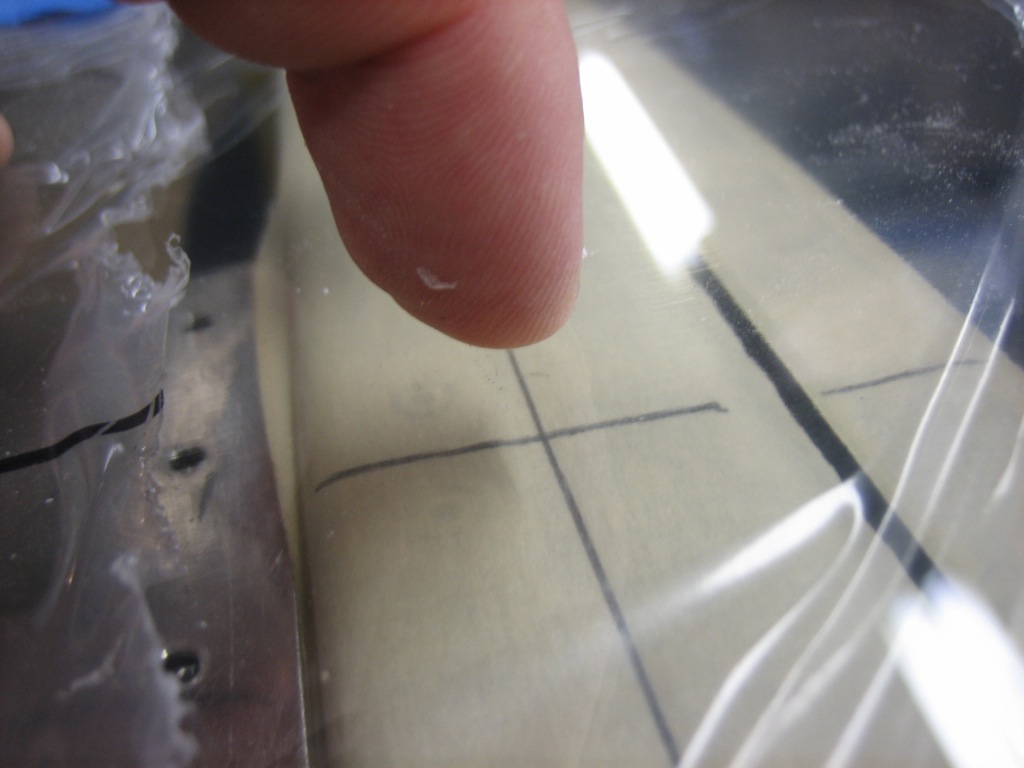

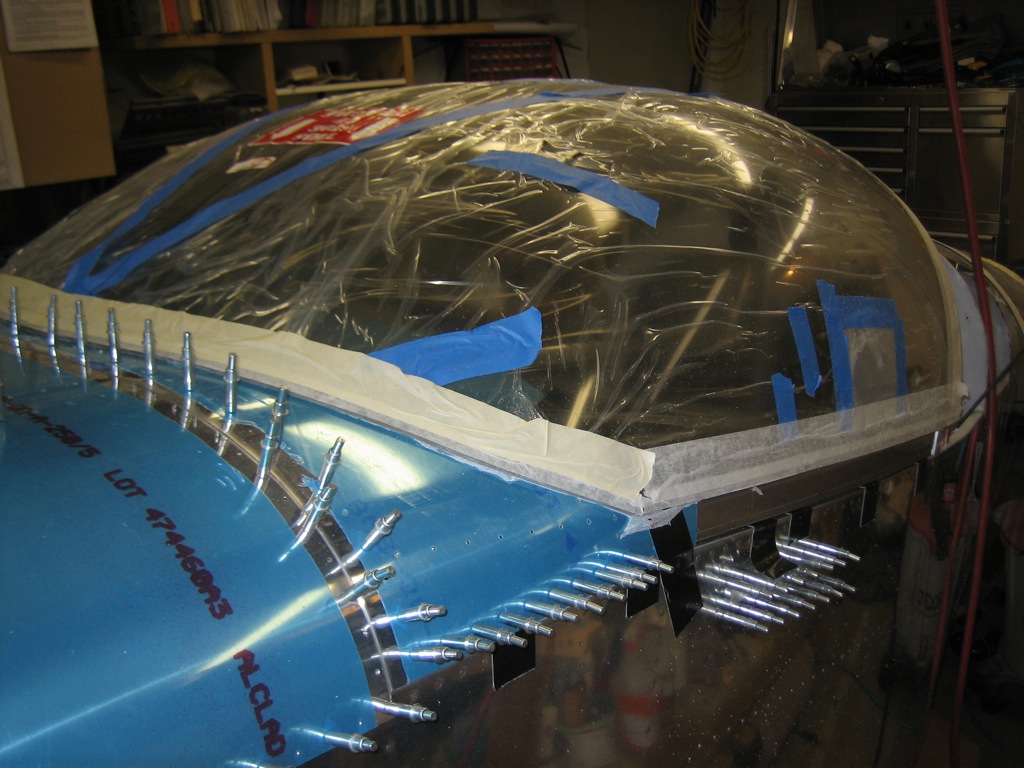

Another RV-7 builder from Paris stopped by tonight and we chatted RV’s for awhile. It was good to finally meet him as we’ve only exchanged emails up to this point (hi Frédéric!). After he left, I rearranged the workbenches and pulled down the canopy. I forgot to take a picture of it, but I then drew a centerline down the canopy to use as a reference point.

