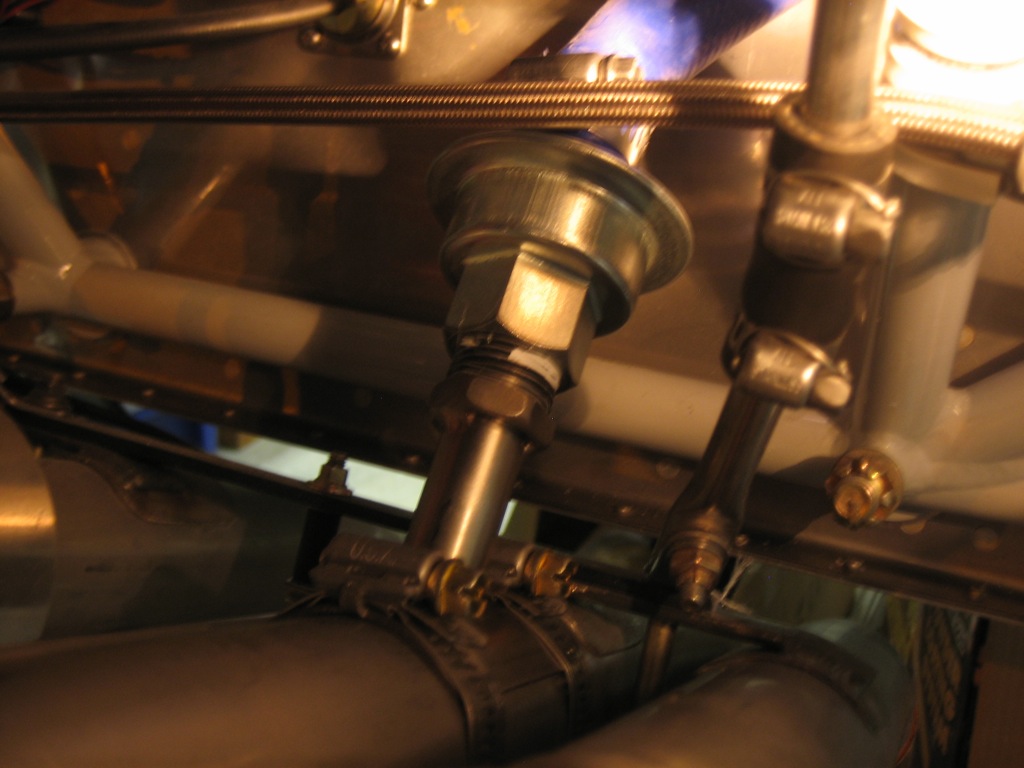

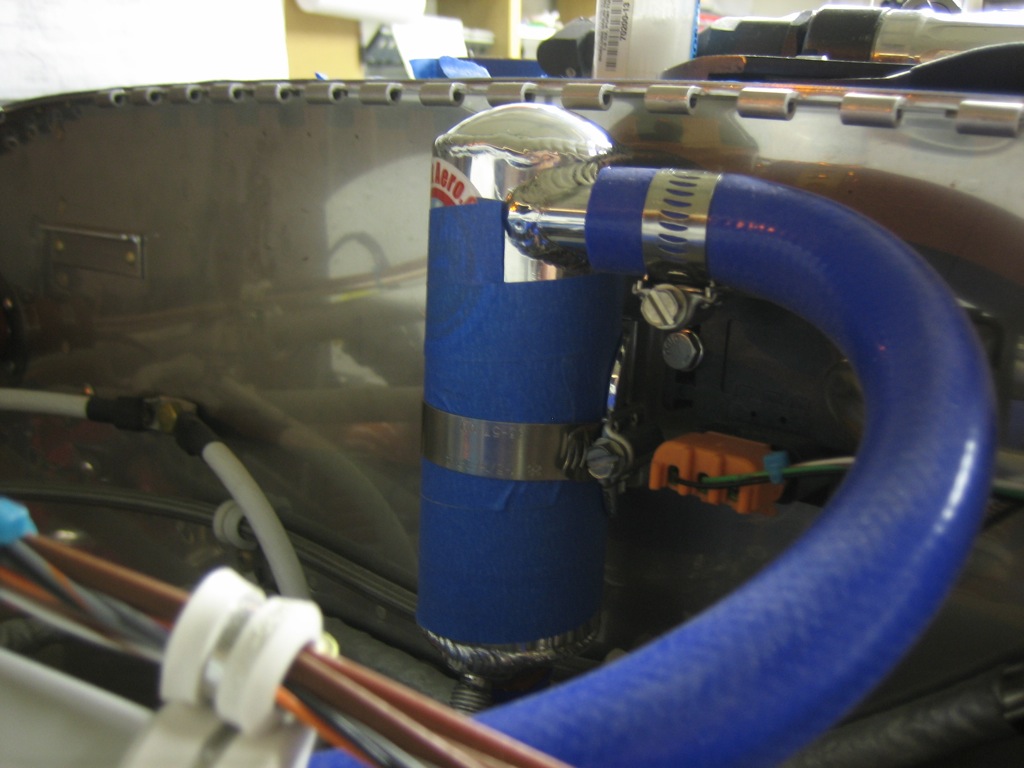

I decided to install an oil separator to keep oil off the belly, and the unit from Anti Splat Aero seems to be the best unit on the market. I ordered their install kit which comes with everything needed except a couple of bolts. I first removed the plug in the side of the engine just in front of the propeller governor pad. I installed a reducer then an AN823 elbow. The kit comes with an AN822 elbow, but there isn’t enough clearance from the engine mount to install that.

