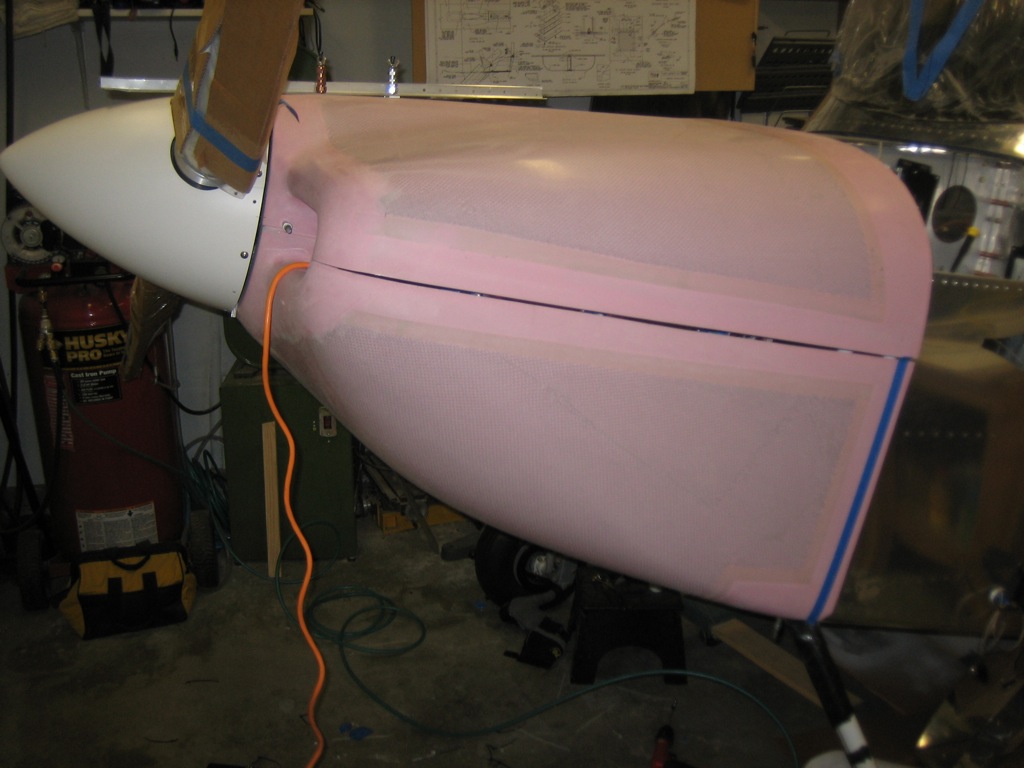

I got an email from Joe Blank at Van’s today. After reviewing my cowl fitting issue further, they now think my cowl is made correctly and that if I trim the aft edge all the way around, I should have enough overlap on the sides to make a straight joint.