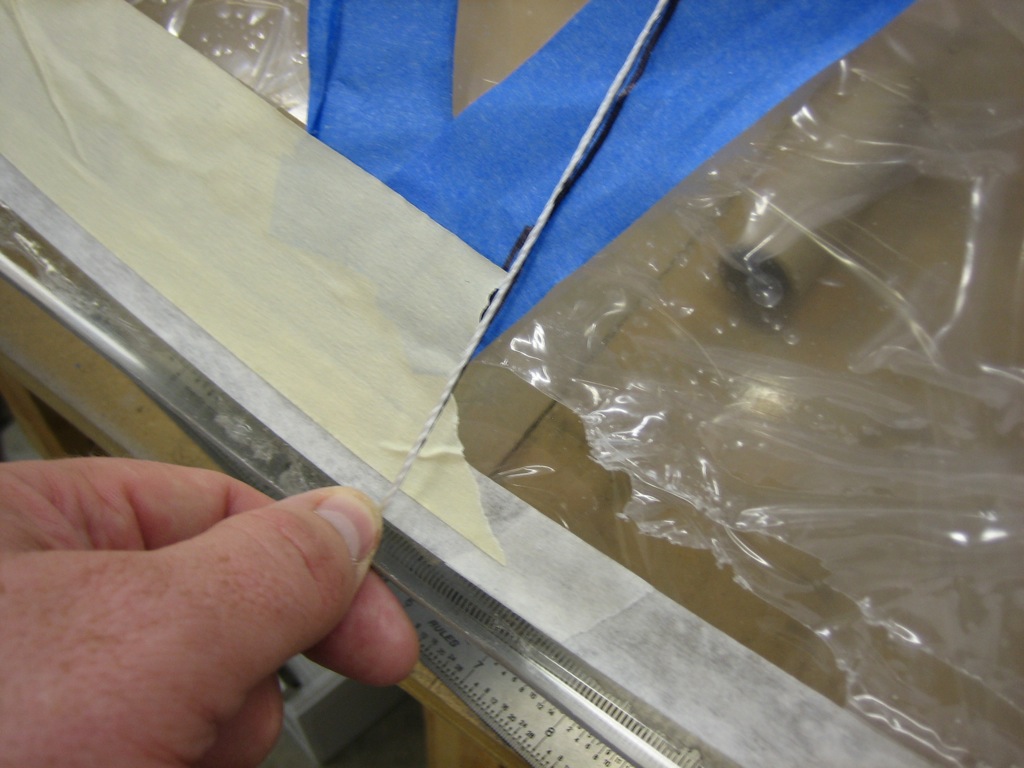

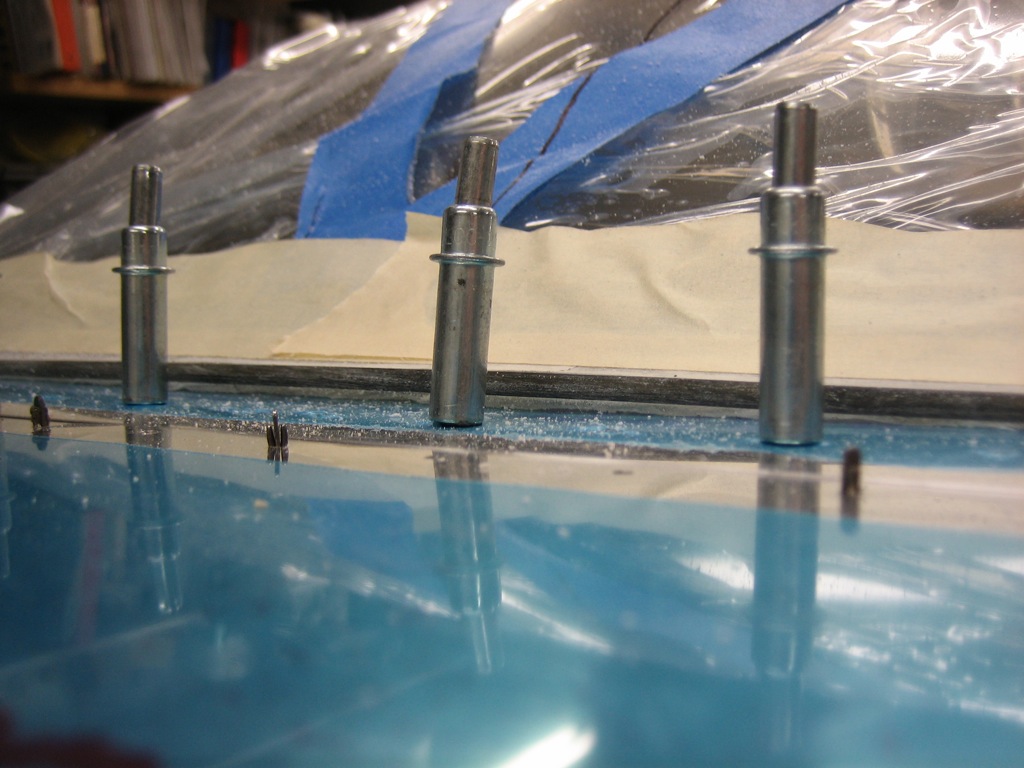

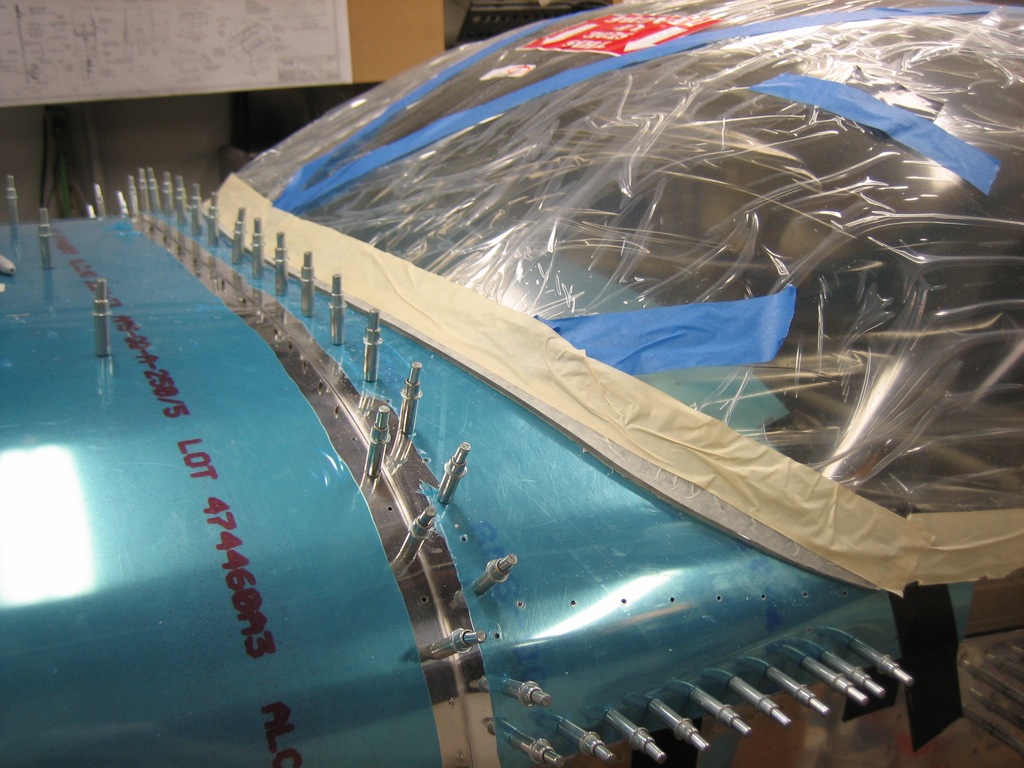

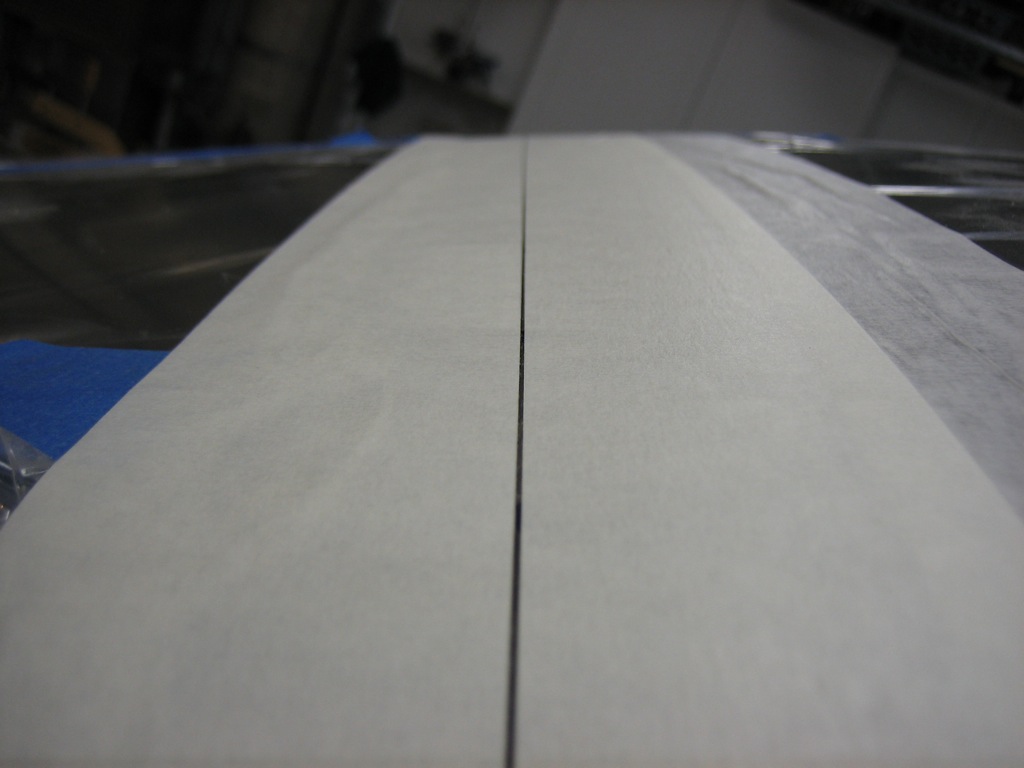

