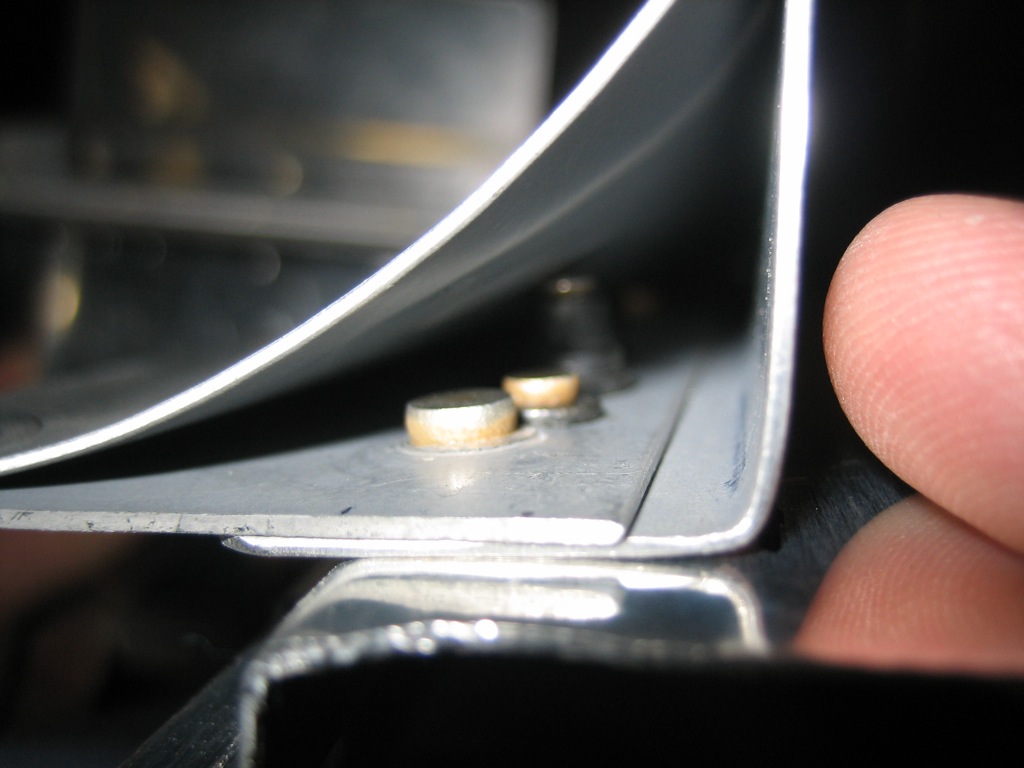

I meant to post this a few days ago, but here’s the flange nicely centered in the hole. I picked up some aluminum screen material to rivet between the ramp and flange to keep out bugs and debris.

