In order to make sure the cowl returns to the same position each time, I drilled a piece of scrap aluminum angle to the top cowl so that it aligned with the spinner. The clecos didn’t really hold in the fiberglass, so I ended up putting some scrap aluminum on the other side and using some wing-nut draw clecos to anchor this firmly.

I also made a series of marks around the spinner to serve as reference points.

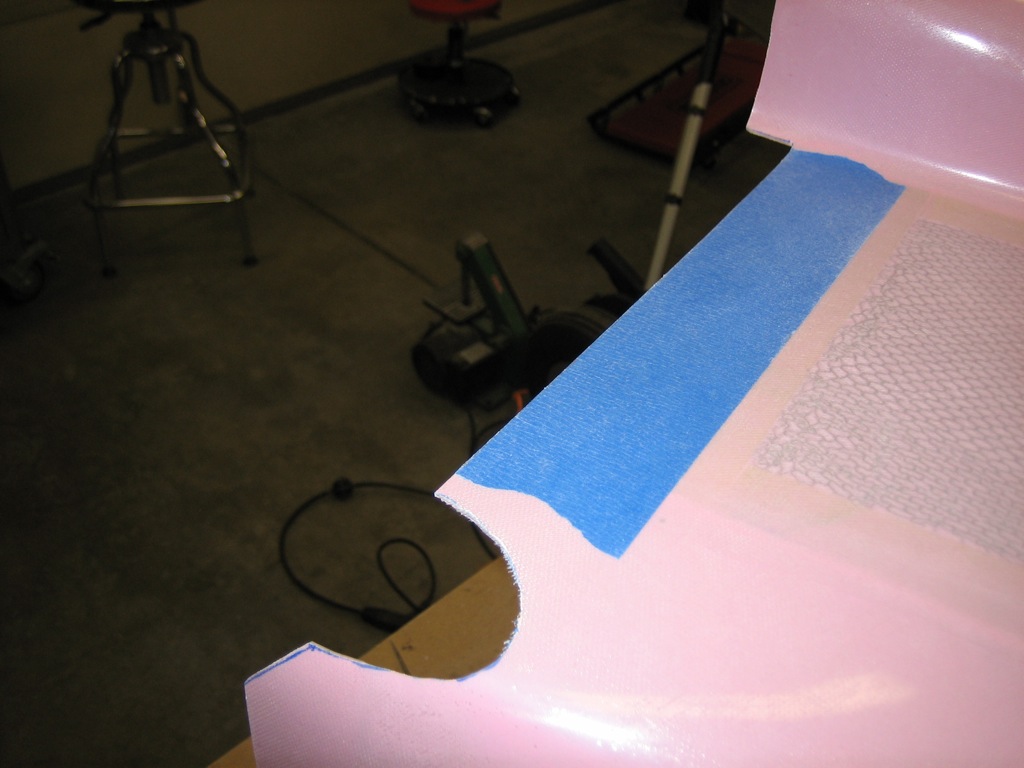

With the cowl in its final location, I put a light inside the cowl and put some masking tape along the cut line.

I did the rough cut with the cutoff wheel to within about 1/16″ of the line. After putting the cowl on and off a few more times, I was able to iteratively trim the line with a vixen file so that these edges align with the firewall flange. I’ll trim the exit once I’m happy with how everything is fitting.

While I had the cowl in its final position, I took the time to position all of the exhaust pipes so there was an even gap all around them. Each pair of pipes will be clamped together and then everything is loosely anchored to the engine mount. I also made some marks on the pipes that are even with the shortest pipe. I’ll cut all of these so that all of the ends are even.

Here’s a shot showing how much clearance I have all around. I have about an inch of clearance top and bottom and about two inches on each side. The pipes look like they aren’t vertically aligned here, but that’s just because the lengths vary.

I drilled and installed the pipe clamps. The bottom steel straps needed to be bent to conform to the pipes.