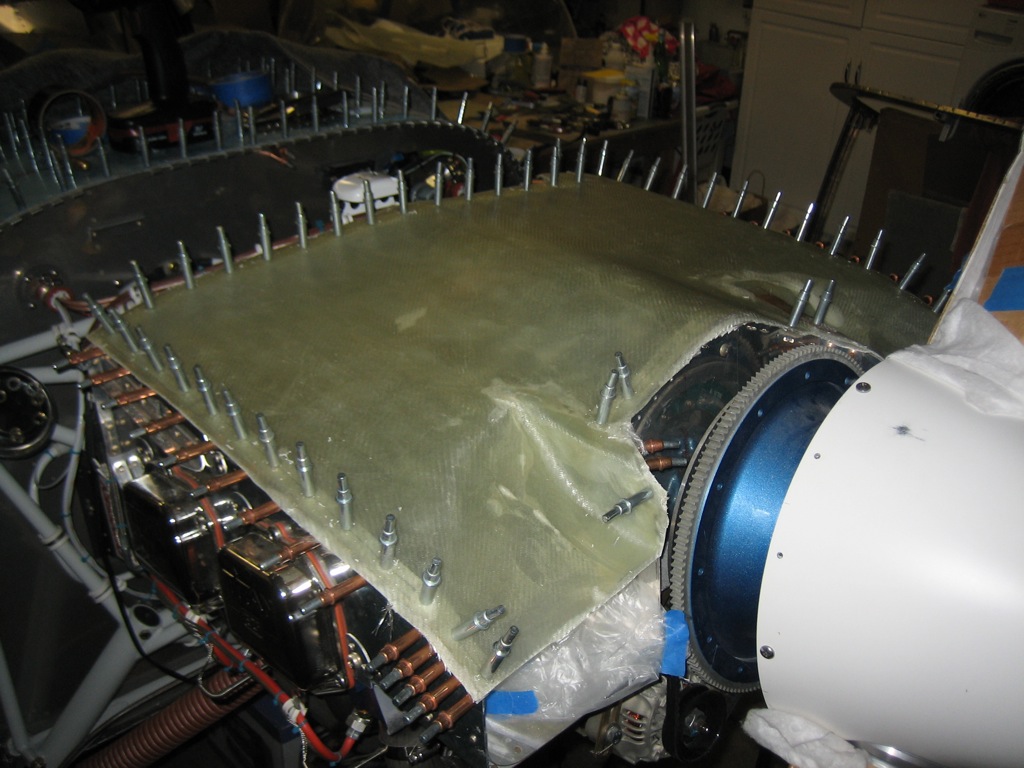

I drilled the plenum to the mounting angles through the holes I drilled in them yesterday. I shined a light through the plenum so that I could see the holes. They’re only drilled out to #40 now, but I’ll open them up for #8 screws once the mounting angles are riveted and I know everything is in it’s final location. The spacing varies somewhat around the perimeter based on the length of the various mounting angles, but they’re predominantly between 1 5/8″ and 1 7/8″. They’re tighter at the front outside corners where the plenum turns sharply downward.

I pulled the plenum and baffles off so that I could rivet the mounting angles to the baffles. The engine hasn’t been this naked in a very long time.

I started cleaning up and riveting the mounting angles to the baffles. The mounting angles need quite a bit of time with the deburring disks on the die grinder due to the fairly deep marks put in them by the shrinker/stretch dies. Notice that the aft rivet (on the far right in this picture is flush on the outside because the #4 cylinder baffle tucks in here.