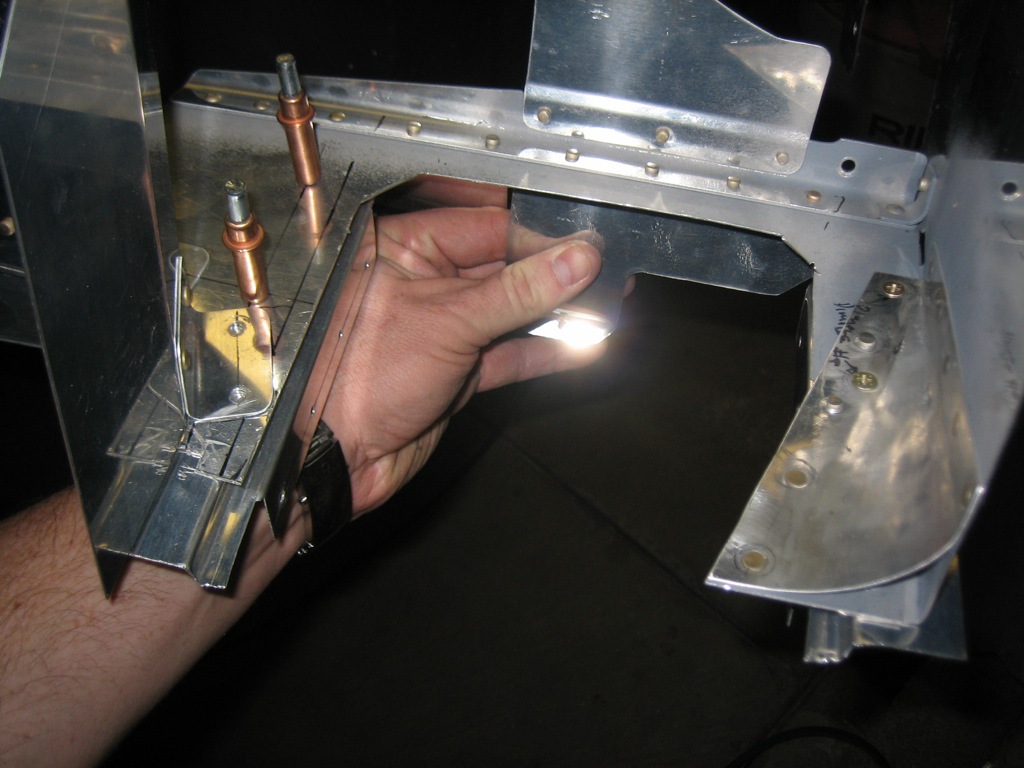

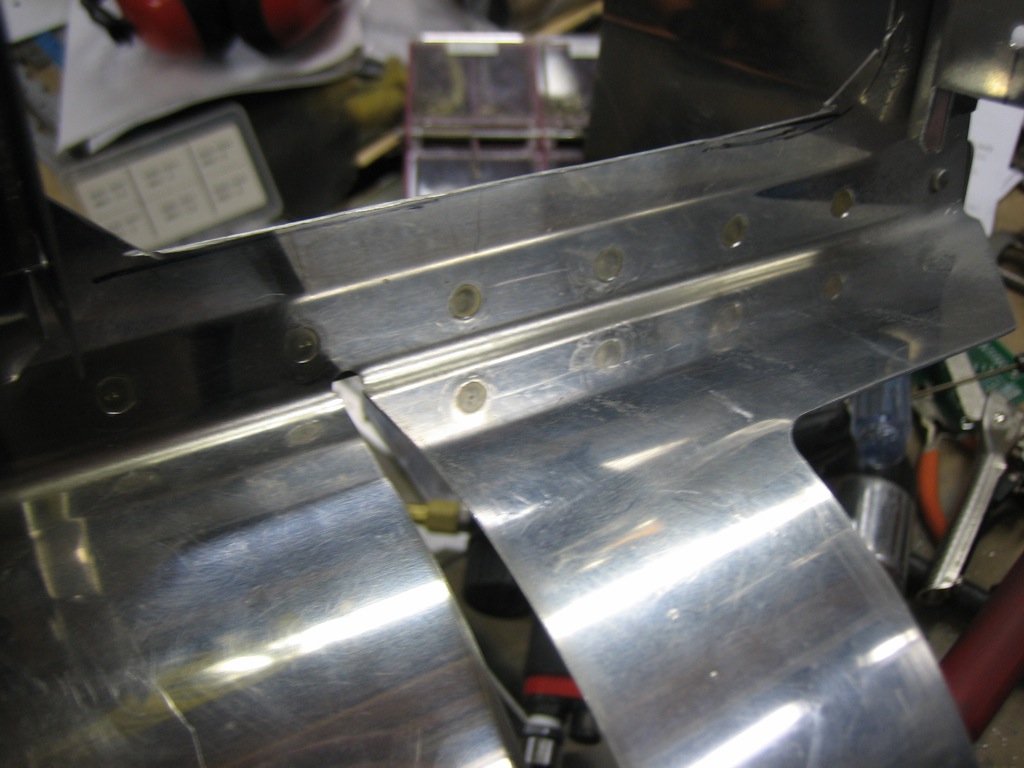

I cut out the opening for the air filter. This is significantly undersized and the opening will be made large enough to install the air filter from the top.

