I put the plane up on jacks and dropped a couple of plumb bobs along the center line. I then snapped a chalk line on the floor so I can use it as a reference for aligning the gear leg fairings and wheel pants.

I created a second chalk line parallel to the aircraft centerline, but 38 5/8″ away which was roughly under the centerline of the wheel pant. I then used a piece of scrap aluminum with a square corner to measure up from the ground 8 5/8″ front and back to get the wheel pant parallel to the centerline of the airplane. I blocked up the aft end with my chock to hold it there. After aligning the wheel pant left to right (as shown in the next picture), I used one of my laser levels to mark where to drill (I aligned it with the hole with the front half of the wheel pant off and then reinstalled it).

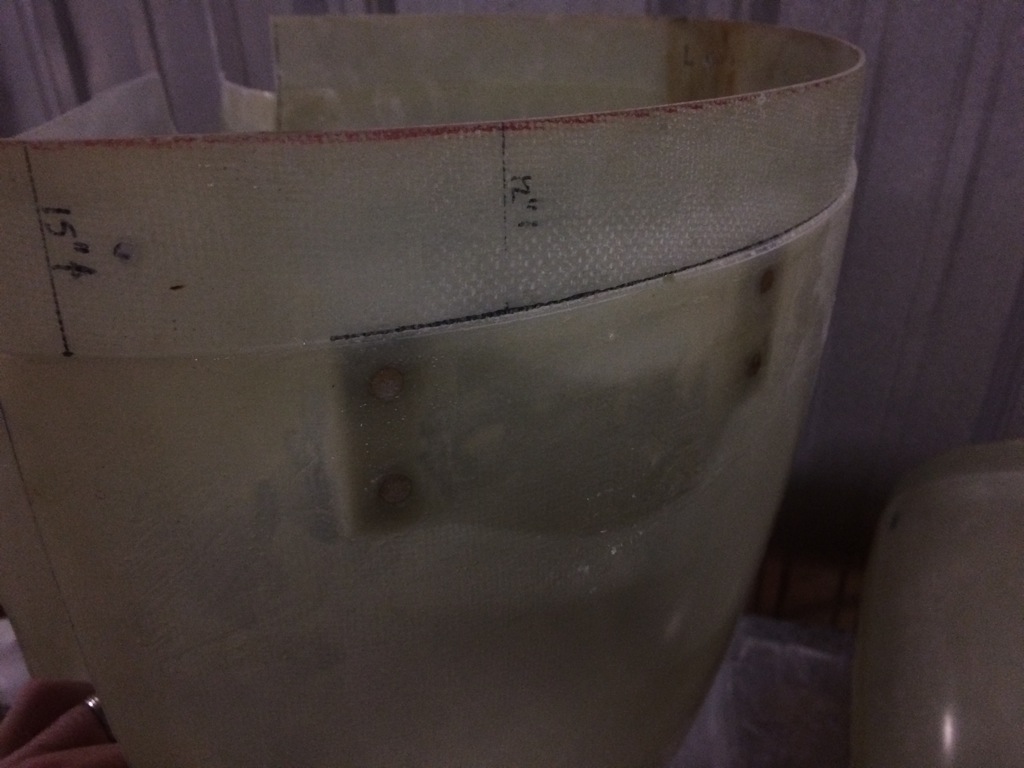

The aft edge of the wheel pant needed to be pulled out a little bit to align with the centerline, so I used a ratcheting strap to the aircraft jack to pull it out until it aligned with the chalk line I snapped. After everything was aligned, I drilled the holes through the inner fairing mount to lock in the position.

Before drilling the lower intersection fairings to the wheel pants, I needed to ensure the gear leg fairing is aligned. I wrapped a piece of fishing line around the fairing and held it with a piece of blue tape. I dropped a plumb bob down from the intersection of the fishing line and leading edge of the fairing and made a mark on the floor. I measured out from the centerline and up to the fishing line so that I could make the fishing line exactly parallel to the aircraft centerline.

I transferred those measurements to a board that I positioned under the tail of the plane and then drilled a small hole at that position. I ran the fishing line through the hole and tied it off to the tailwheel.