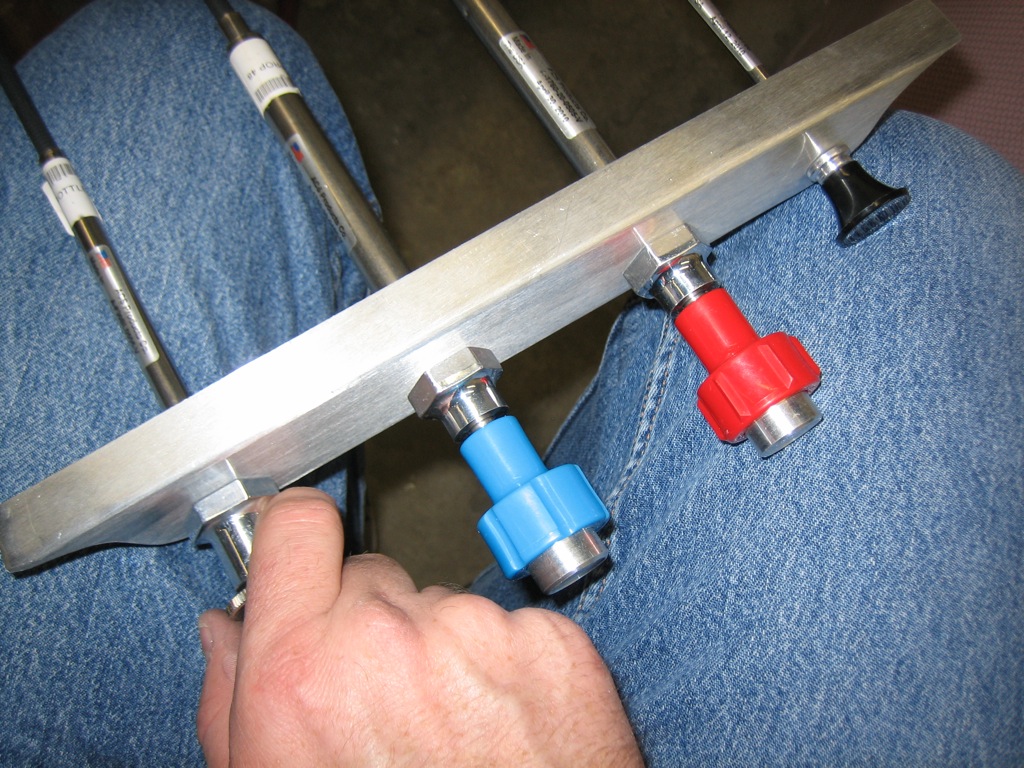

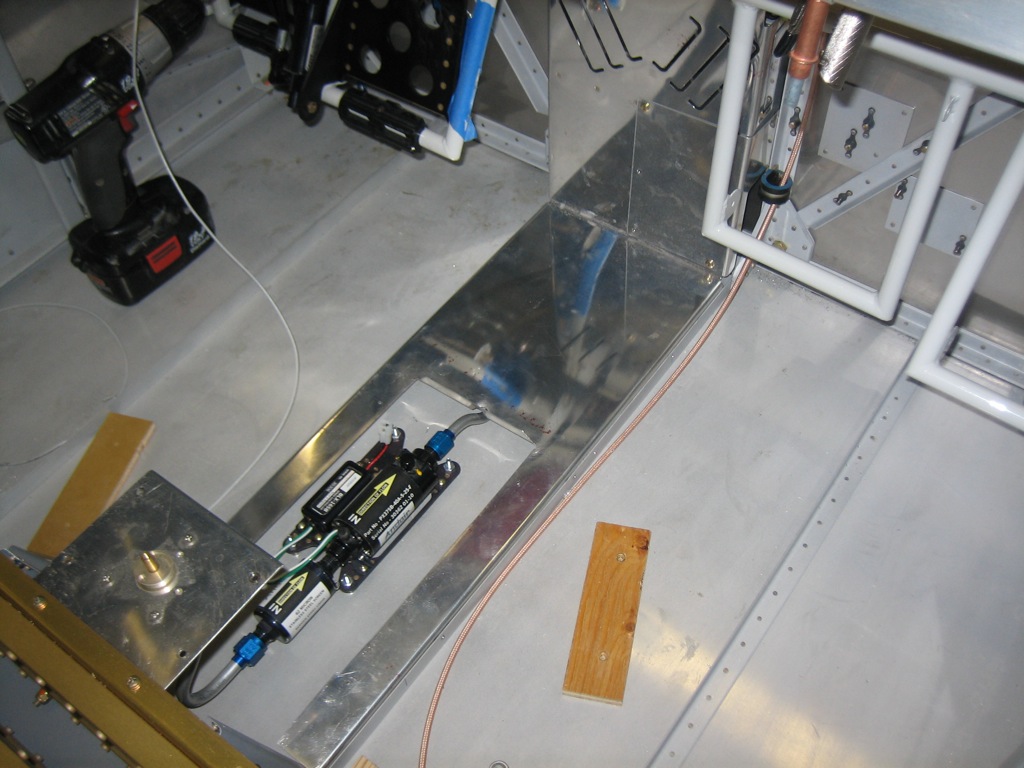

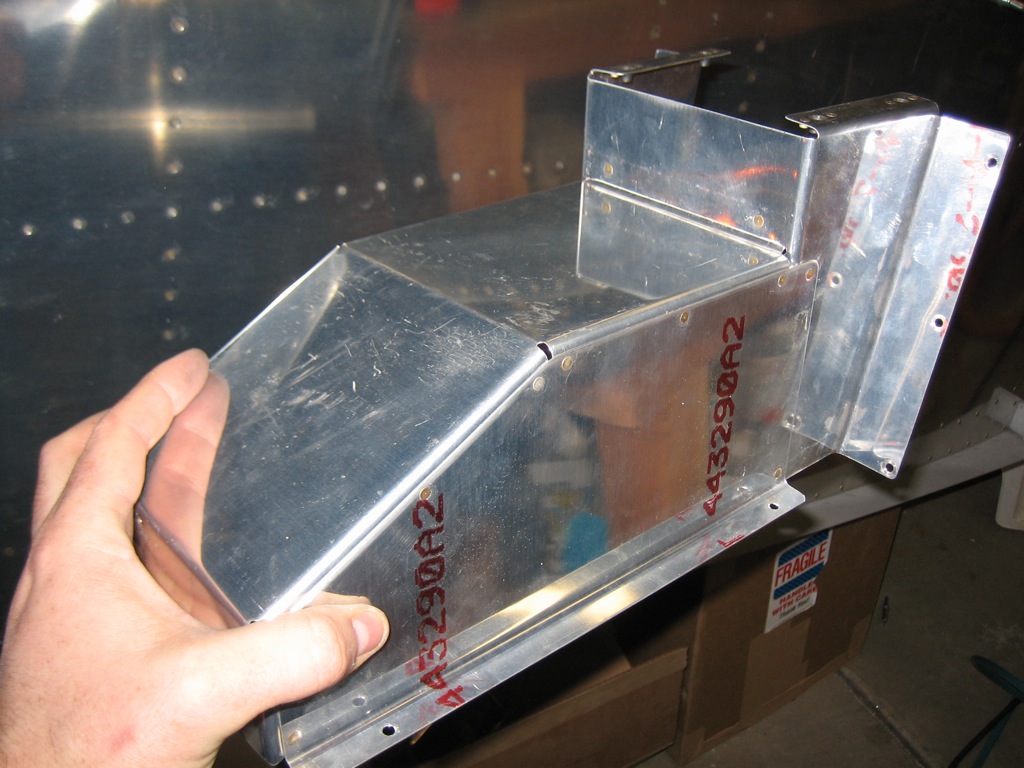

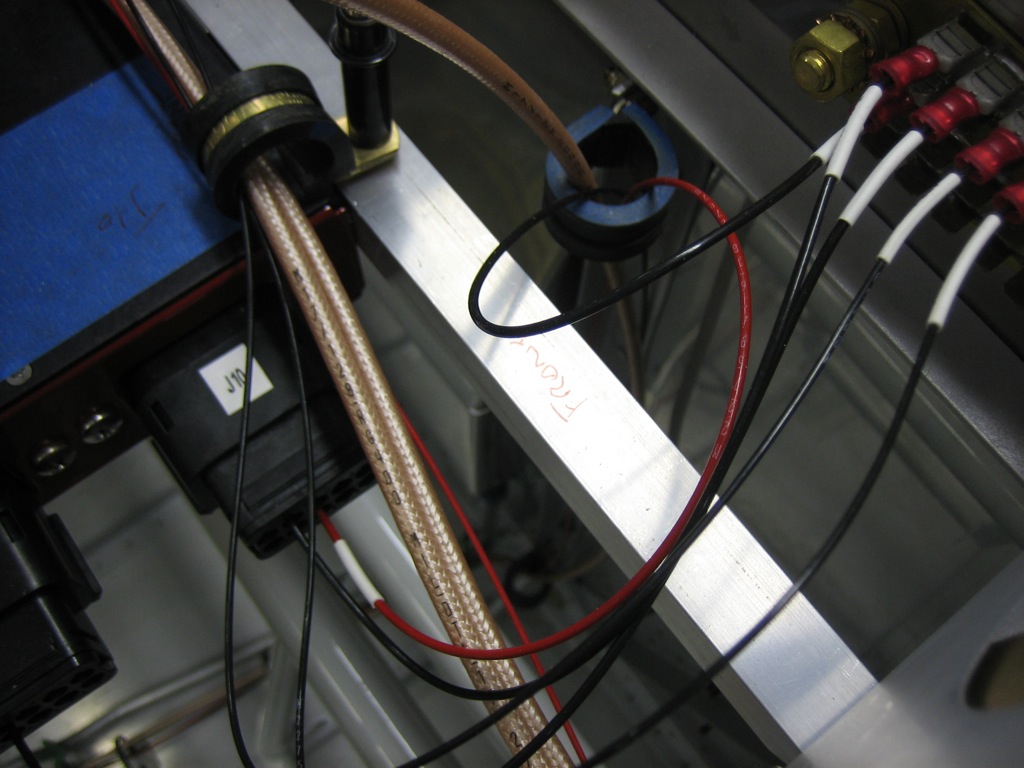

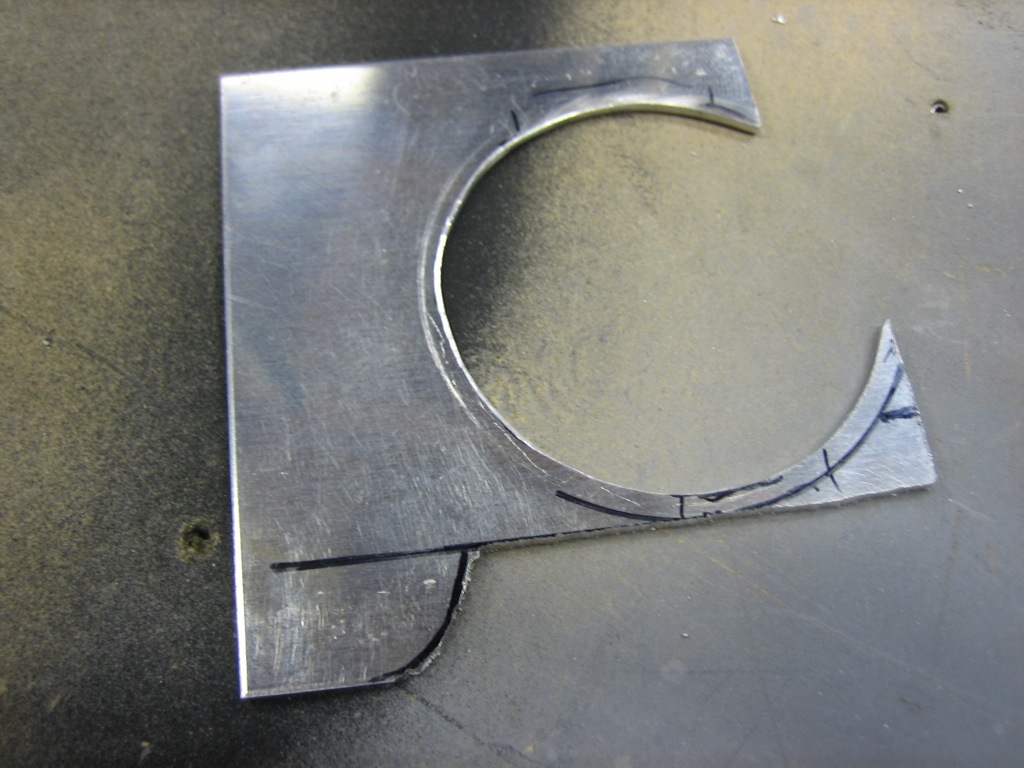

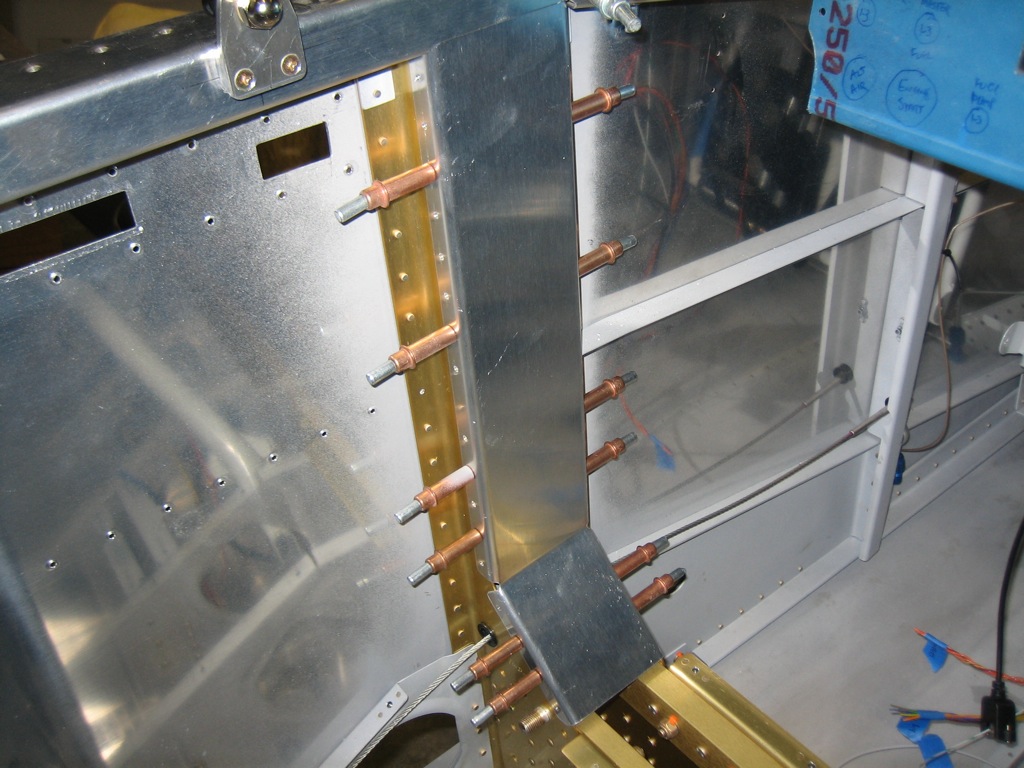

Anyway, tonight’s little project was to determine the mounting position for the control cables. I used the stock bracket that came with the kit to mock up a potential control spacing to see if there were any conflicts before drilling the actual bracket that I bought from Experimental Air. My original goal (and what I mocked up here) was to put the three engine controls in the center, the parking brake on the left and the cabin heat on the right. This resulted in 2″ between the outer knobs and the outboard engine controls and about 2 7/16″ between each of the engine controls. After playing with it for a few minutes, I decided that this was too tight and that the cabin heat knob should be removed from the bracket.

