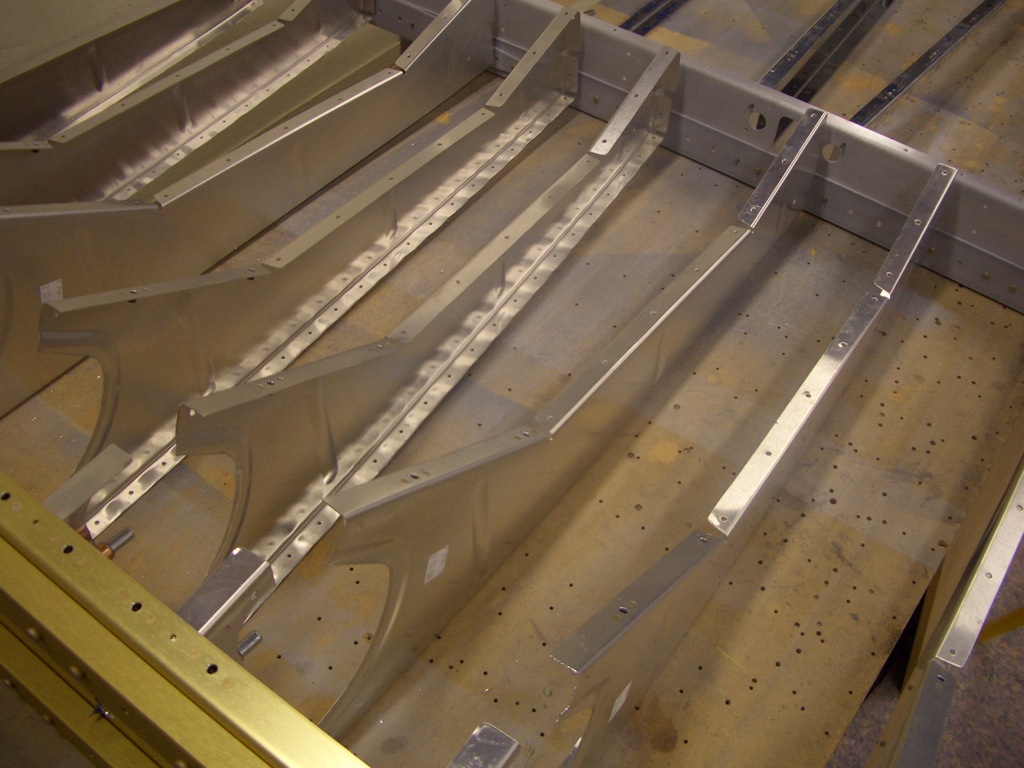

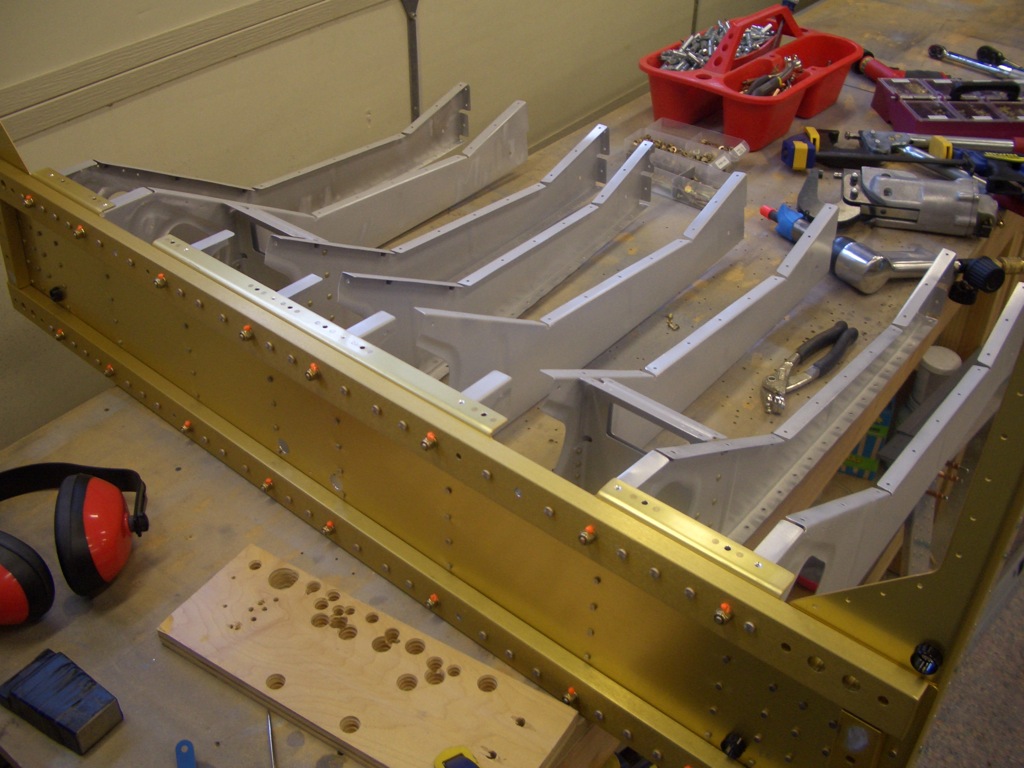

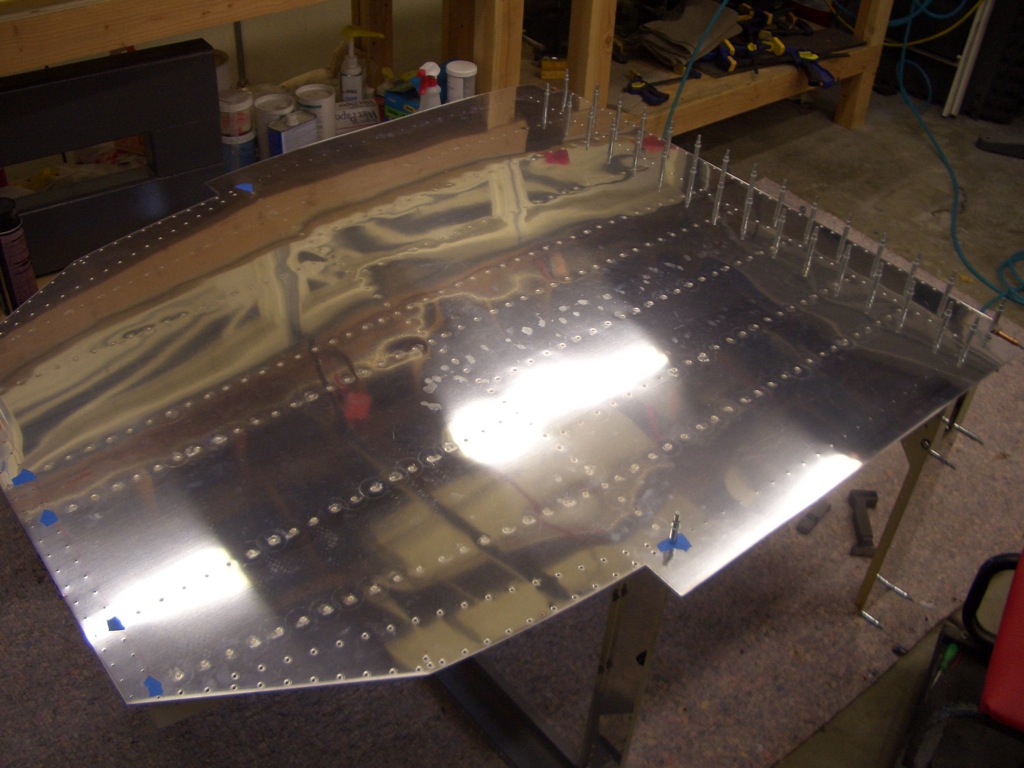

I started tonight by match drilling the bottom skin to the seat and baggage ribs as well as the F-704 and F-705 bulkheads. Next I got started on the F-623 side ribs. There is a joggle in these that makes it look like it could nest inside F-705, but this is apparently a holdover from the RV-6 and must be cut off.