I slipped a small piece of static line over both lines and slid it close to the trailing edge of the fairing. Amazingly, the left fairing was already perfect. I had previously aligned it with the upper intersection fairing, but I didn’t expect it to come out this perfect.

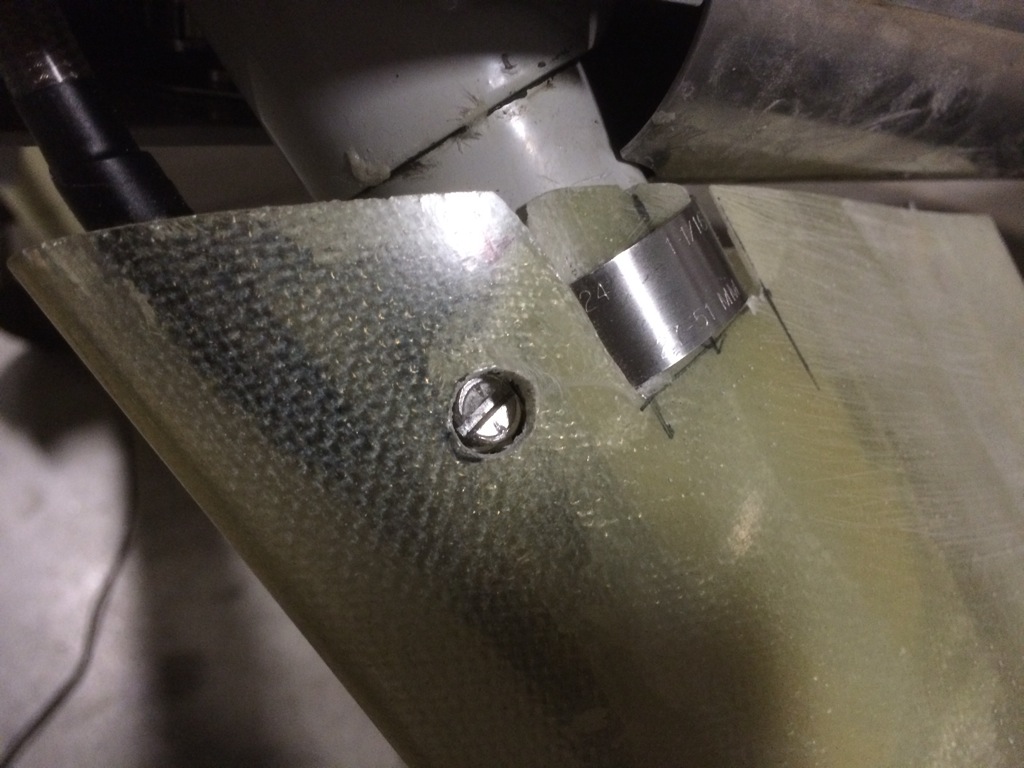

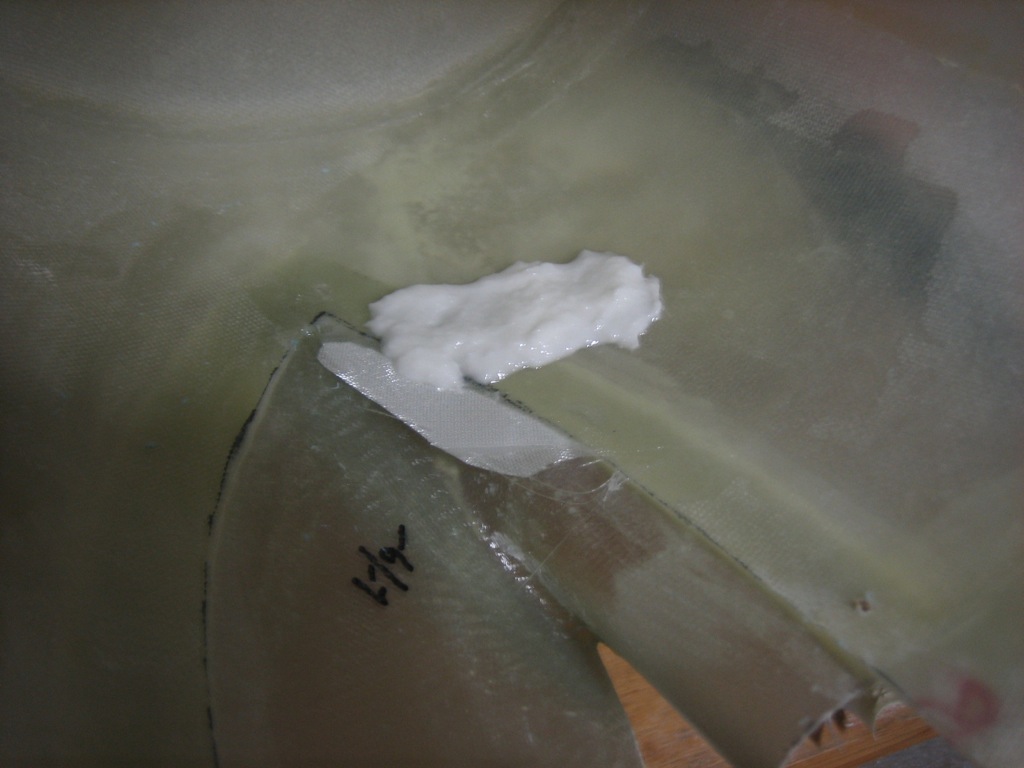

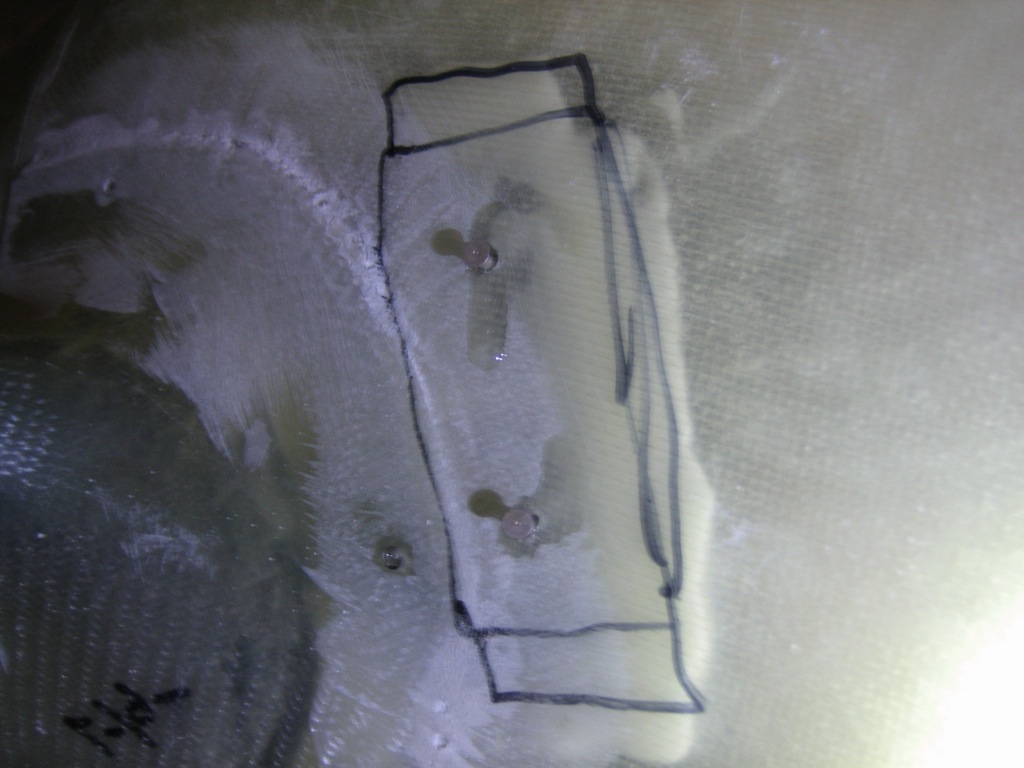

With the gear leg fairing aligned, I could install the lower intersection fairings to lock in the angle. I drilled the front and back halves with several 1/8″ holes each.

I then slid the upper intersection up tight and drilled a few holes to lock it into position.

Madeline was a big helper today, bringing me tools whenever I needed them.

I wrapped up the other side and then took the plane back off the jacks. Although the jacks are very stable, we live in earthquake country and I didn’t feel comfortable leaving it up on the jacks overnight.