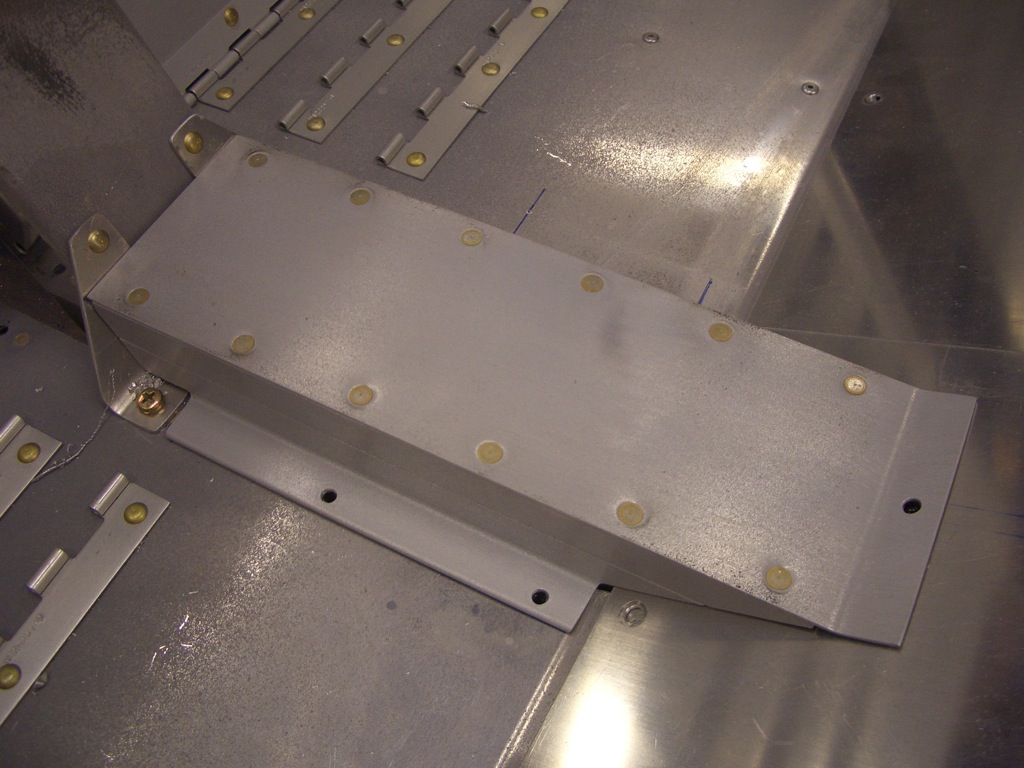

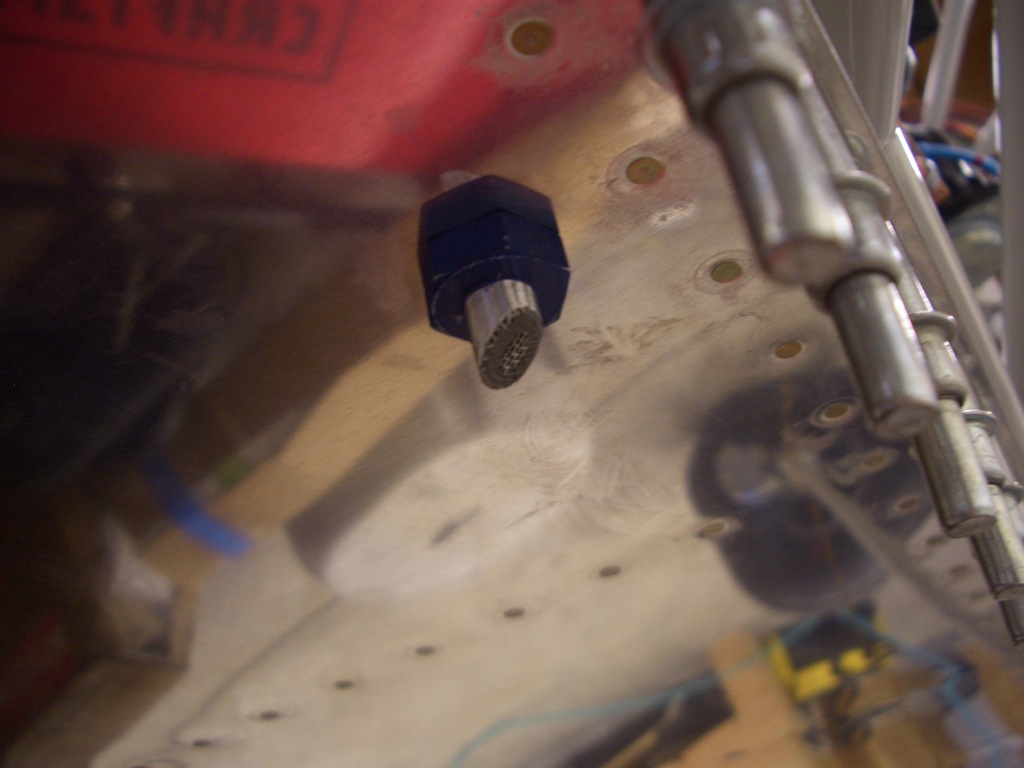

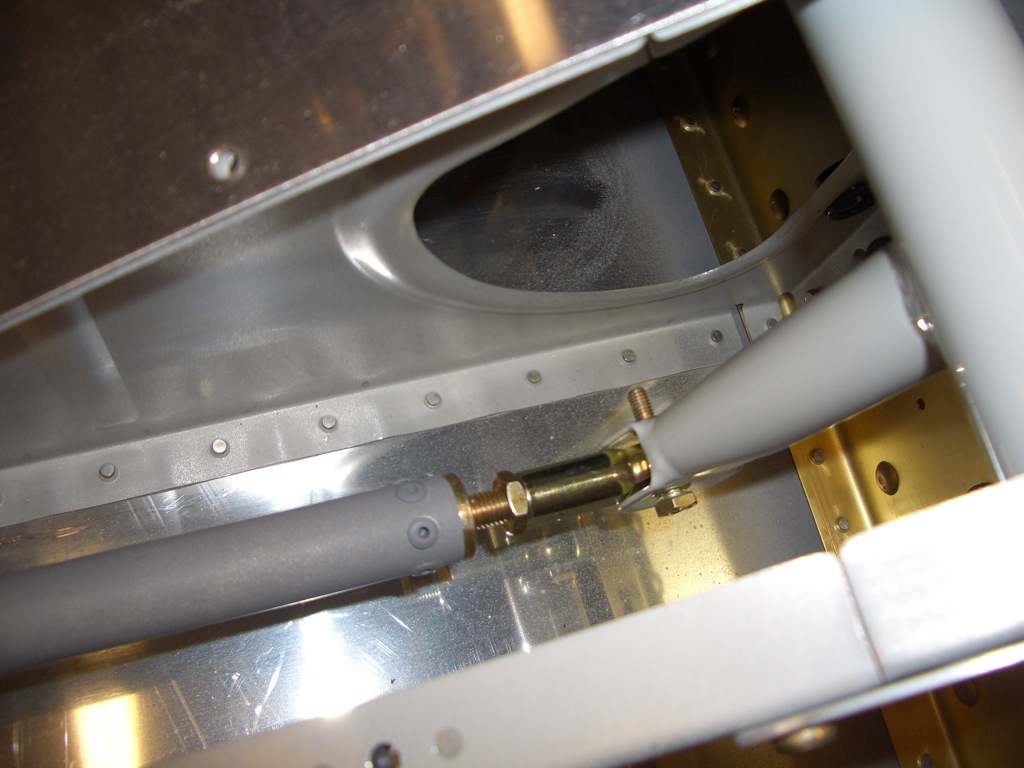

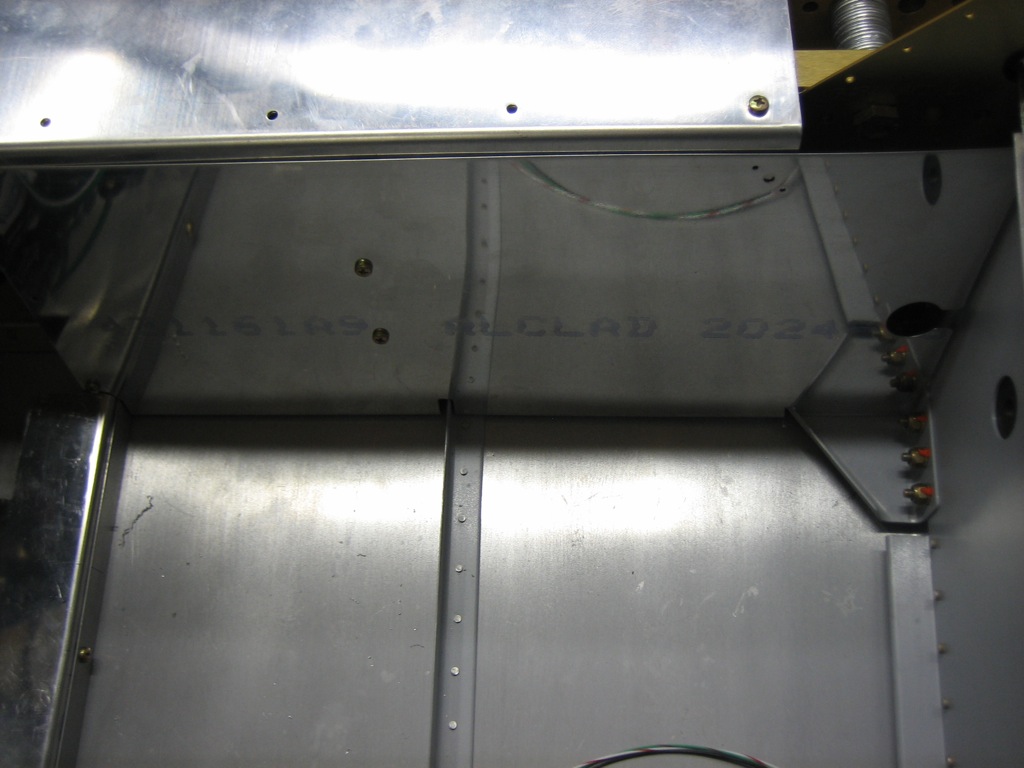

Now that the proseal has cured, I trimmed the excess screen and mounted the fuel vents through the floor just behind the firewall.