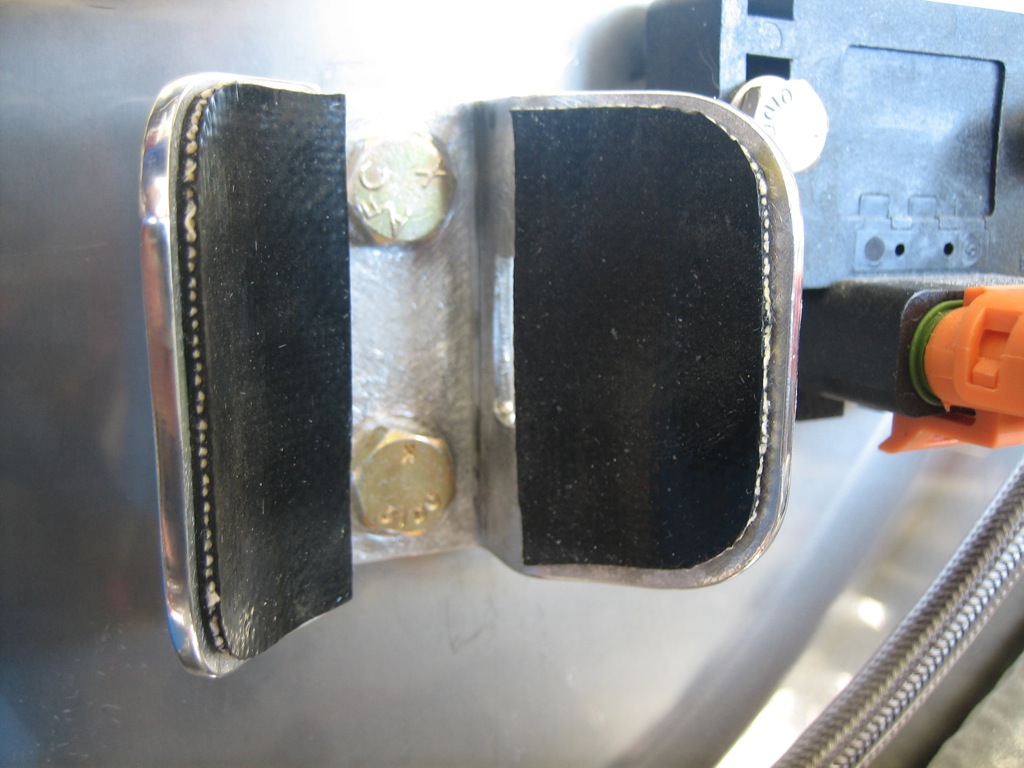

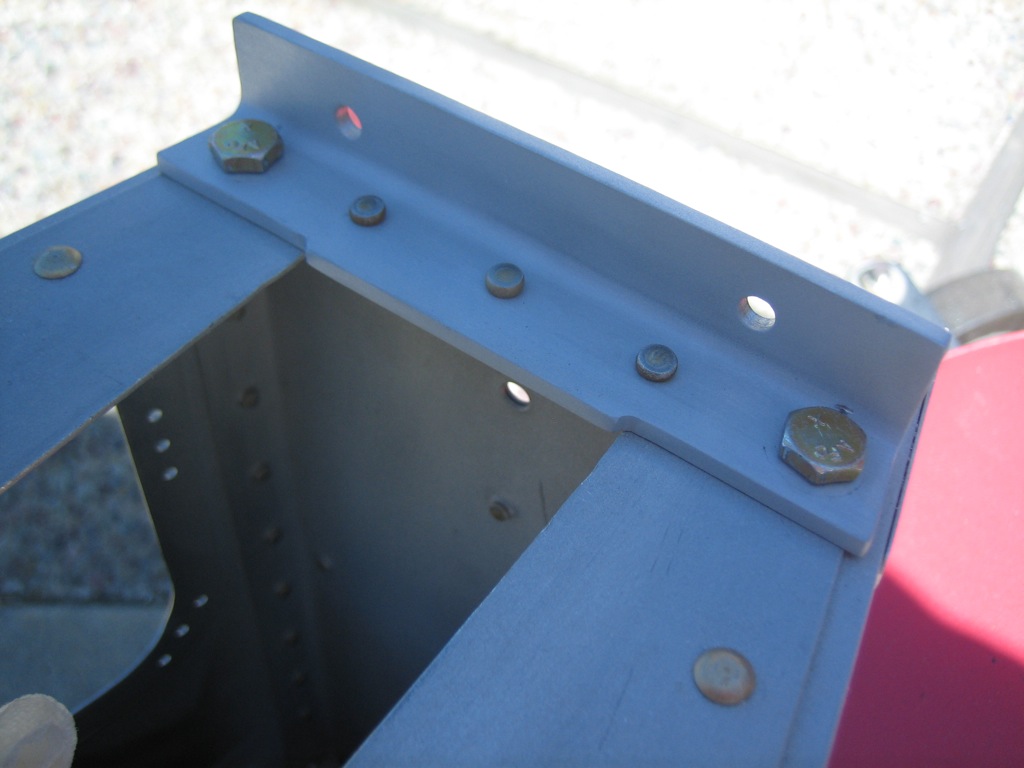

I ordered the polished aluminum oil separator, but the aluminum mounting bracket looks pretty rough next to it.

I purchased an aluminum polishing kit from Harbor Freight a while back, so I broke that out and polished up the visible parts of the bracket. The picture is pretty crappy, but this looks really nice.

