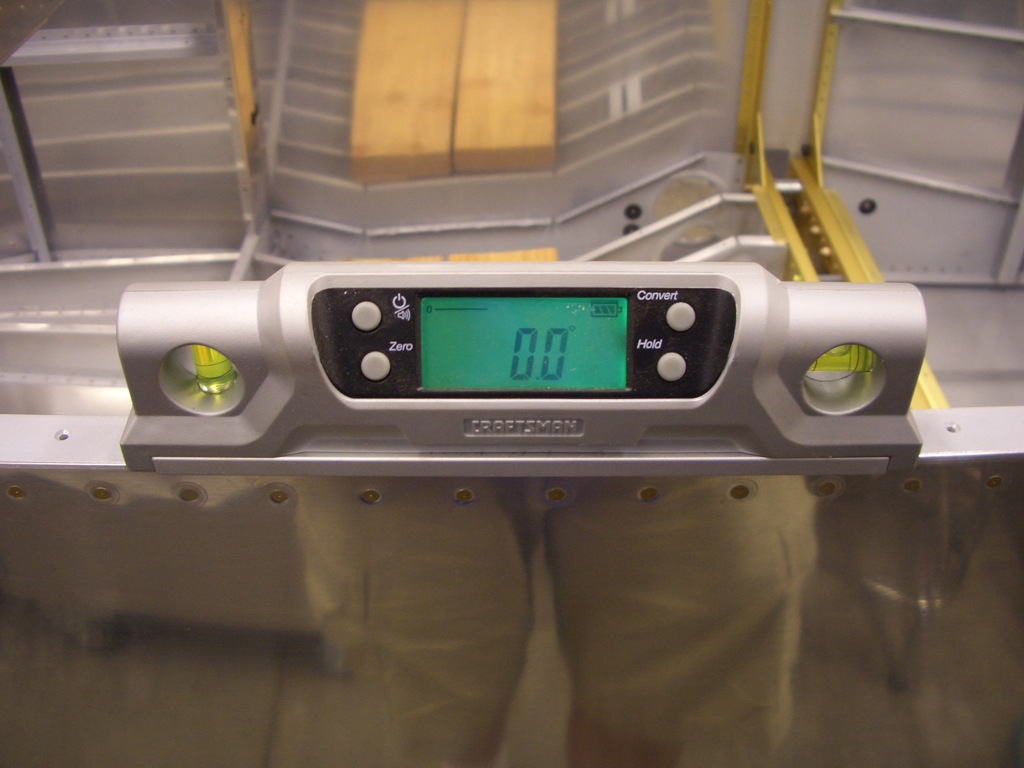

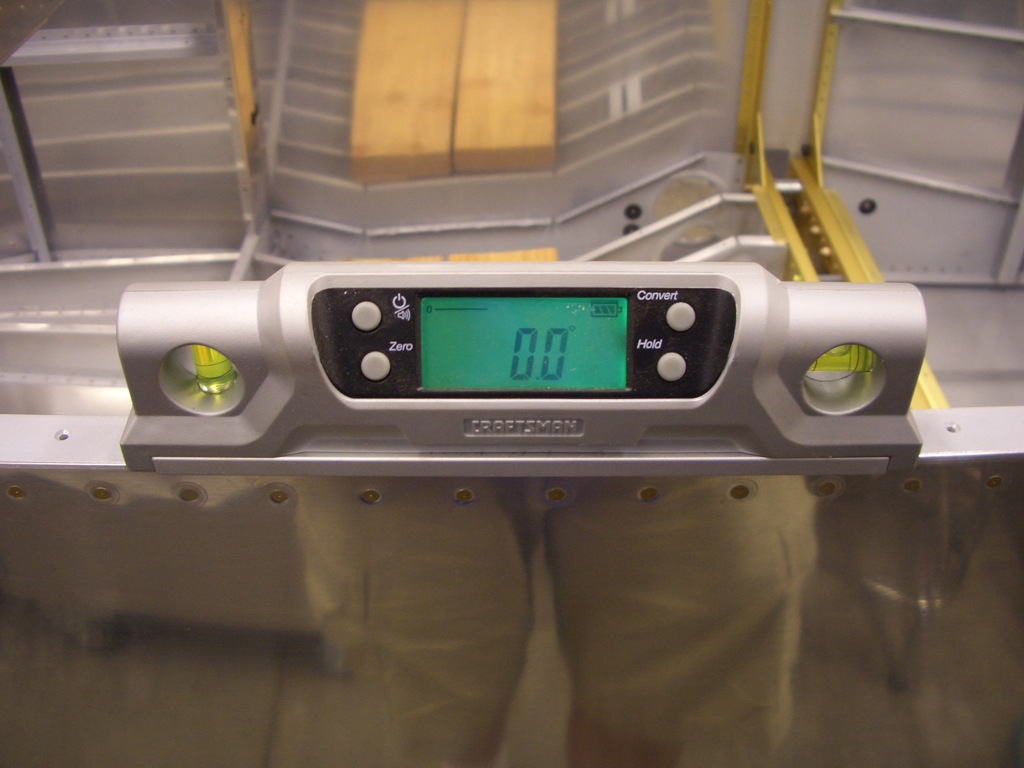

Afterward, I leveled the fuselage front to back. Here is the reading along the longerons between F-704 and F-705.

