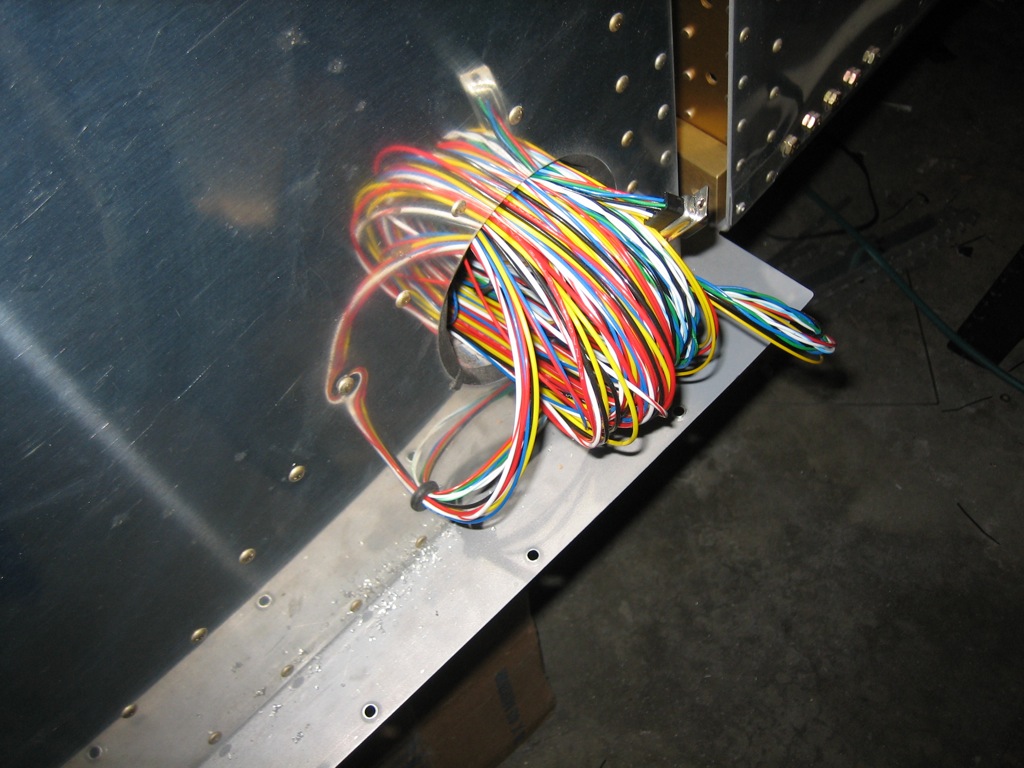

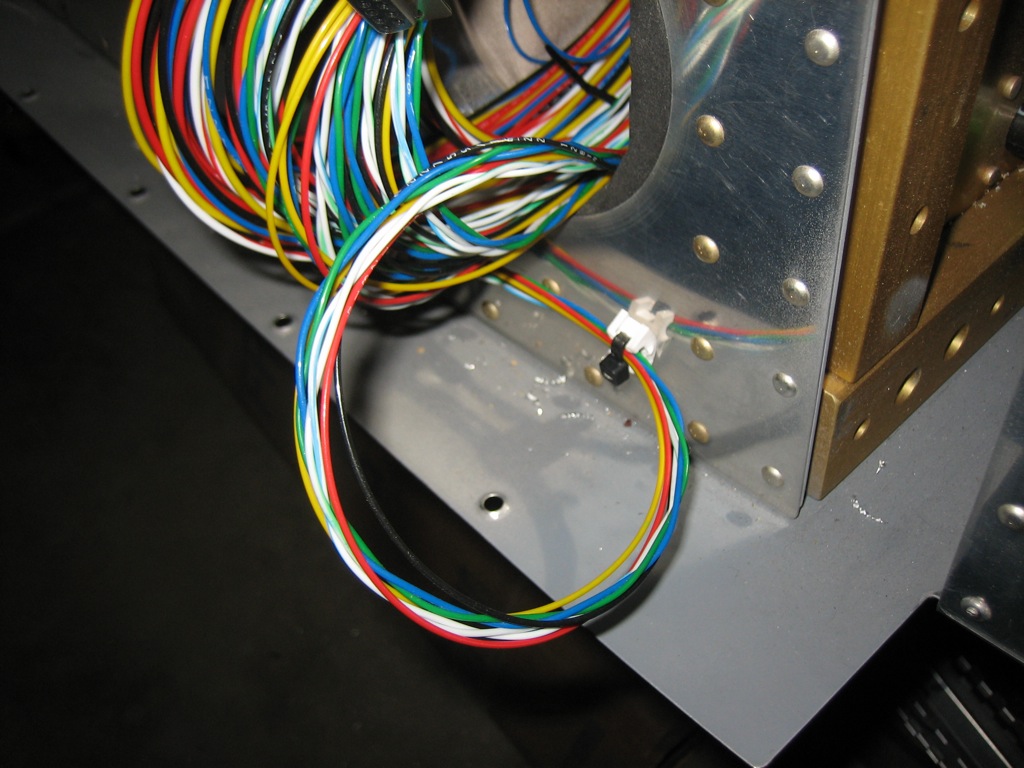

I drilled holes in the sides of the fuselage for the wing wire runs and fished them through along with a grommet. To keep the wires out of the way, I coiled them up and tucked them back into the aileron push-rod hole.

The wing tip wiring will go straight into the wing wiring conduit from the hole I drilled, but the roll servo cable turns forward from there and then needs to go up to a hole near the top of the wing to route down to the servo. I pop-riveted a wire clamp to the side of the fuselage to anchor the cable and keep it away from the aileron pushrod.

I also received the Dynon ADS-B receiver today and spent some time deciding where to mount it. There’s basically no place up front that is easily