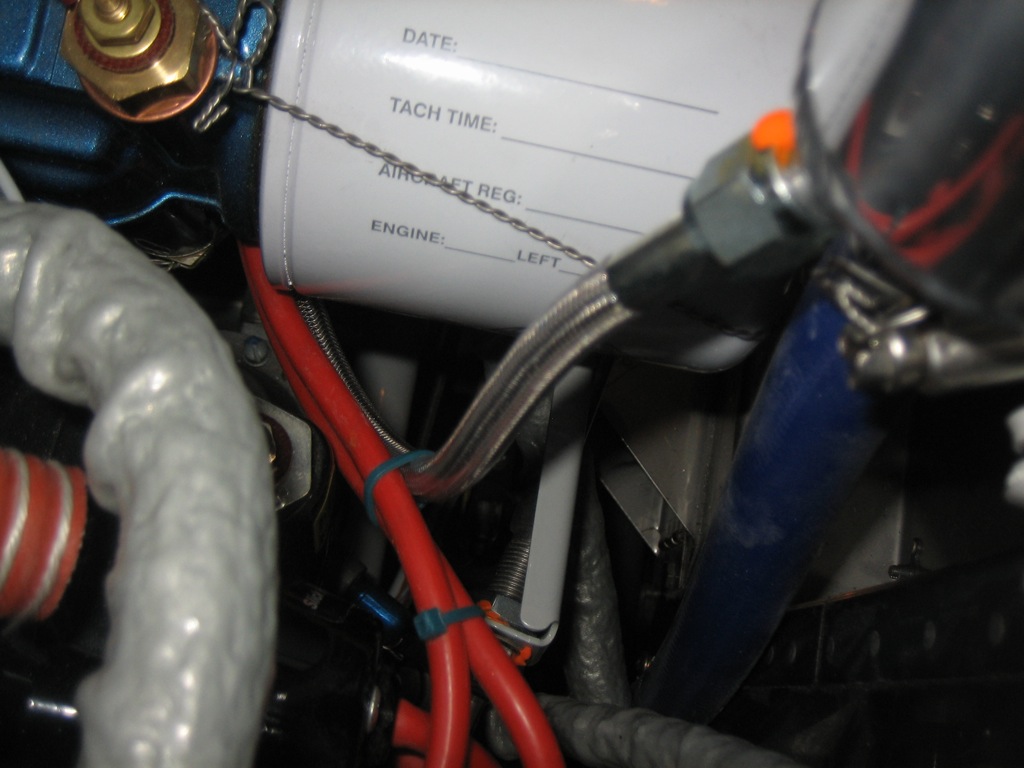

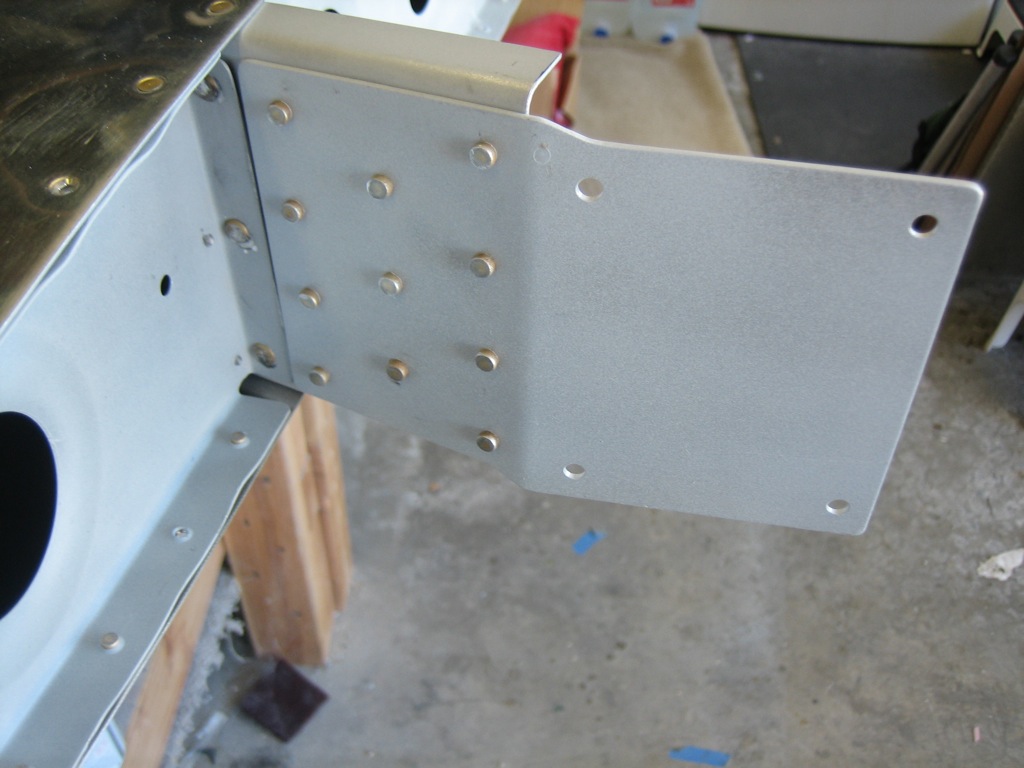

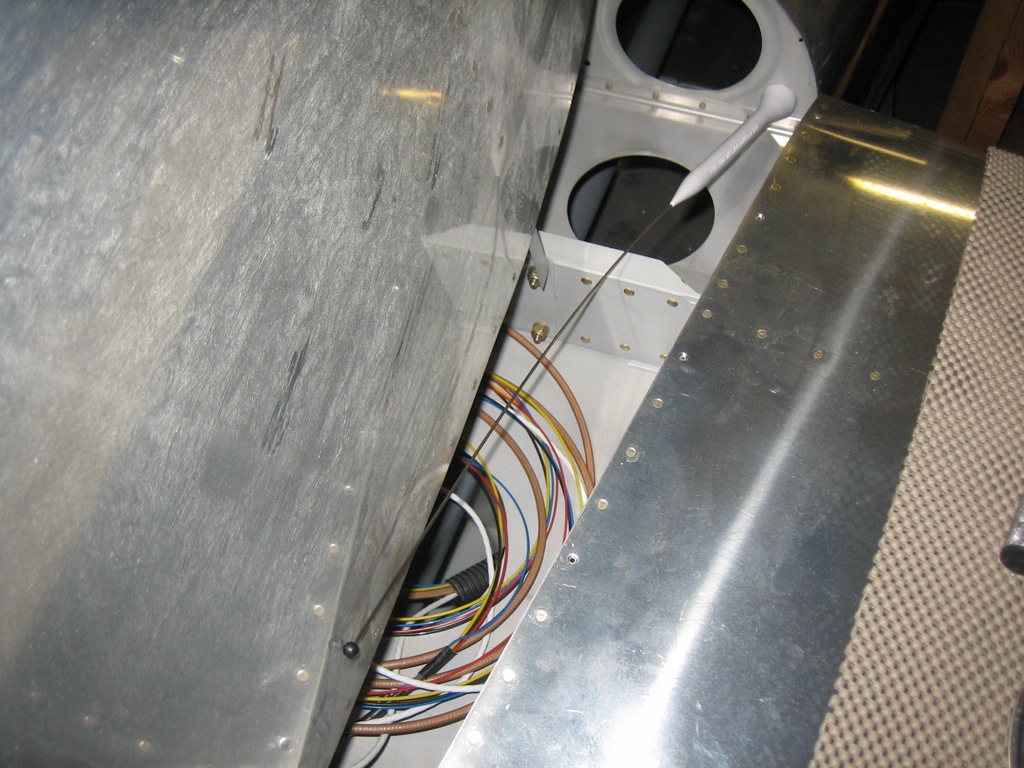

I drilled the bracket to the firewall and Jenn helped me bolt it in place. I then fit a short section of the included silicone hose from the breather fitting up to the intake on the oil separator.

I mounted the separator as high and as far to the right as I could so that it clears the oil filter and it won’t interfere with installing and removing the top hinge pin. Unfortunately, that plus the wrong elbow means the included oil return line is too short. I’ll call them tomorrow and see if they can send me a longer hose.