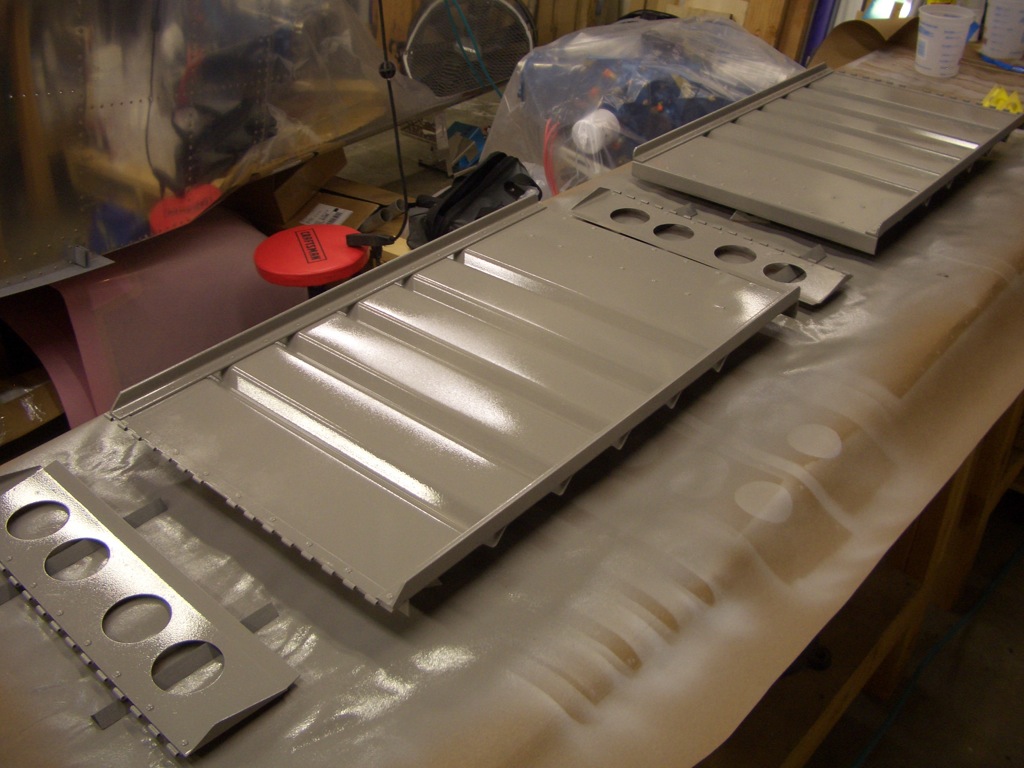

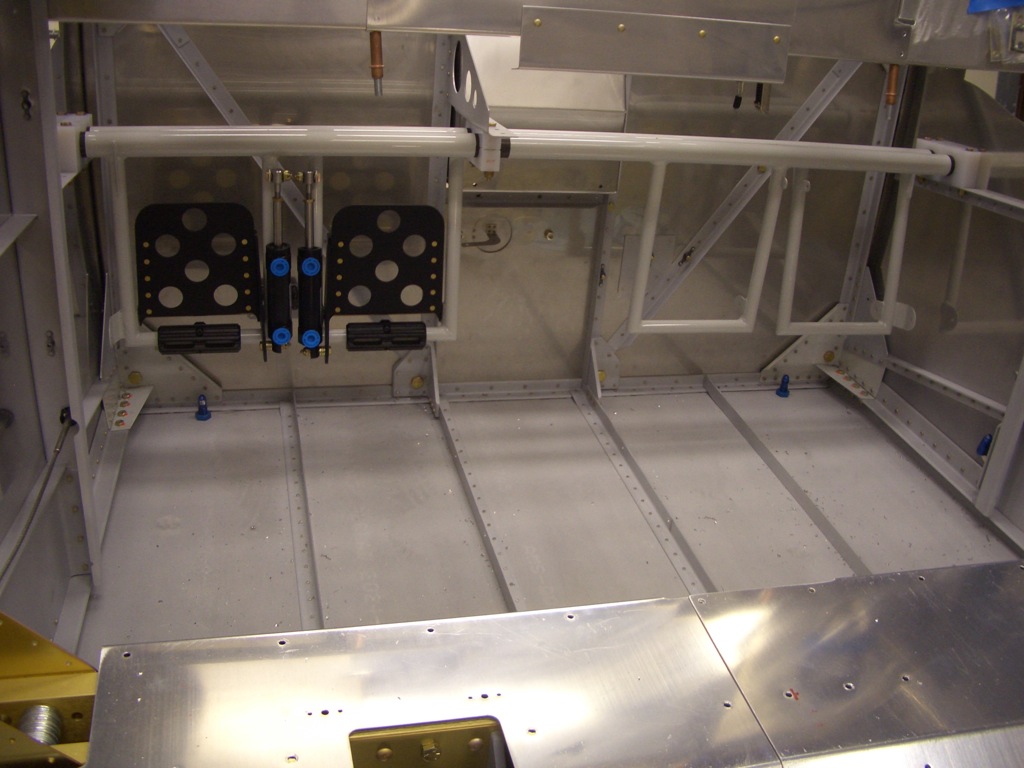

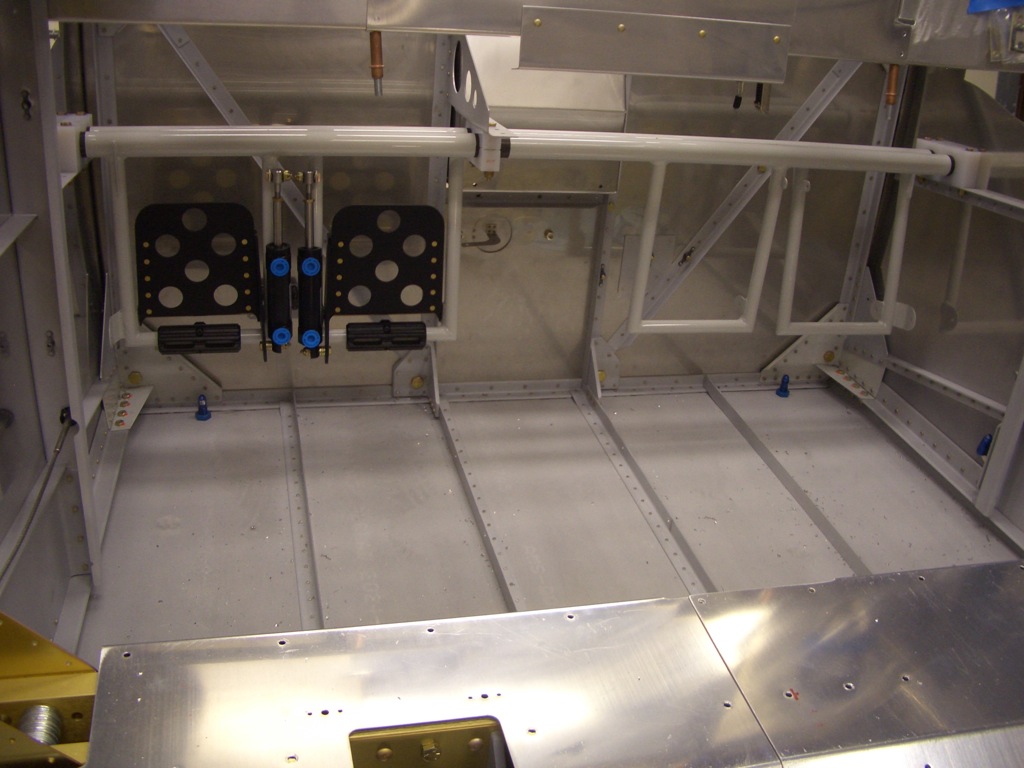

I got some parts back from the metal finisher where I had them black anodized. The primary components were the parts for the brake pedals. I quickly riveted them together. The brake pedals will get a lot of wear over the years, and this should keep them looking like new.

