My tech counselor, Brian Dal Porto, stopped by tonight to check out my progress. The last time he stopped by was near the end of the wing construction which was about 19 months ago (holy crap, has it really been that long?). He checked out my fuselage construction, as well as engine installation and wiring. He said everything looks good and there wasn’t anything I needed to change which is great.

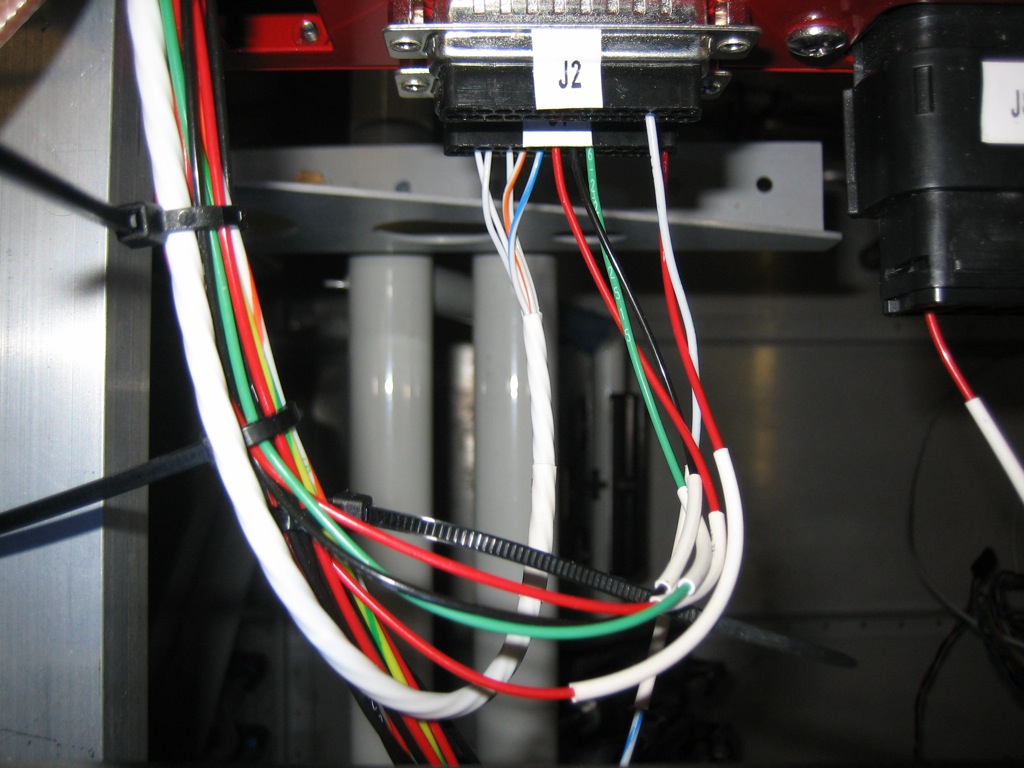

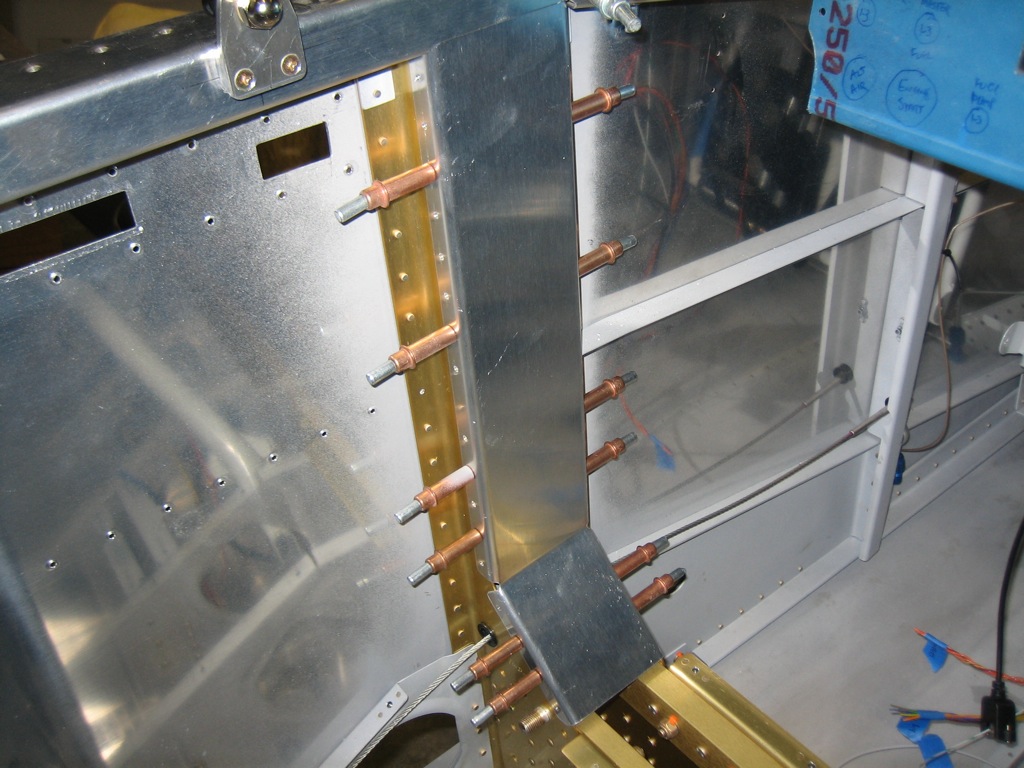

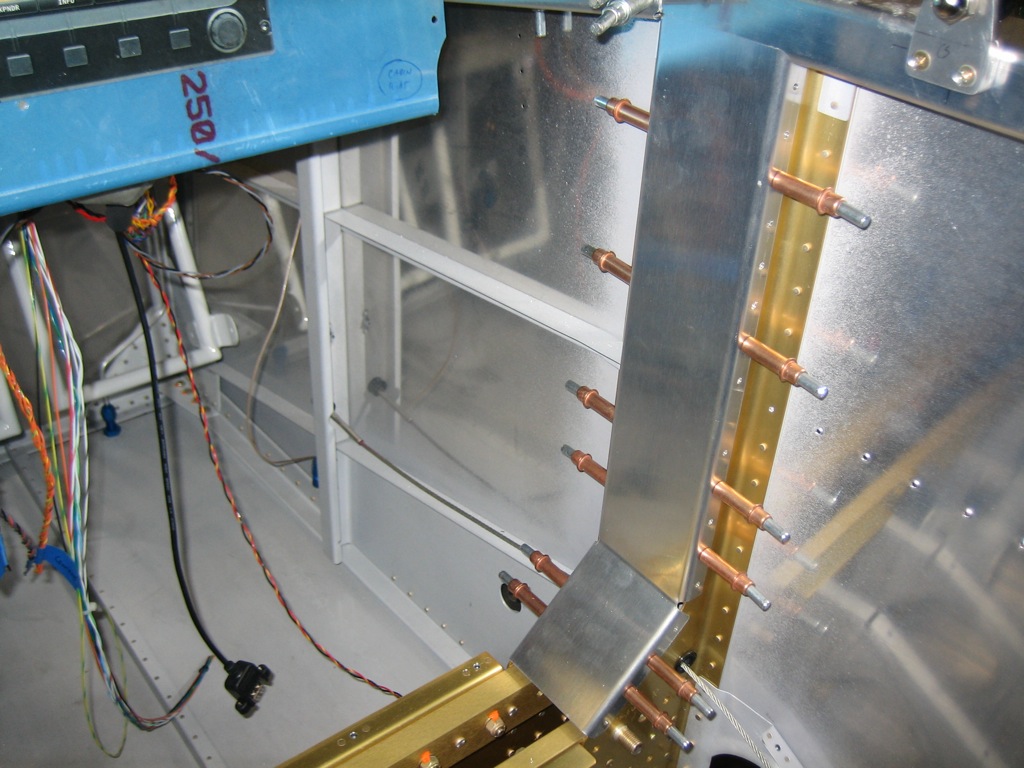

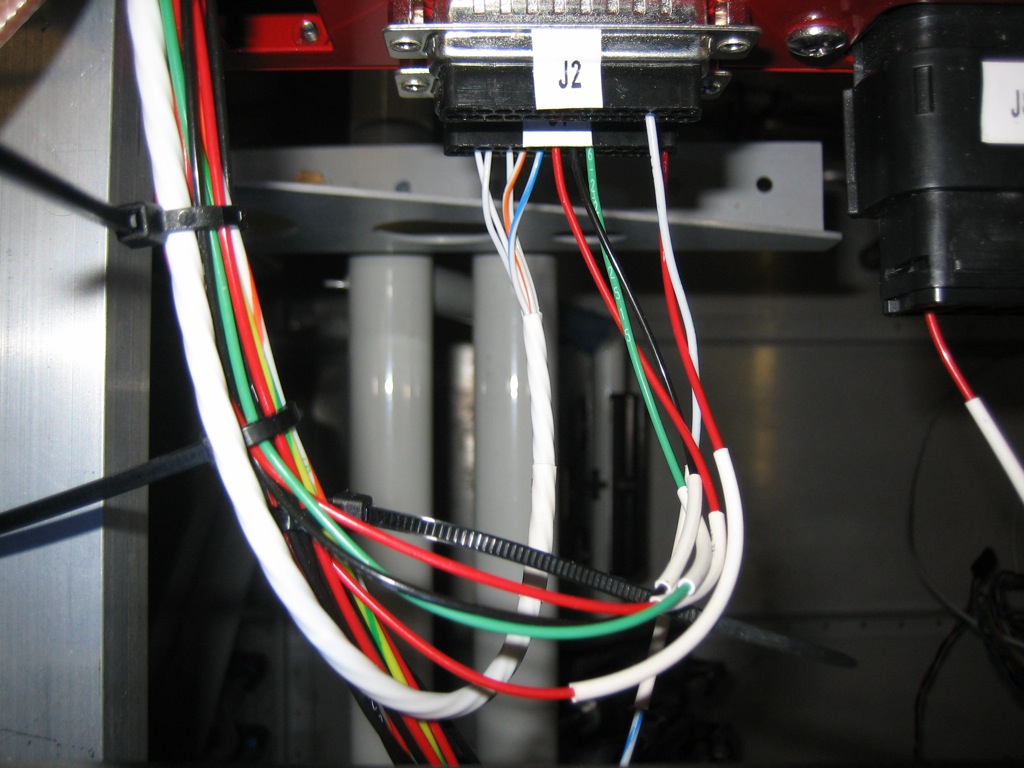

After he left, I took care of a couple of small tasks before heading in to get some work done for my day job. First up, I ran a cable for the elevator trim. This is a 5-conductor cable from Ray Allen that is specifically meant for wiring their trim systems. It contains five 26AWG wires that match the colors of the wires coming out of the trim and position sensor boxes. I was hoping that one 25′ cable would be enough to do both the aileron and elevator trim wiring, but it was quite a bit short. I’m going to replace my flap position sensor wires with another piece of this, so another 20′ should be plenty for the aileron trim and flap position. Here’s the wire where it comes out of the J1 connector on the VP-X (the five small wires that come out of the connector and go into the larger white cable. You can’t see it, but there is a heat shrink label on the cable.