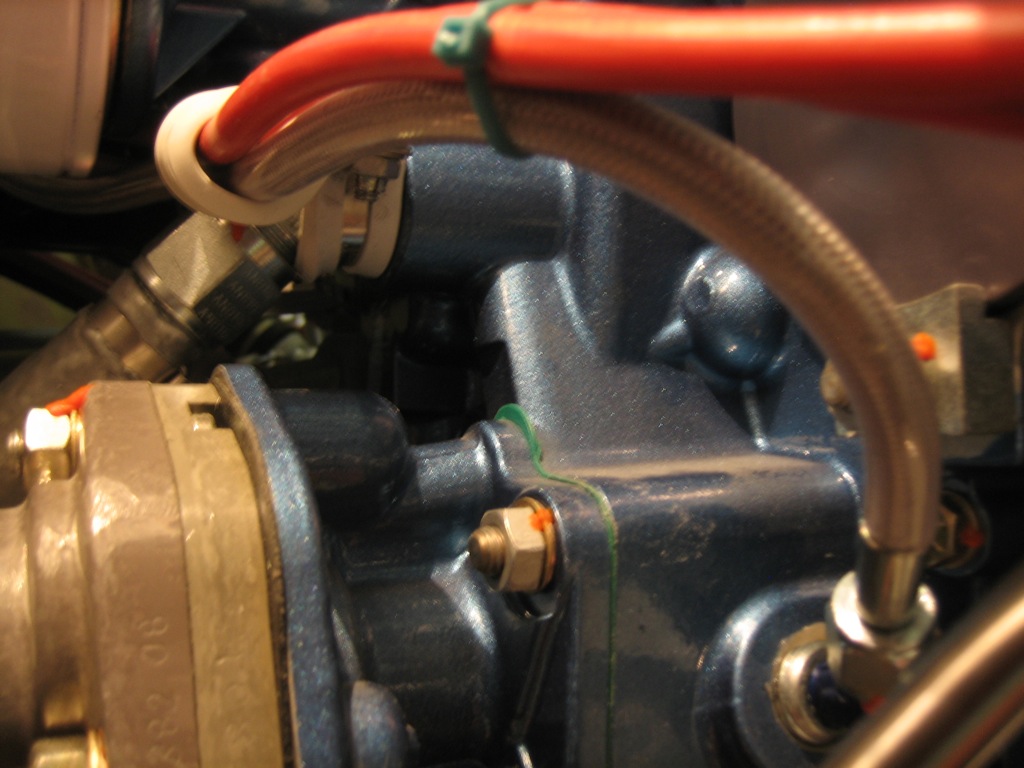

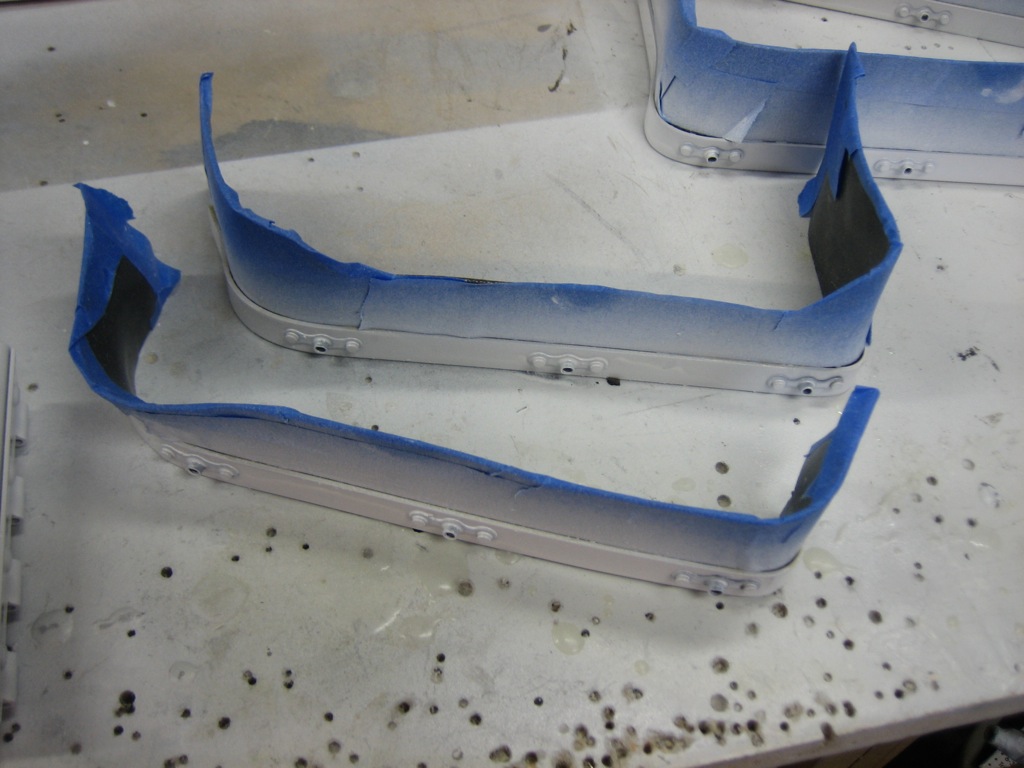

I pulled off the #2 exhaust pipe and drilled a 3/4″ hole in the top.