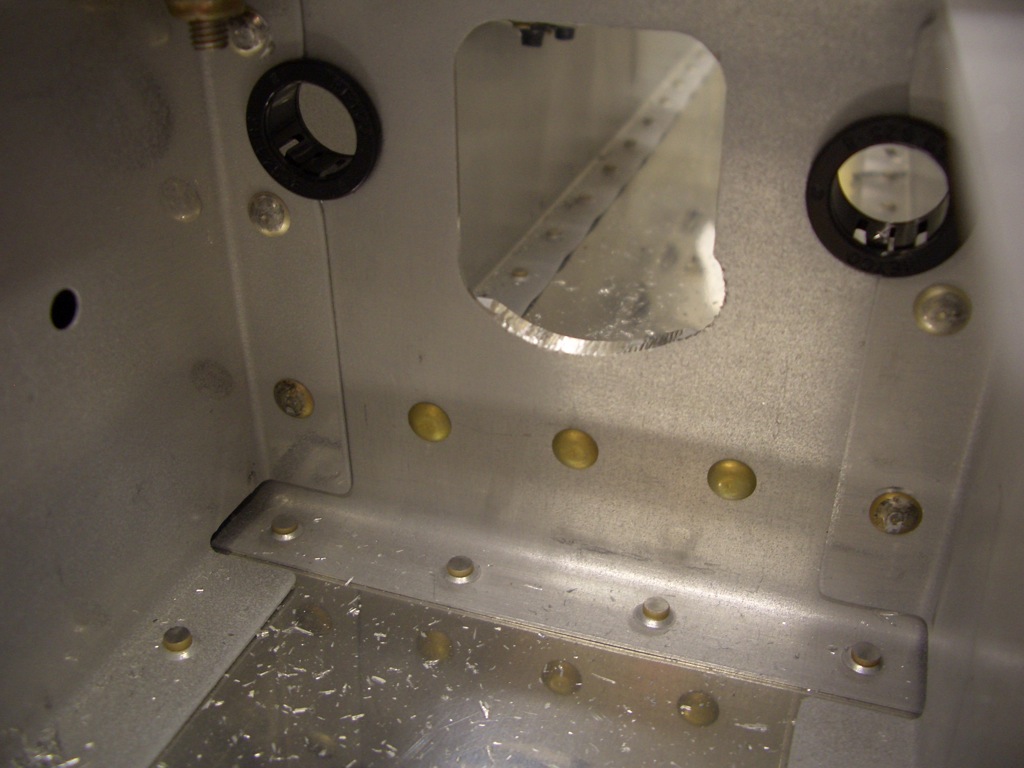

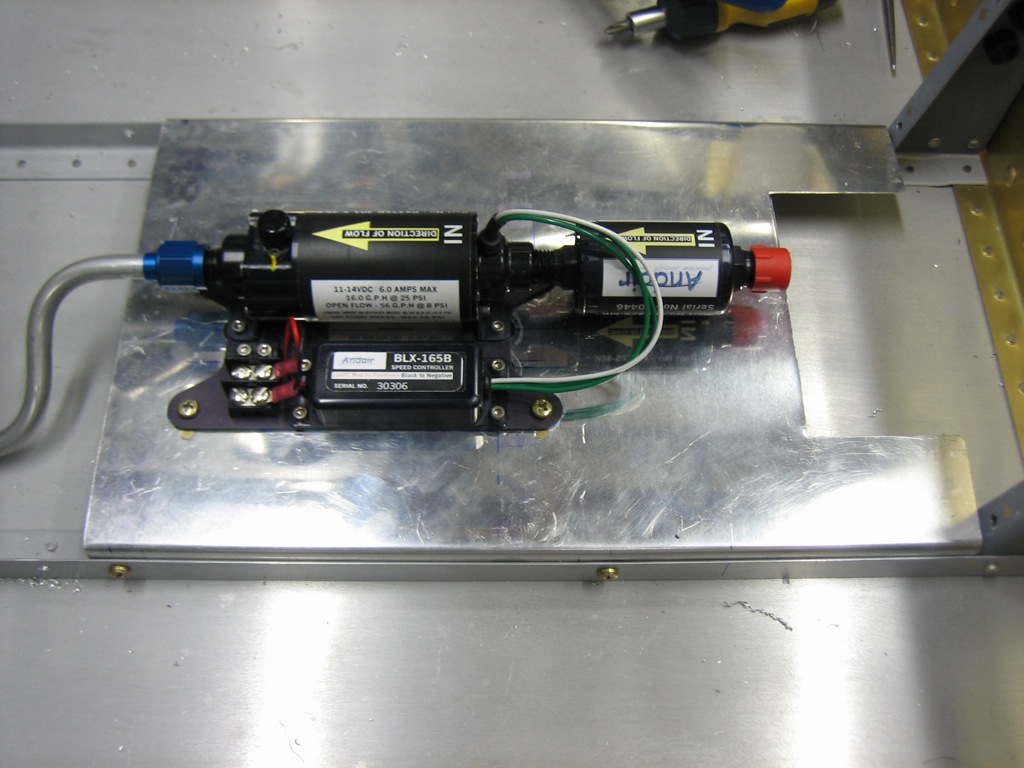

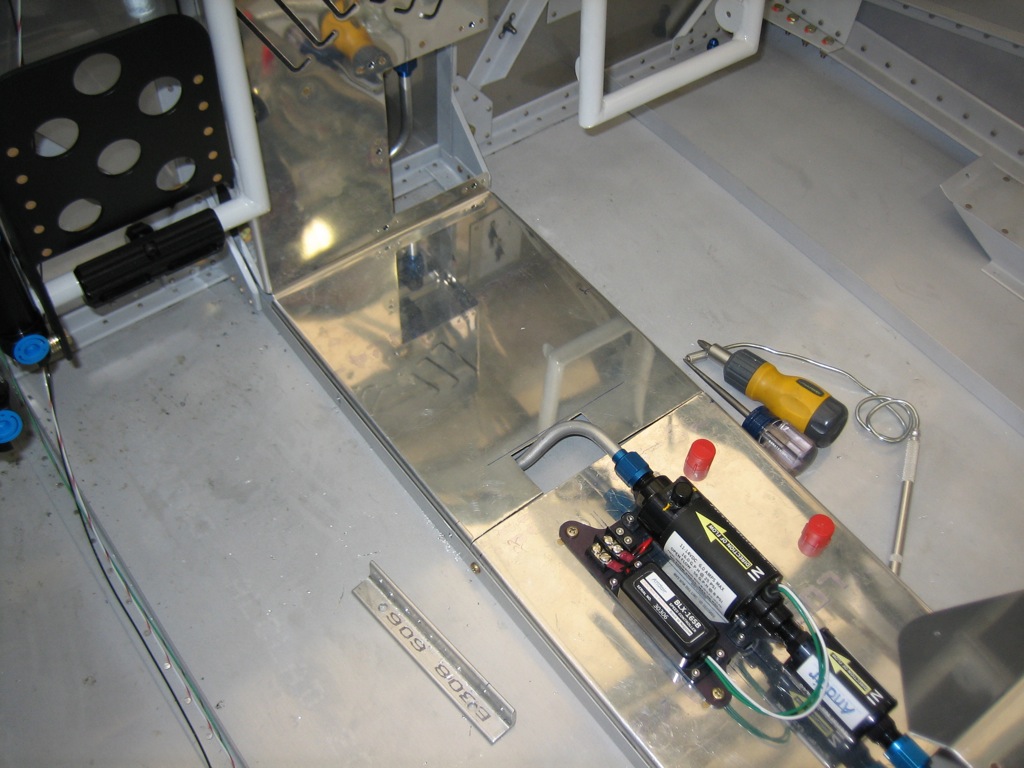

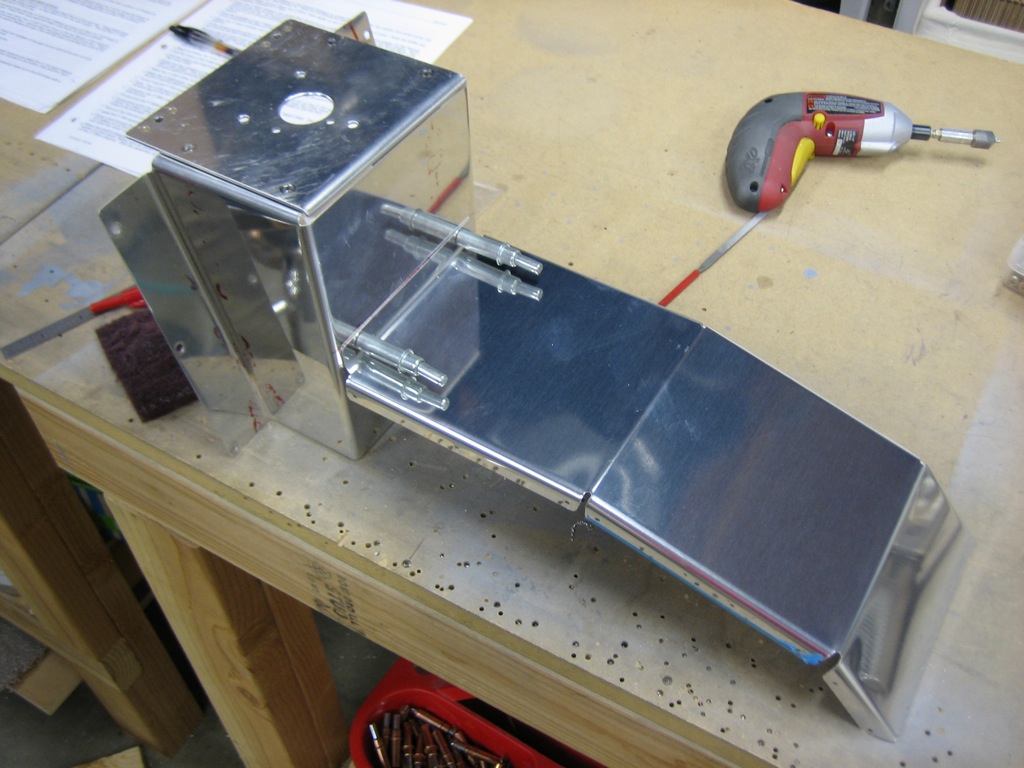

Since I was already paying the minimum shop fee, I threw in a couple of other components. This is the brake fluid reservoir and transducer manifold.