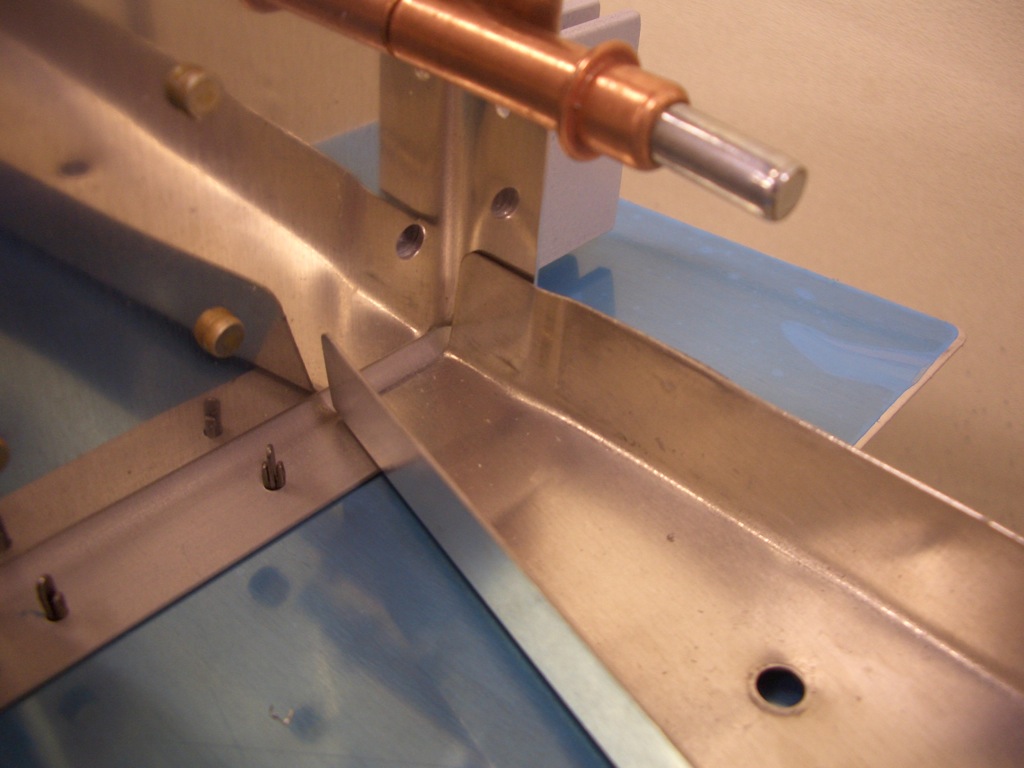

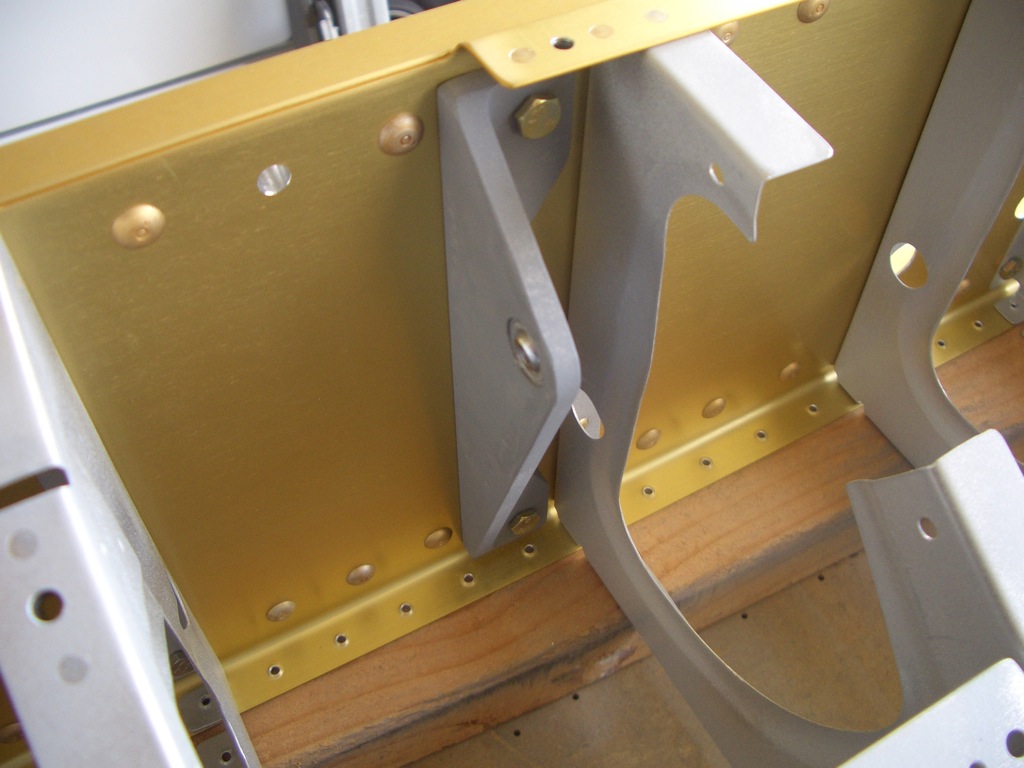

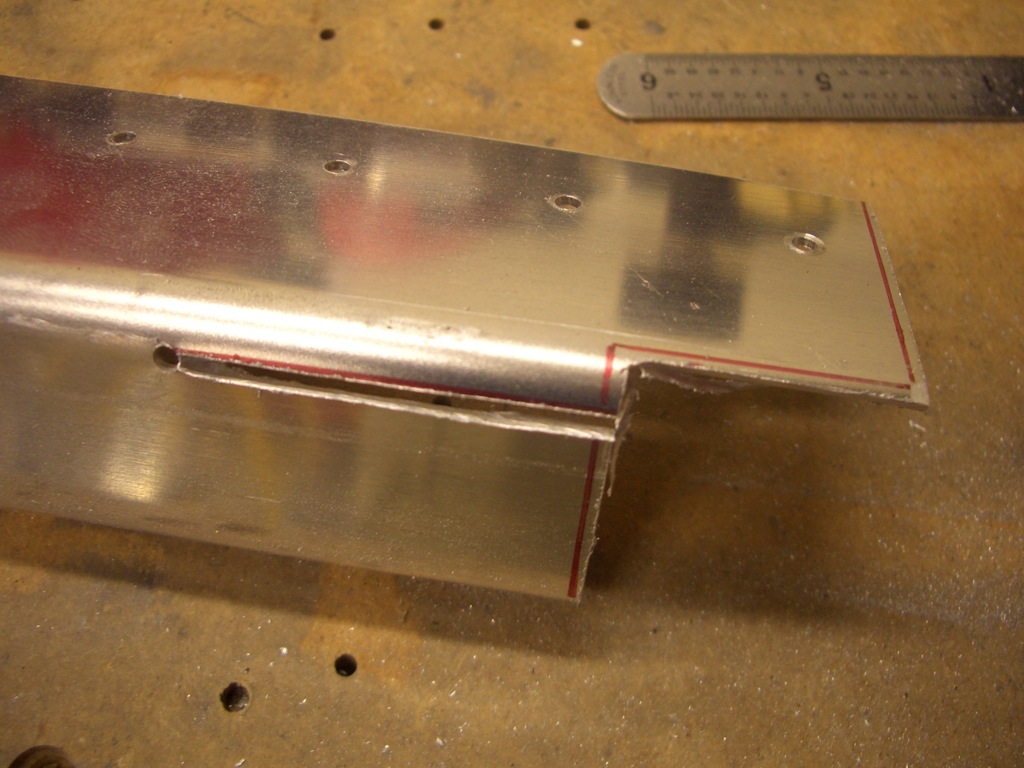

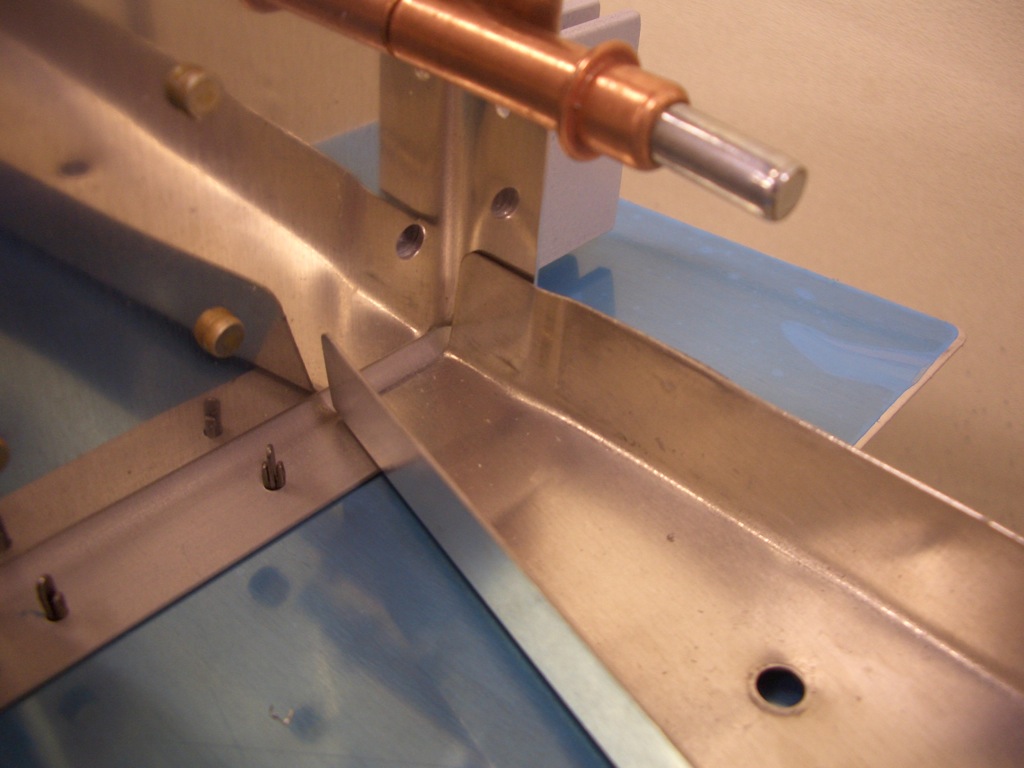

The side rib should sit behind F-705 like this. They will be connected with a strap that has to be fabricated.

