Vertical Power released version 1.3 of their VP-X firmware today. I installed it and it resolved the issue with the reversed trim buttons on the SkyView. Now, whether I press the coolie hat on the stick to the right or press the “Right” button on the SkyView, the stick goes right.

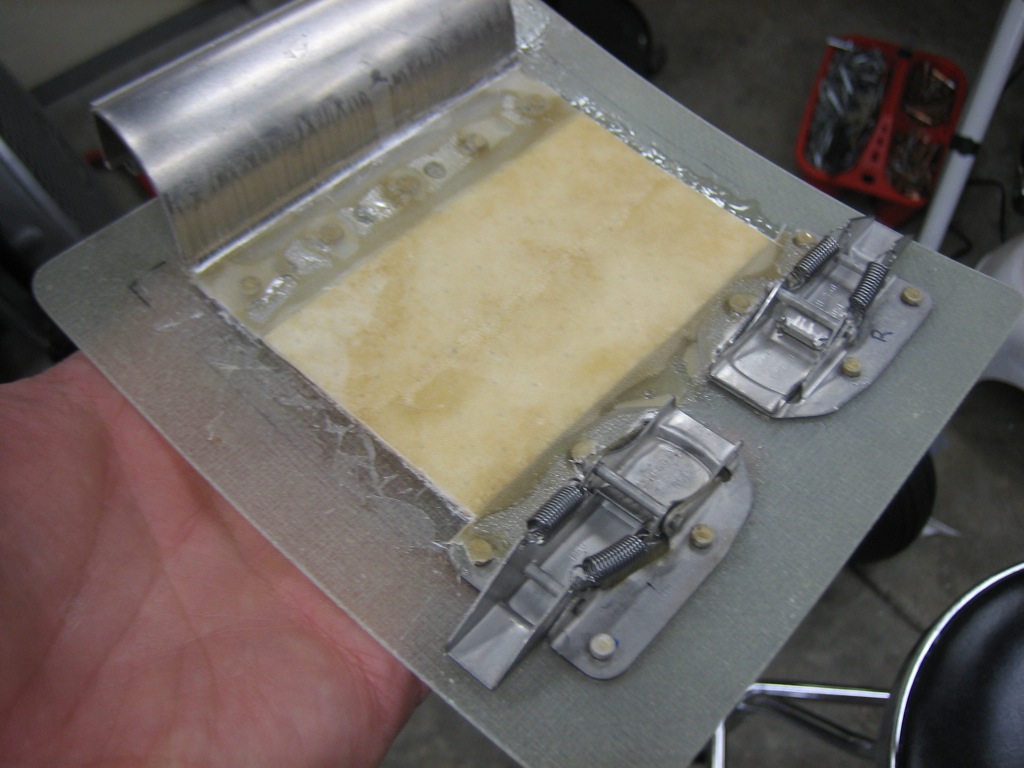

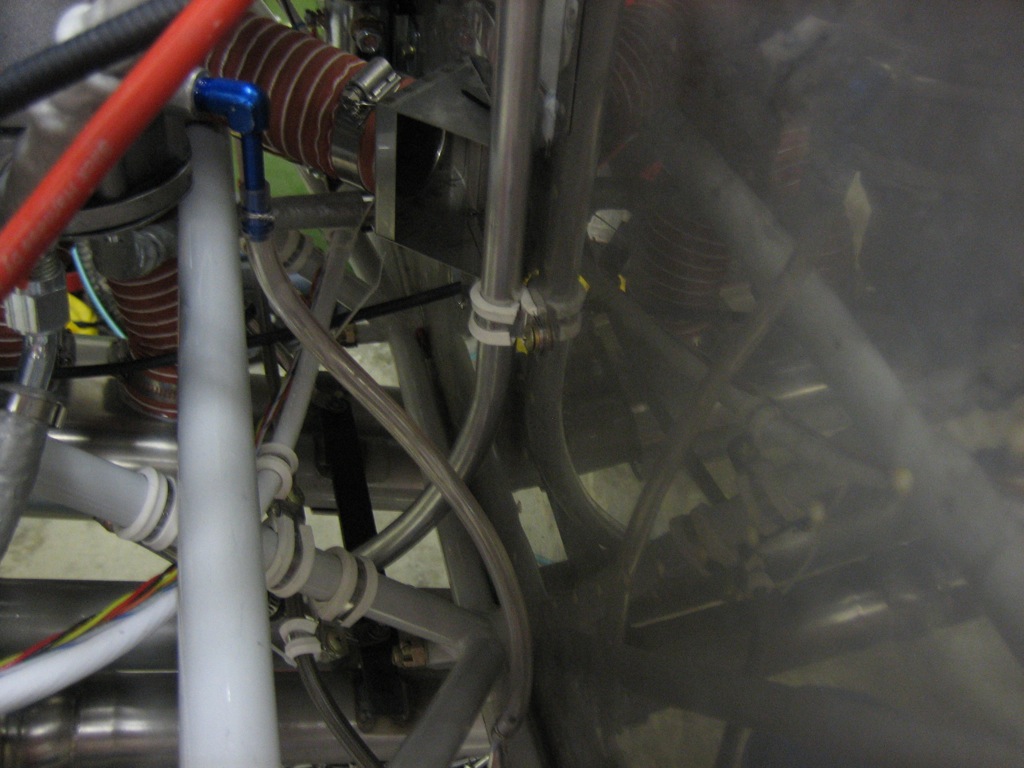