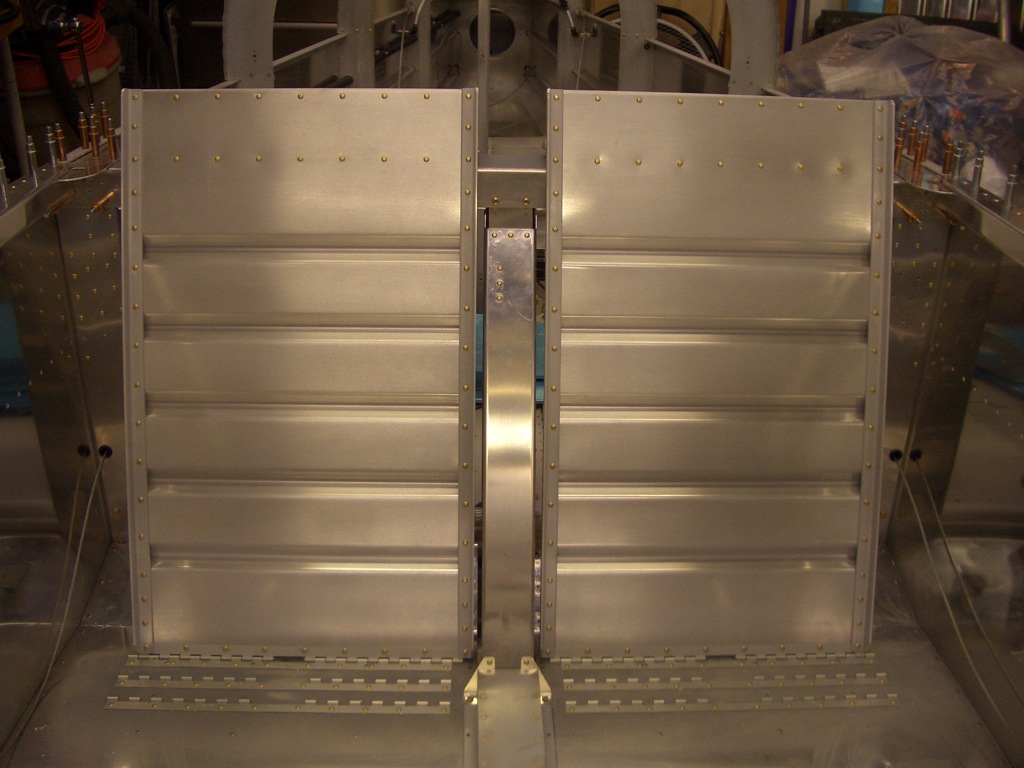

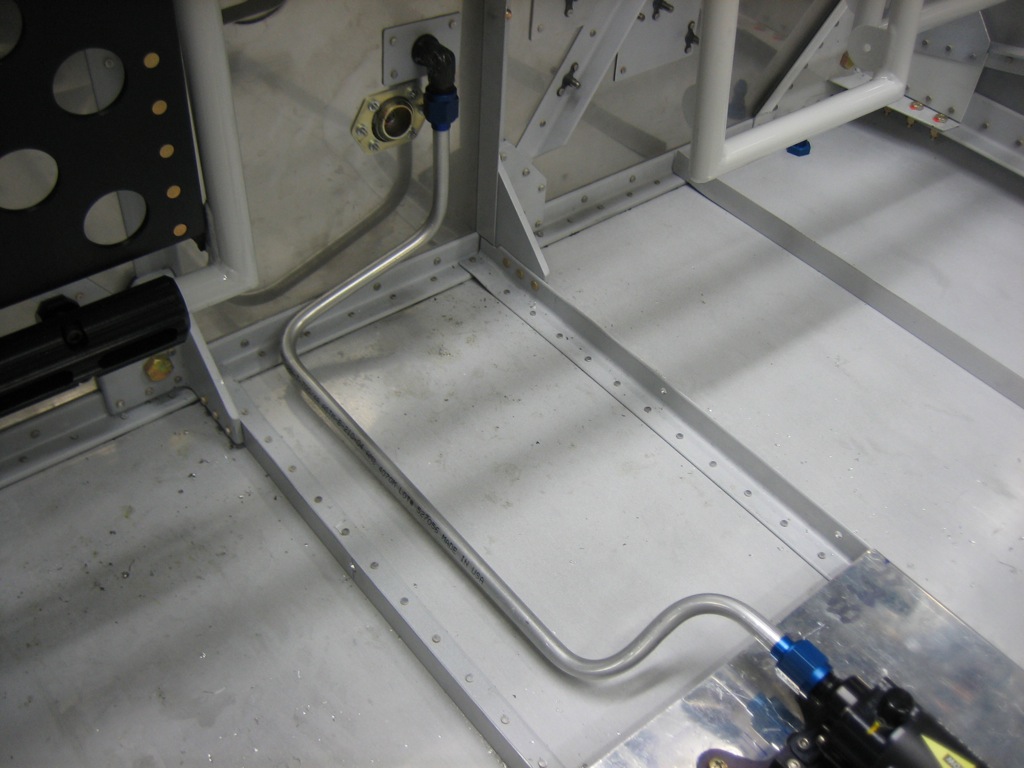

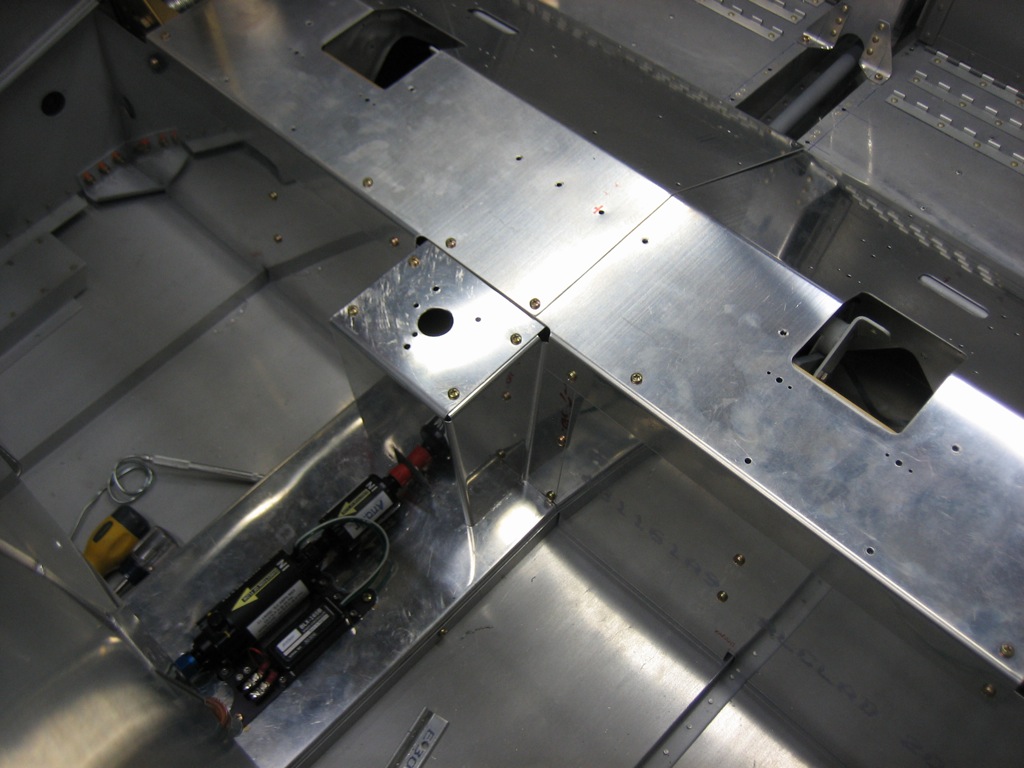

I mounted the brake pedals as well as the master cylinders and some rudder pedal extensions from

JD Air Parts. These parts are all black anodized, so they look great together.