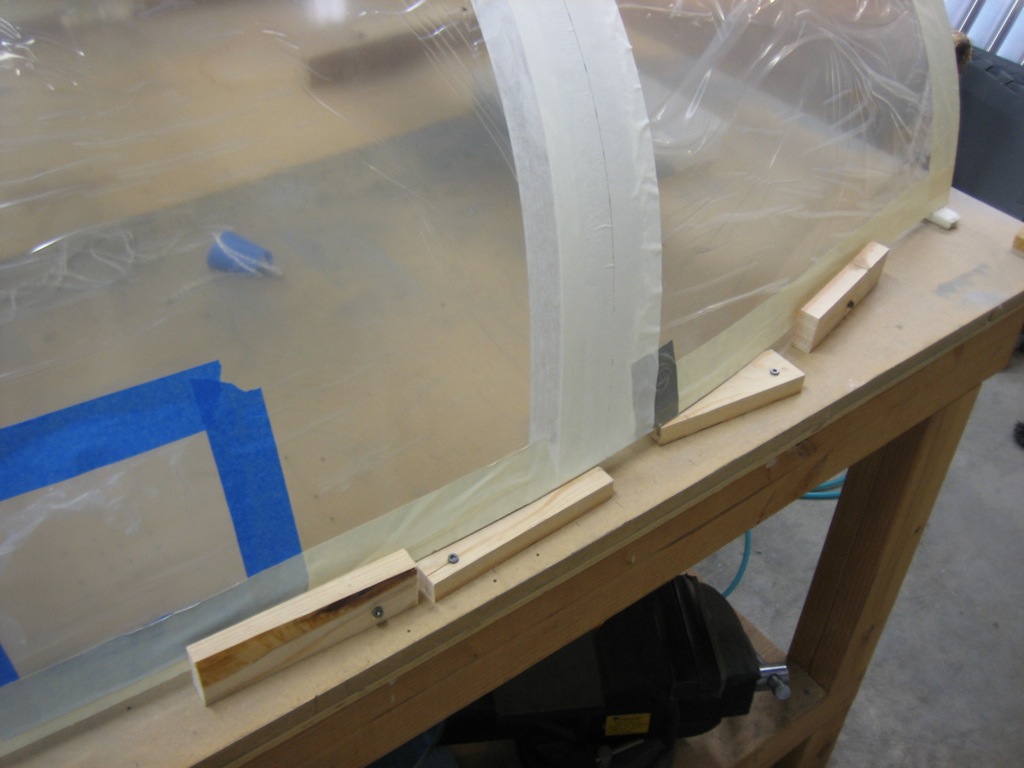

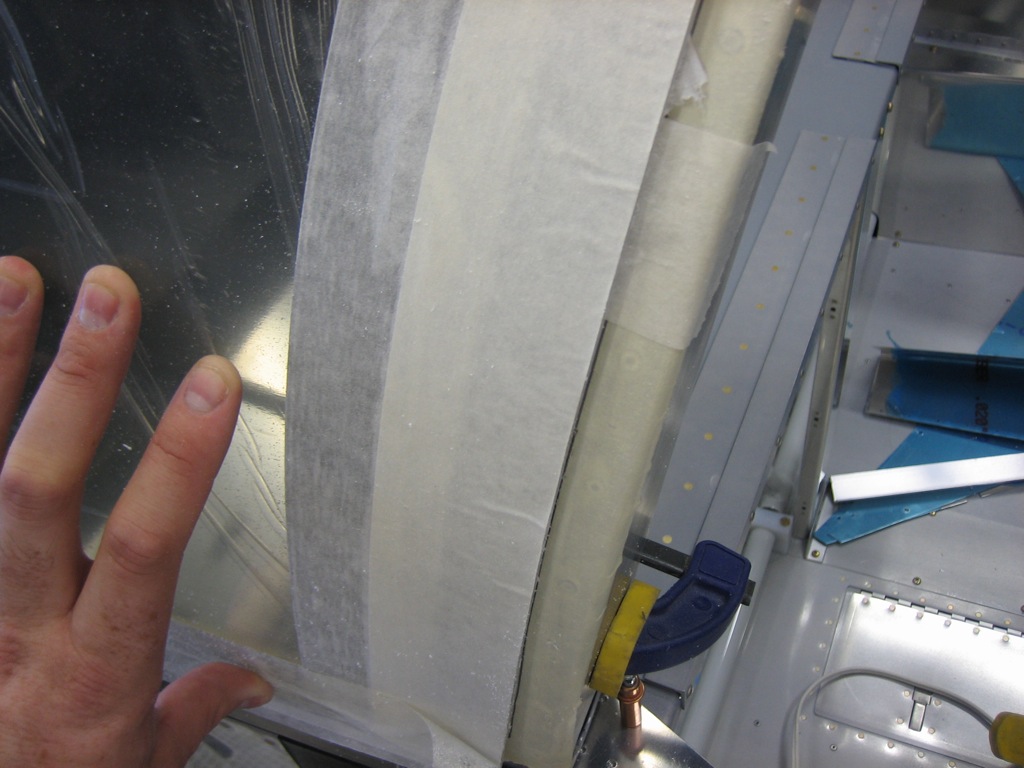

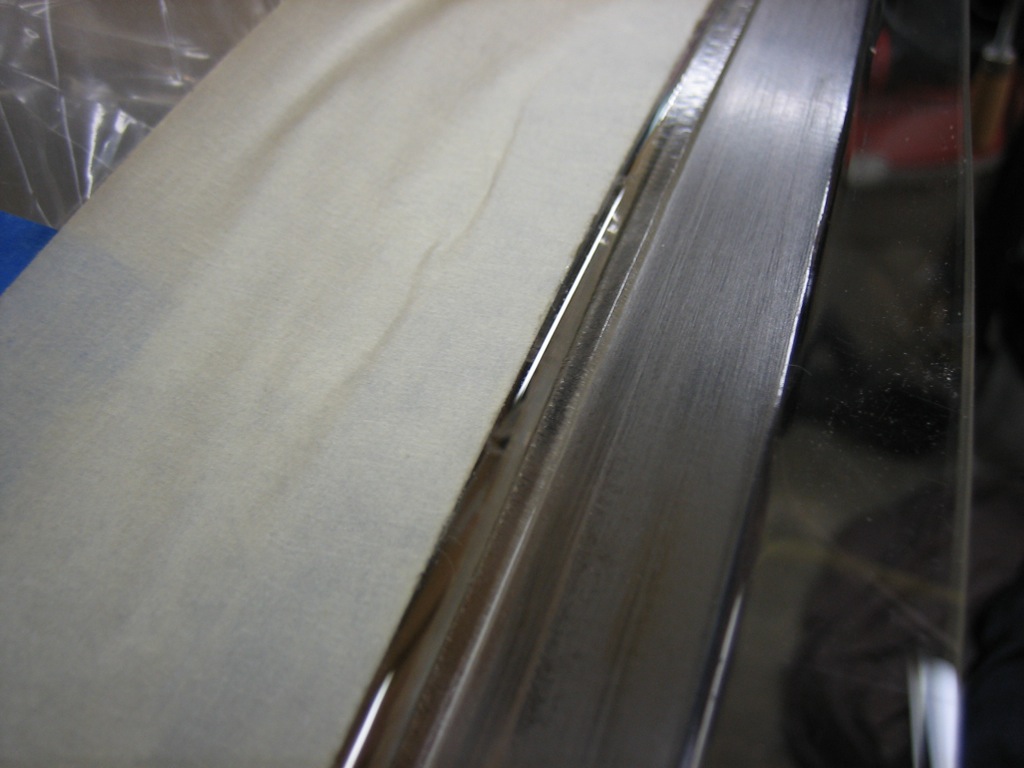

First up is to trim off all of the clamping marks on the edges. I started with the front edge by cutting back the plastic and taping a cut line with some masking tape.

