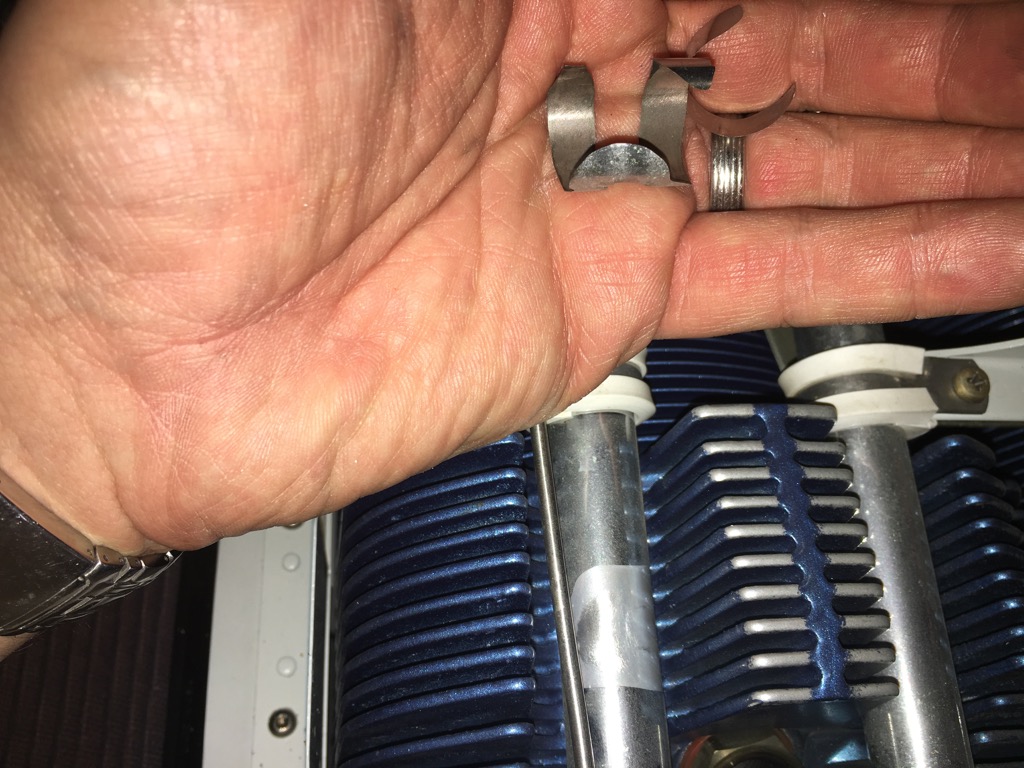

One of the fiberglass ears at the top of the gear leg fairings broke off on the left fairing.

The one on the right is cracked all the way through and is likely to break soon.