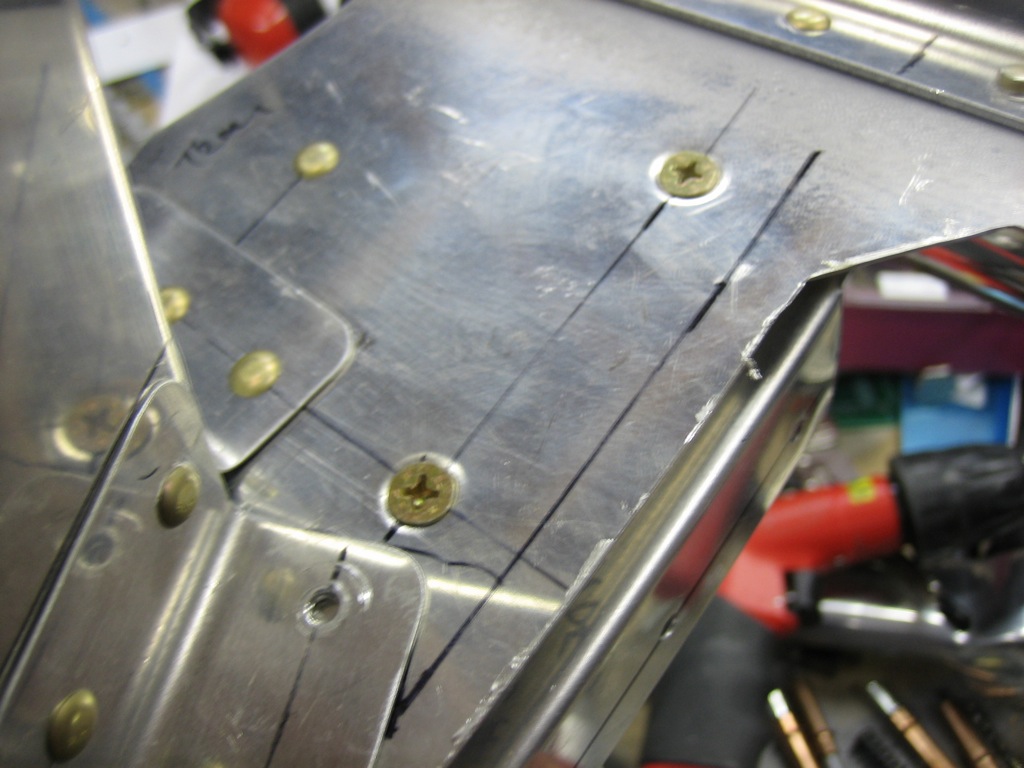

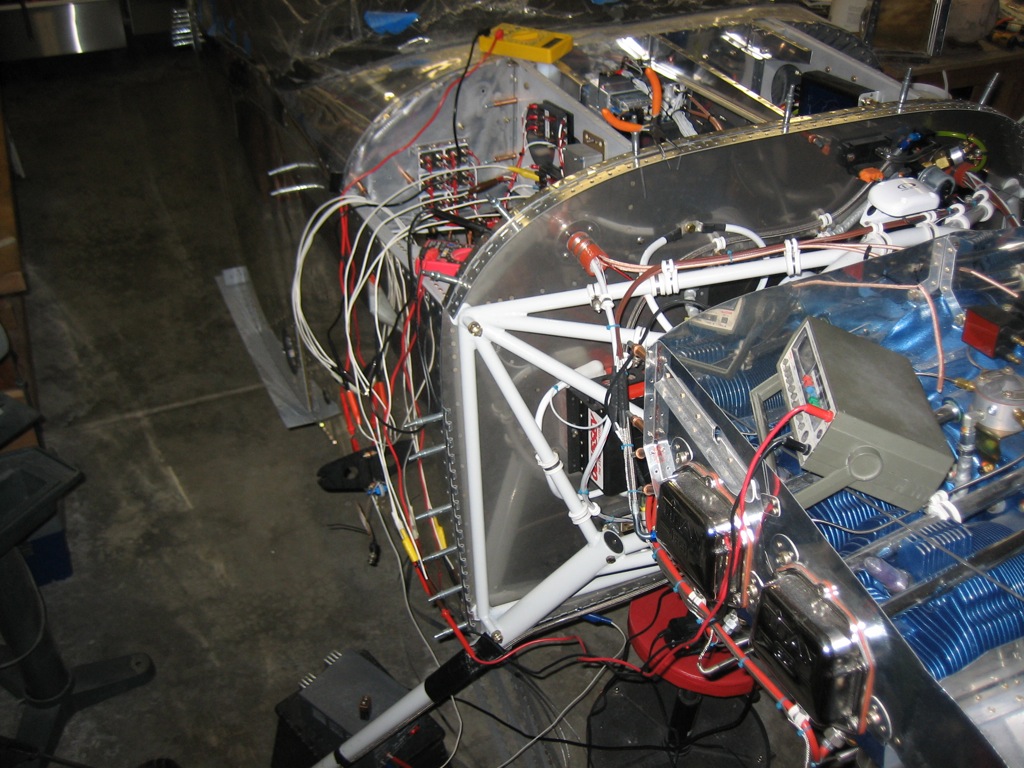

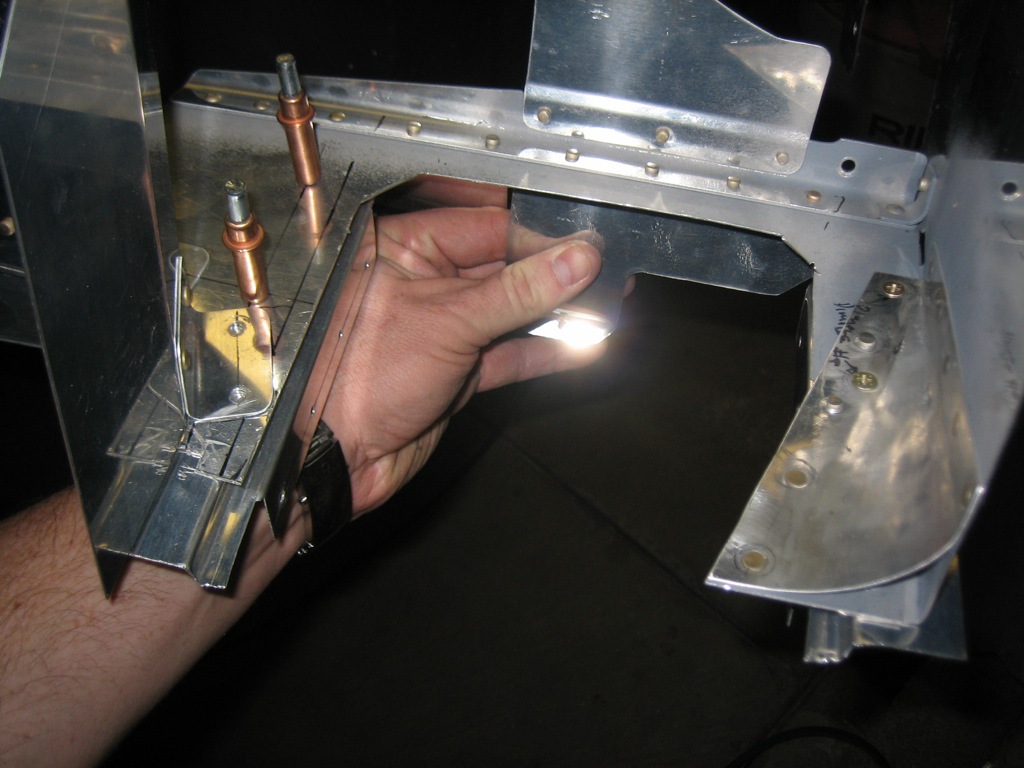

I then reworked the conical gusset a bit. This is not normally installed with the snorkel, but I really didn’t like the way the cowl inlet intersection worked without it, so I’m going this route. The edge of the gusset will cover up a very small amount of the filter, but there will be enough of a gap that air can still flow through the entire filter. I replaced the aft most rivet in the gusset with an AN515-8R8 screw that goes through the ramp and snorkel mounting flange. I added a second screw between the next two rivets forward (which both had to be reversed so that the flush head is on the bottom so that the shop heads don’t interfere with the filter flange).

There’s a third screw at the forward end of the flange, but this screw installs from the bottom because of the conical gusset. The nutplates are K1100-08 for the flush head screws.