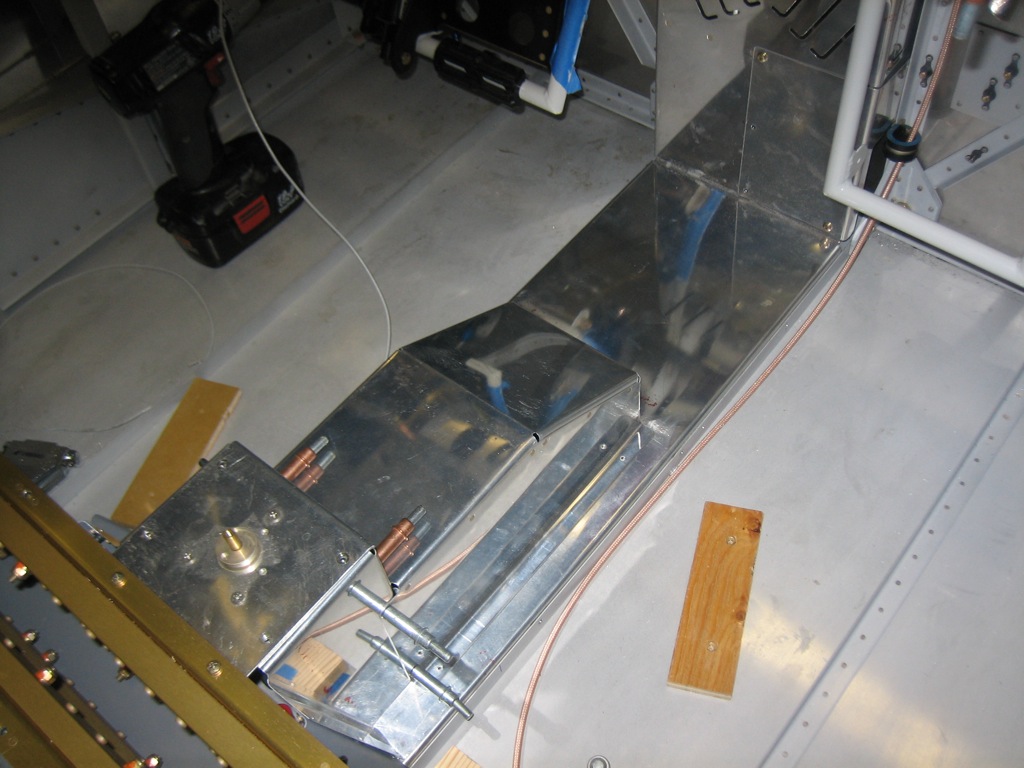

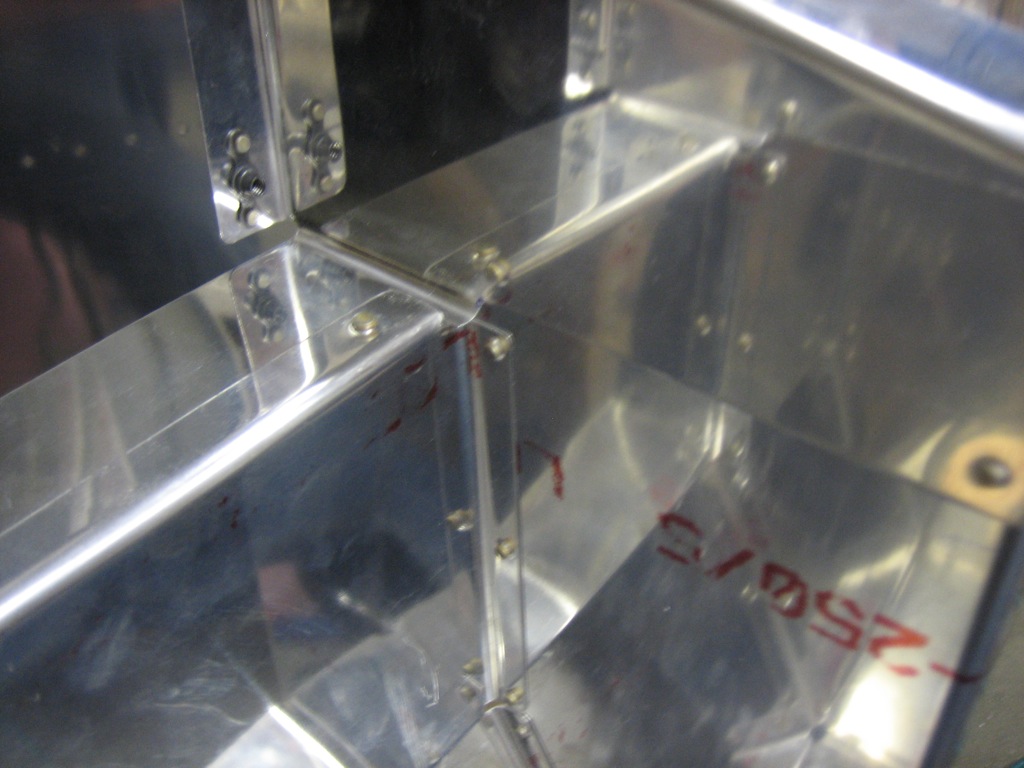

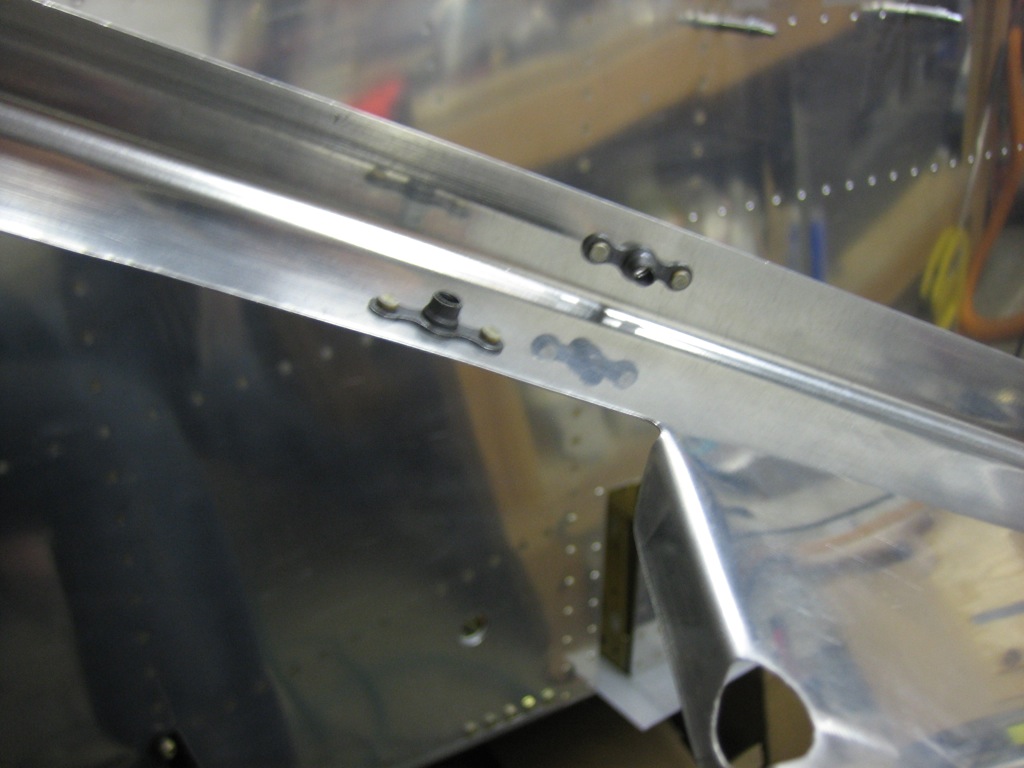

As you can see, I also moved the parking brake knob over to the right side of the bracket so that it’s out of the way. This also has the advantage of bringing the engine controls closer to me. The three engine controls are spaced 3″ apart and the parking brake knob is a hair over 2 1/2″ from the mixture knob. You can also see that I drilled the holes lower than the center of the bracket. They’re 3/4″ up from the bottom edge which leaves plenty of room to provide labels for each of the controls.