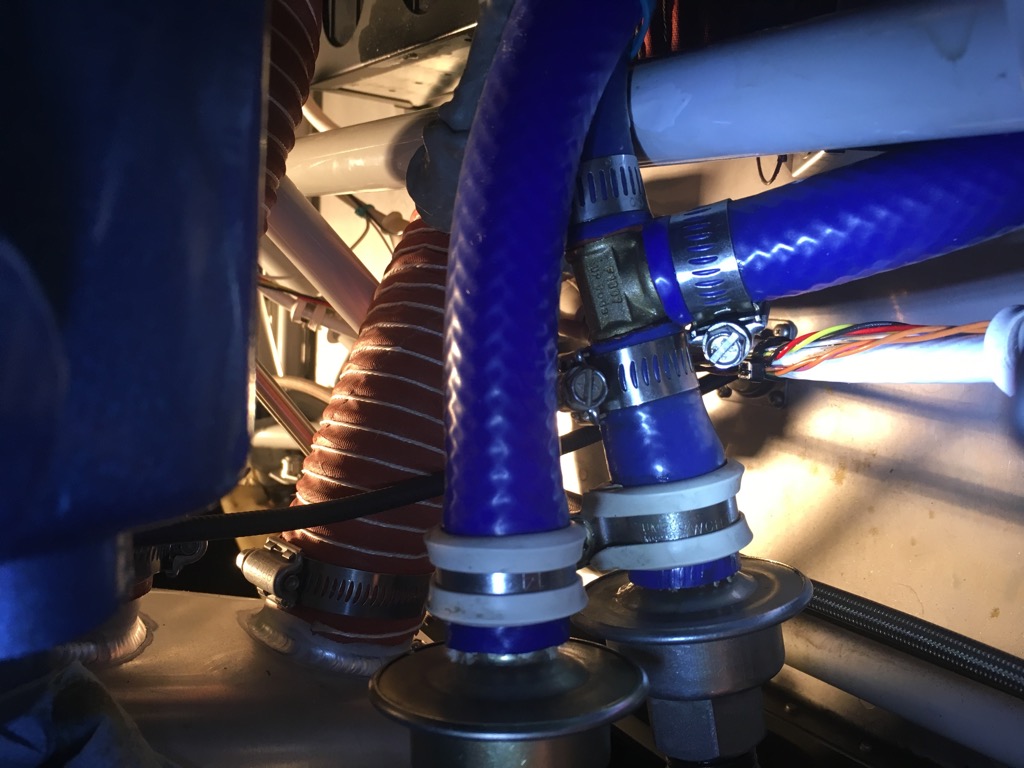

I had used electrical tape to hold the brake hose to the gear leg. This broke in most of the spots, so I took it all off. I didn’t get a picture of it, but I just wrapped the electrical tape around the gear leg and then used some zip ties to secure the brake hose.

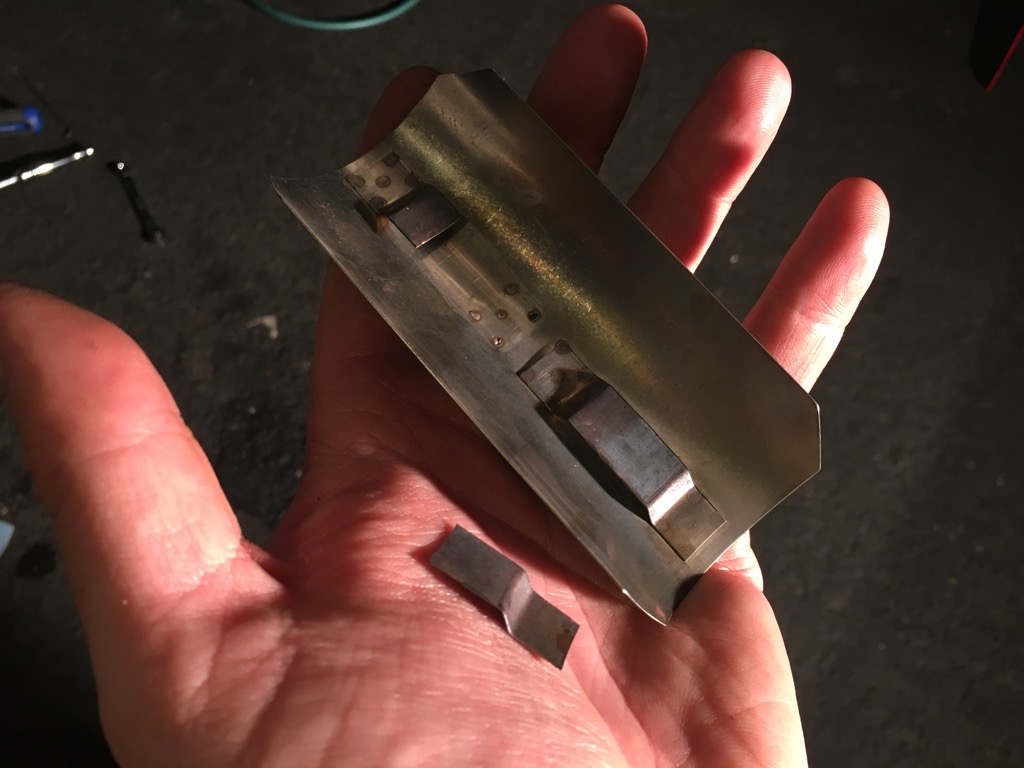

I pulled the tailwheel fork off to clean and lubricate it. While it was off, I swapped the control arm with one that has a hole for a tie-down hook.