Finally, I mounted the rudder pedals in the plane and torqued all of the bolts.

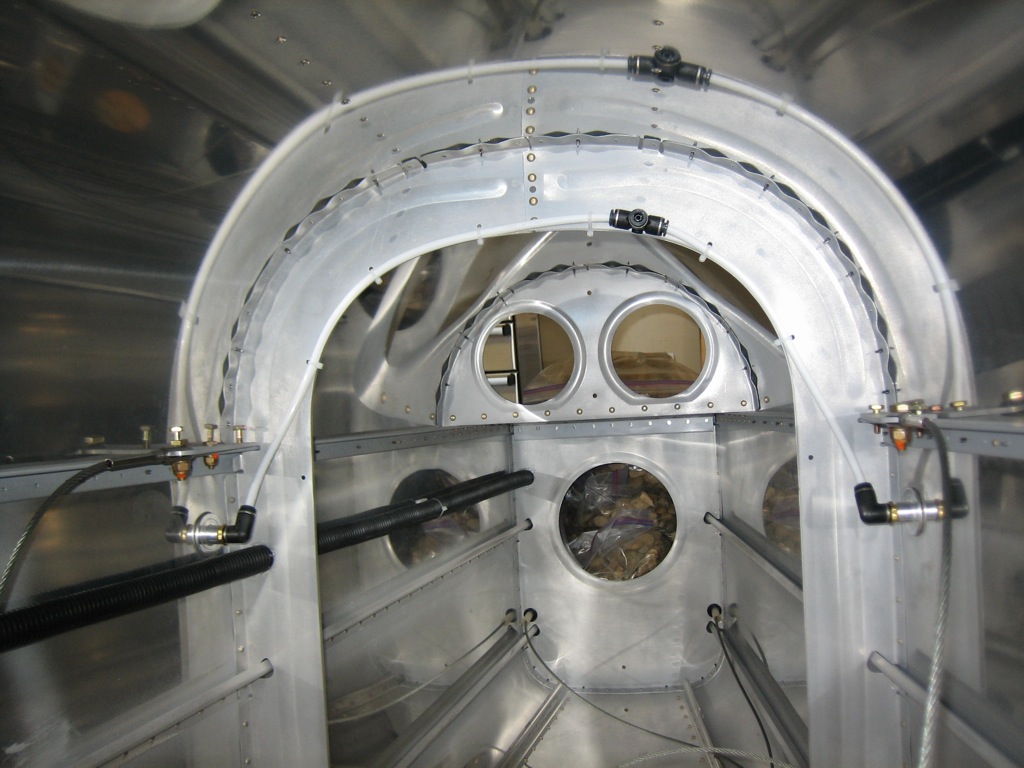

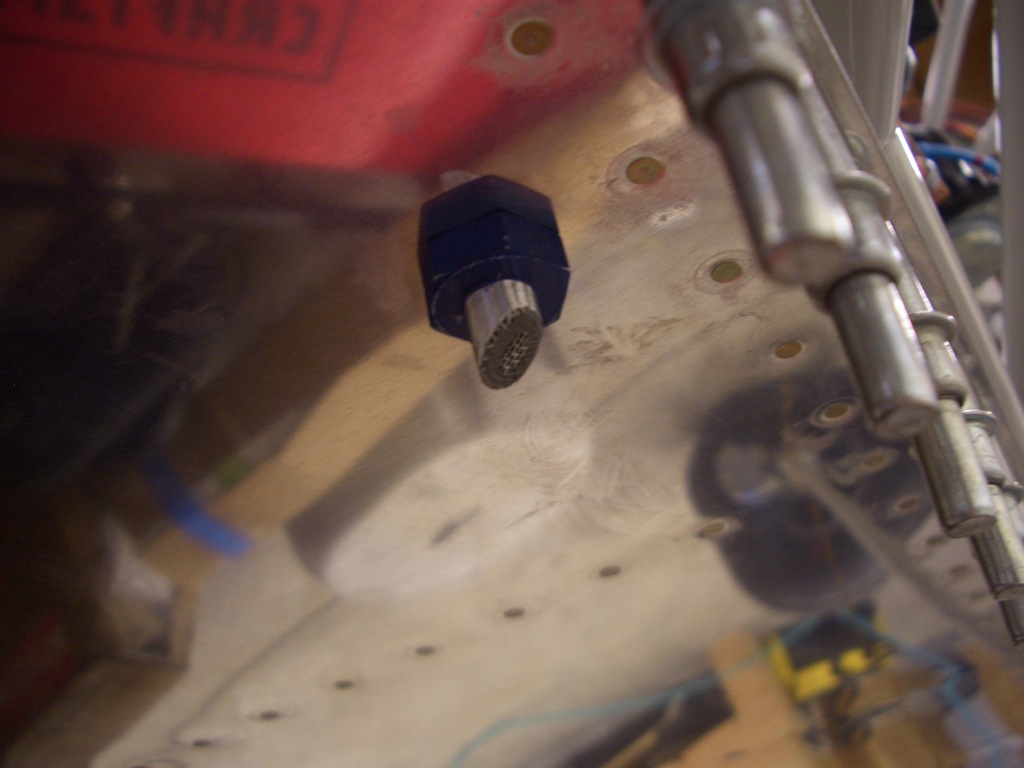

The last thing I did for the night was to install the brake fluid reservoir on the firewall.