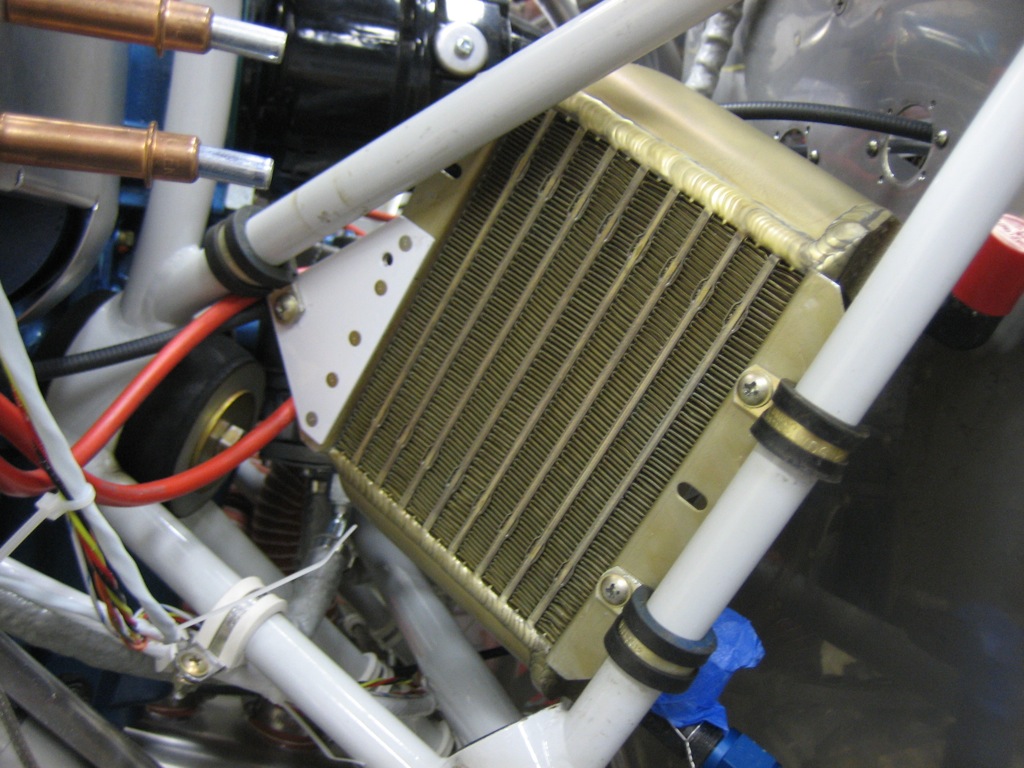

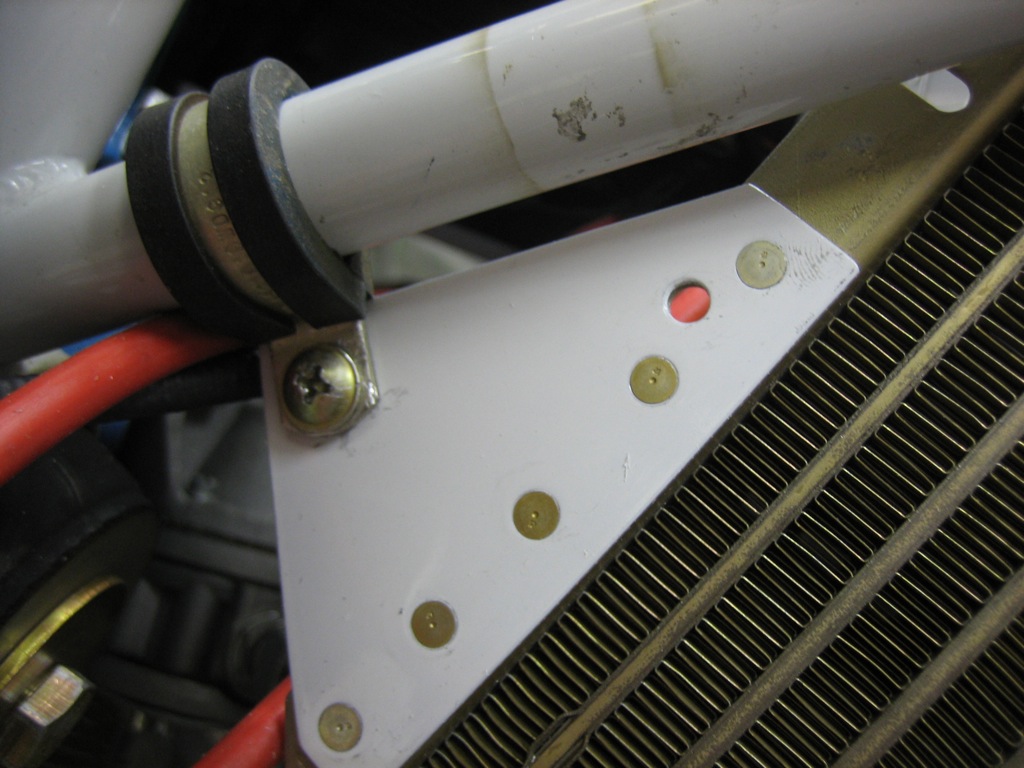

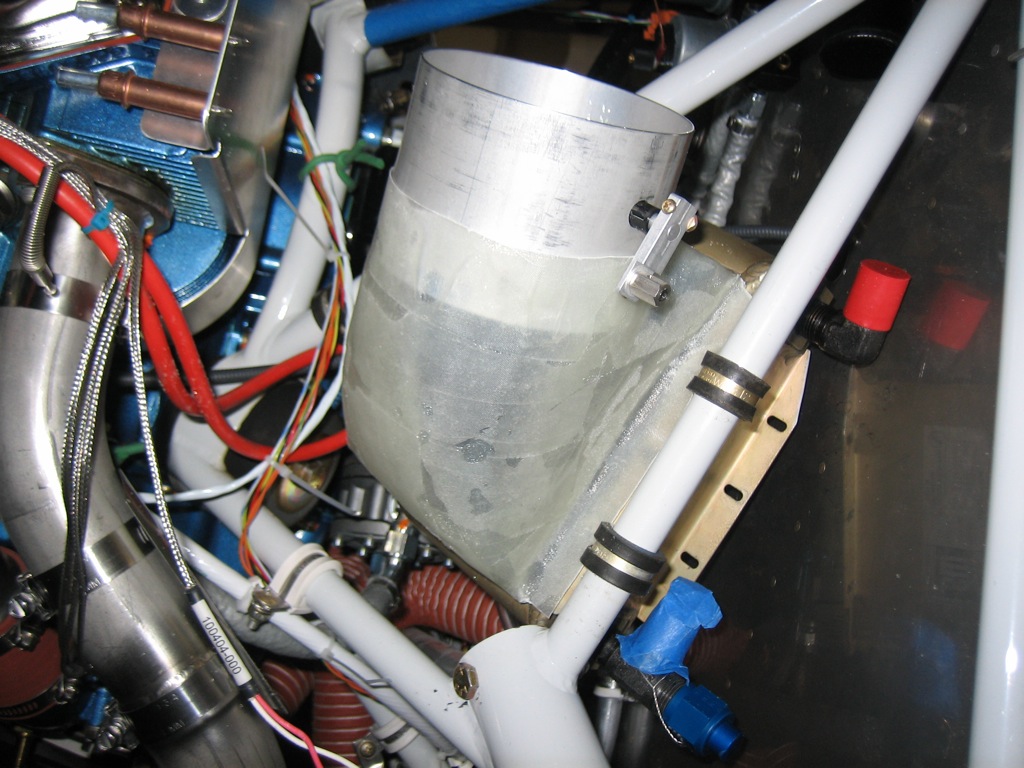

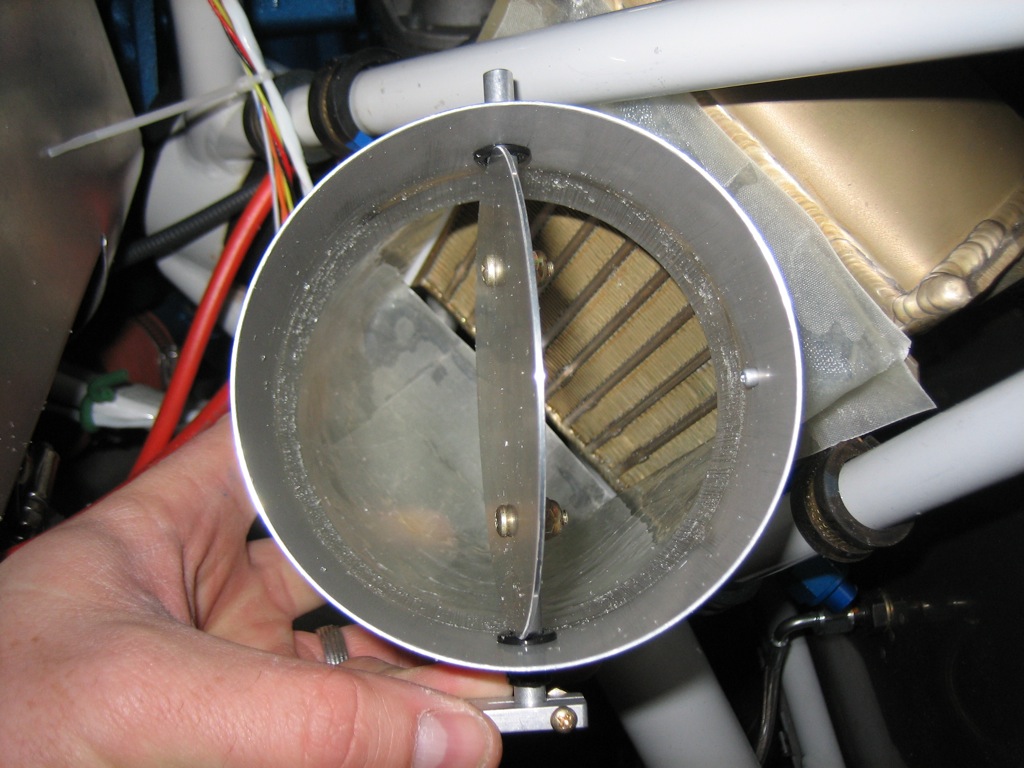

I spent the rest of the night messing around with the oil cooler position. I think I’m finally pretty happy with the location. I ended up turning the oil cooler over from the way I had it so that the oil cooler hoses attach on the bottom. With the oil cooler mounted on the baffles, it’s higher than the oil return line on the engine, so oil drains out of the oil cooler automatically during oil changes. With the oil cooler mounted on the engine mount or firewall, it’s below the oil return line, so most of 1 qt of oil would be trapped in the oil cooler during oil changes. I did some research on this, and this is not too uncommon on certified airplanes, and the way to deal with it is to make the oil hoses enter from the bottom and put a tee in the lowest fitting. One side of the tee will go back to the engine, and the other side will just contain a cap. During oil changes, this cap can be removed to drain the oil out of the cooler and hoses.