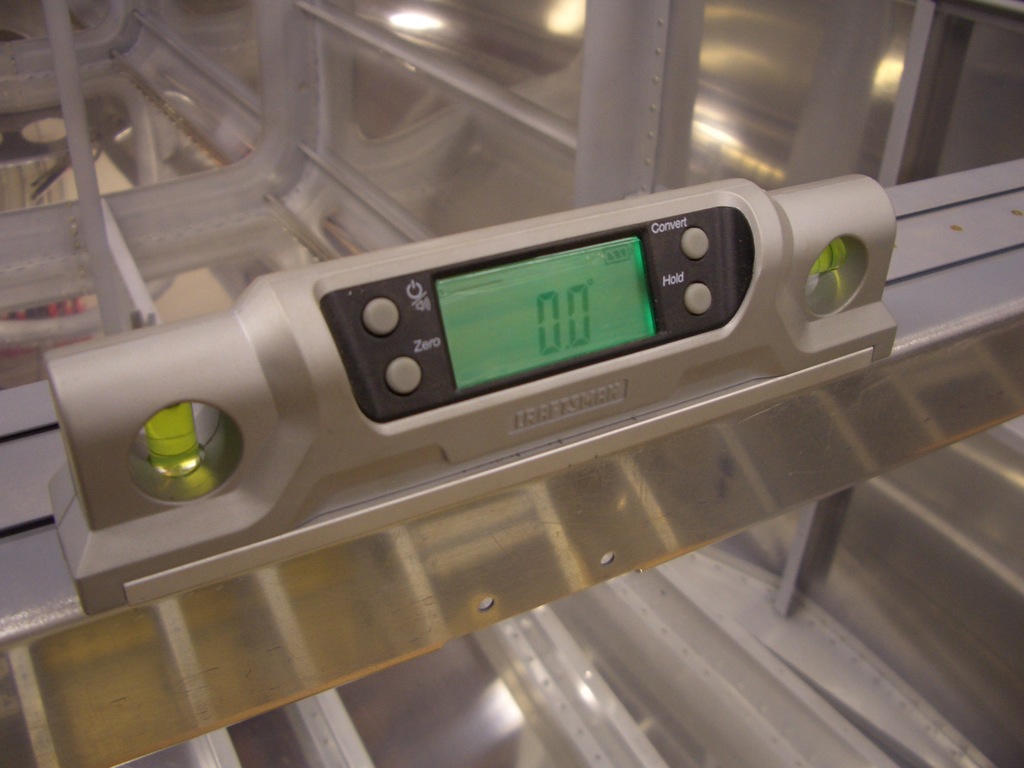

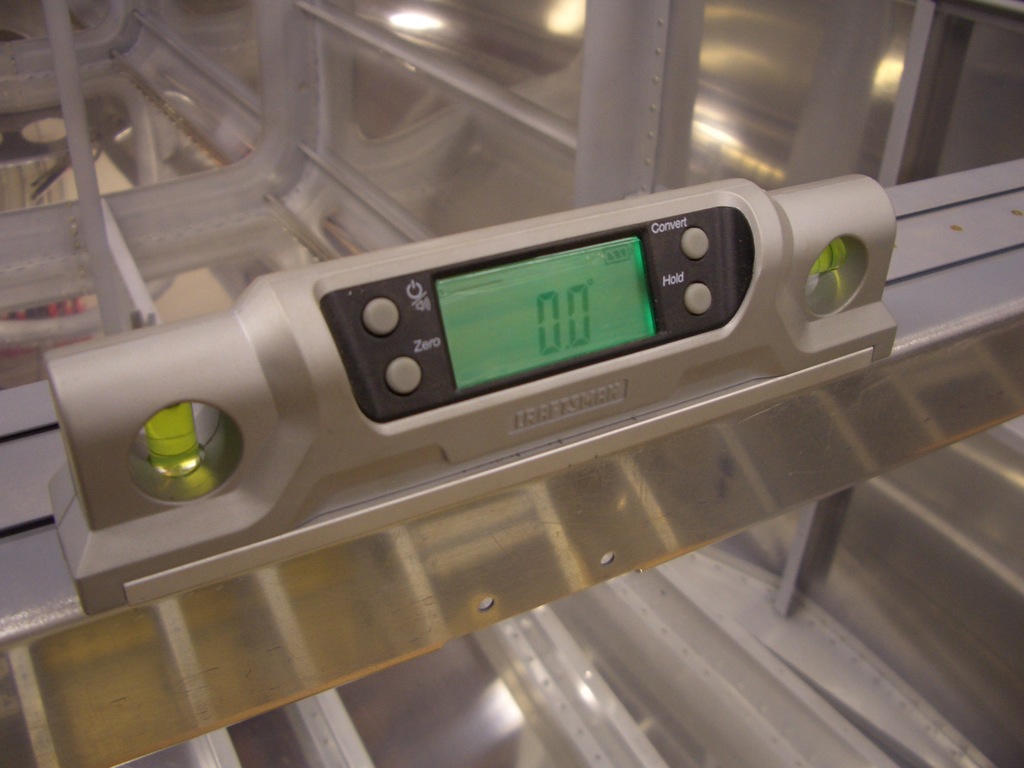

I also leveled the fuselage side to side at several points along the fuselage to ensure there was no twist. Here is the reading at F-705.