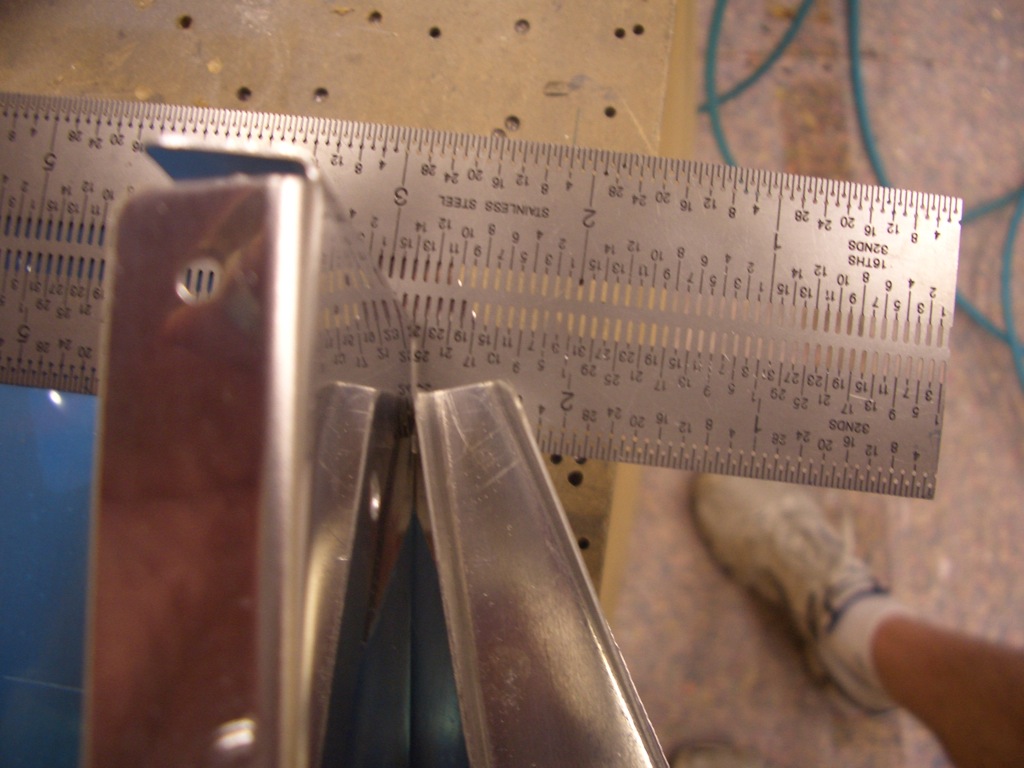

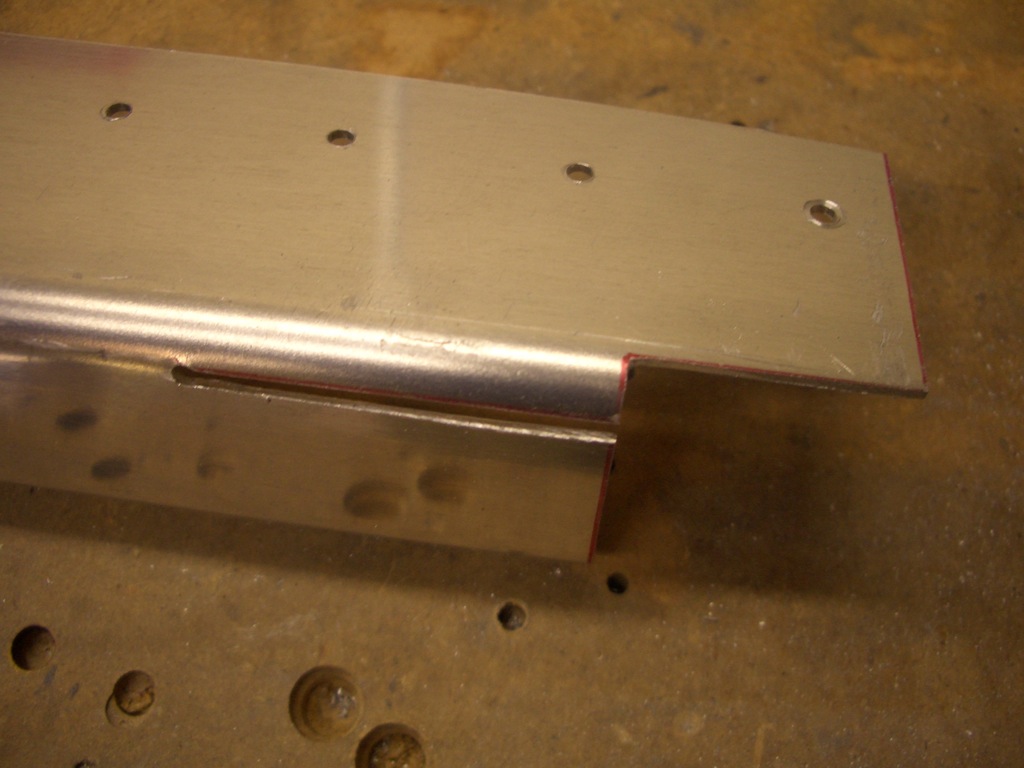

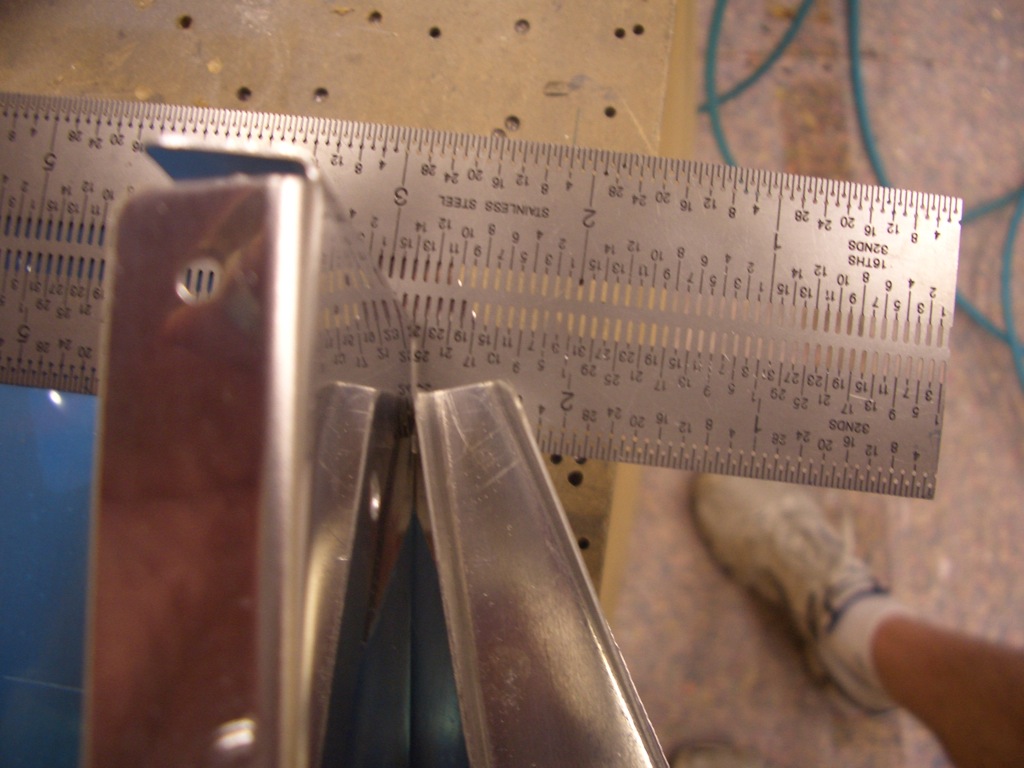

The aft end of the side rib must be cut off as well. I positioned a ruler where the front edge of the F-706 bulkhead will sit and marked the rib.

After cutting of the ends, I clamped the rib in place and match drilled it to the bottom skin.