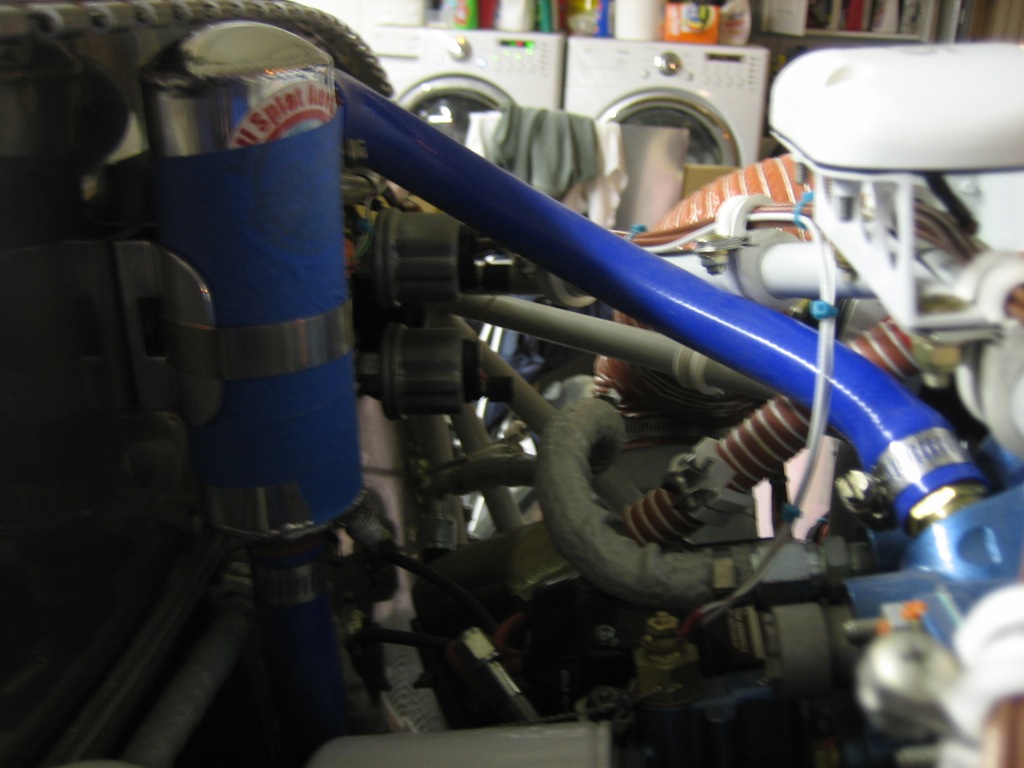

The vacuum valve mounts on the exhaust pipe like this. The slight angle pressurizes the line so that only higher pressure from the crankcase will push gases into the exhaust pipe. This has a reed valve inside that only allows flow from the crankcase into the exhaust pipe and not the other way.

Update: This is backward; the opening should face towards the tail end of the exhaust pipe. This was fixed long before first flight. As always, please read the directions and don’t assume I know what the hell I’m doing :-), yada yada yada…

