Now that the firewall is out of the way, I got started on the center section. First up is to enlarge the holes in the side supports to allow the rudder cables to pass through. These are drilled out to 5/8″ for an SB625-7 snap bushing.

The side supports are then positioned using a couple of close tolerance bolts so that the rivet holes can be precisely match drilled. These bolts are seriously snug. Even with some lubricating oil, I had to push these rather firmly to get them through the holes.

I also noticed something odd when laying out all of the pieces. Van’s apparently mismarked the forward and after center sections (the aft section was marked fwd and vice versa). This may have just been a marking error, but if the center section was flipped end for end when the wing spars were match drilled, then the close tolerance bolt holes may not line up precisely when the wings are mated. I’ll call Van’s on Monday to see if they think this is an issue. Hopefully their drilling jig won’t let this sort of mistake happen.

Update: I spoke with Ken at Van’s and he’s about 99% sure this is simply a marking mistake. He didn’t know if their drilling jig would let them drill the center section backward, but said that if I wanted to be 100% sure, I could simply install the center section onto each wing using the close tolerance bolts to see if the holes lined up.

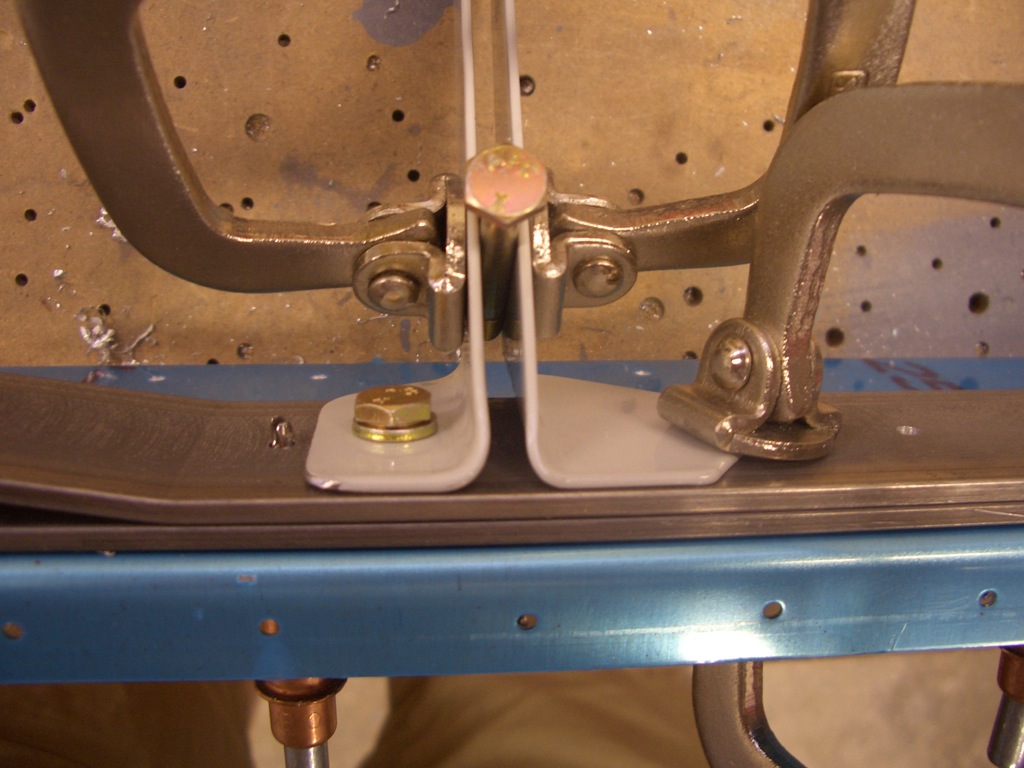

The aft center section needs some spacer bars match drilled to the spar web. Using some AN4 bolts, I positioned and clamped the spacer in place.

There is a pilot hole in the spar web and side support, but then you need to drill through the 5/8″ spacer. Since it would be easy to get this hole slightly off of perpendicular to the surface, I broke out my drill cups to ensure that these holes are exactly perpendicular.

There are a few more 5/8″ holes that need to be drilled in the forward and after center section spar webs for snap bushings that will allow for wiring runs to penetrate the center section. Here are the two in the forward center section. The plans call for SB625-7, but I ordered extra SB625-8 snap bushing to give myself a little more room for wire runs.

Here are the corresponding holes in the aft center section. The seat ribs rivet here which is why there are two vertical rows of rivets. Like most builders, I wonder why they didn’t just move these over a half inch or so so that they wouldn’t interfere with the rib. As it is, I’ll have to cut away part of the rib flange to make room for the snap bushing. I also ended up with the minimum edge distance on one of these holes (3/16″). Nothing to worry about, but it would have been a non-issue if they have simply moved their holes inboard a bit.

There are also outboard holes in both center sections for snap bushings. If you zoom in on the picture, you can see that the hole slightly cuts into the side support. Again it seems odd that they didn’t move these holes inboard a tiny amount to eliminate this interference.