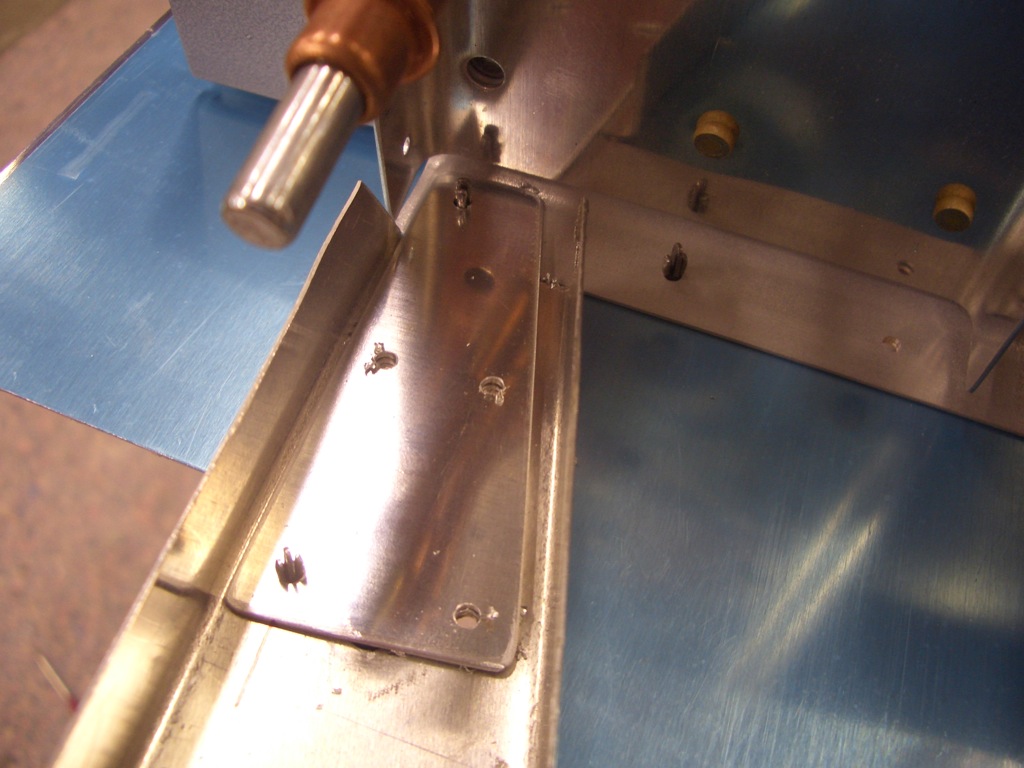

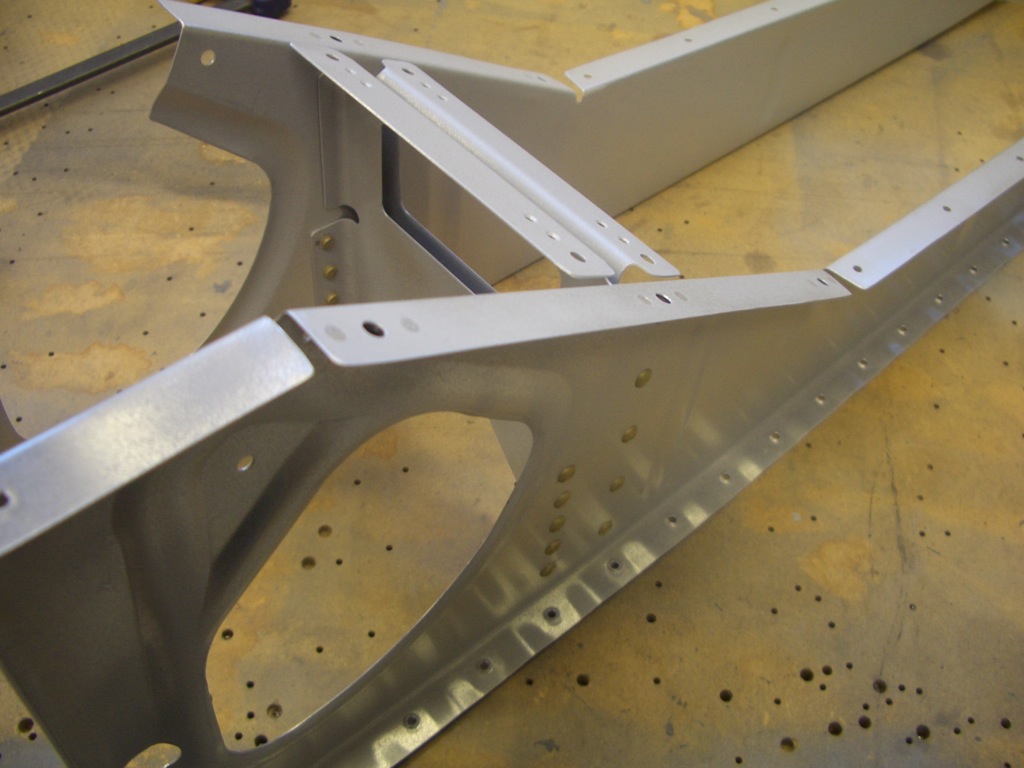

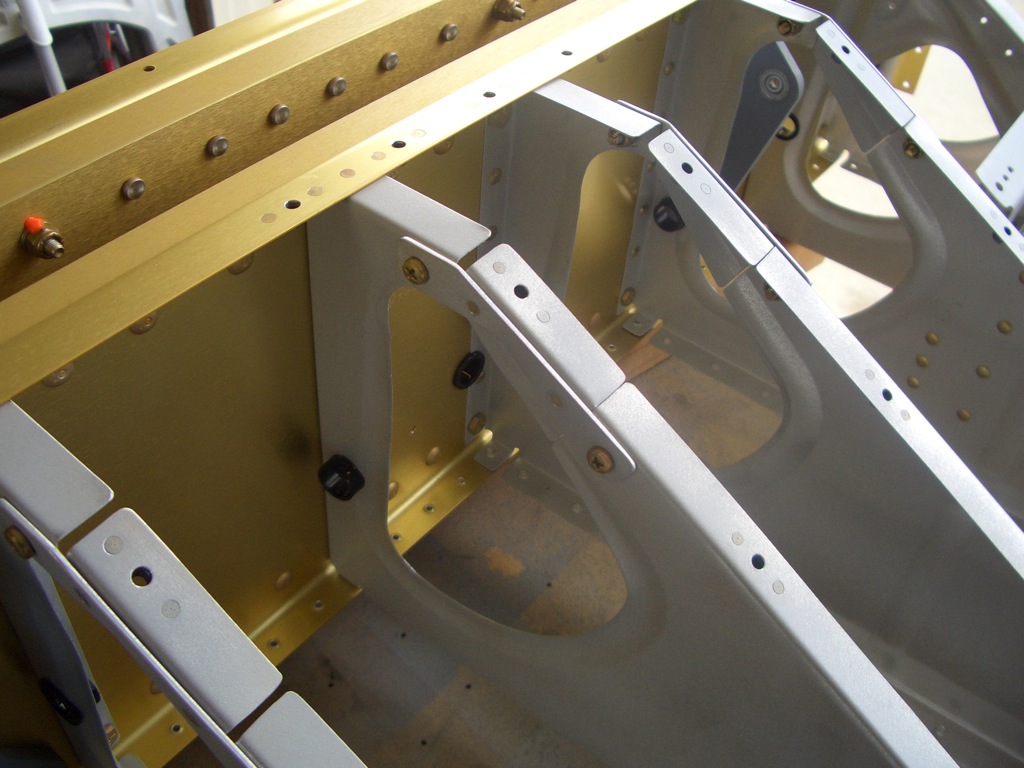

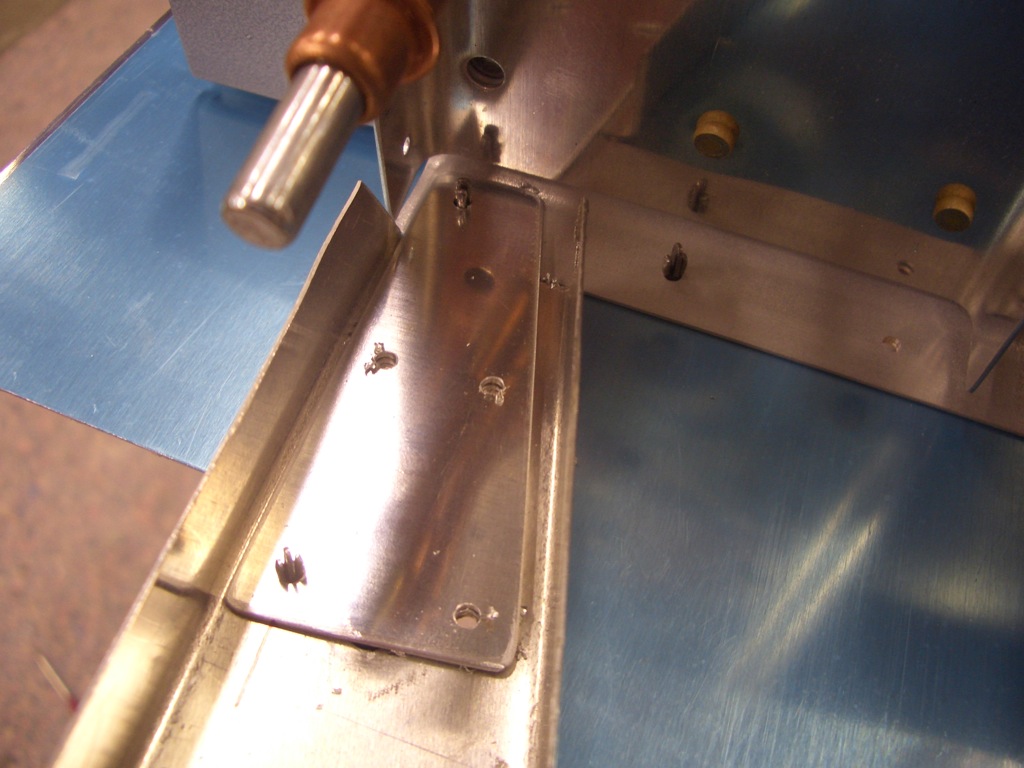

The plans specify attachment straps that connect F-623 to F-705 that are 3/4″ wide. This is too wide to hit just one row of rivets here, but not wide enough to catch both rows. Most builders just narrow the strip to 1/2″ and catch just the outer row of rivets, but I decided to make the strip a little wider and catch both rows of rivets.