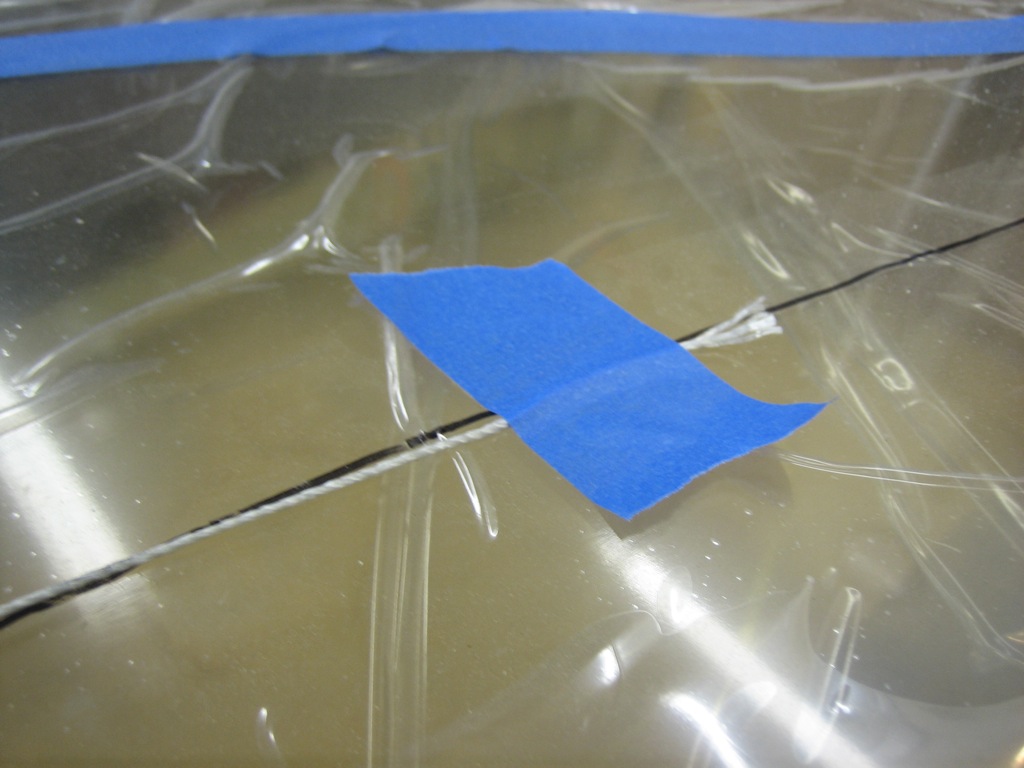

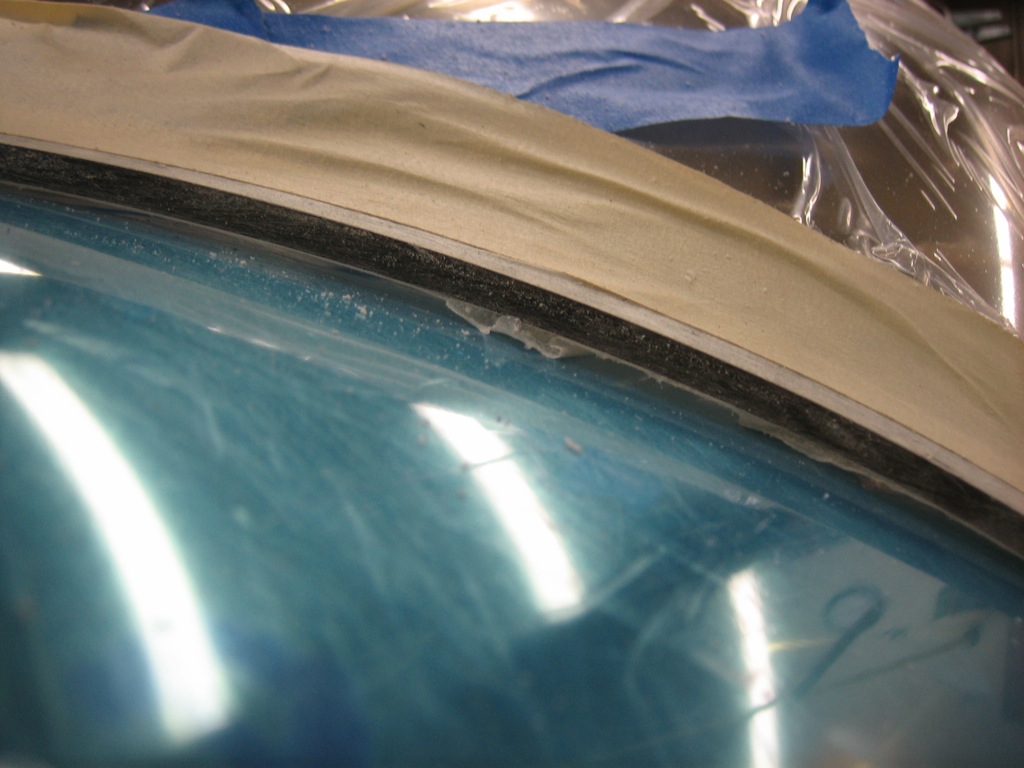

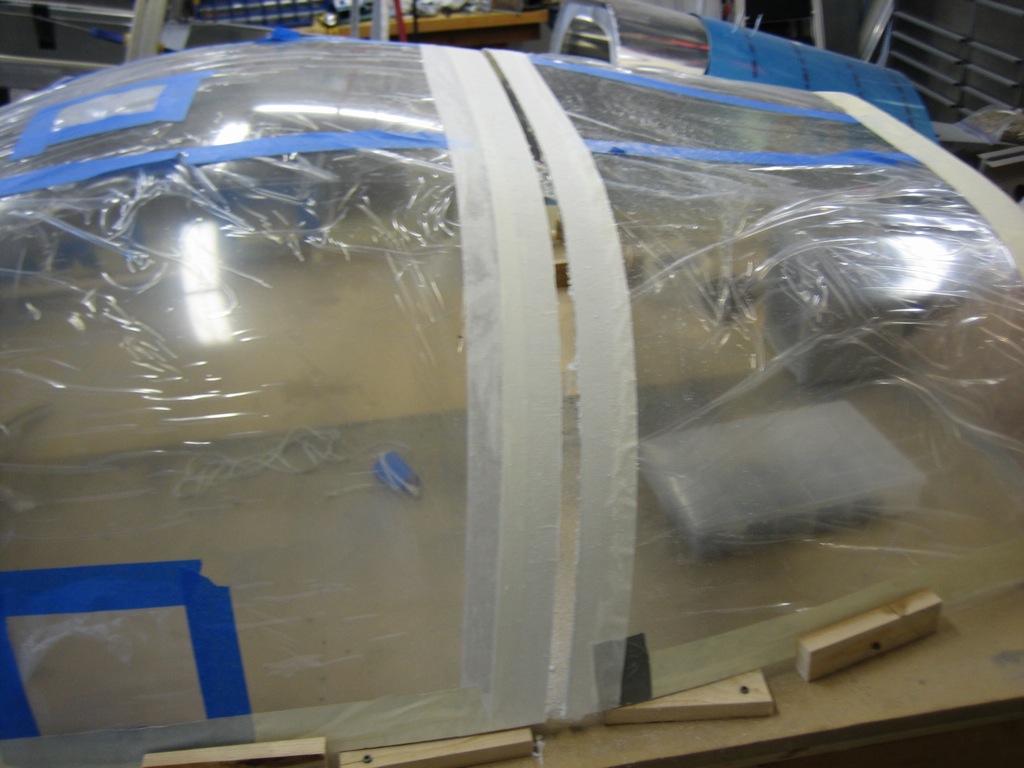