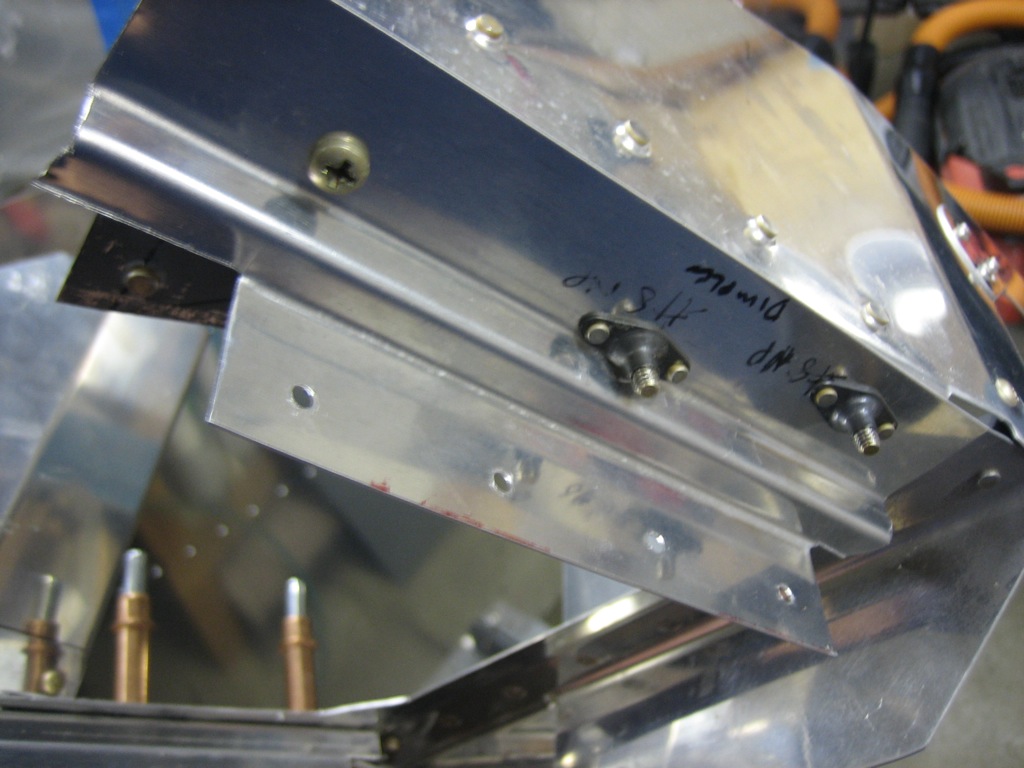

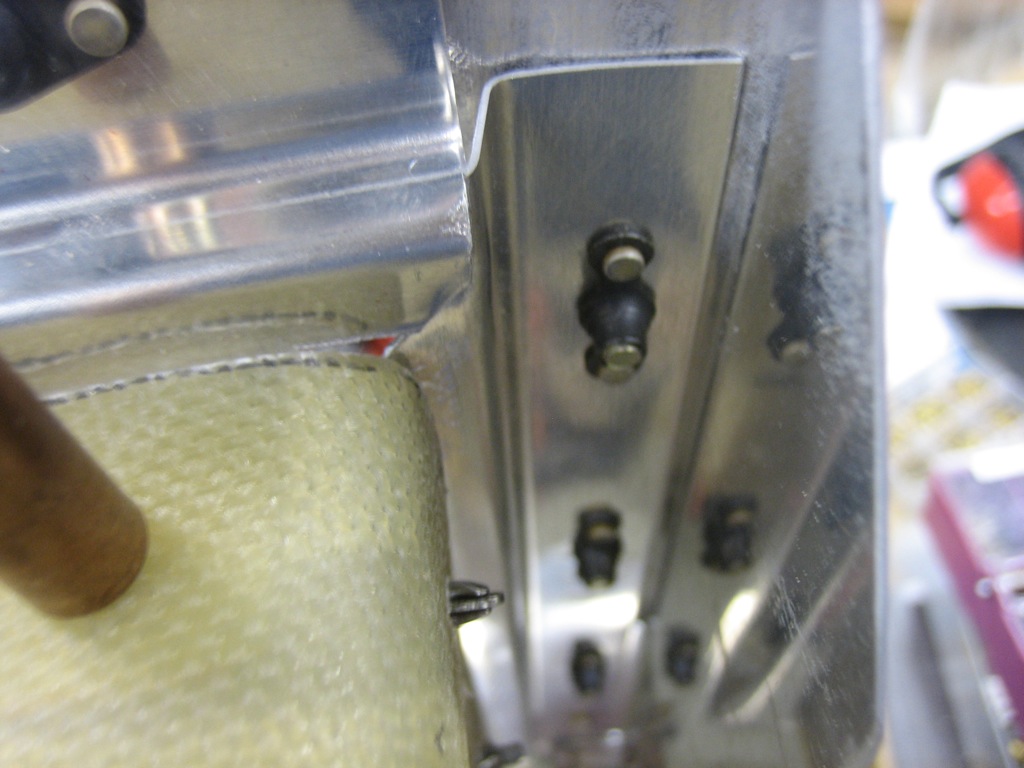

You can see that this screw goes into a K1000-08 nutplate that I mounted under the conical gusset. I used an AN509-8R6 screw because of the tight clearance.