And at F-704.

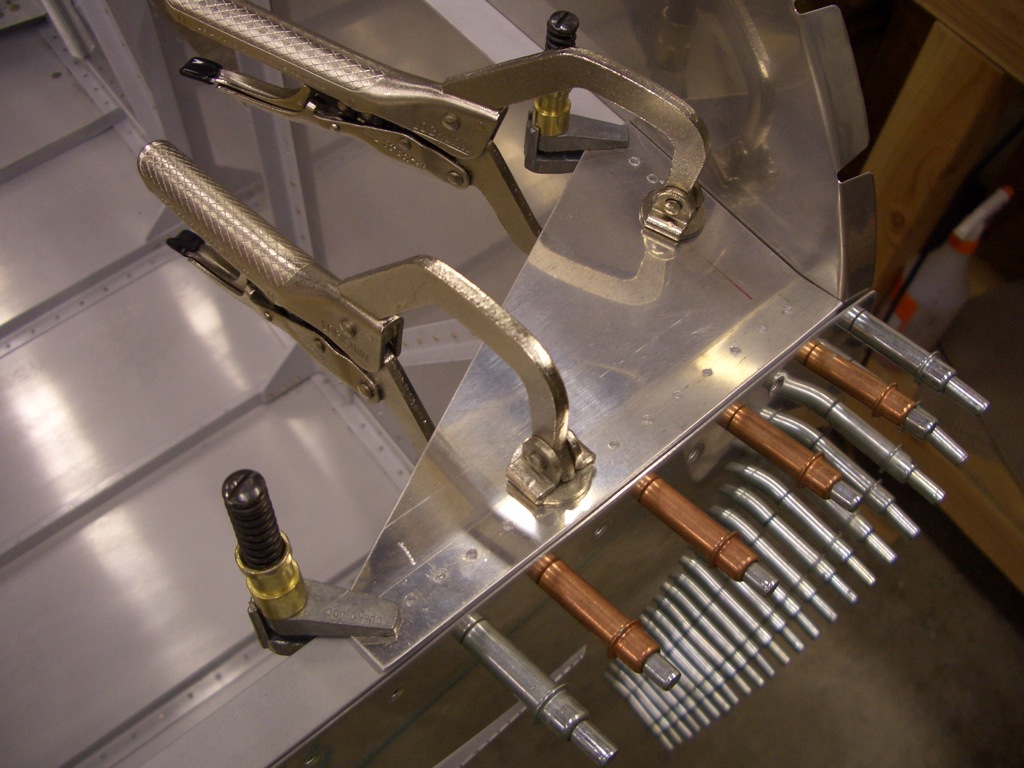

And at F-710. I doubled checked all of the readings with a bubble level and them clamped the aft deck in place.