The aft attachment straps will have edge distance problems if fabricated according to plans. Instead, I made the strap widen somewhat as it exits F-623 so that the aft rivet (on the right in the picture below) will have sufficient edge distance on all sides.

I clamped the two side ribs together to transfer the cut marks from one to the other.

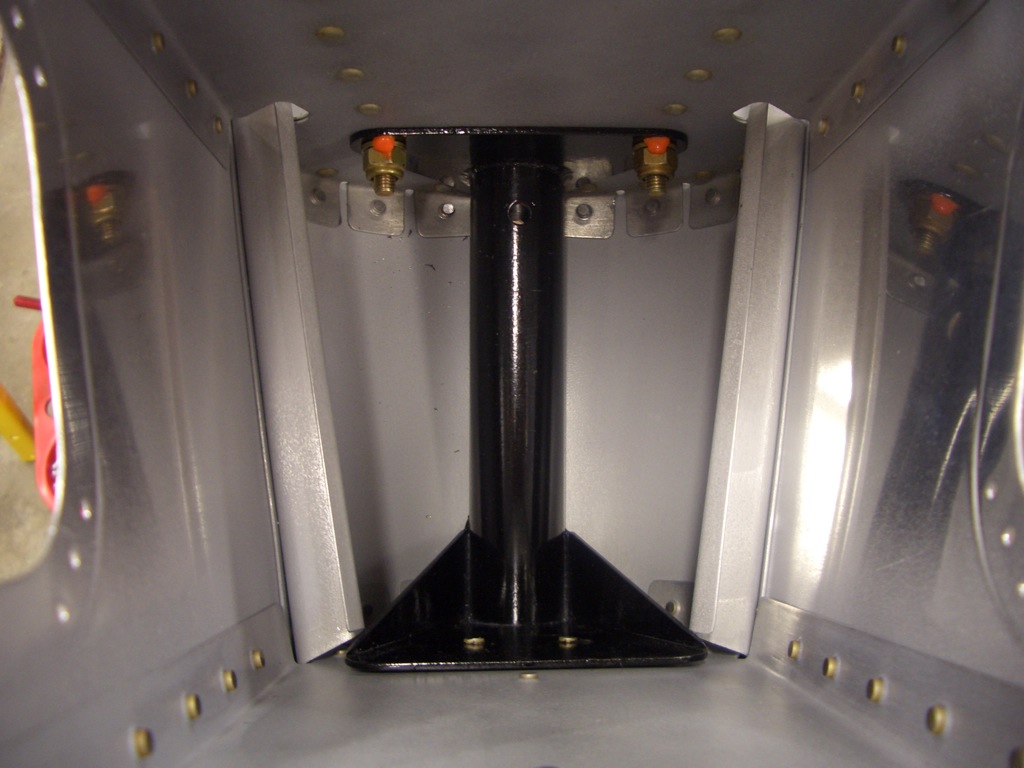

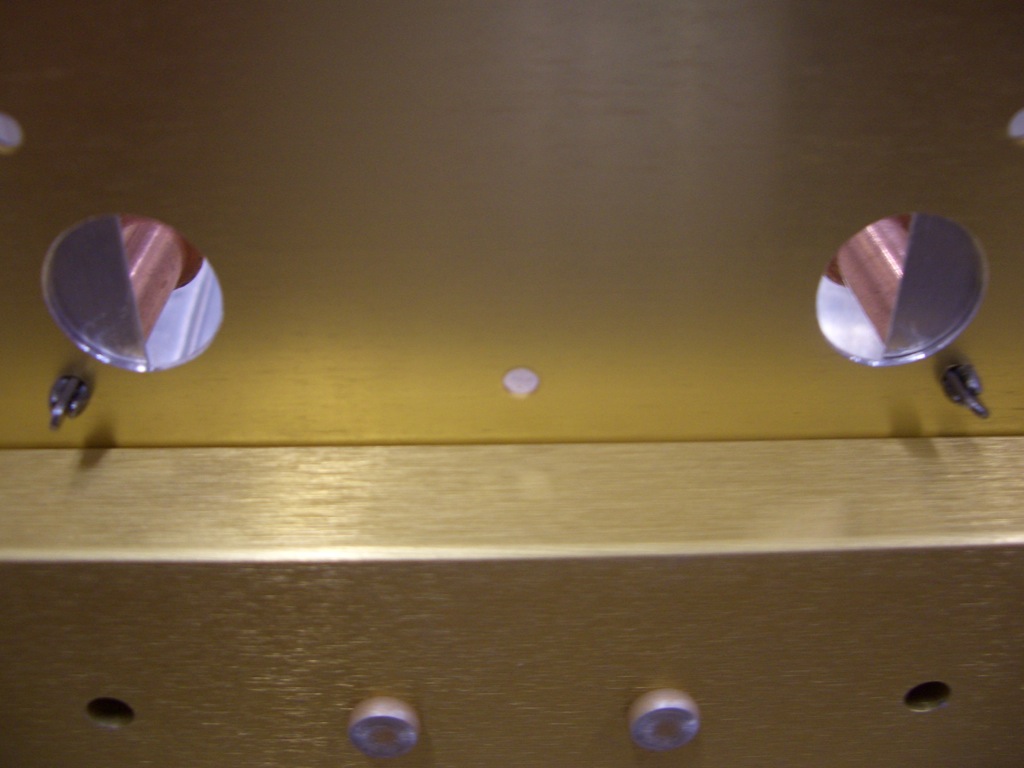