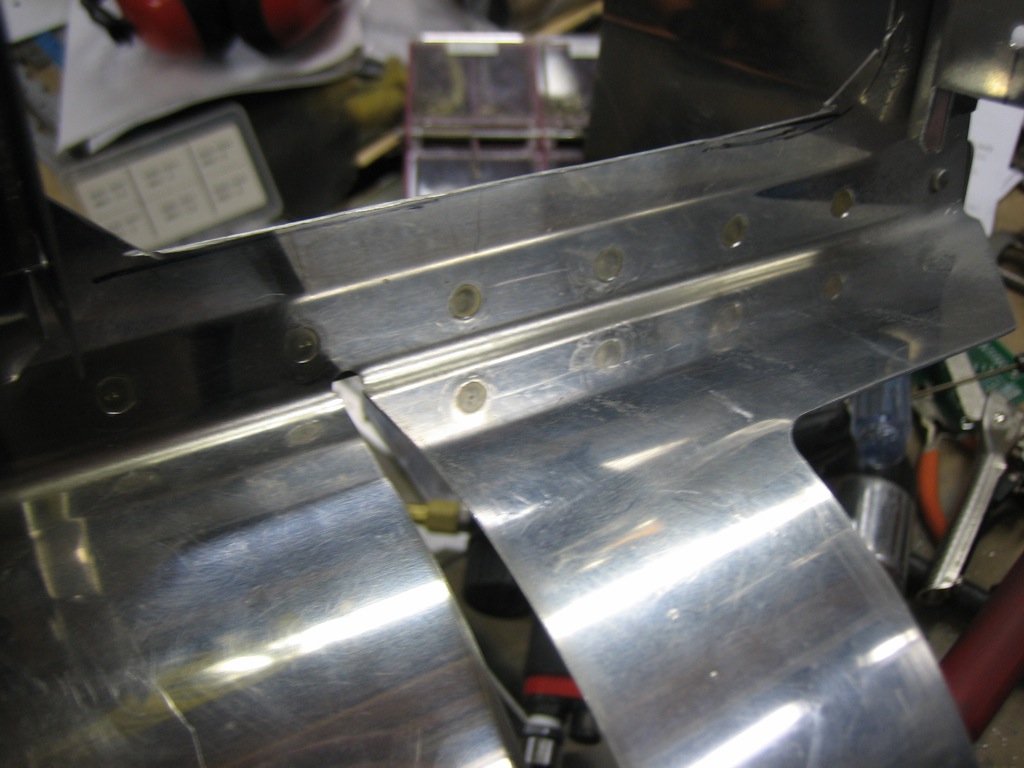

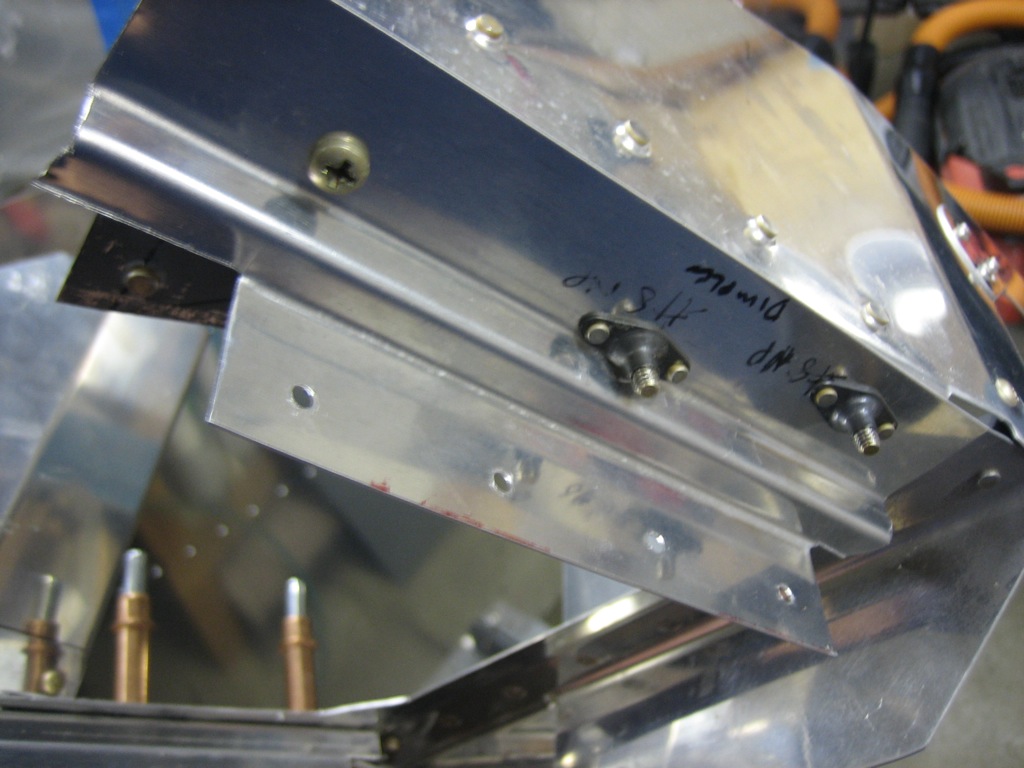

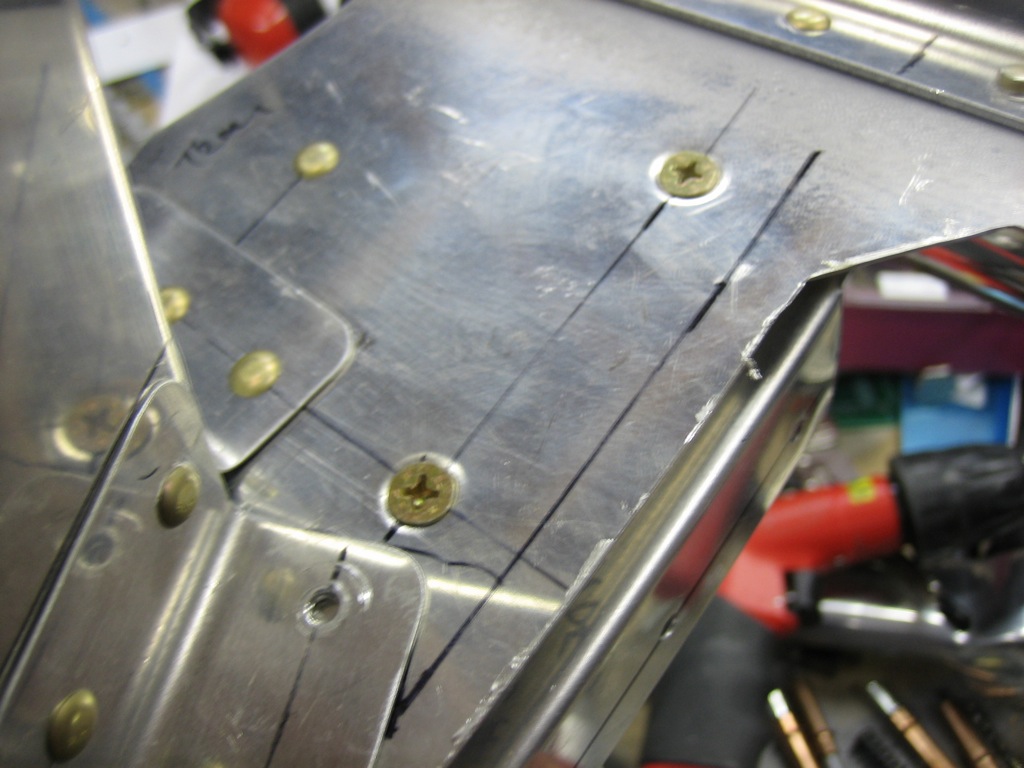

The other flange just has some more AN515-8R8 screws. I’ll add a third screw at the forward end after I figure out how I’m going to deal with the bracket in the lower left.

