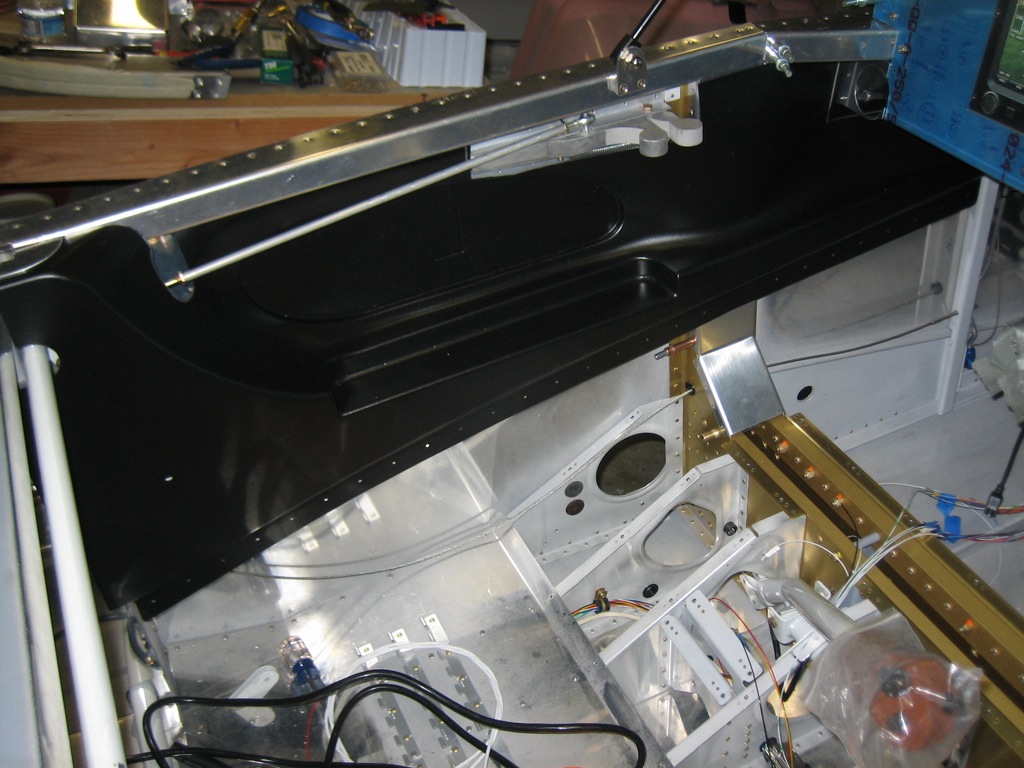

Luke at Classic Aero Designs recently sent me the unfinished Aviator side panels so that I could custom fit them to my plane. Since I’m using shorter air vent brackets and an after market canopy latch, I asked him to leave them uncut so I could trim them to exactly fit my air vent brackets and canopy latch handle. They marked the planned cut lines in silver ink. I cut around the air vent, and you can see they would have removed way too much material.

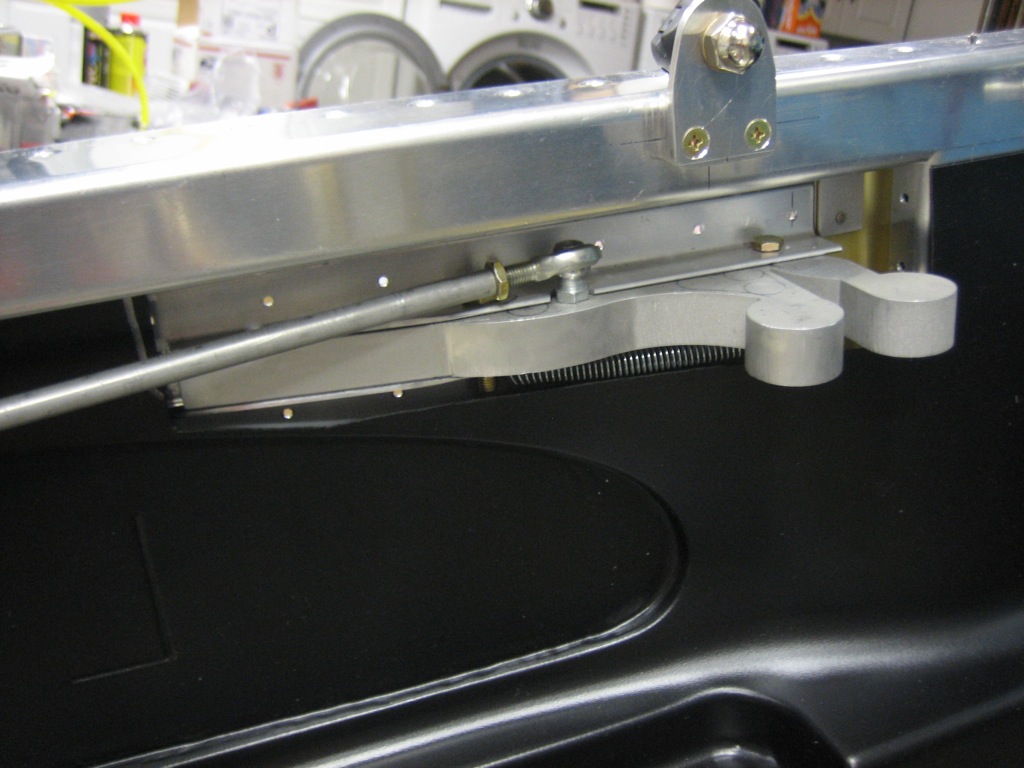

I also trimmed the aft end to tick under the canopy latch plate and to fit around the canopy latch torque tube. The marked cutout to the right is for the rod that connects the canopy latch handle to the idler arm.