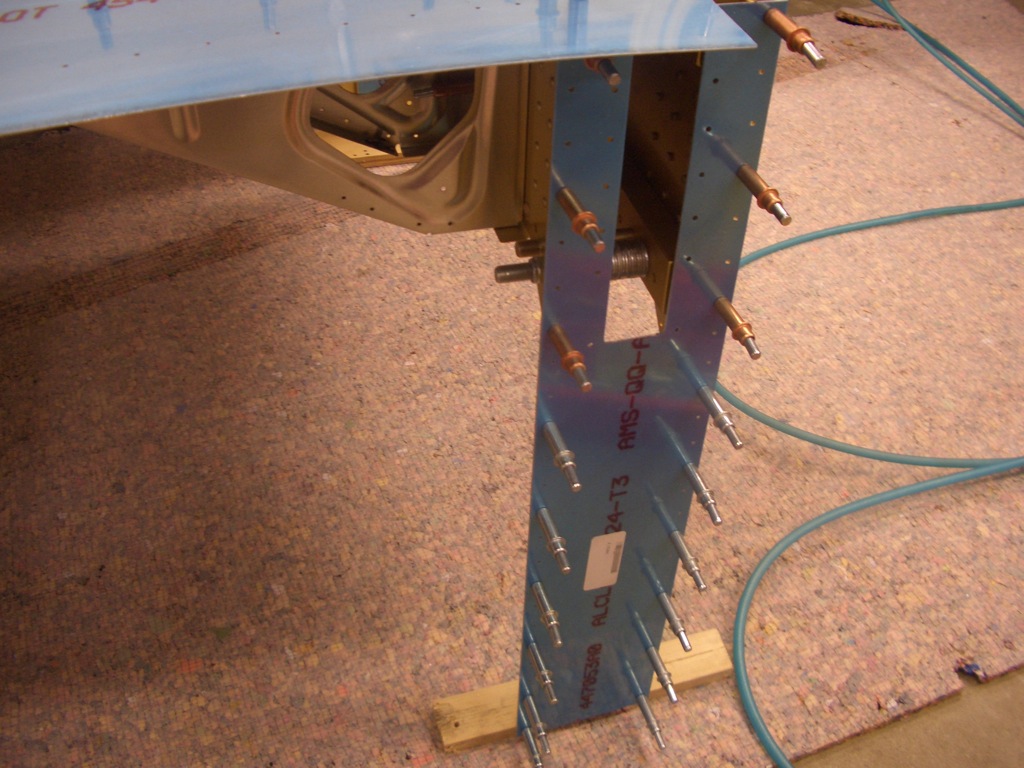

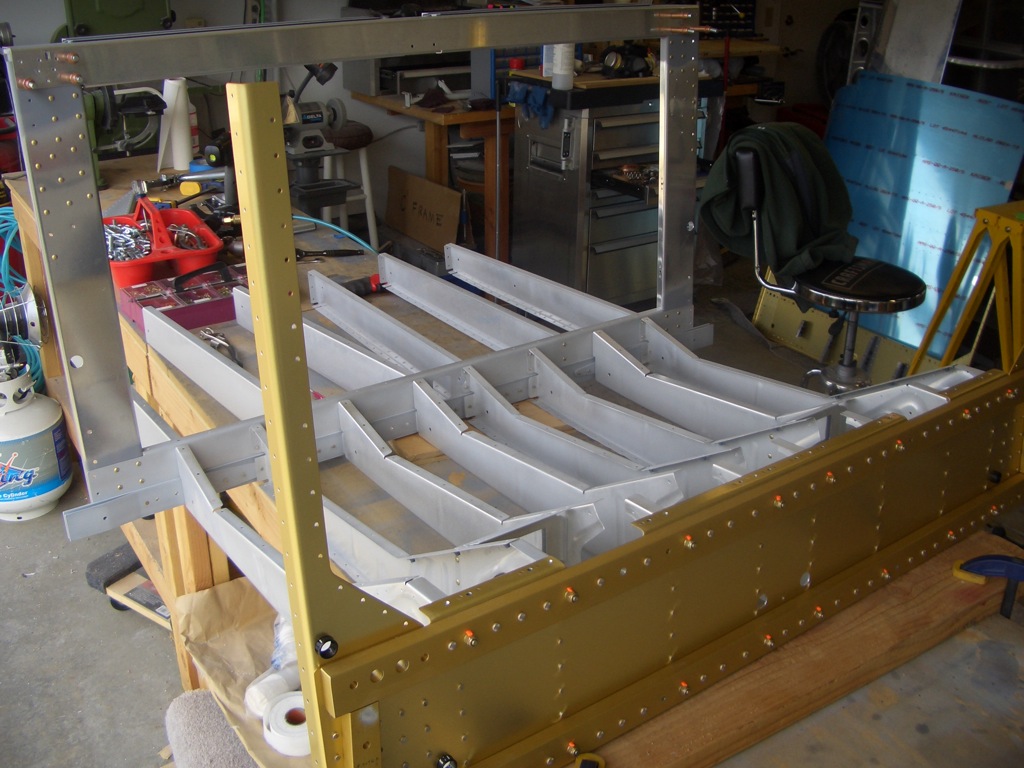

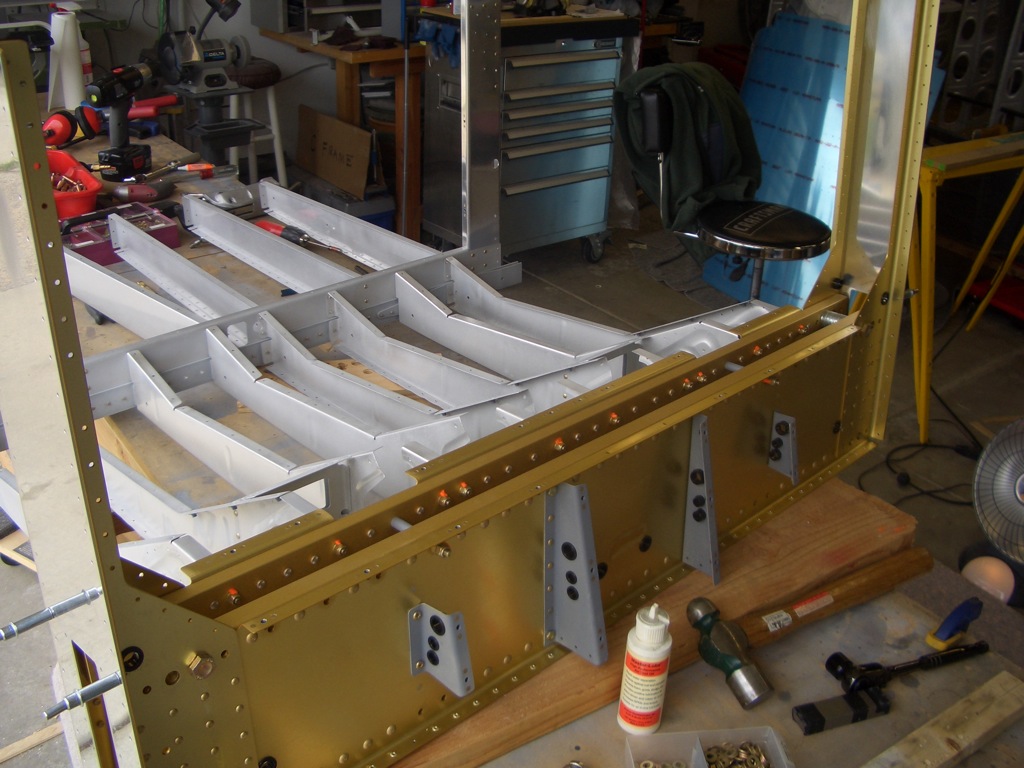

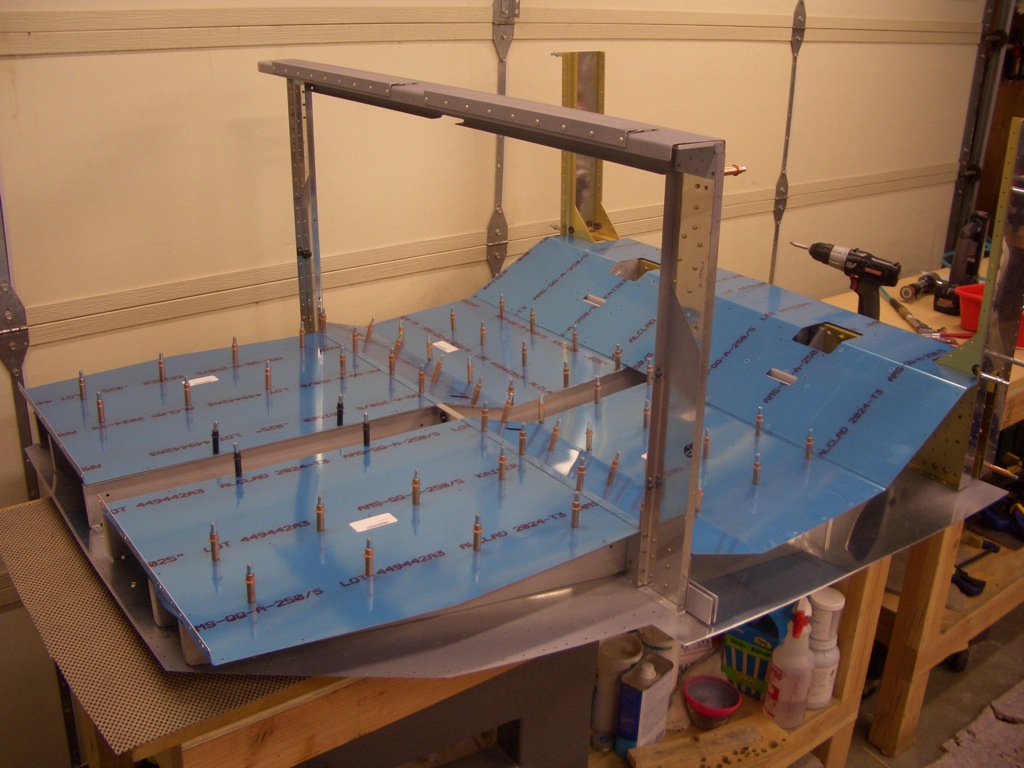

I clamped the two halves of F-704 together using the spacers I made and some hardware store 7/16″ bolts. I put two of the close tolerance bolts in place (one in each end) to ensure the bulkhead halves were perfectly aligned since the hardware store bolts allowed a little slop.