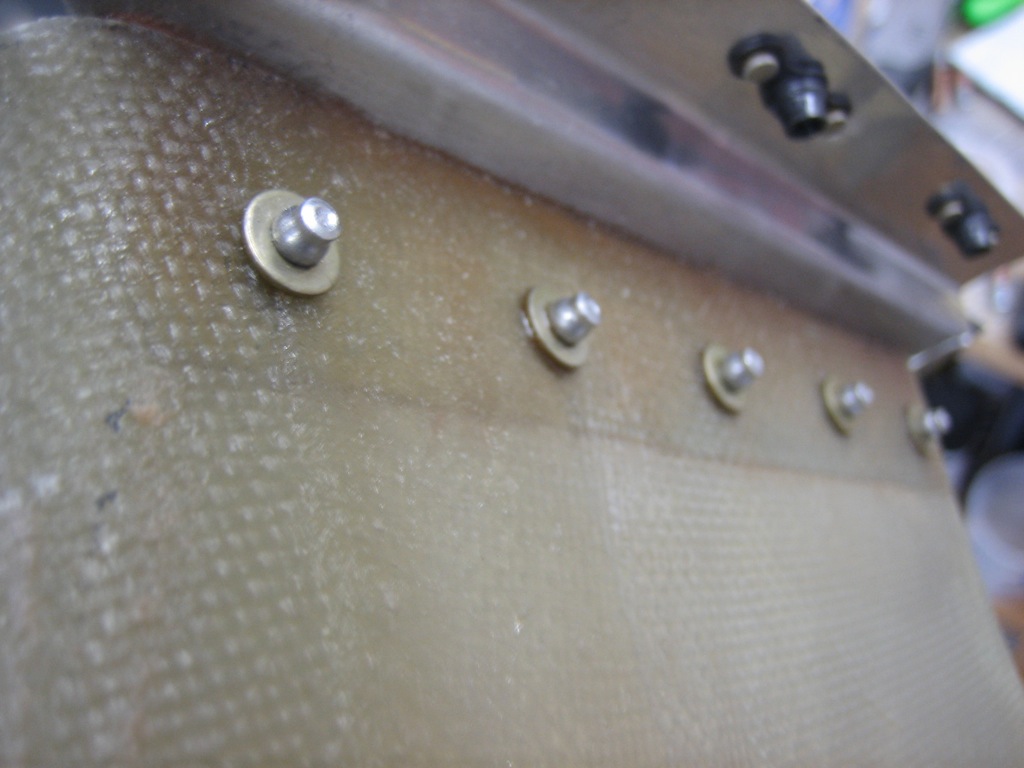

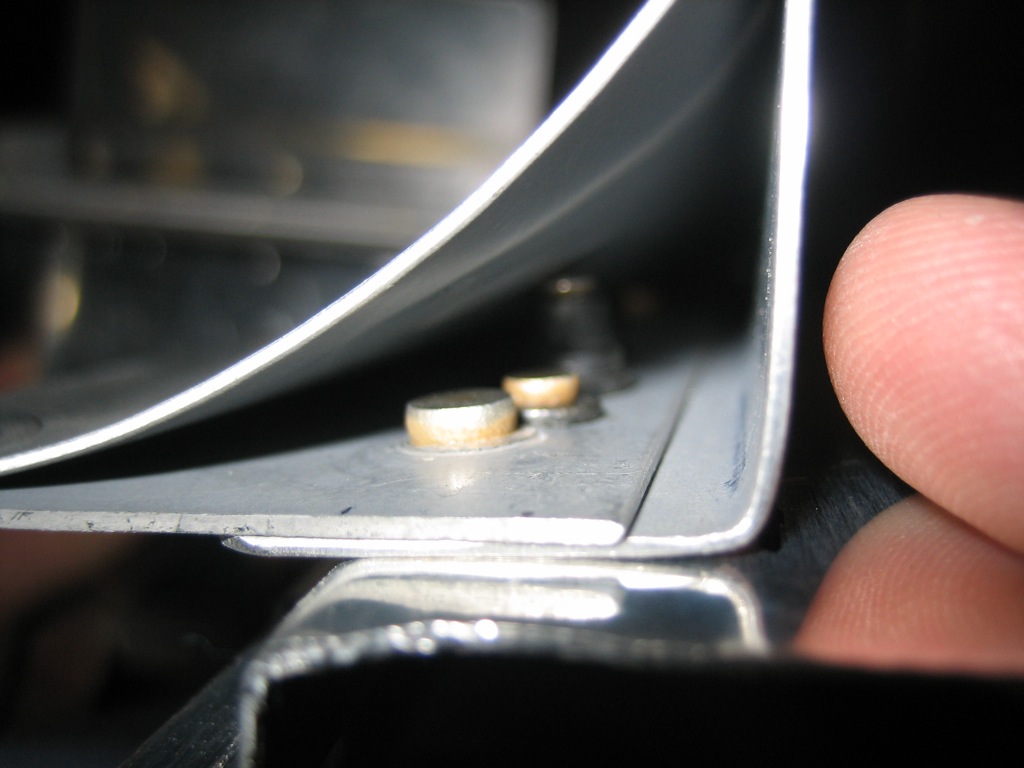

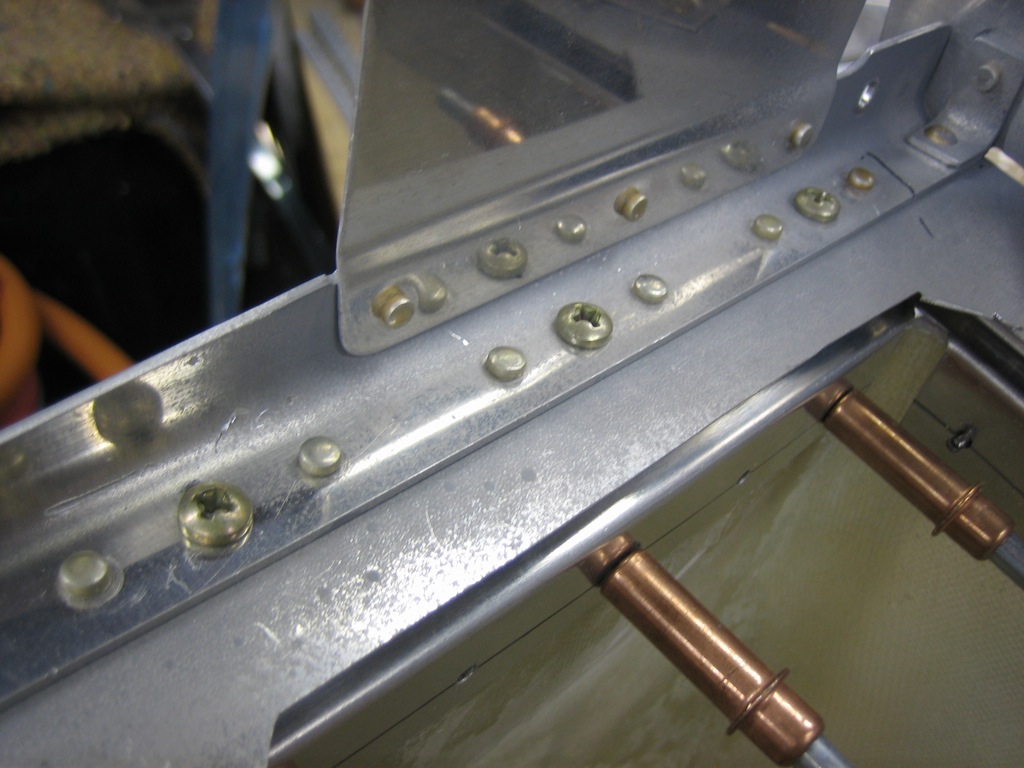

I also replaced 6 of the rivets along the aft edge with ones that are flush along the bottom side since the aft snorkel mounting flange sits against this surface.