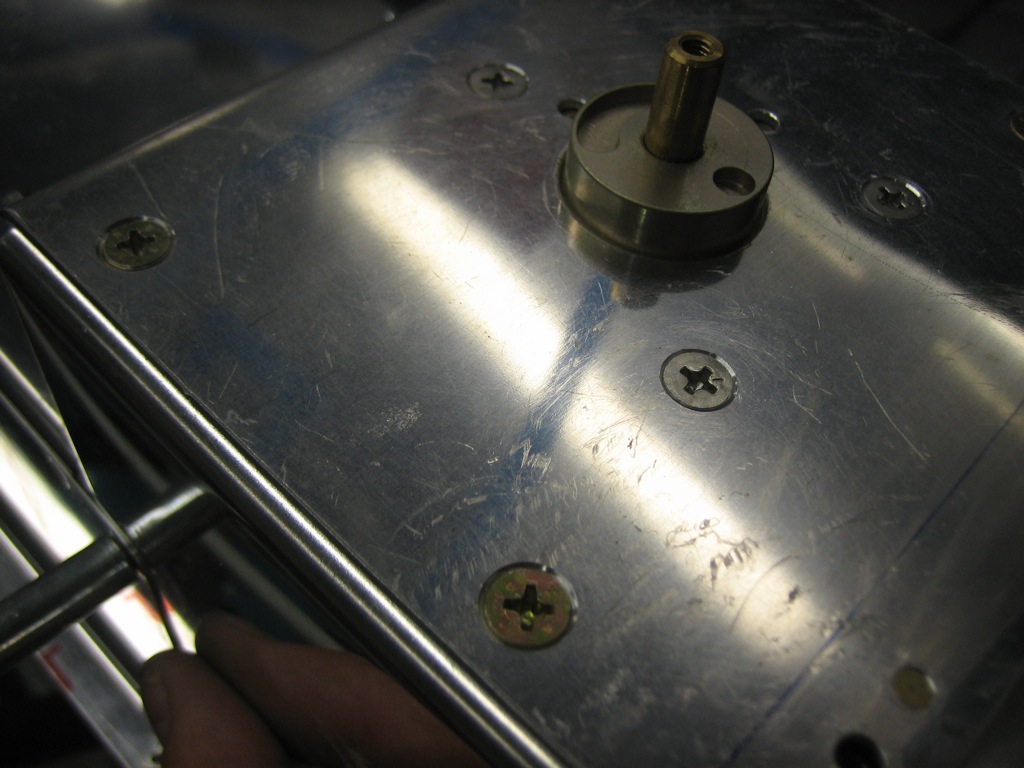

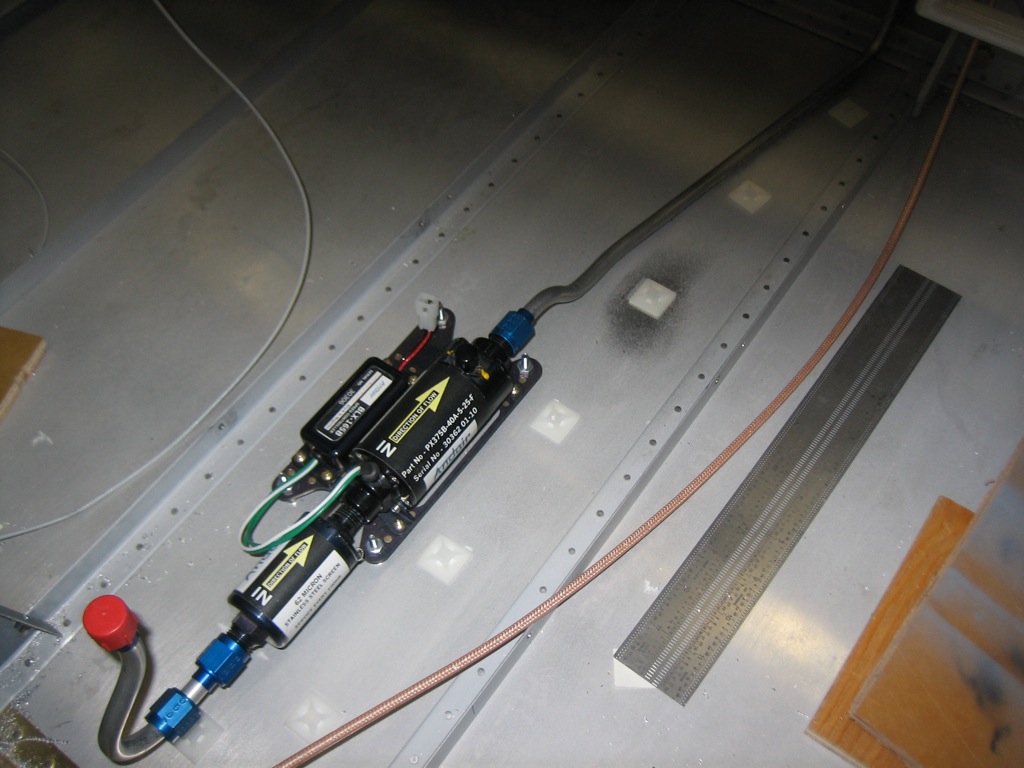

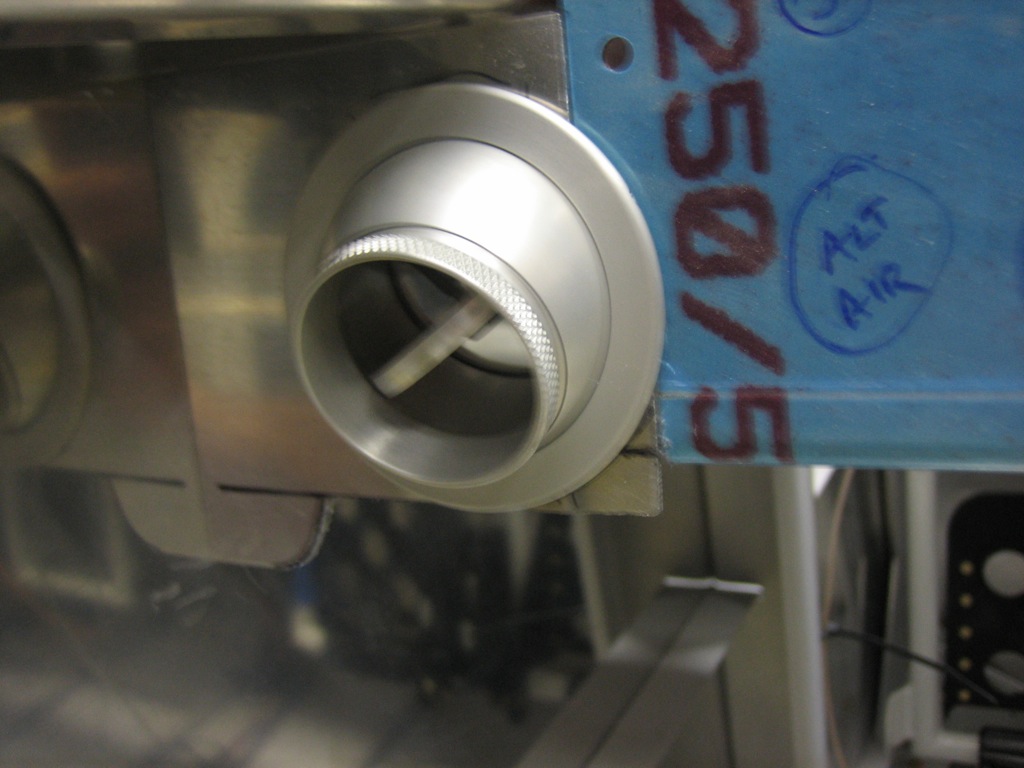