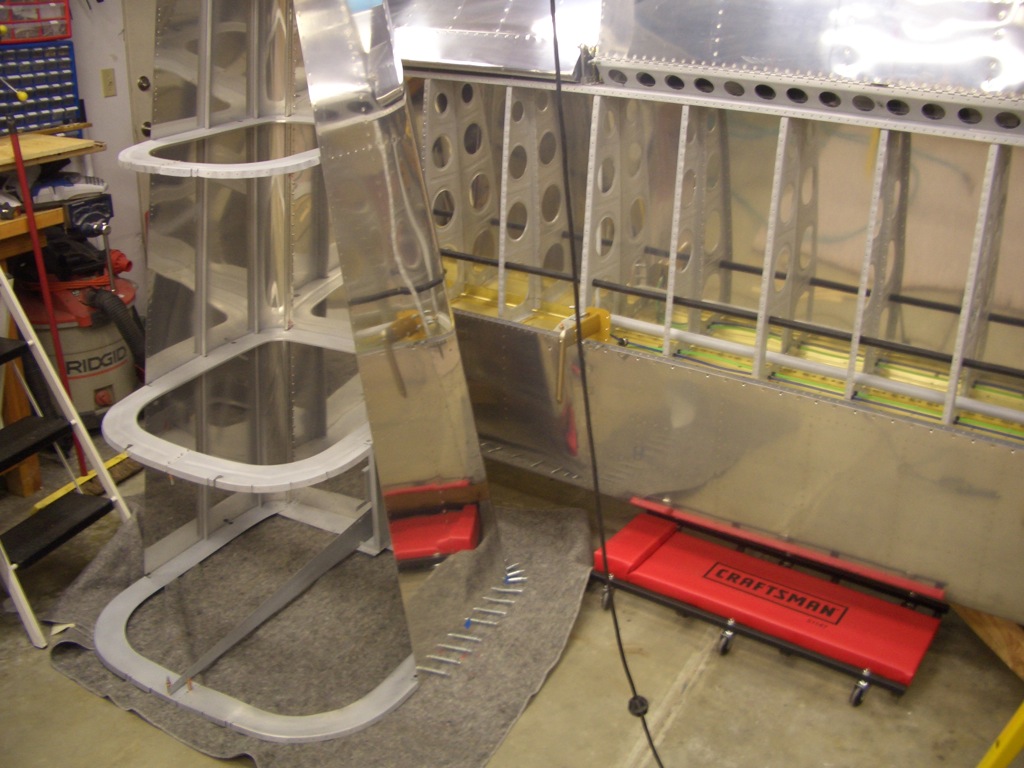

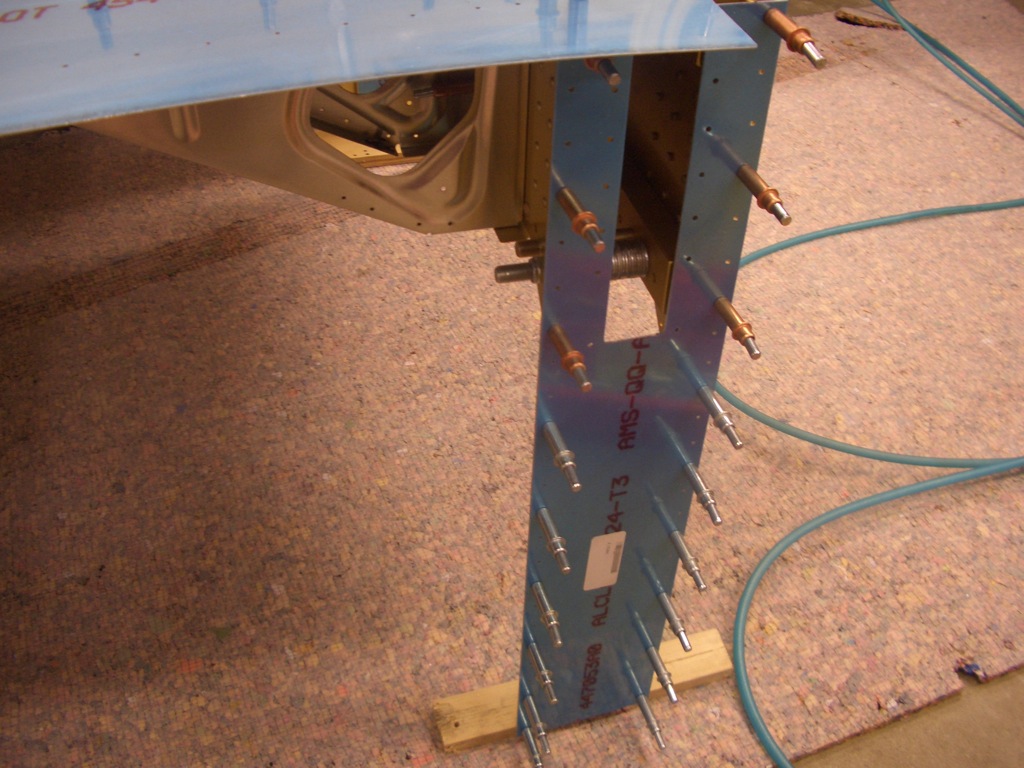

I then clecoed the side skin doublers in place and match drilled them to the F-704 side pieces.

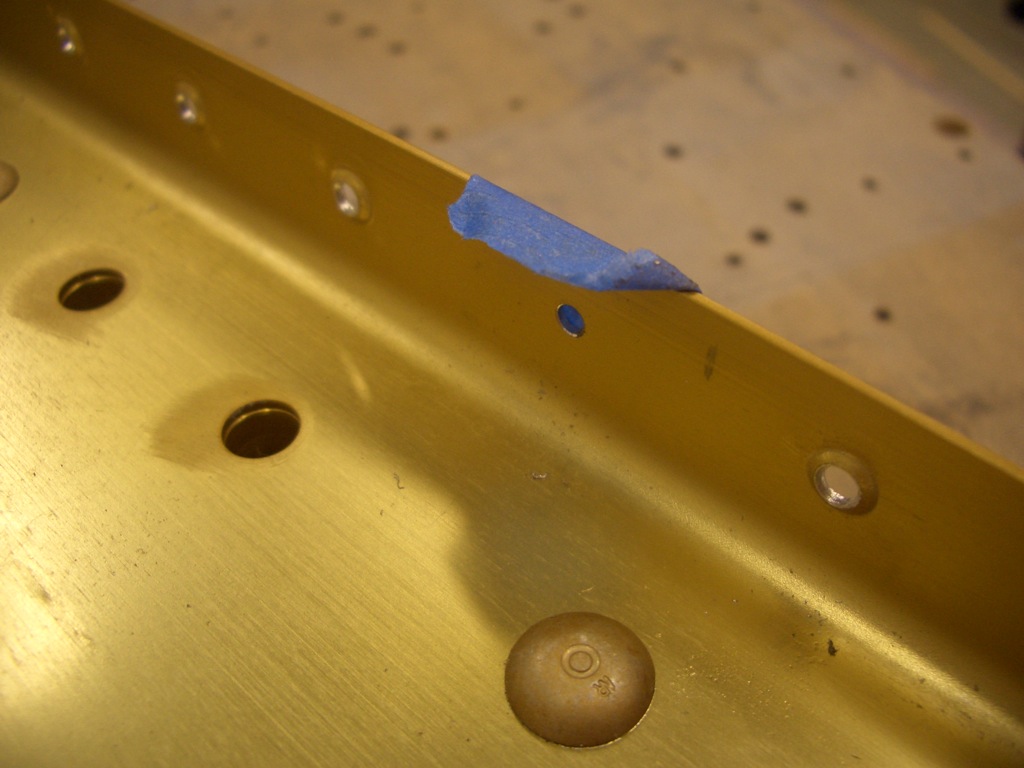

Four of the rivets along the front edge of F-704 must be countersunk so that the F-704 flange isn’t dimpled. This is to allow the floor stiffeners to nest against this flange.

The bottom skins is only 0.025″ thick, which is not thick enough to take a countersink for a 3/32″ rivet. This causes the countersink to penetrate slightly into the F-704 flange. This is ok in this particular case.

Afterward, I removed the bottom skin and baggage ribs.