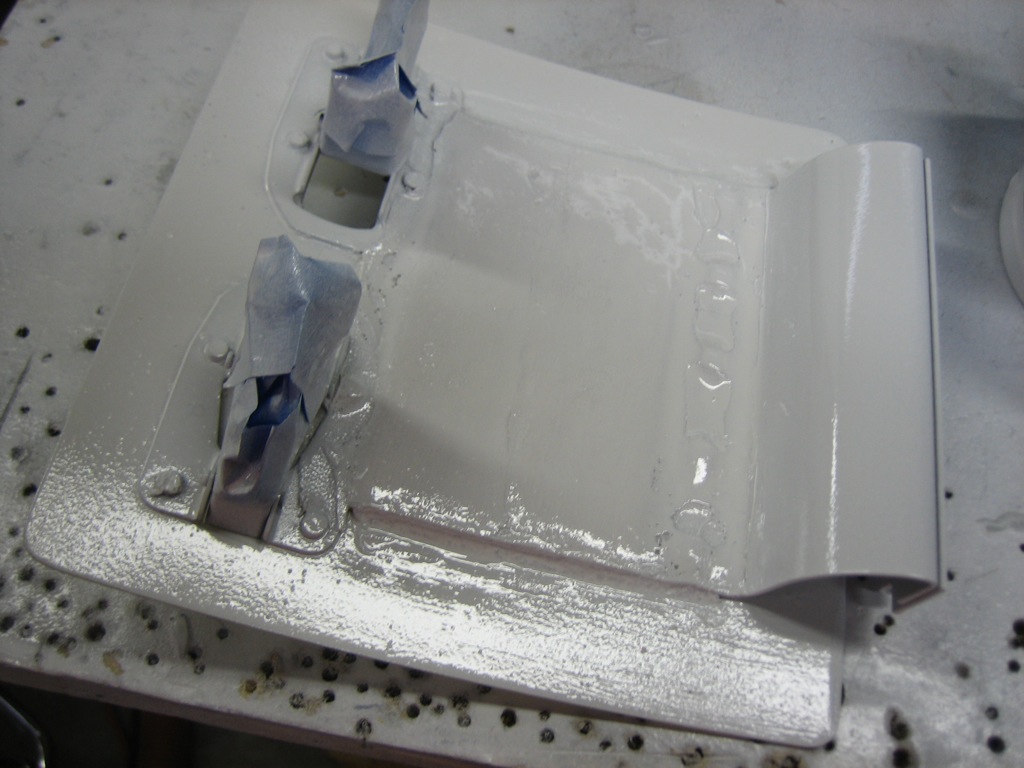

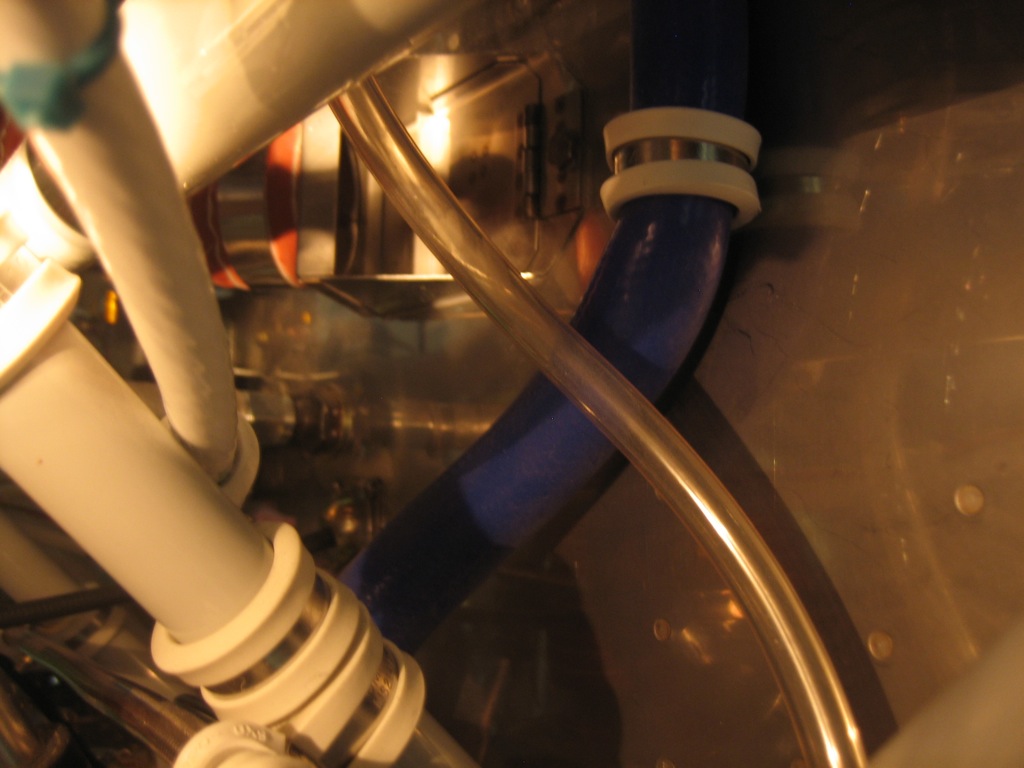

The output of the oil separator goes straight down the firewall. You can see that it just clears the oil filter.

The drain line goes through a clamp on the firewall and then into the vacuum valve.

This location for the vacuum valve easily clears the engine mount, exhaust support straps, brake line and starter cable.