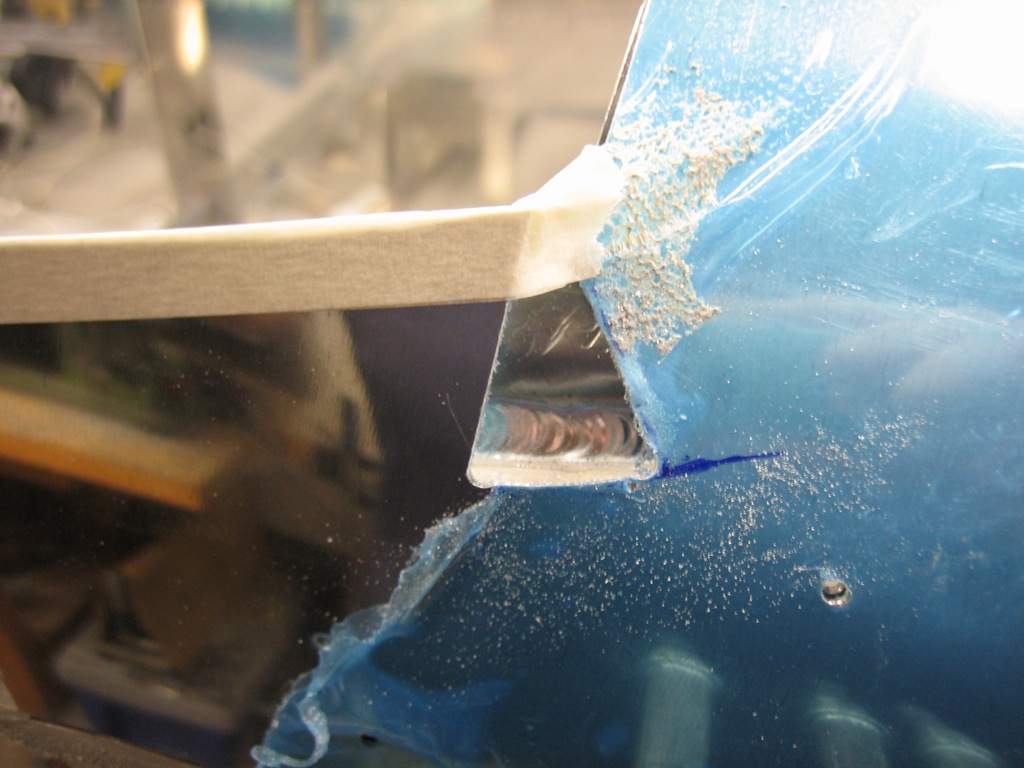

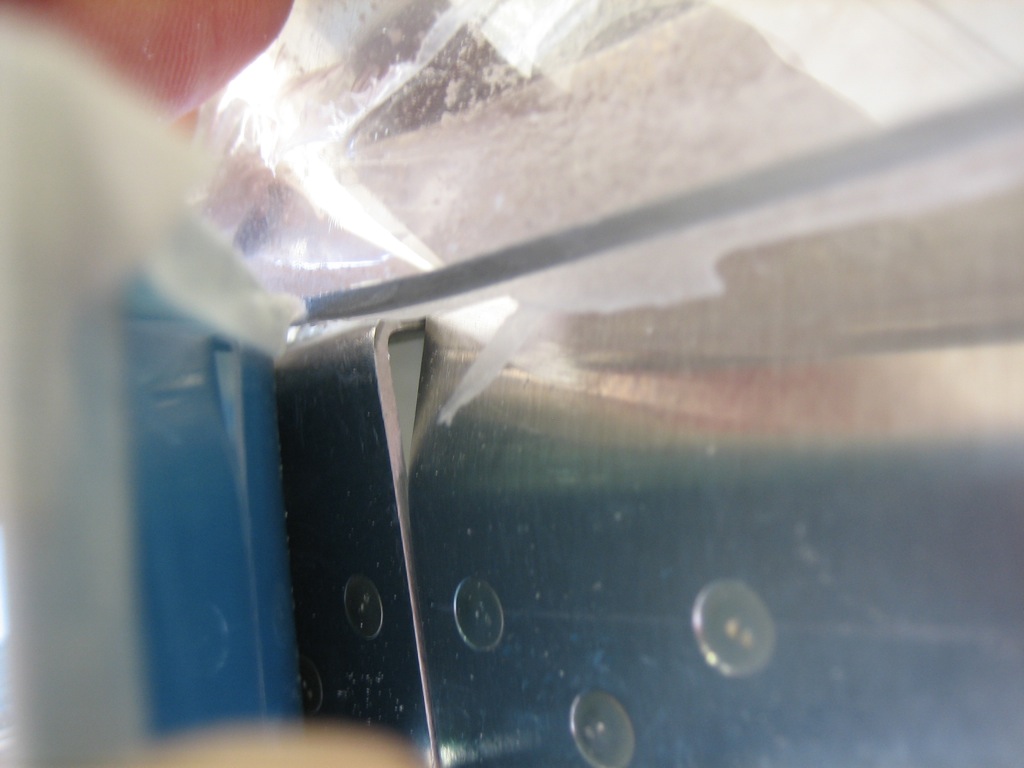

Here’s a closeup of the clamping flange and taped cut line.