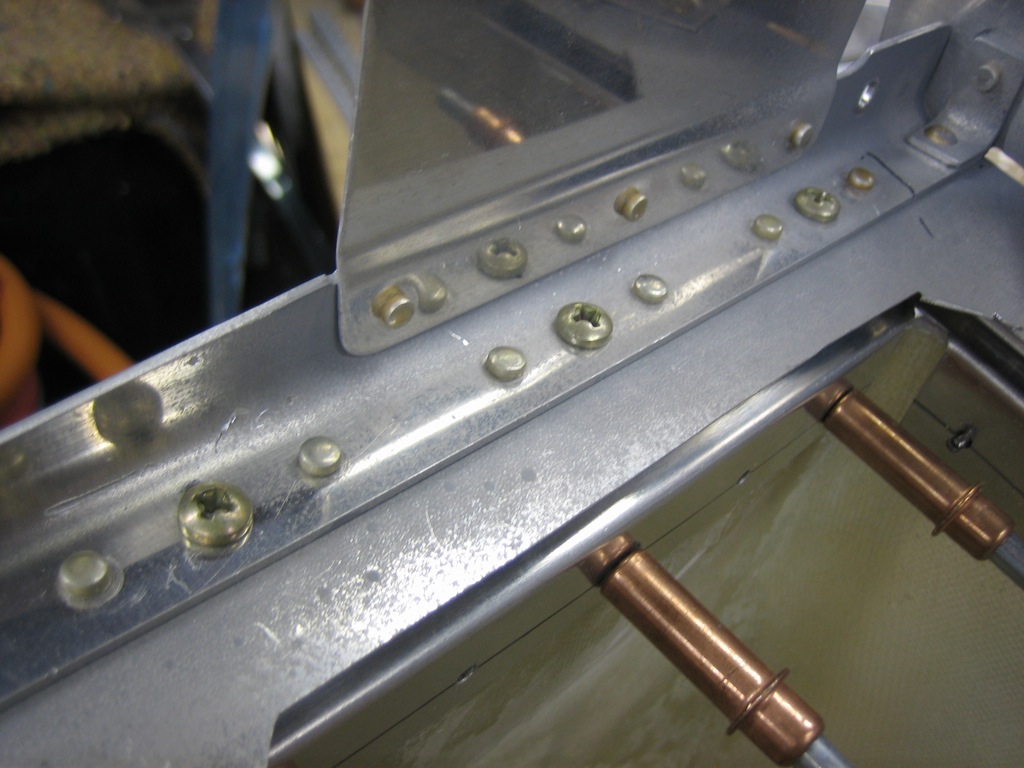

I then drilled three additional holes for AN509-8R8 screws that attach the aft snorkel mounting flange.

I also installed some K1000-08 nutplates along this flange.