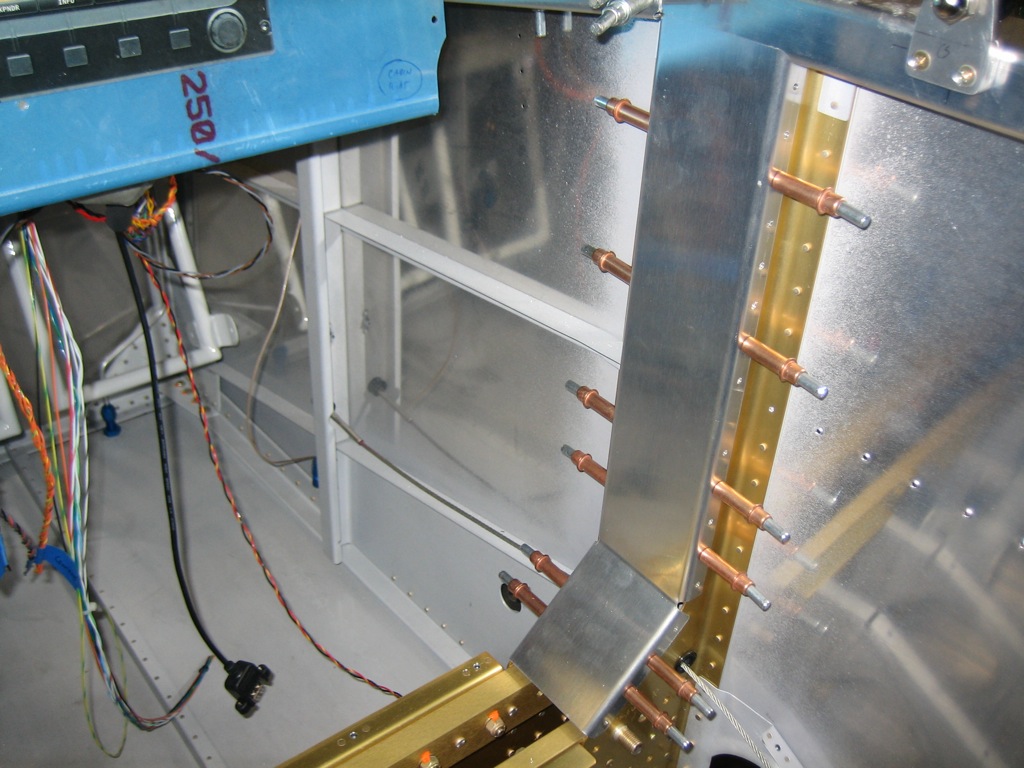

A top view shows that my hand has plenty of room when operating each knob.