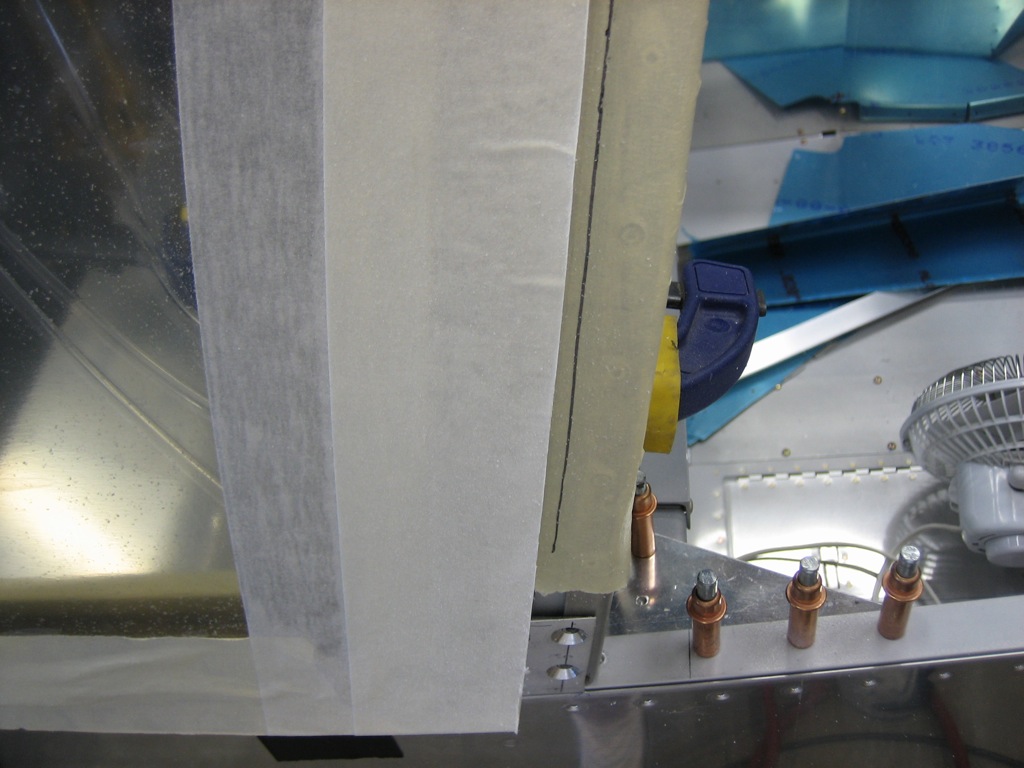

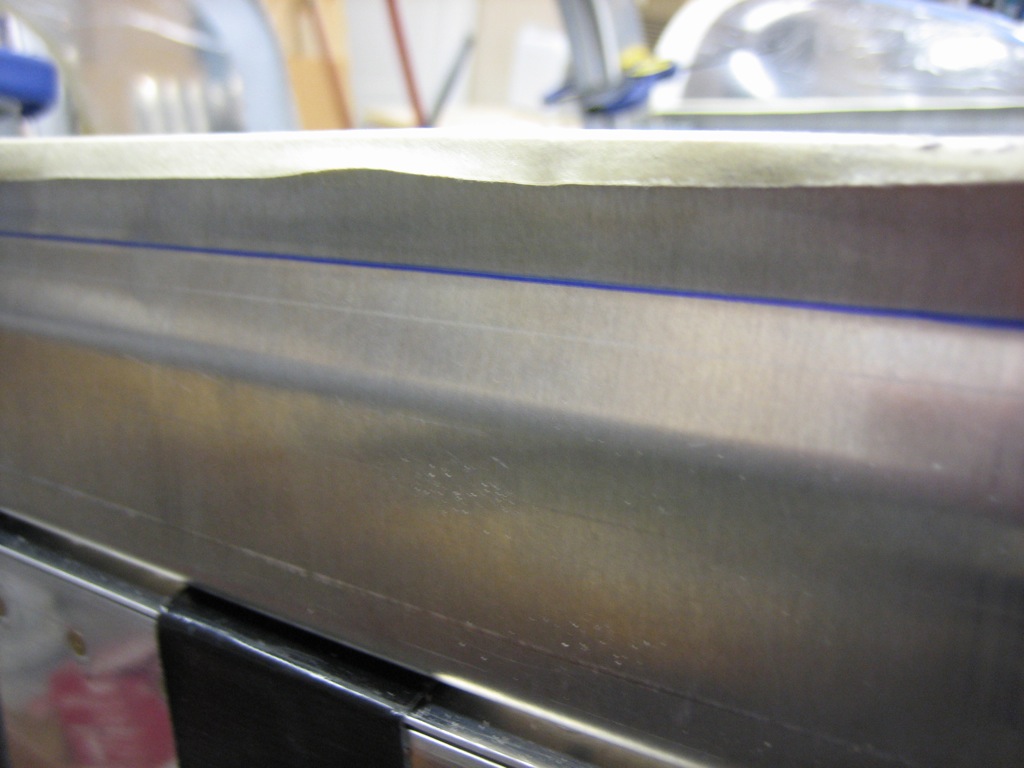

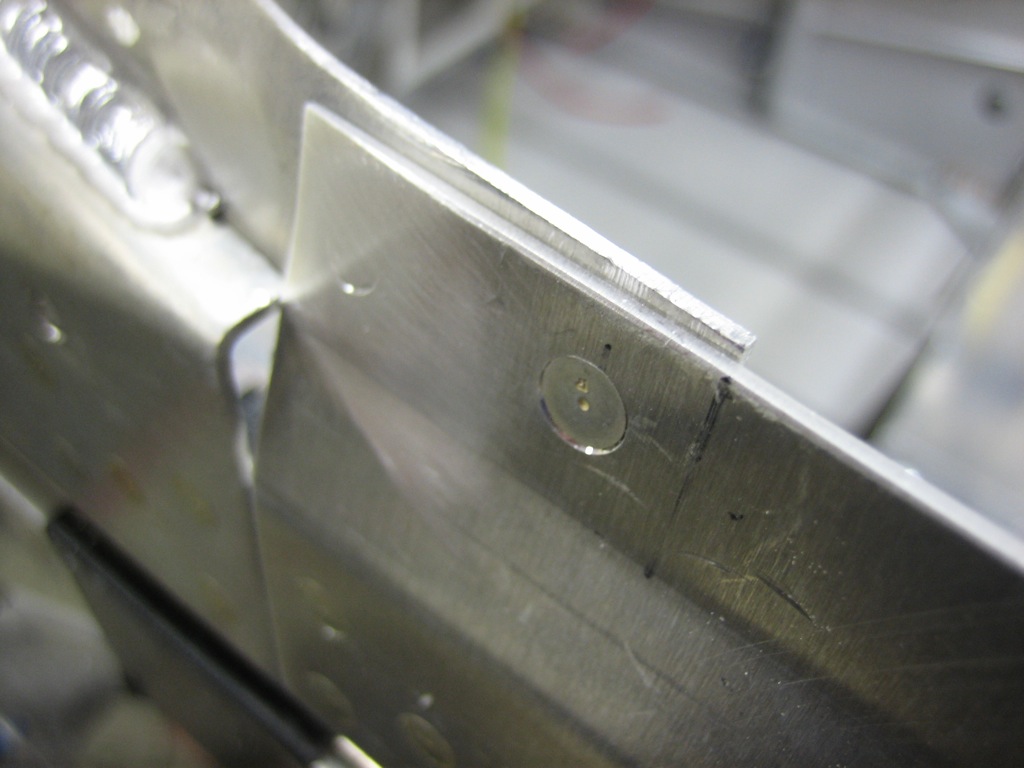

It probably took five minutes to cut off the flange. I’m using the cutoff wheel that Van’s ships with the finish kit. I’ve installed it on my 90º angle die grinder which helps keep it aligned with the cut line.

I’m covered in fine plastic snow. I’m not looking forward to all of the cutting that I’ll need to do on this canopy.