accessible since I’m trying to make sure that every box in the plane can be accessed and removed if necessary. I ended up deciding to order one of Van’s ELT mounts that fits between the left side stringers and mount it there. It’s a fairly short run of coax from there back to where the UAT antenna will be mounted about 2′ behind the transponder antenna.

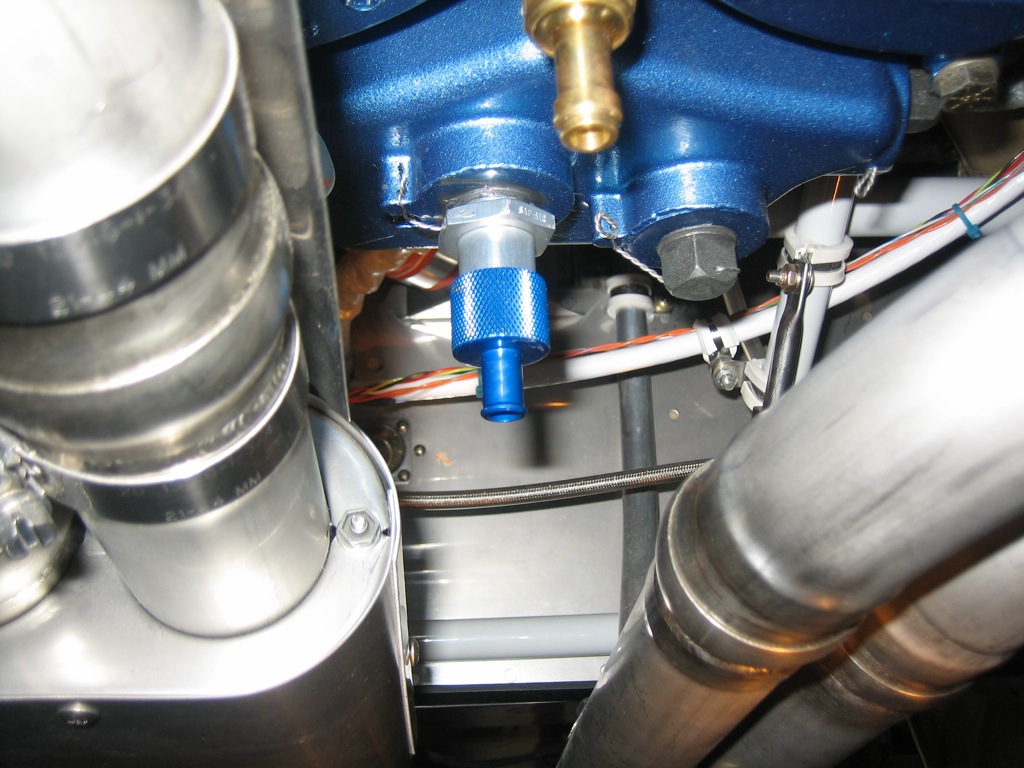

I decided to replace the Curtis quick drain on the right that came with my engine with the one from Saf-Air. Not only is it better made, double sealed and rebuildable, but it’s 2 3/8 oz lighter! That’s a huge weight savings for only $80. There are other parts on the plane that I spent hours on trying to shave out less weight than this simple change.

Here’s the valve installed and safety-wired.