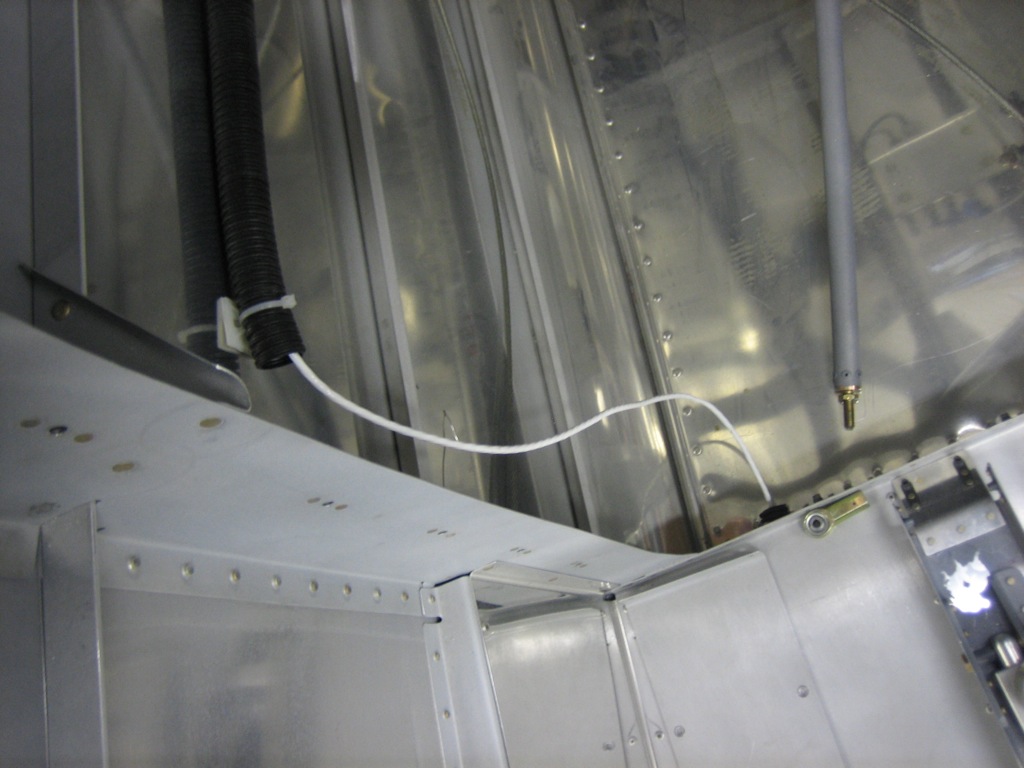

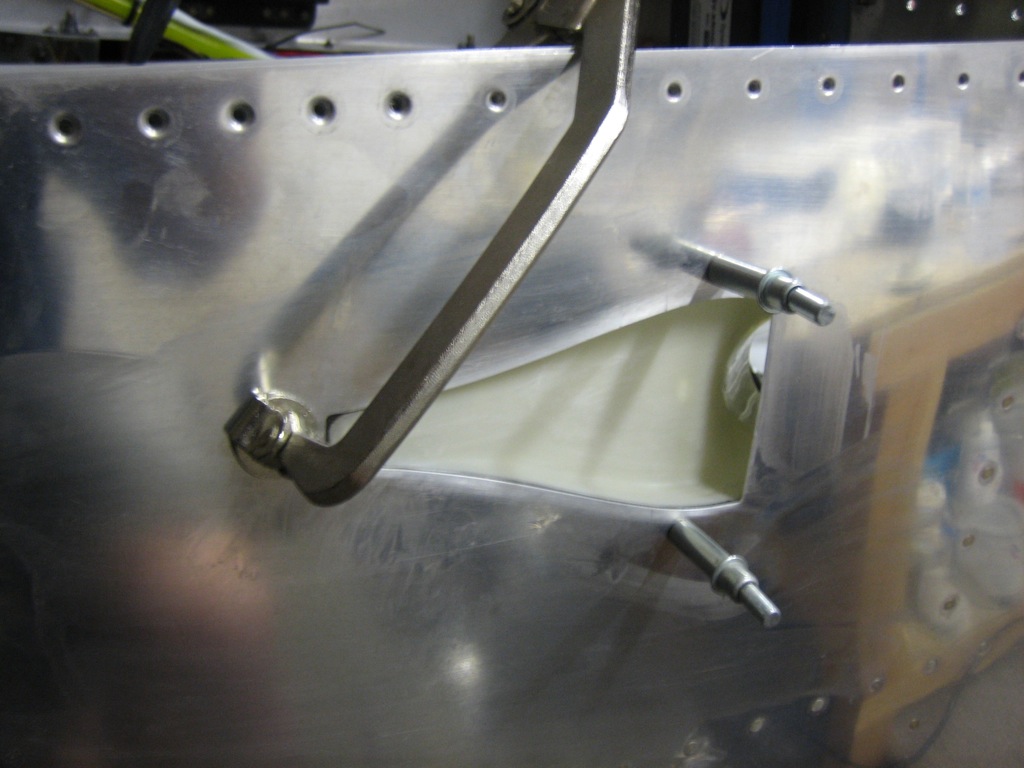

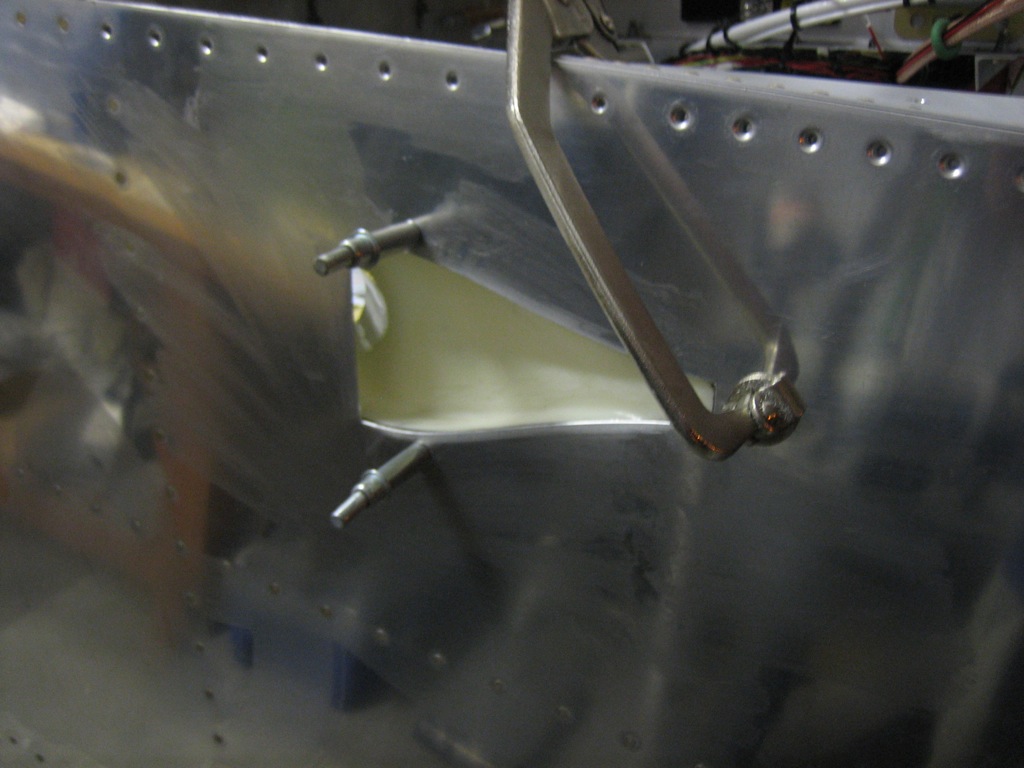

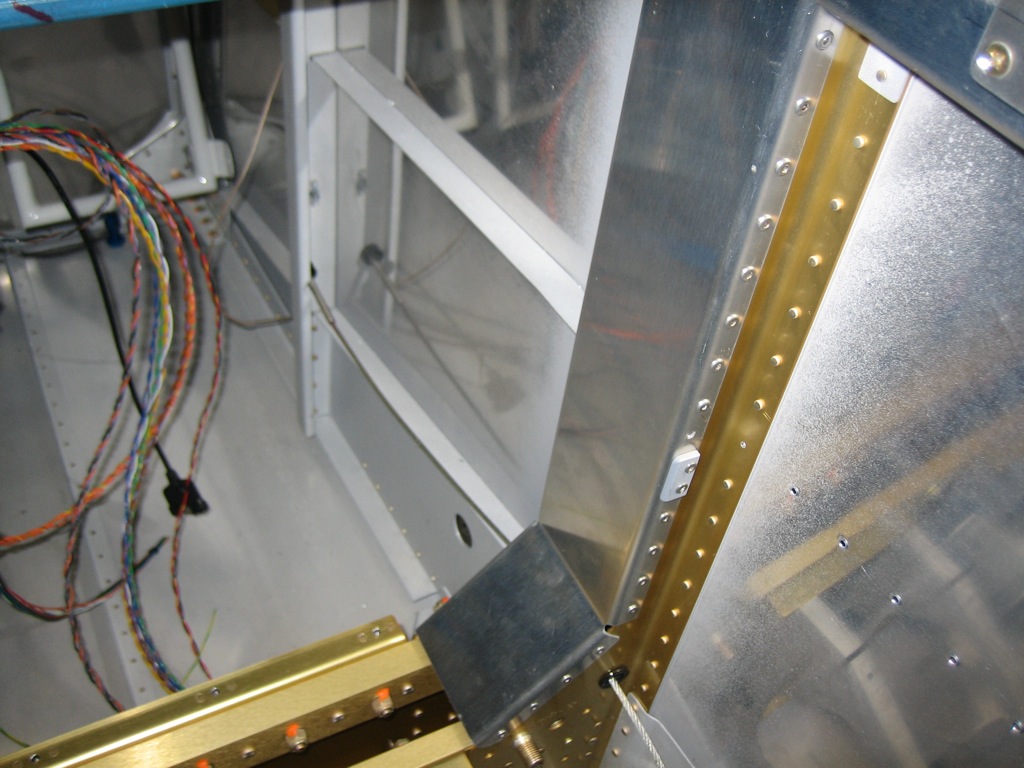

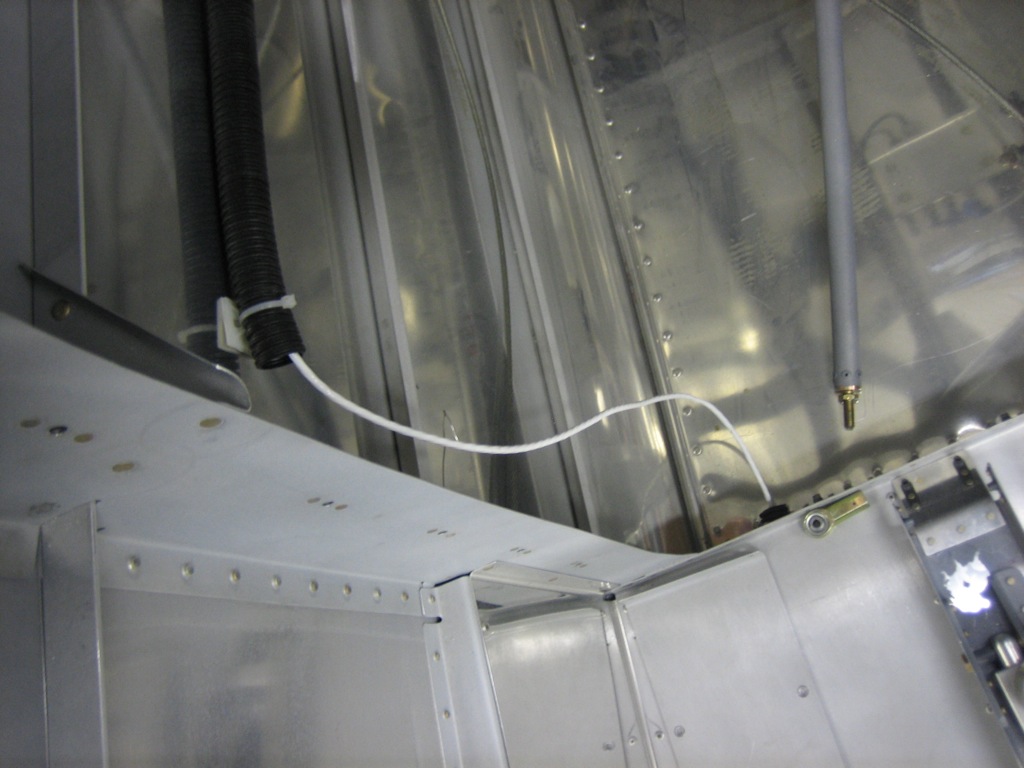

The cable runs down the forward center tunnel and under the copilot’s seat and through the right conduit and comes out here behind the baggage bulkhead. There will be an adel clamp here securing this to the bulkhead as it runs up to the tail conduit (along with the tail position/strobe wires).

There’s a few extra feet of wire back here. I’ll cut it to length when I mount the tail.

