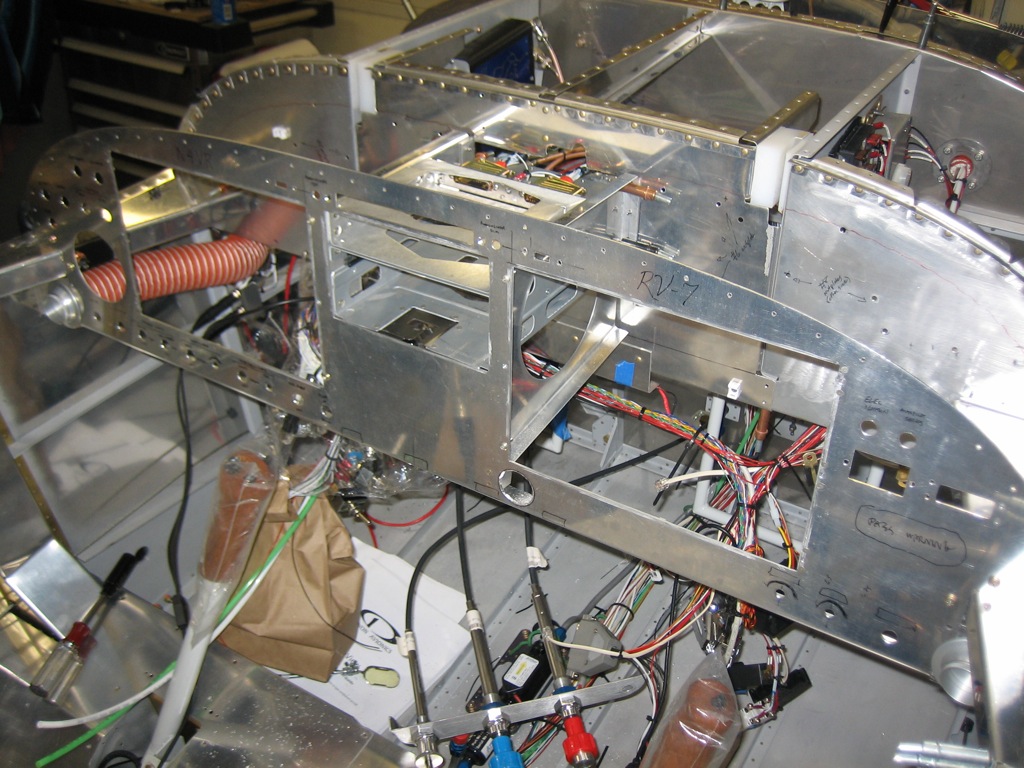

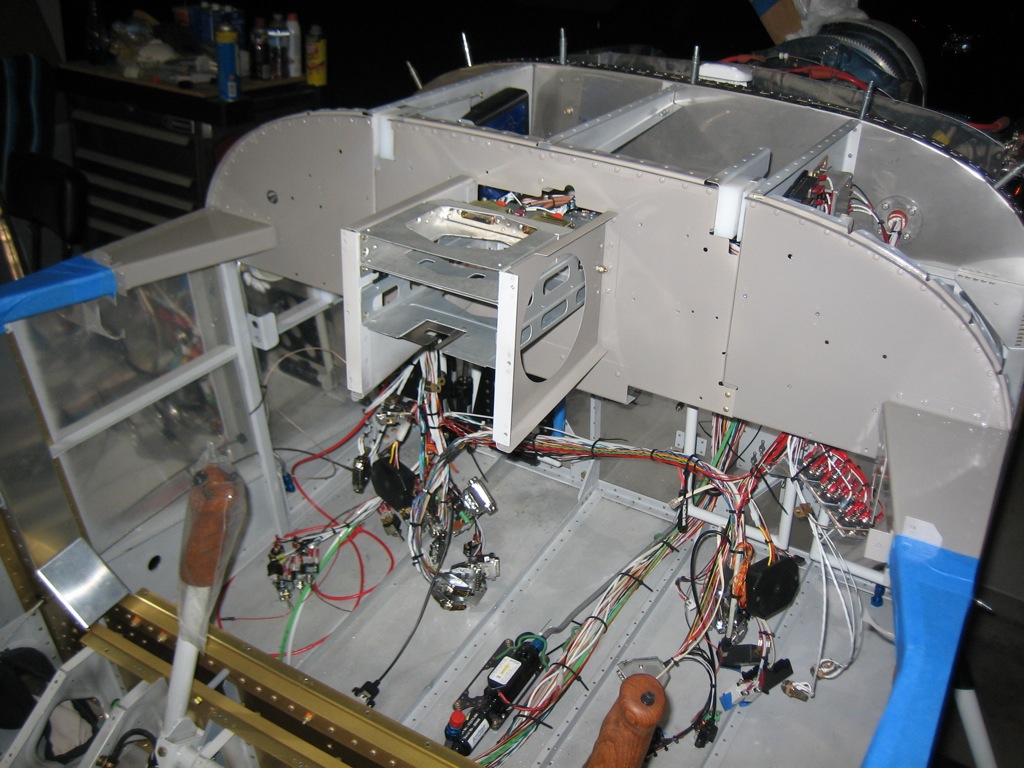

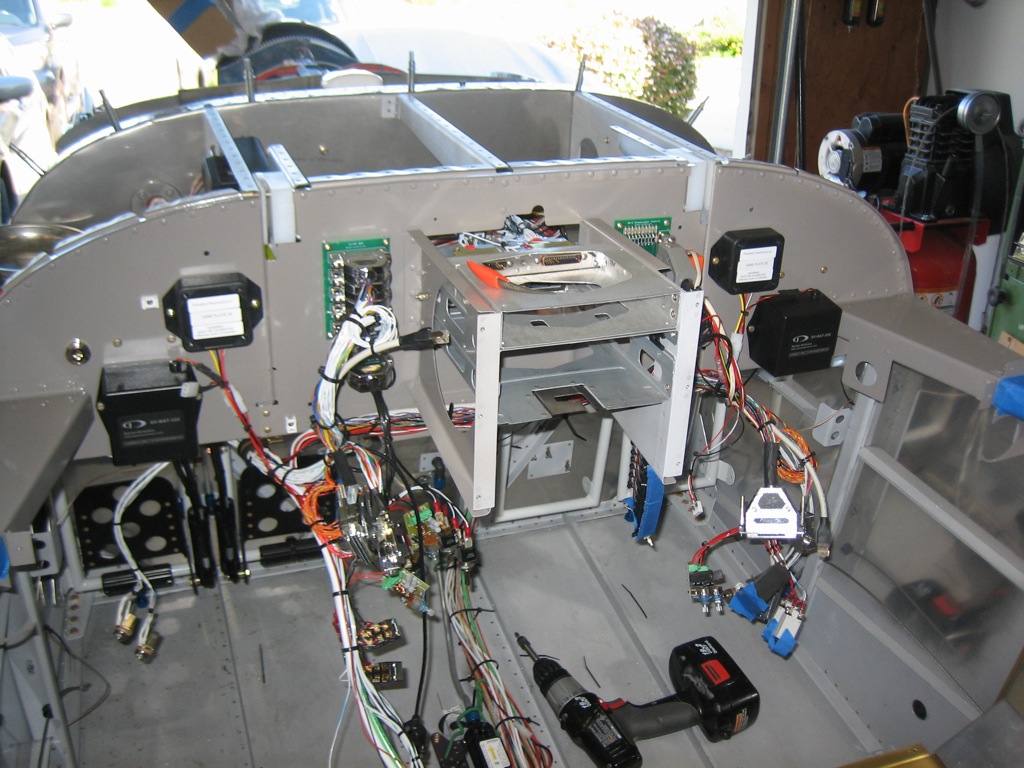

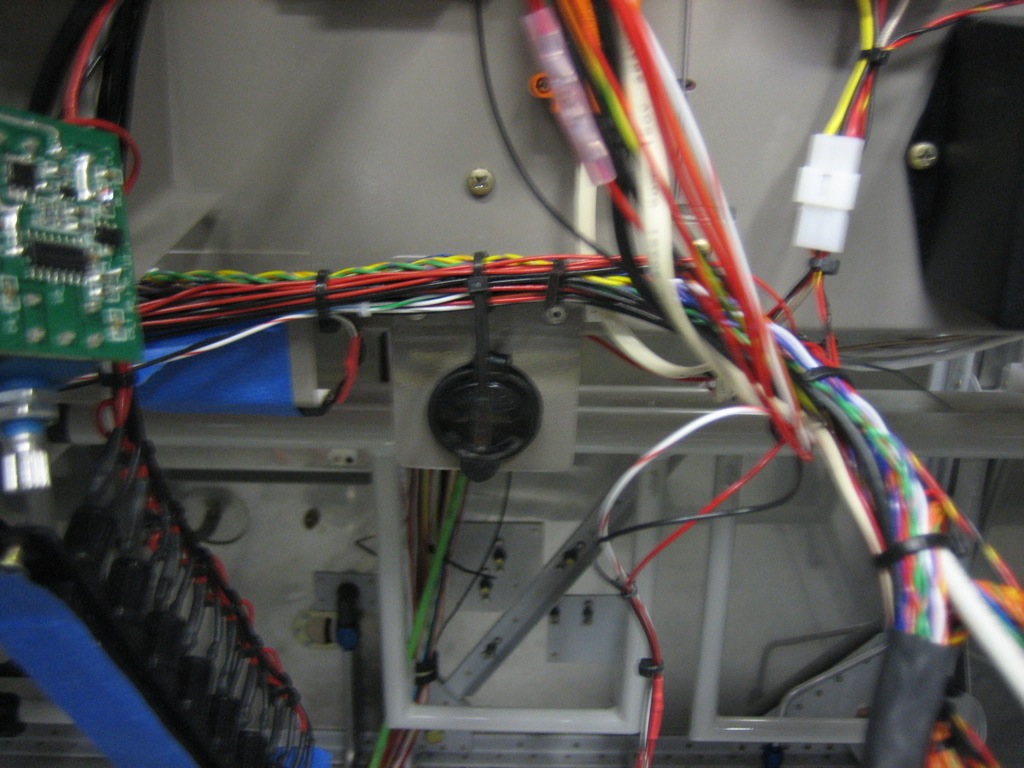

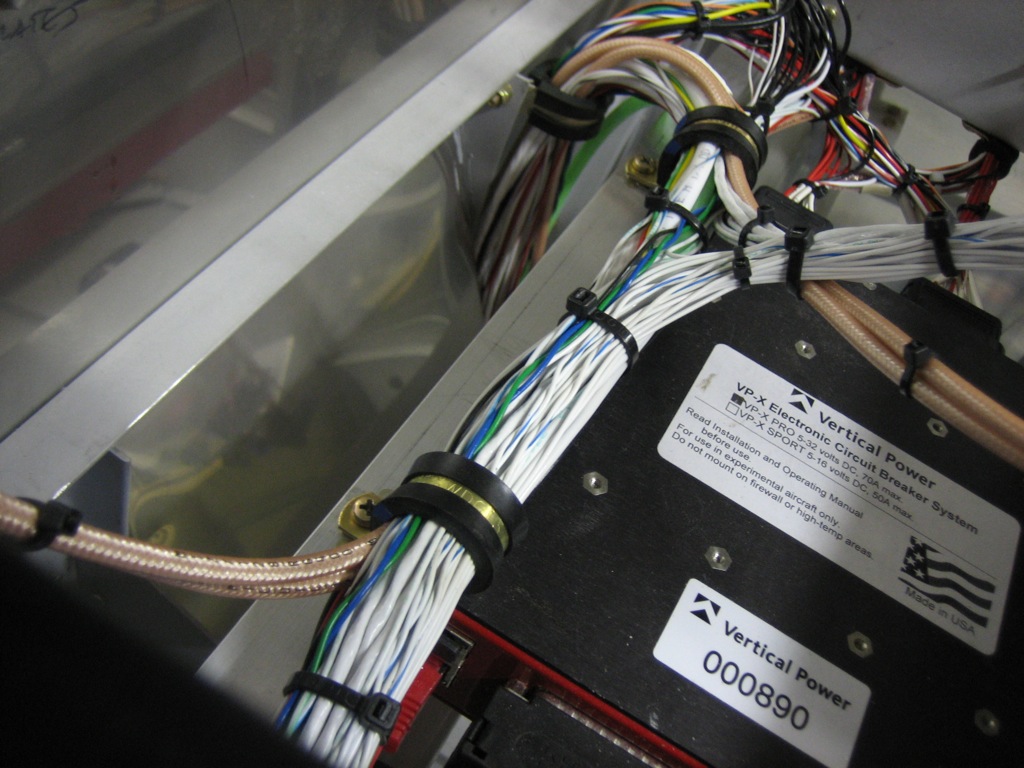

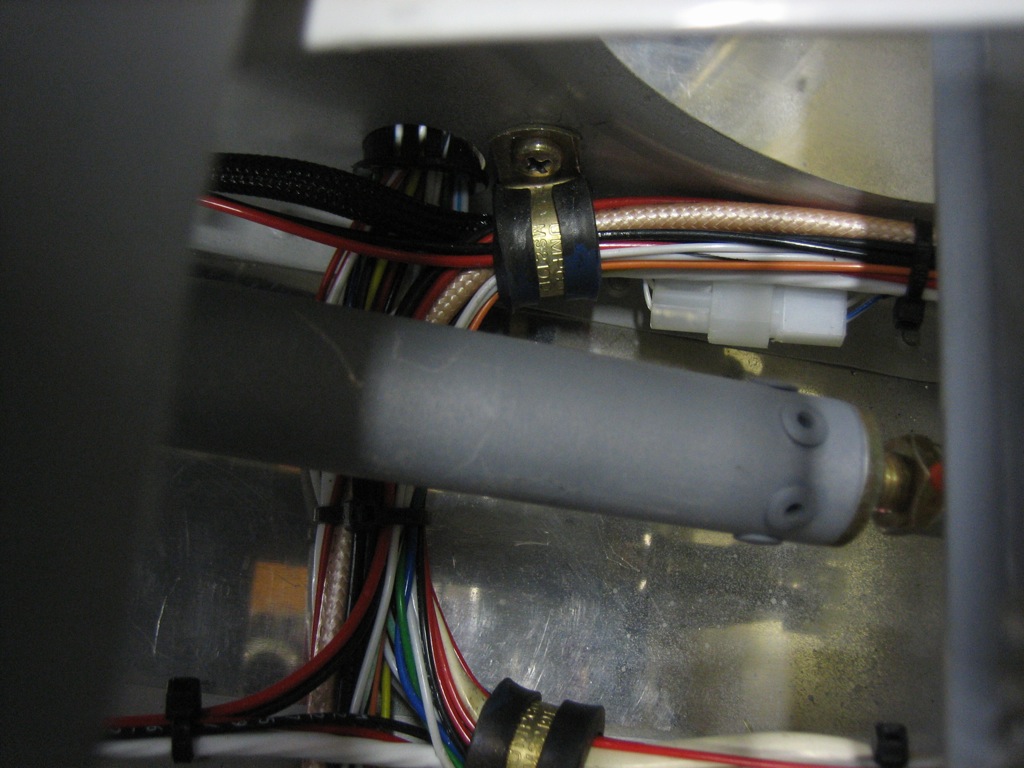

