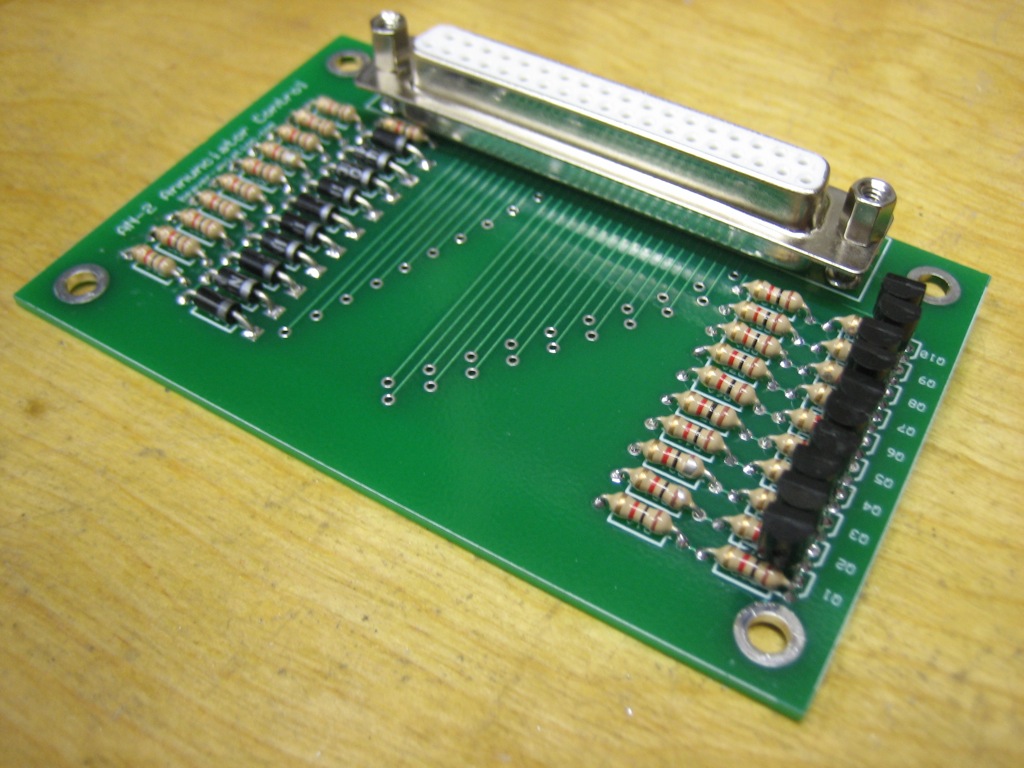

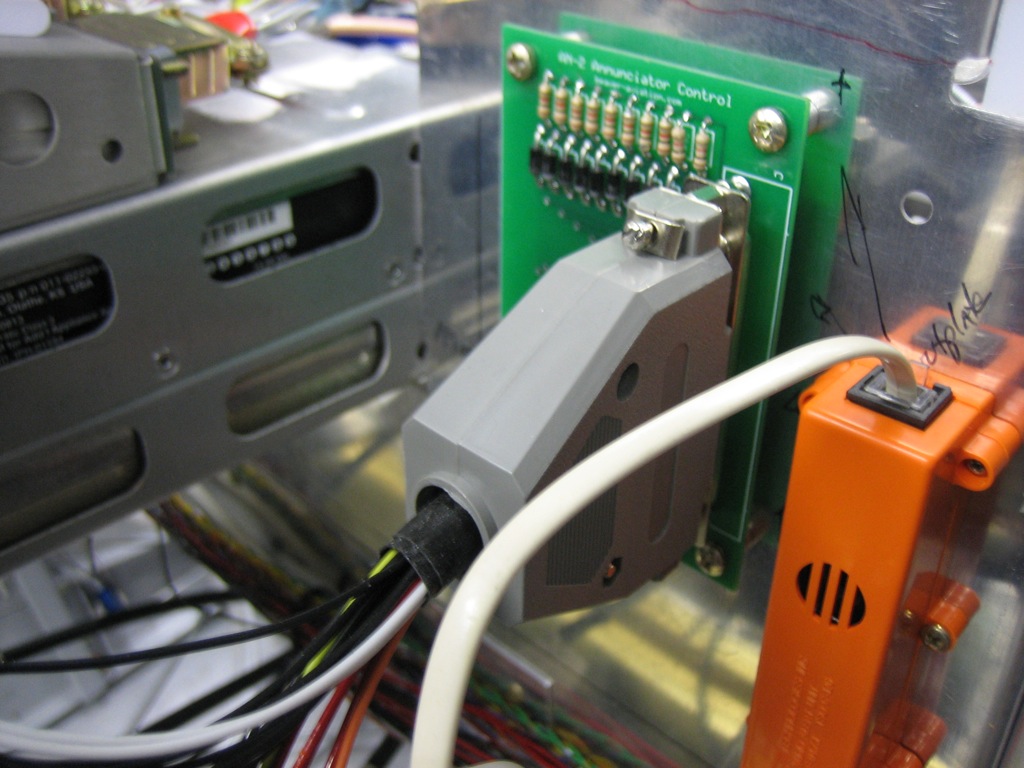

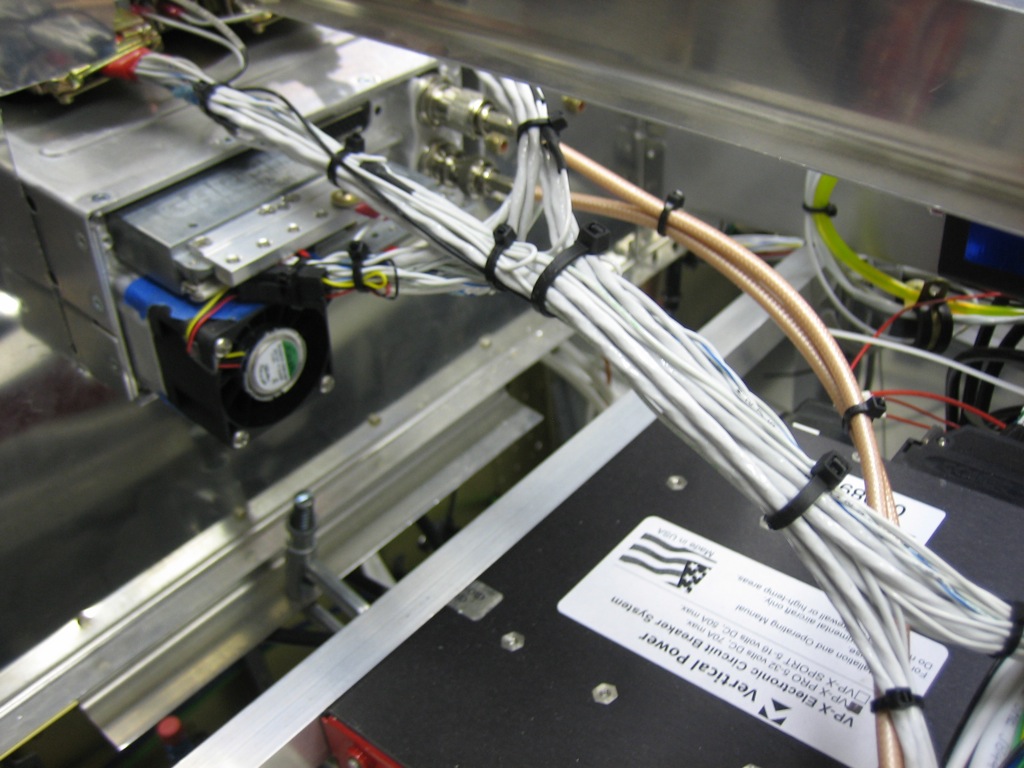

I mentioned a few weeks ago that there was a flaw in my annunciator control circuit. I redesigned it to provide a pull down resistor for the transistor base and a pull up resistor for the transistor collector. I received the circuits yesterday and quickly assembled one, but it was not working as expected. It was late, so I put it off until tonight.