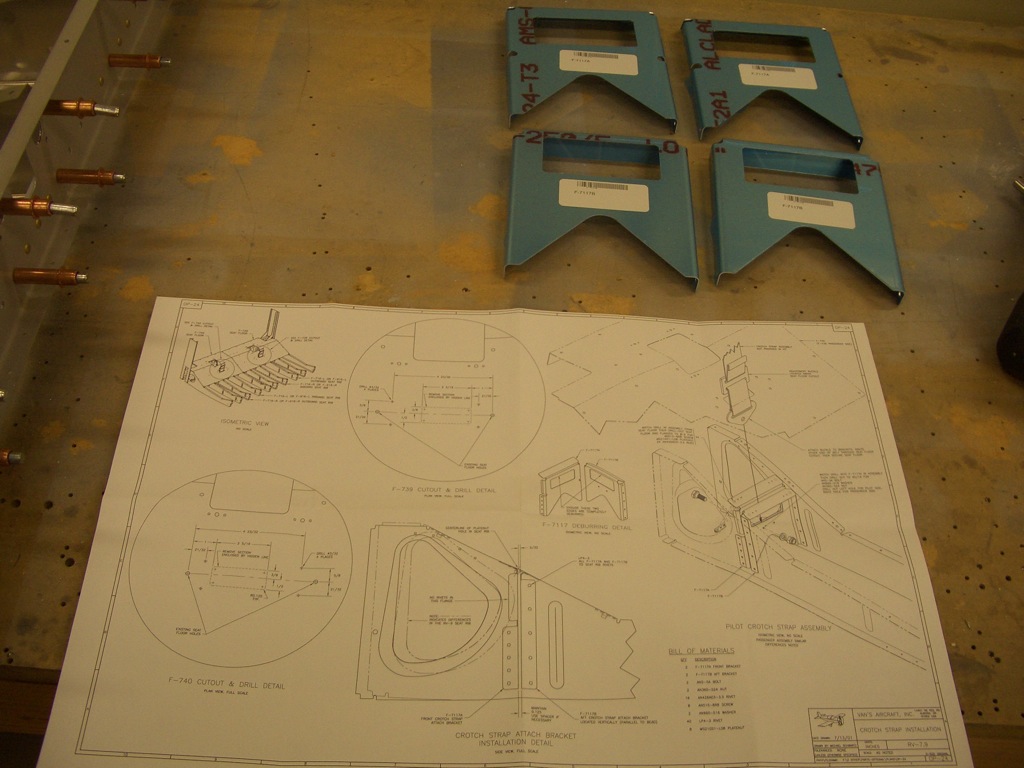

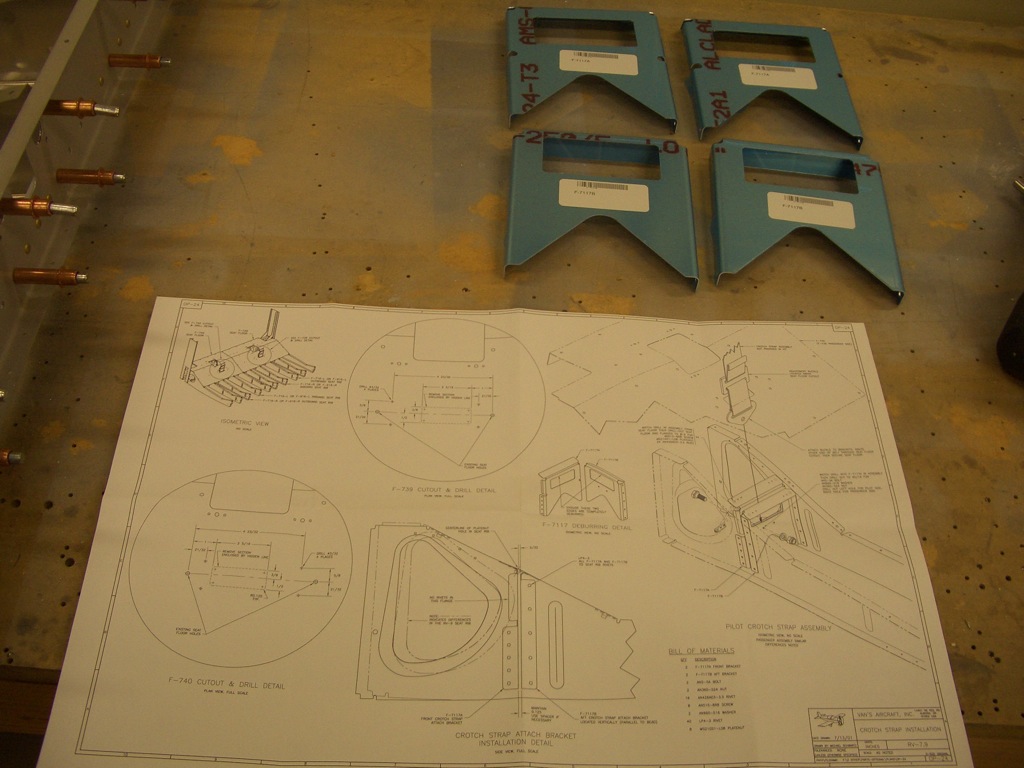

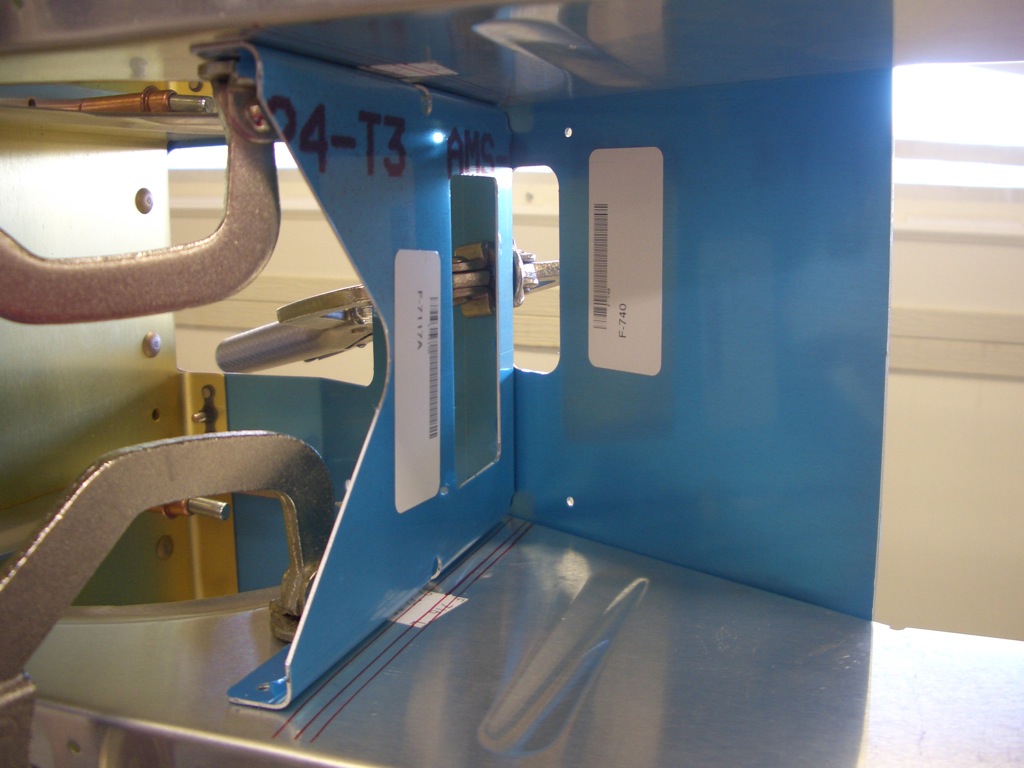

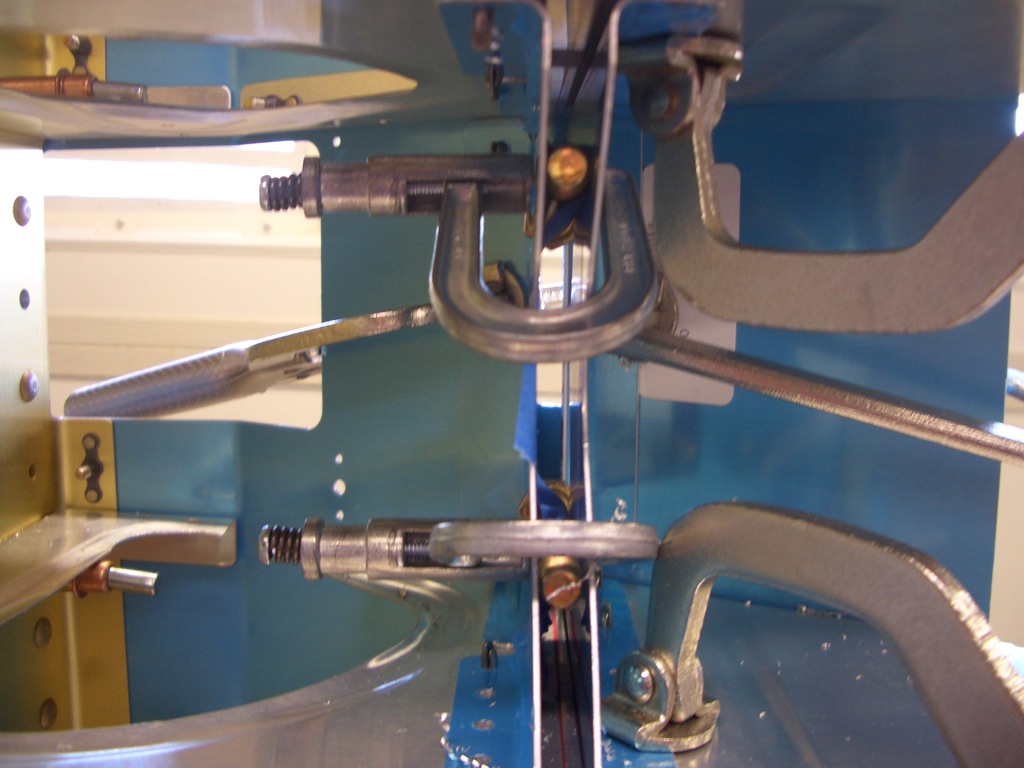

I pulled out the crotch strap install kit, but I need to get up really early tomorrow, so I’m going to call it a night.