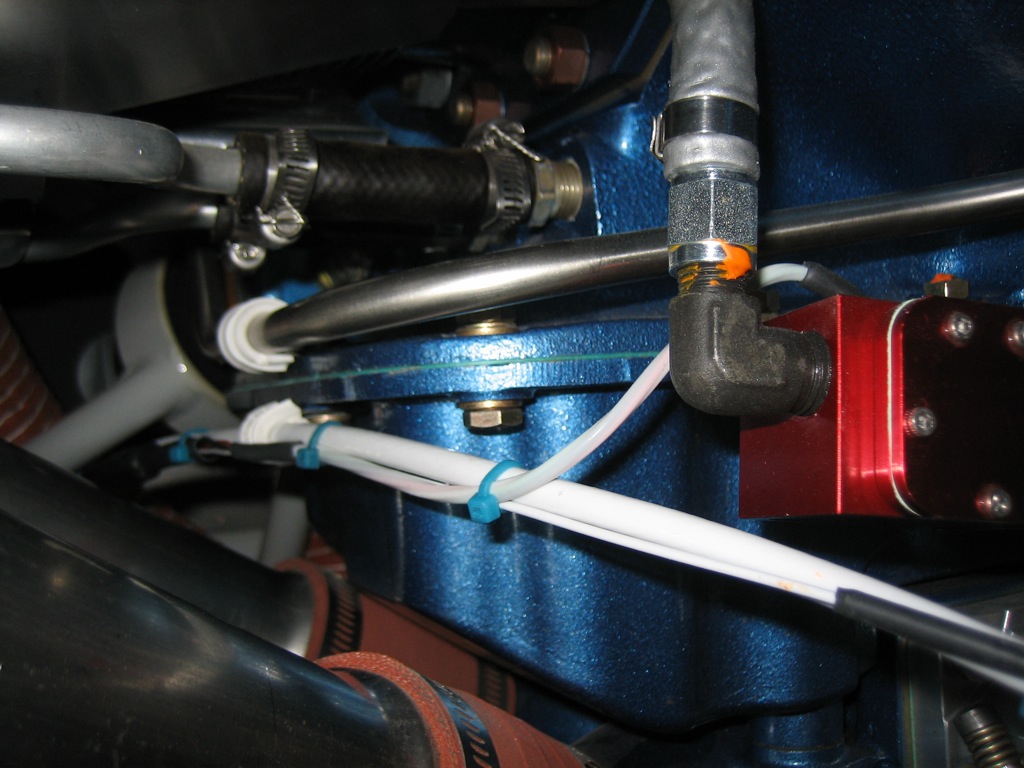

I finished up the fuel flow sensor wiring run by crimping knife connectors on the wires from the EMS and attaching them to the wires from the FT-60 (red cube). I covered