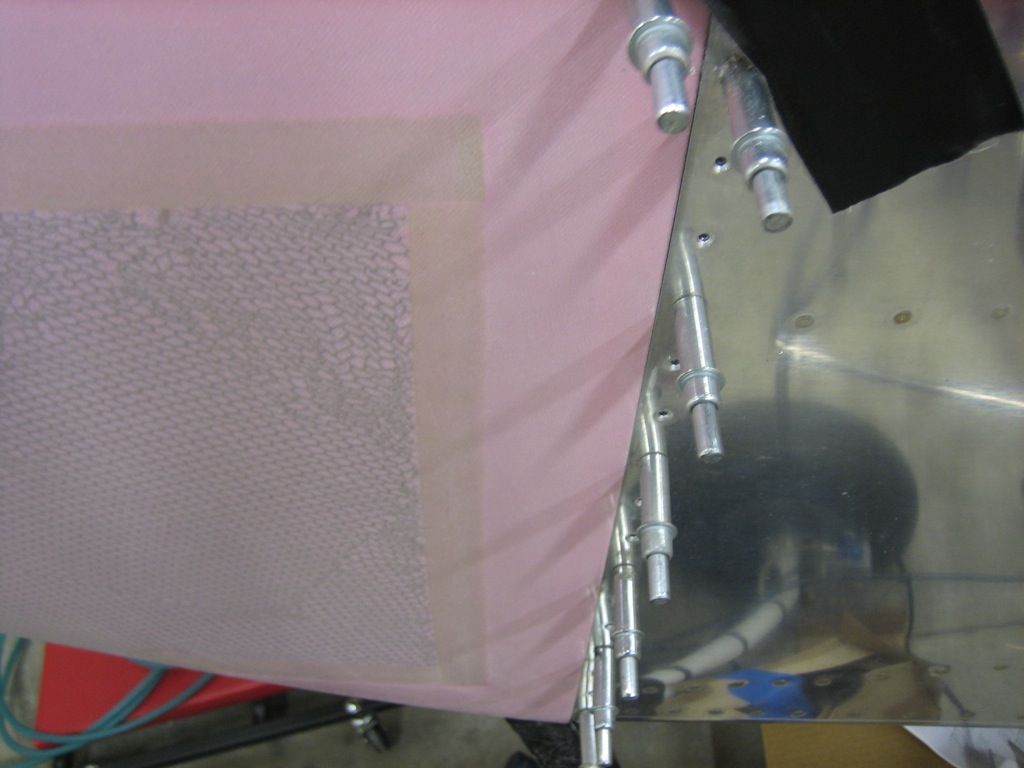

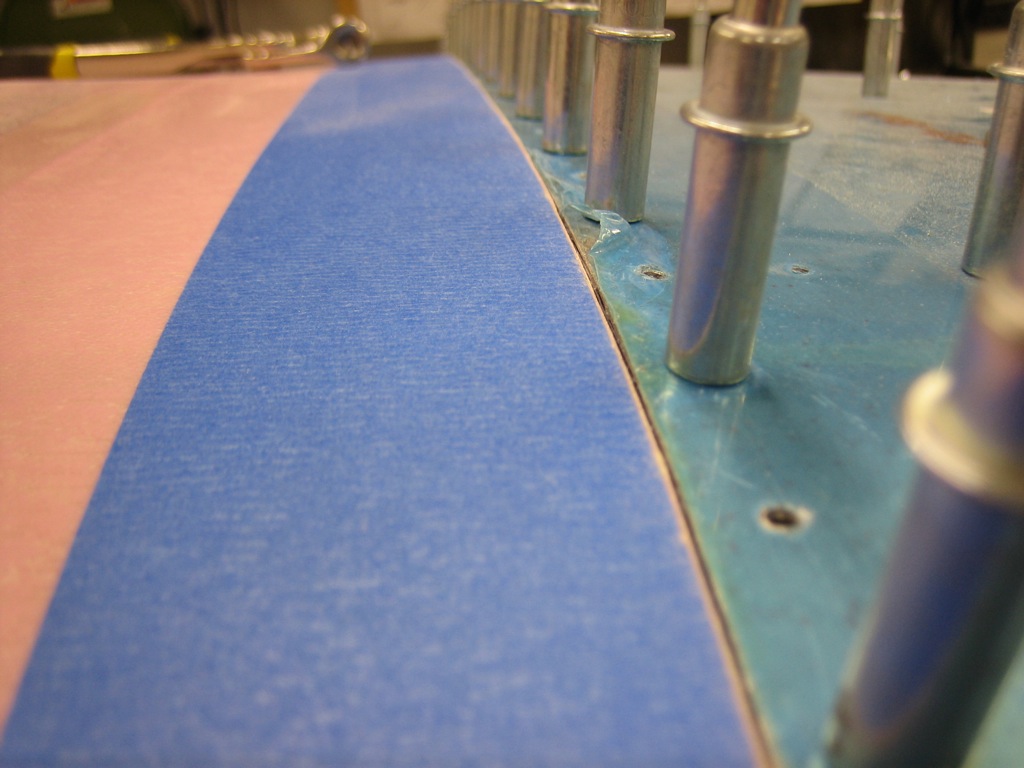

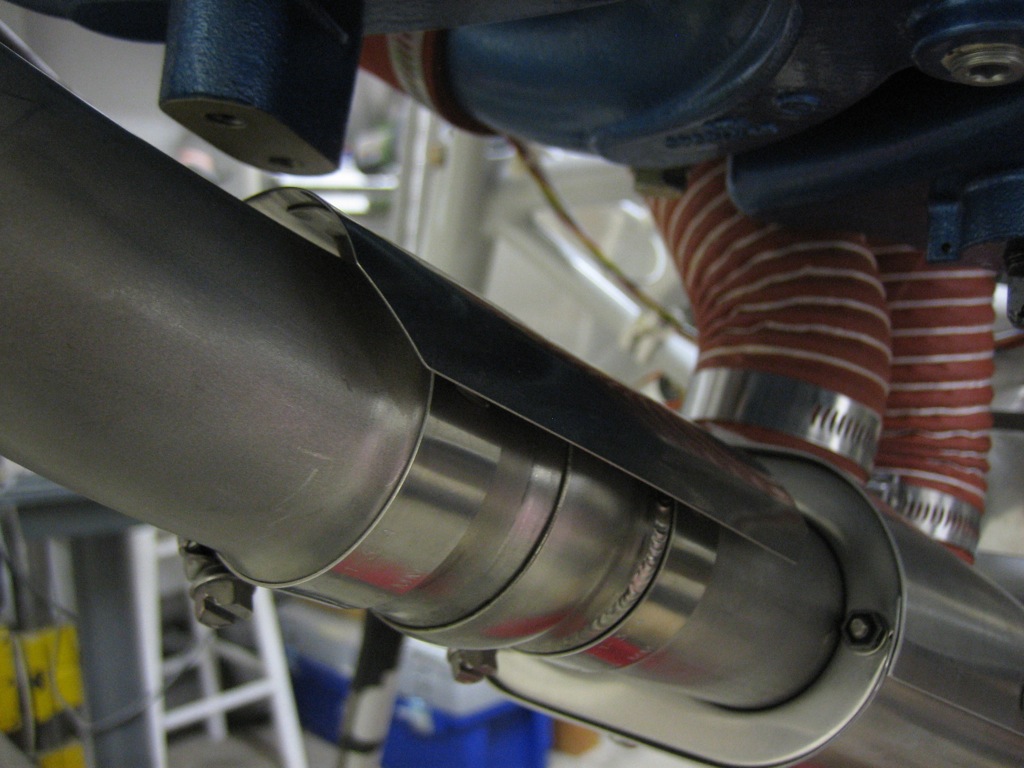

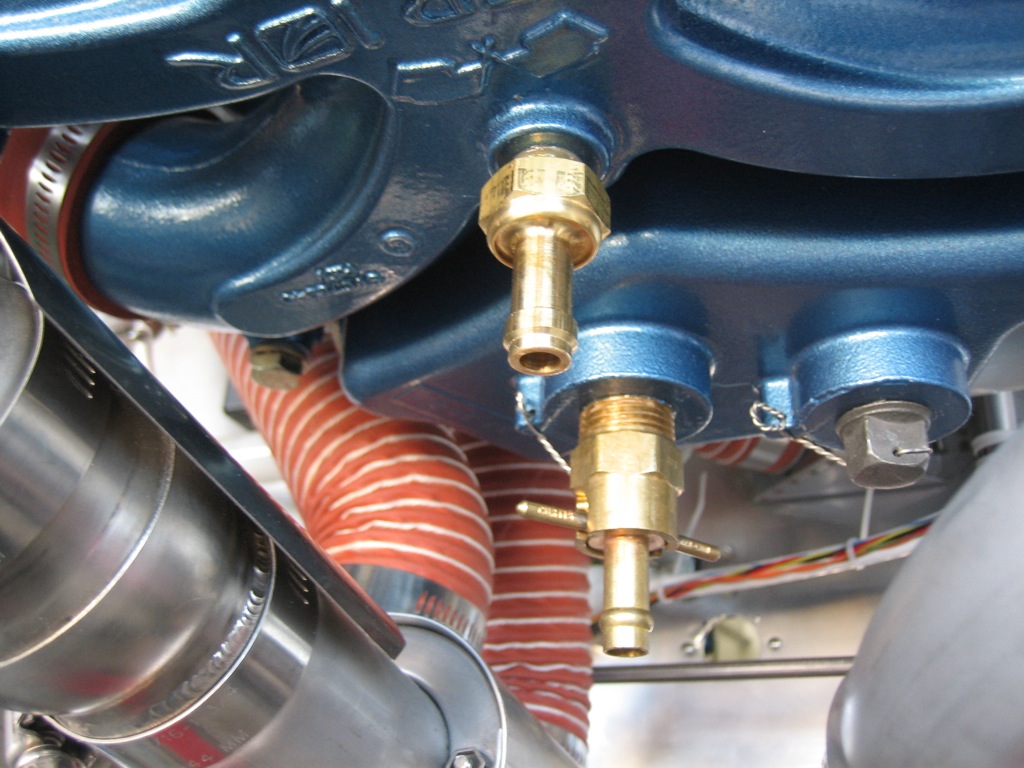

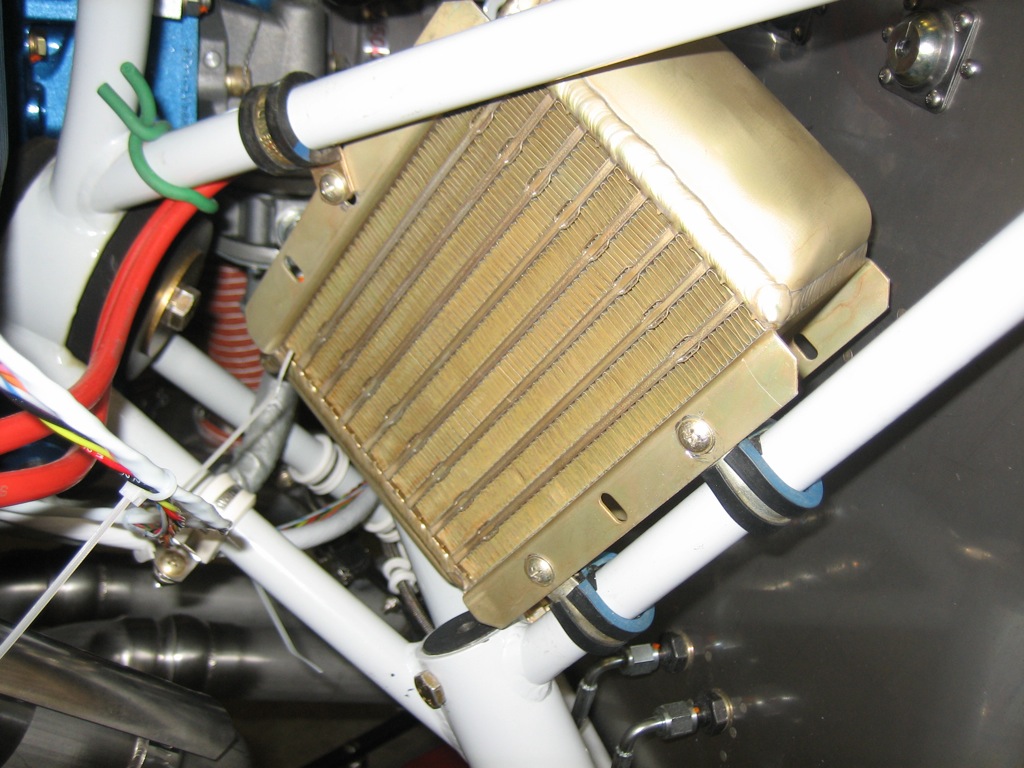