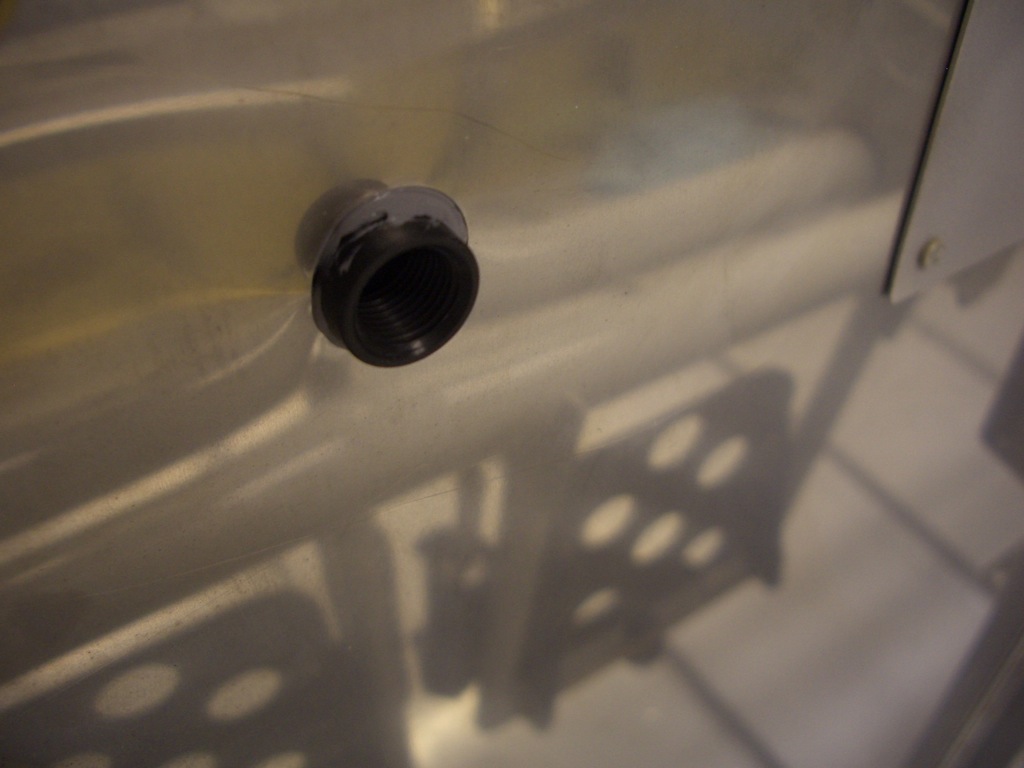

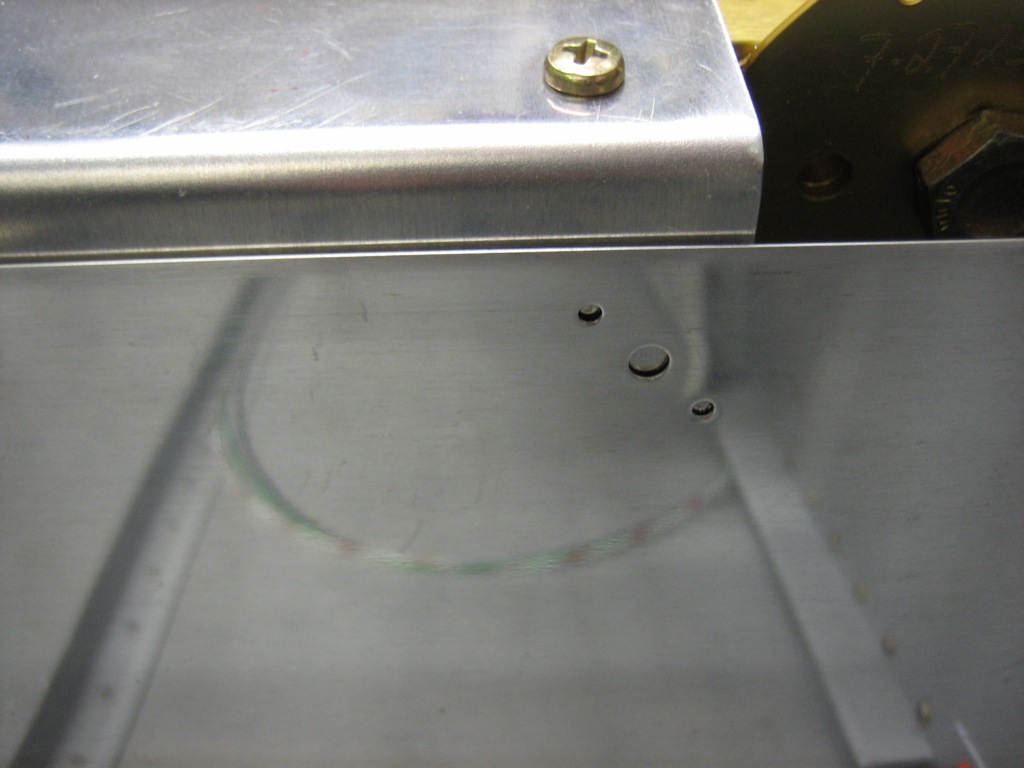

You can see on the inside that I used some firewall sealant around the hole through the firewall.