each of the knife connectors and the whole bundle of connectors with some heat shrink tubing and secured the wires with some Tefzel zip-ties.

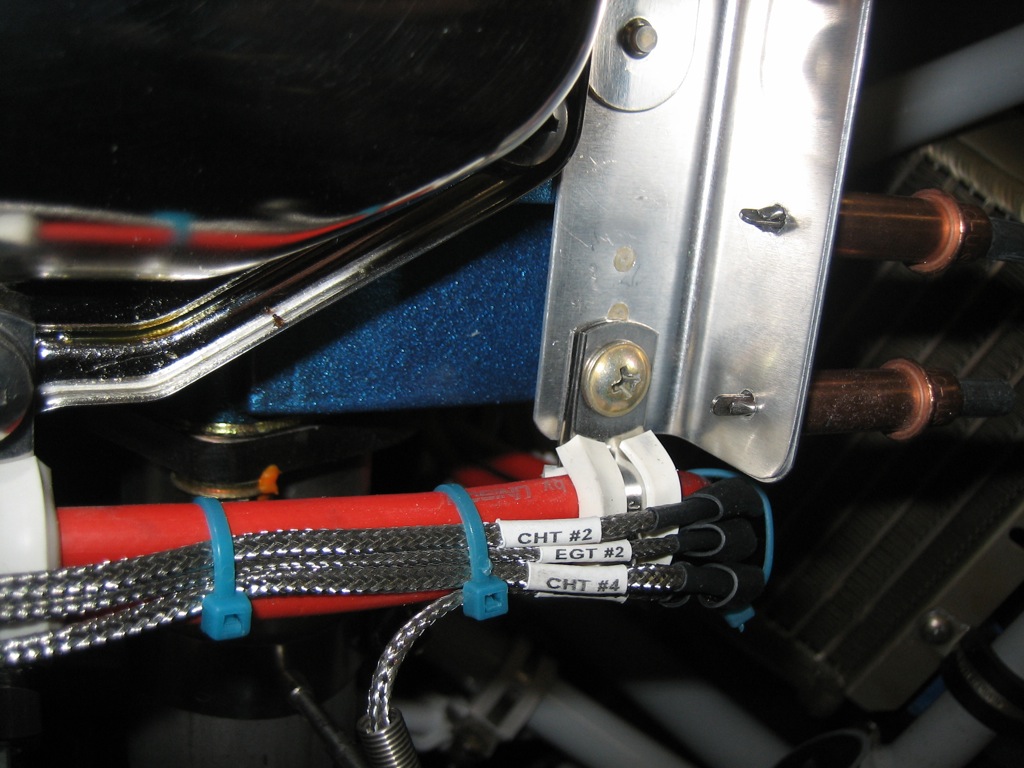

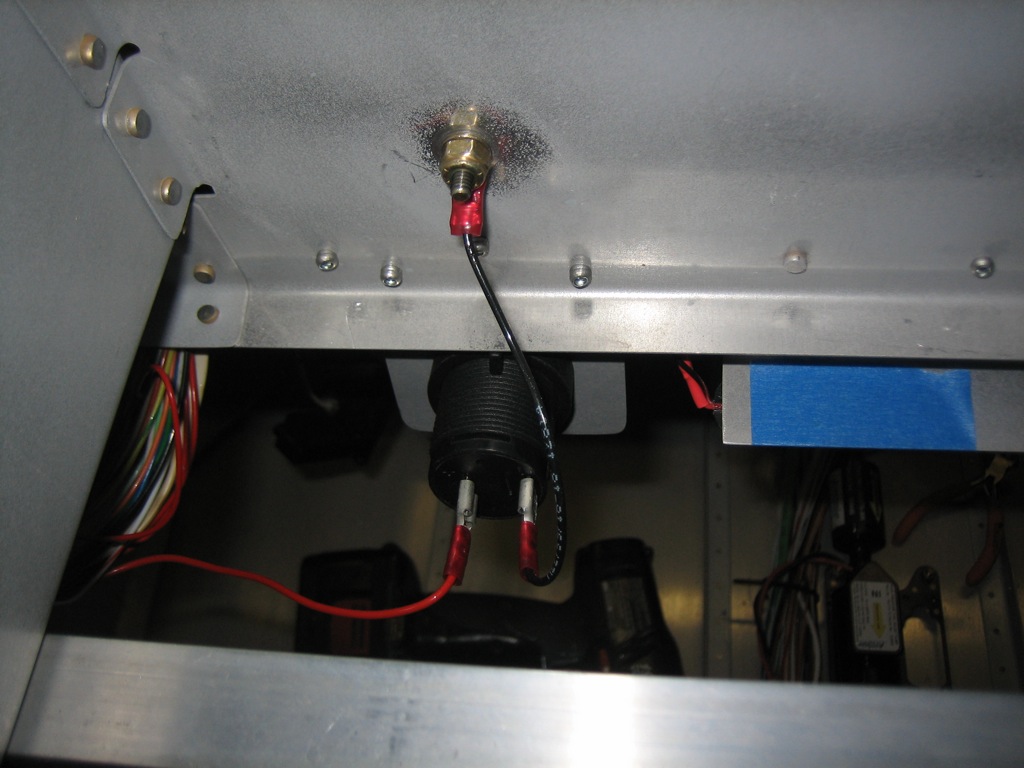

The bundle of ignition, EGT and CHT wires running aft from the #4 cylinder weren’t well supported. I riveted a K2000-3 nutplate to the side baffle and used a two-wire adel clamp to secure the bundle to the baffles. This prevents these wires from flexing down and contacting the #4 exhaust pipe (or flexing up and contacting the baffles under negative G conditions). Other than hooking up the starter wire just before first engine start and the coax wires to the electronic ignition coils, I believe all of the firewall forward wiring is complete. Other than final hookups of wing and empennage components (lights, roll servo, OAT probe, etc.), I believe all of the firewall aft wiring is complete as well.