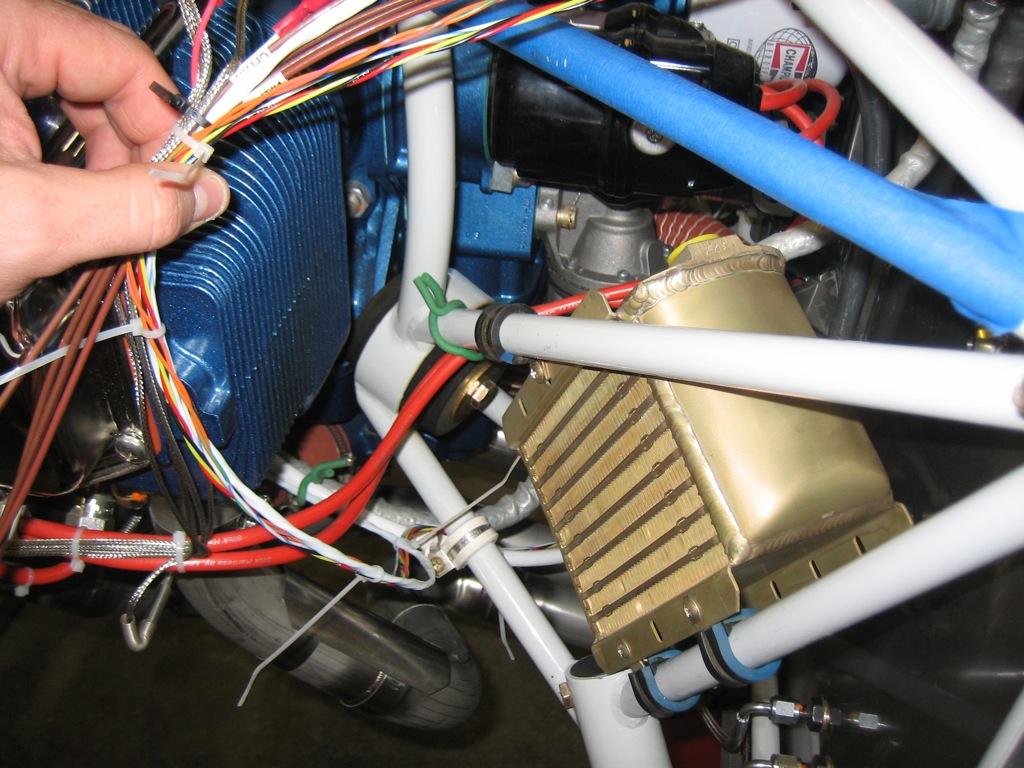

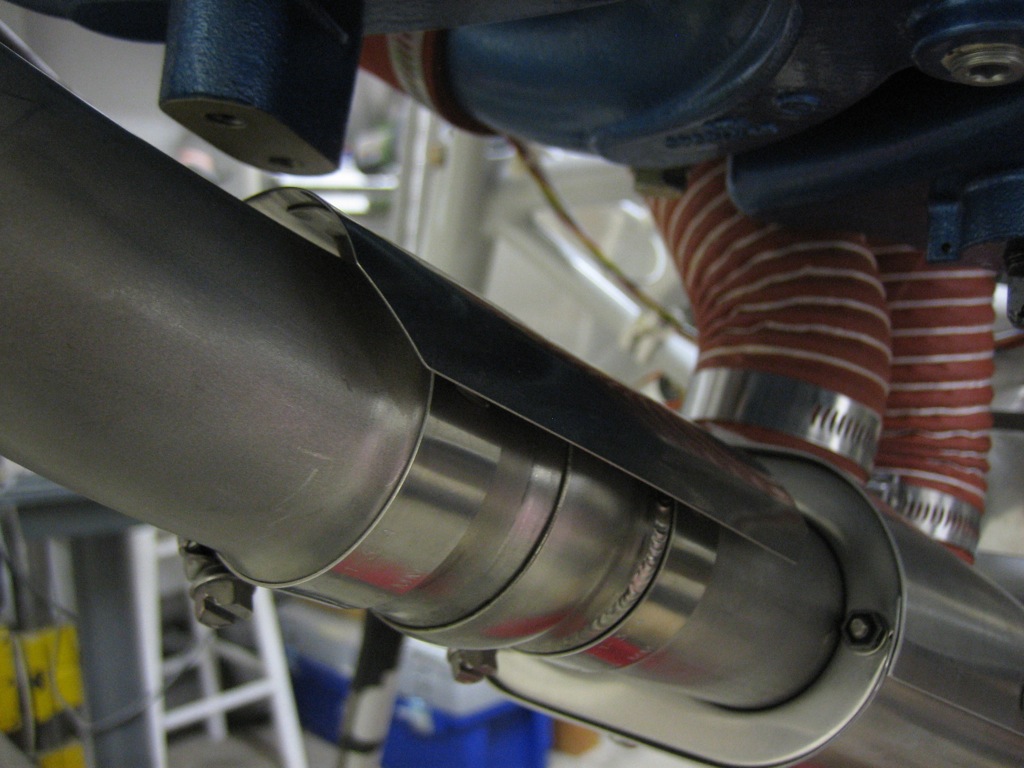

I also received a couple more 4″ exhaust heat shields. I mounted one on the #4 pipe to protect the wires running through this area.

I also mounted two on the #1 pipe. The first is just above the heat muff to protect the throttle cable.

The second is a little farther up the pipe to provide some protection for the alternator wires and fuel flow sensor.