I got started tonight trying to diagnose the misbehaving circuit. The first three annunciator lights were working as expected, but all of the others (both some high and some low triggers) were misbehaving. I measured the voltages at various points in the circuit, but they really didn’t make sense. It was almost as if I had installed PNP transistors instead of NPN transistors. I checked the bag from Radio Shack and they were indeed NPN. I breadboarded a single light control circuit and still couldn’t get it to work properly. At this point, I was beginning to wonder if I had completely forgotten my circuit design skills from university. I was disassembling the breadboard circuit and noticed that the transistor was smoking hot. This shouldn’t have happened because the transistor should either be fully off or fully saturated. In either case, the power dissipated in the transistor should have been essentially zero.

It was really starting to seem like the only explanation was that it was a PNP transistor. I looked up the part number on the transistor, and sure enough it was a PNP. I went through the whole bag from Radio Shack and sure enough, every transistor was a PNP despite the bag indicating they were NPN. I started desoldering the transistors off of the board and noticed the first three (the circuits that worked) were NPNs that I had left over from the first circuit I built. This really pissed me off. I wasted hours trying to diagnose a problem caused by Radio Shack’s mislabeled transistors.

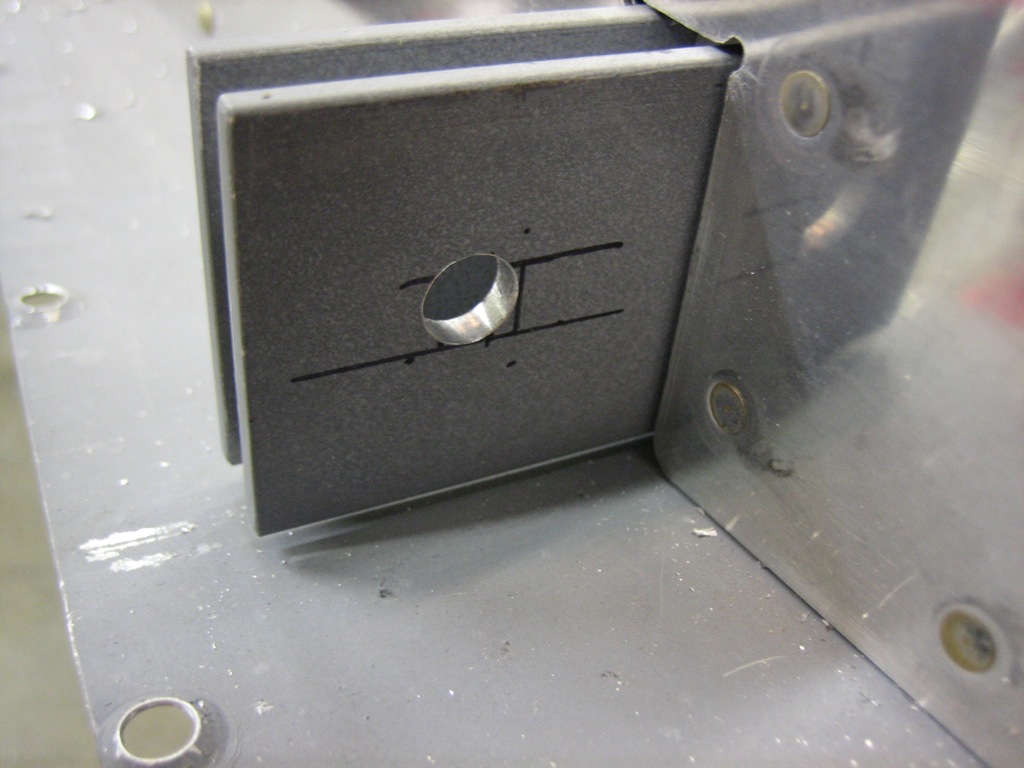

Anyway, I replaced all of the incorrect transistors and unsurprisingly, the circuit worked flawlessly. All of the annunciator lights have nice sharp on/off transitions and work exactly as expected.