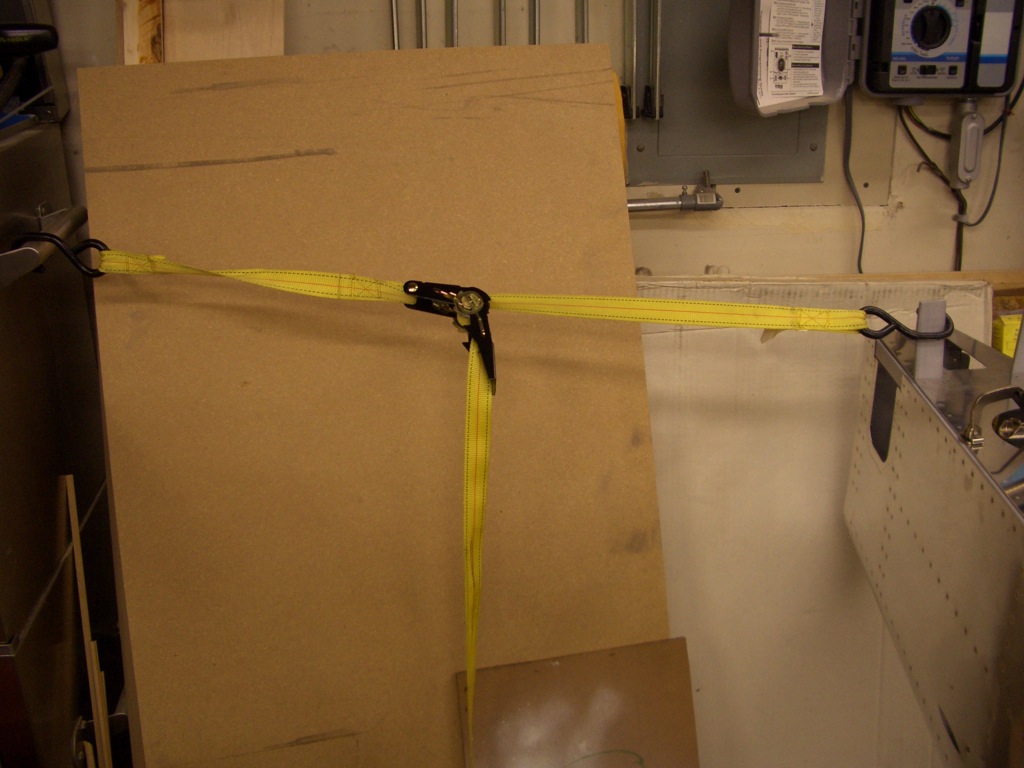

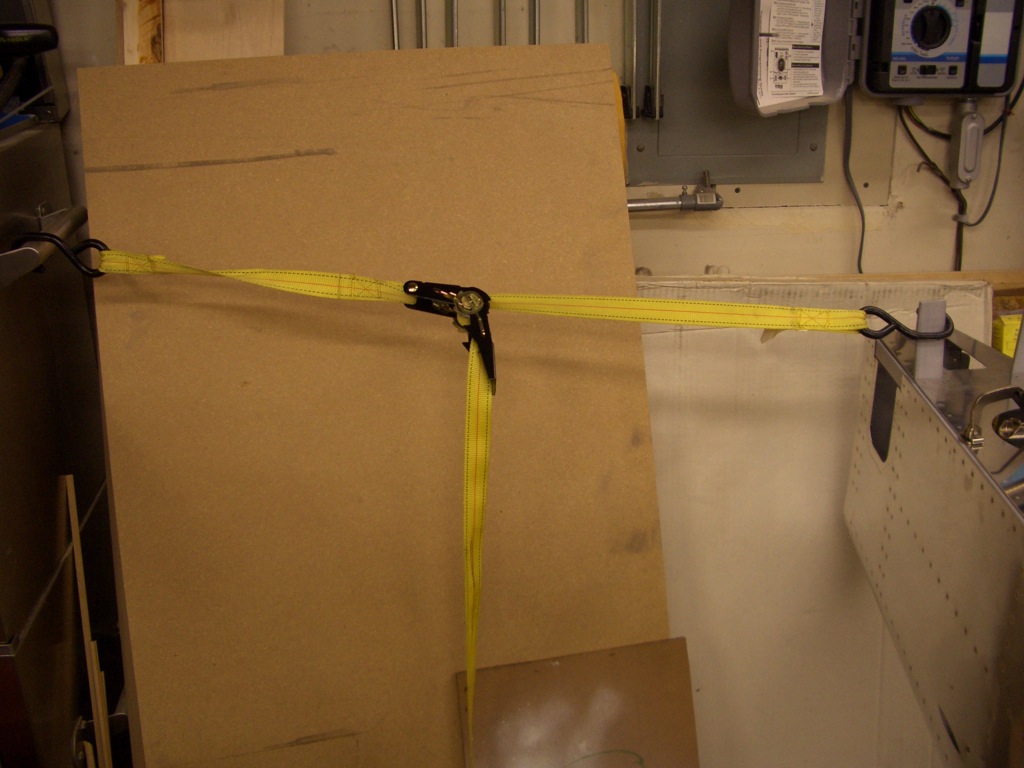

I needed a ratchet clamp to apply a little side load on the aft vertical bars to remove all of the twist. After I tripled checked everything was straight, I drilled the aft deck to the longerons.

Goddamnit! I got my foot caught up in the air hose, pulling my drill and box of rivets to the floor. After swearing a blue streak for a few minutes, I started trying to sort them and then realized it was going to take several hours. This is probably only about $10 worth of rivets, so it’s just not worth my time.