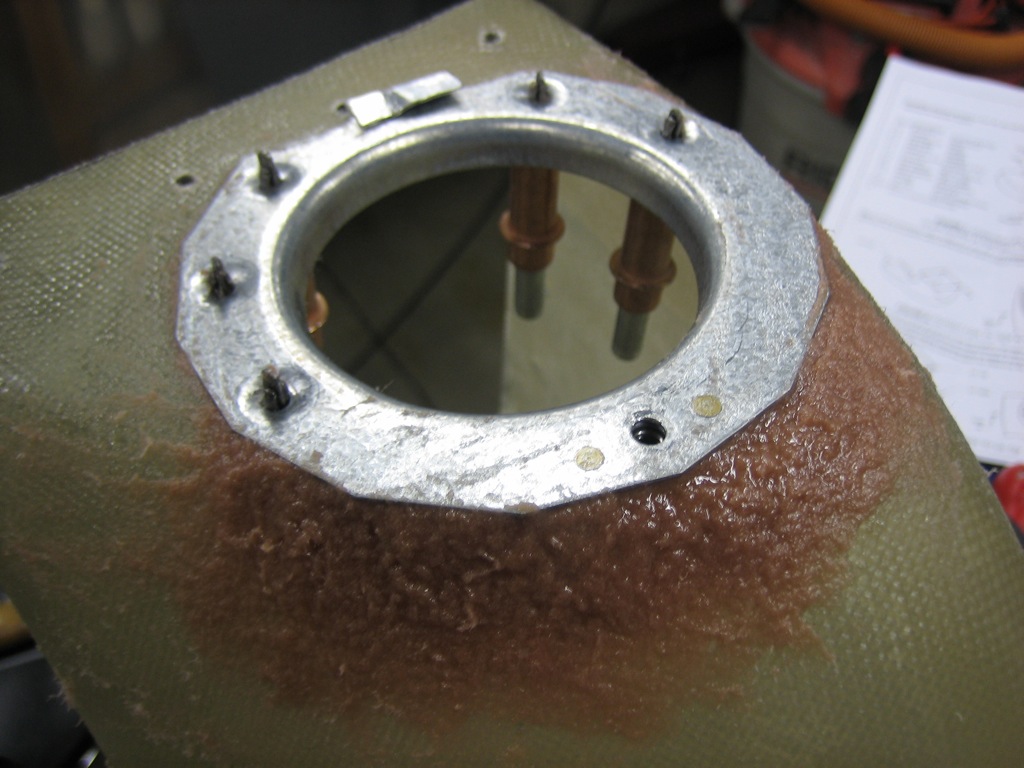

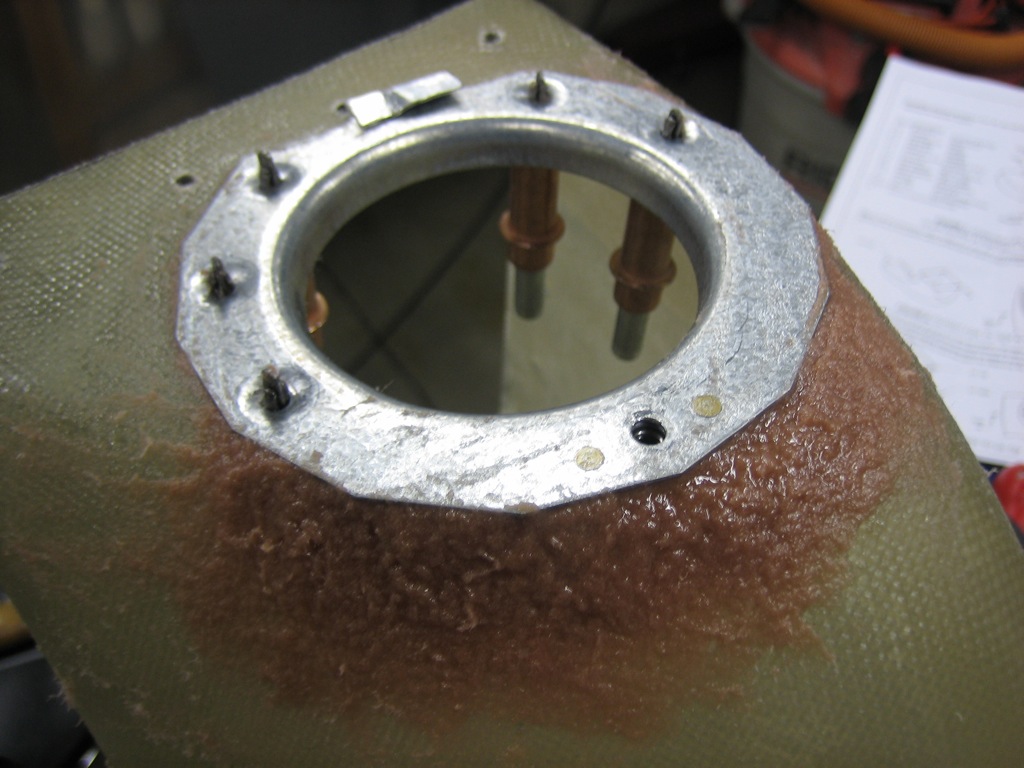

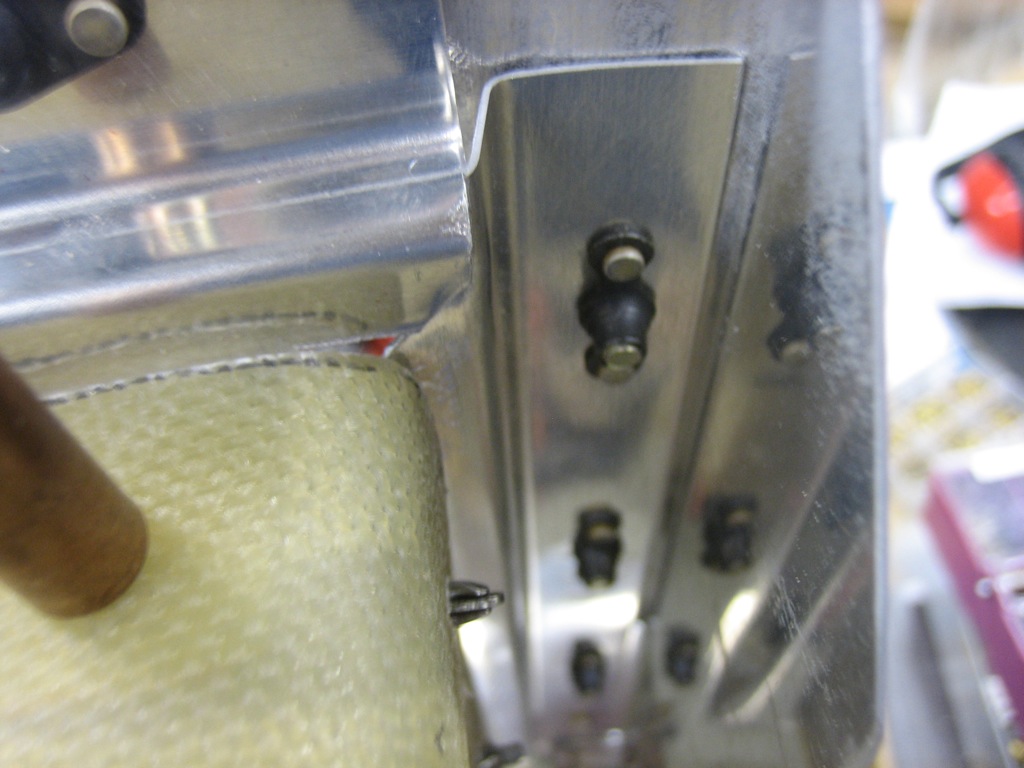

Next up, I drill a 2 5/8″ hole in the side of the snorkel for the alternate air entry.

This flange will be mounted here and a pivoting cover will seal the opening under normal circumstances. If the air filter were to become clogged, I could open this door from the cockpit.

The flange is drilled to the snorkel. The center hole in the bottom of the flange needs to be match drilled to the snorkel using a #19 drill and then later opened up to 1/4″ in the snorkel so that the nutplate can fit through the hole.

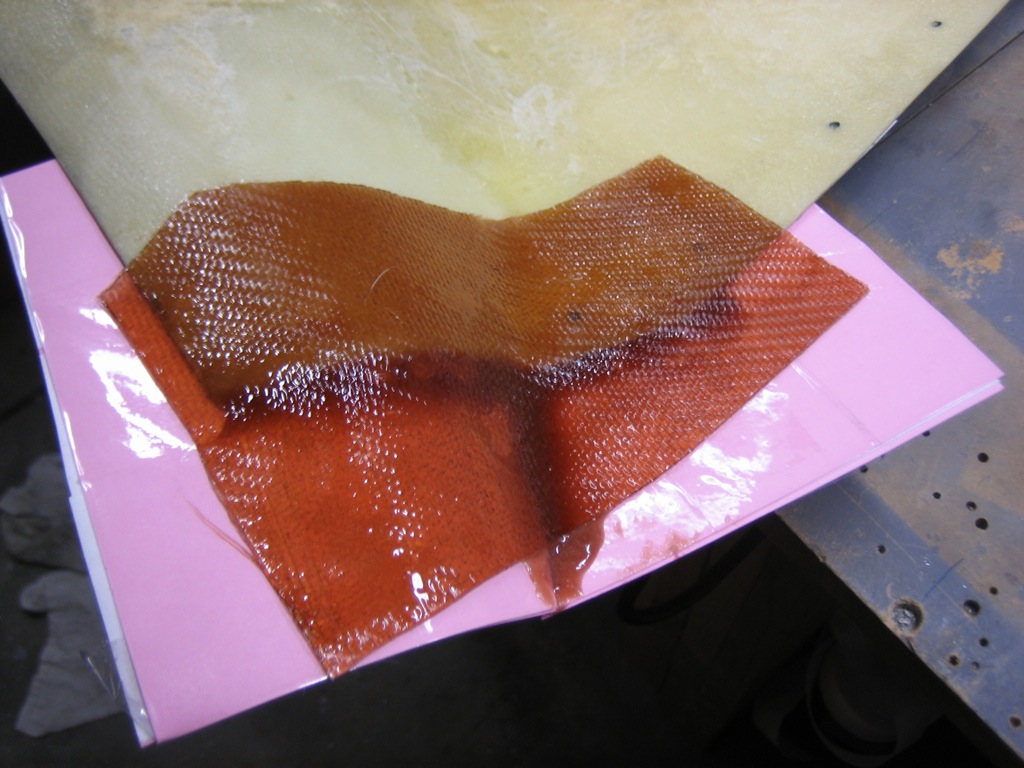

Finally, I sanded and cleaned the surface and flange, then clecoed it down with some epoxy mixed with flox. I then roughly faired in the flange so that there is a nice transition to the snorkel. The flox leaves a fairly rough surface though; I’ll use some filler to smooth this out nicely after it cures.